With rapid technological development, organic electronics has become a new type of device that is being widely studied. Compared with traditional electronic devices, flexible organic electronic devices have more flexible physical properties and can be used in insulating corrosion-sensitive electronic.

Flexible electronics has a wide range of application prospects, from the development of cell phones, tablet PCs, TVs, and other daily electronic products, to the development of medical, information, energy, defense, and other fields, flexible electrical materials can play an important role in applications of insulating corrosion sensitive electronic. Why use silicone for electronics flexible?

Silicone is a new type of material with unique properties and a wide range of applications, with good flexibility and tensile permanently flexible rubber; it has corrosion resistance, high dielectric strength, good transparency, and stability in a wide range of temperatures, can be used for large-area transparent flexible electronic devices or thermally stable device substrate material; it is easy to combine with the electronic material so that the electronic material is fixed to the surface; it's electrical properties are stable over a wide temperature range, is widely used in electronic components. In recent years, from the development of cell phones, tablet PCs, TVs, and other daily-use electronic products, to the development of medical, information, energy, defense, and other fields.

Here’s some information about it:

- What is flexible electronics?

- How to classify electronics flexible materials?

- What are the advantages of silicone?

- How to apply silicone to flexible electronics?

- What will happen to silicone-flexible electronics?

- How to choose silicone raw materials?

1. What is flexible electronics?

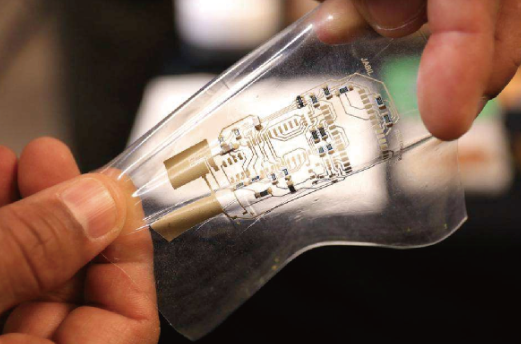

Flexible electronics is a technology that connects inorganic/organic devices to a flexible substrate to form circuits. Compared with traditional silicon electronics, flexible electronics refers to thin-film electronic devices that can be bent, folded, twisted, compressed, stretched, or even deformed into any shape but still maintain efficient optoelectronic performance, reliability, and integration.

2. How to classify electronics flexible materials?

2.1 Metallic materials

Metallic materials are generally gold, silver, copper, and other conductive electrical materials materials, mainly used for electrodes and wires, and coaxial cable connectors. For modern printing processes, conductive nano-inks are mainly used as conductive materials, including nanoparticles and nanowires. In addition to good conductivity, metallic nanoparticles can be sintered into films or lead wire entries.

2.2 Organic Materials

Large-scale pressure sensor arrays are important for the future development of wearable sensors. Pressure sensors based on piezoresistive capacitive signaling mechanisms suffer from signal crosstalk, leading to inaccurate measurements.

2.3 Inorganic semiconductor materials

Inorganic semiconductor materials show excellent piezoelectric properties in the field of wearable flexible electronic sensors. The applications of electrical materials are promising.

2.4 Carbon Materials

Carbon materials commonly used in flexible wearable electronic sensors include carbon nanotubes and graphene. Carbon nanotubes have high crystallinity, good electrical conductivity, large specific surface area, microporous size that can be controlled by the synthesis process, etc., and the specific surface utilization rate can reach 100%.

Graphene is characterized by lightness, thinness, transparency, and good electrical and thermal conductivity. It has extremely important and broad application prospects in the fields of sensing technology, mobile communication, information technology, and electric vehicles.

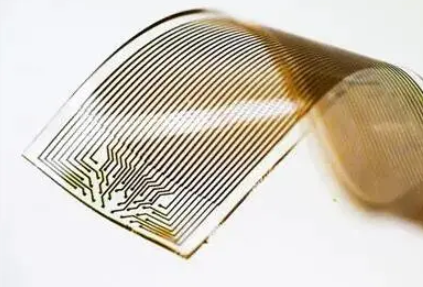

2.5 Flexible substrate

To meet the requirements of flexible electronic devices, thin, transparent, flexible, and stretchable. Properties such as insulation and corrosion resistance have become key indicators of flexible substrates.

Common flexible materials are Polyvinyl Alcohol (PVA), Polyester (PET), Polyimide (PI), Polyethylene Naphthalene Dicarboxylate (PEN), electronic grade silicone, paper, textile materials, and so on.

Polyimide material has the advantages of high-temperature resistance, low-temperature resistance, chemical resistance, and good electrical properties. It is the most promising material for flexible electronics. Only in the choice of the flexible substrate, in addition to high-temperature resistance characteristics, the transmittance of the flexible substrate, surface roughness, and material cost are factors that must be considered when choosing.

PET is cheap and has good light transmission, but has a low conversion temperature, between 70 and 80°C.

Electronic grade silicone can be used in many electrical materials applications, and is ideally suited for sealing of electrical connection and insulating corrosion-sensitive electronic, this type of permanently flexible rubber can last a long time, and so on.

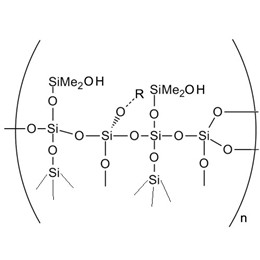

Polydimethylsiloxane (PDMS) is a widely recognized flexible material. Its advantages include easy availability, chemical stability, transparency, and good thermal stability. In particular, the differentiated properties of adhesion and non-adhesion under UV light make it easy to adhere electronic materials to the surface. The produced flexible films can also be used as flexible device substrates.

3. What are the advantages of silicone?

Silicone is a class of organic polymers composed of carbon, hydrogen, oxygen, and silicon elements, with the following significant advantages as electrical materials.

3.1 Flexibility

Silicone has excellent flexibility properties, its permanently flexible rubber can be bent or stretched in the case of maintaining its performance stability, and is suitable for applications in flexible electronic devices. Compared with traditional electrical materials, silicone is more flexible and ideally suited for the needs of devices with different shapes and curves.

3.2 Transparency

Silicone has excellent light transparency, and high transmittance of visible light and infrared light, compared with bulky silicone-based, silicone is more suitable for the production of transparent flexible electronic devices, such as smart curtains, etc.

3.3 Biocompatibility

Silicones are biocompatible and suitable for non-corrosive curing system and can come into contact with the human body without causing allergic or irritating reactions. Therefore, silicone has great potential for application in the field of healthcare, such as wearable medical devices, biosensors, and so on.

4. How to apply silicone to flexible electronics?

Silicone in the field of flexible electronic devices has a wide range of applications, the following focus on three areas of research progress.

4.1 Wearable devices

Flexible organic electronics can also be applied to the field of wearable devices. Compared with traditional smart devices, flexible organic electronics can better meet the needs of users, can be personalized design, and have good flexibility.

Silicone's flexibility and biocompatibility make it ideal for making wearable devices. For example, flexible electrodes made from flexible silicone can be used for functions such as heart rate monitoring and body temperature detection. In addition, flexible display panels and sensors in wearable devices, etc., can also be fabricated using silicone permanently flexible rubber for a better human-computer interaction experience.

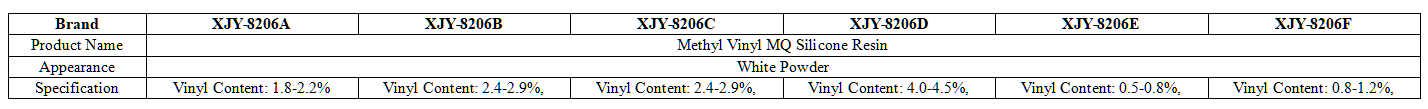

XJY-8206 Methyl Vinyl MQ Silicone Resin is a solid powder resin, that can be used as reinforcing filler for additive molding silicone rubber(room temperature vulcanizing), and as a basic raw material for high transparent and high hardness silicone. It can be used to make wearable medical devices, biosensors, and so on.

4.2 Smartphones

Silicone applications in smartphones are mainly reflected in the folding screen under-screen fingerprint identification and so on. Flexible silicone is more resistant to folding than glass or hard plastic, which can realize the feasibility of folding screen cell phones. At the same time, silicone can also be attached to the underside of the screen to create a flexible fingerprint identification module, which improves the security of the phone and is convenient for users.

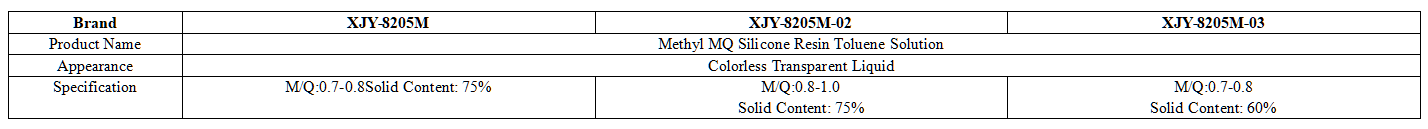

XJY-8205M Methyl MQ Silicone Resin Toluene Solution is an important raw material for silicone pressure-sensitive adhesive.

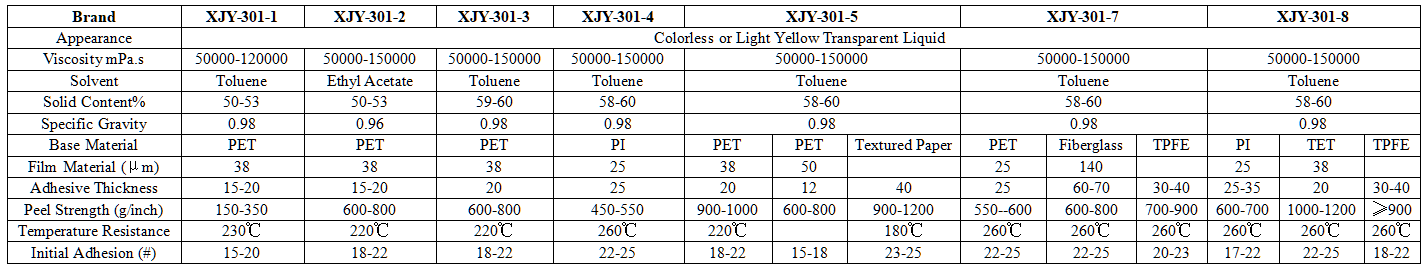

XJY-301 Silicone Pressure Sensitive Adhesive is a specific structure of silicone resin and high molecular weight polydimethylsiloxane complex, it is a kind of adhesive applied in specific scenario conditions, and it has the characteristics of high-temperature resistance, high stability, good electrical insulation, good transparency, etc. It is widely used in electronic protective film, cell phone displays, and other electronic fields.

4.3 Electronic skin

Flexible organic electronics can be used in the field of medical devices. Flexible organic electronics can replace the traditional multi-parameter detection equipment and are ideally suited for non-corrosive curing system, for medical equipment users more comfortable, but also more convenient to carry. At the same time, flexible organic electronics can be used flexibly on the skin to provide more portable medical services.

E-skin is a flexible sensor similar to human skin, which can sense and monitor human physiological signals in real-time. As the main substrate of the electronic skin, silicone can realize the real-time detection of facial expressions, finger activities, and other subtle movements, with a wide range of medical, health, and human-computer interaction applications.

5. What will happen to silicone-flexible electronics?

Although silicone has achieved certain research progress and application results in the field of flexible electronic devices, its future development is still huge in the space.

5.1 R&D of new types

In the future, new types of silicones can be developed to improve their performance and stability to meet the performance requirements of flexible electronic devices.

5.2 Multi-field cooperation

The application of silicone in the field of flexible electronic devices requires interdisciplinary cooperation, including science, electrical engineering, biomedical, and other fields of experts to participate in order to provide a more comprehensive solution for the development and application of silicone.

5.3 Expanding application areas

In addition to the existing wearable devices, smartphones electronic skin, and other fields, silicone is ideally suited for non-corrosive curing system, can also be in the energy field, environmental monitoring photovoltaic devices, and other aspects of in-depth research and application, to broaden its application areas.

6. How to choose silicone raw materials?

The research on the application of silicone in flexible electronic devices is being deepened, and its advantages, challenges, and insulating corrosion-sensitive electronic prospects for future development are worthy of attention. With the progress of science and technology and interdisciplinary cooperation, electronic-grade silicone makes flexible electronic devices better, and silicone is ideally suited for non-corrosive curing system, bringing more convenience and innovation to our daily lives. How to make your products specifically formulated and ideally suited for the market's needs?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry as well as more than 15 related patents and technical support, can have large-scale production and adequate ventilation. Our silicone raw products can meet the needs of the electronics field and support the provision of diversified customized solutions.