Circuit boards are a very important part of the electronics manufacturing process. To ensure the performance and longevity of the circuit boards, they are usually potted. Potting protects against moisture, dust, and vibration, which is essential for the stability and reliability of the board.

Different circuit boards differ in material and application, so it is necessary to choose the appropriate potting material. Common potting materials include polyurethane, epoxy resin, silicone, etc. So why choose silicone potting compound for PCB?

Polyurethane potting compound is less resistant to aging and ultraviolet rays; Epoxy resin potting compound is easy to crack when the temperature conditions change too much, not moisture-proof. Silicone potting compound has no restrictions on the shape of the construction substrate, can be used in a variety of lines in the line of complexity, and can play a protective; Silicone potting compounds after curing have electrical insulation, can prevent electrical appliances in the use of the phenomenon of electricity, and can be a larger range of protection of electrical components; Silicone potting compounds have a better for the softness and shock resistance, suitable for circuit boards have a certain degree of seismic requirements of the occasion. Silicone potting compounds can improve the performance and reliability of the circuit board in power supplies.

Here’s some information about it:

- How to classify potting adhesive for PCB?

- What is the silicone potting compound?

- Why apply silicone in the electronics field?

- How to improve potting compound when adding silicone resin?

- How to use silicone potting compounds?

- How to make silicone potting compound performance better?

1. How to classify potting adhesive for PCB?

Circuit board potting is a common electronic manufacturing process, used to protect and fix the electronic components and their connections on the circuit board by applying a specific adhesive on the surface of the circuit board or between the components to form a protective potting layer. There are three main types of potting adhesives for PCB boards, polyurethane potting adhesive, epoxy resin potting adhesive, and silicone potting adhesive. In the preparation of the PCB board how to choose the adhesive?

1.1 Polyurethane potting compound

Polyurethane potting adhesive temperature requirements do not exceed 100 ℃ degrees, after potting it will have more vapor bubbles, and potting conditions are in a vacuum and have adhesion between epoxy and silicone.

Its advantages are excellent low-temperature, shockproof performance is still available. The disadvantages are that the high-temperature resistance is poor, the surface of the cured colloid is not smooth and has poor toughness, aging resistance and UV resistance are weak, and the colloid is easy to discolor. The polyurethane potting compound is only suitable for potting indoor electrical components that do not generate high heat.

1.2 Epoxy resin potting compound

The advantages of epoxy resin potting adhesive are excellent high-temperature resistance and electrical insulation ability, simple operation, very stable before and after curing, and excellent adhesion to a variety of metal substrates and porous substrates. The disadvantage is the weak resistance to hot and cold changes, by the hot and cold shock is prone to cracks, resulting in water vapor from the cracks penetrating into the electronic components, and the moisture-proof ability is poor. And after curing the gel hardness is high and brittle, easy to strain the electronic components.

It is only suitable for potting room temperature conditions and the mechanical properties of the environment do not have special requirements on electronic components.

1.3 Silicone potting adhesives

Silicone potting adhesives advantages are strong anti-aging ability, good weather resistance, excellent impact resistance; it has excellent resistance to hot and cold changes, after fast curing, can be soft pliable rubber used in the temperature range of -60 ℃ ~ 200 ℃ to maintain the flexibility, do not crack or thermal expansion; it has excellent electrical properties and insulation capacity, potting effectively improve the insulation between the internal components and lines, improve the use stability of electronic components;it has no corrosion of electronic components and curing reaction does not produce any by-products; it has excellent repair capability, can be quickly and easily after the sealing of components out of the repair and replacement; it has excellent performance and flame retardant ability, effectively improve the heat dissipation of electronic components and the safety factor; low viscosity, good mobility, able to penetrate into the small gaps and under the components; room temperature curing can also be cured at room temperature. It also cures at room temperature, has good self-bubbling, is more convenient to use and the curing contraction rate is small, with excellent waterproof performance and shock resistance.

Silicone has a wide range of typical applications, can provide deep section cure, suitable for potting a variety of electronic components working in harsh environments.

2. What is silicone potting compound?

Silicone potting compounds are a low viscosity two-component condensation type adhesive, that can be fast room temperature deep curing. It can be applied to PC (Polycarbonate), PP, ABS, PVC, and other materials and metal surfaces, with excellent bonding properties, which is suitable for cable and wire, circuit boards, solar panels, power cord bonding, power supply boxes, electronic transformers, battery modules, component modules, electronic modules, LED/LCD high-power lighting, display modules, substation cabinets, substation boxes and other applications of potting/sealing.

3. Why apply silicone in the electronics field?

With the development of science and technology, electronic components and logic circuits tend to be denser, multifunctional, miniaturized, and modular, thus putting forward higher requirements for the stability of electrical appliances. To prevent moisture, dust, and harmful gases from intrusion electronic components, slow down the vibration, prevent external damage, and stabilize the parameters of the components, to minimize the adverse effects of the outside world, potting is needed for electronic applications.

The increase in electrical power requires a potting compound with good thermal conductivity and insulation properties. If the heat can not be conducted promptly, it is easy to form a local high temperature, which may damage the components, thus affecting the reliability of the system and the normal operating cycle. Because of its excellent physicochemical properties, silicone has become the first choice for potting, and then adding high thermal conductivity filler will be able to get a thermally conductive and insulating silicone electronic potting compounds. As the process continues to mature, high thermal conductivity electronic potting silicone will play an increasingly important role in the application of electronic appliances.

4. What are the advantages of adding silicone resin in potting compound?

(1) Low viscosity, strong maneuverability

(2) High and low-temperature resistance, excellent weather resistance

(3) Outstanding thermal conductivity

(4) Excellent electrical insulation, stability, and definition

(5) Good adhesion to most metals and plastics

(6) Solvent-free, halogen-free

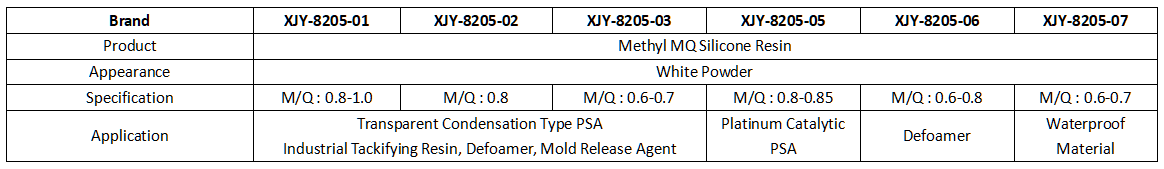

XJY-8205 Methyl Vinyl VMQ Silicone Resin is a solid powder resin, that can be used as reinforcing material in liquid silicone rubber. Adding silicone MQ resin to the potting compound can enhance its high and low-temperature resistance, prolong the service life, apply to various materials, and be applied to various electronic components in power supplies, including PCB boards.

4.1 What are the performance improvements of potting compound after adding XJY-8205 silicone MQ resin?

(1)In PCB circuit boards, electronic components, ABS plastics, etc., its adhesion has been significantly enhanced than ordinary potting compounds;

(2)Silicone potting compound has good fluidity, and can be poured to the fine points;

(3)Silicone potting compounds have small shrinkage, during curing, and have better waterproof moistureproof, and anti-aging properties;

(4)It can cure at room temperature and has good self-bubbling, is more convenient to operate and use;

(5)It has good marina resistance, adhesive force lasting, maintains the rubber elasticity in the range of -60 ~ 250 ℃, and has excellent insulation properties.

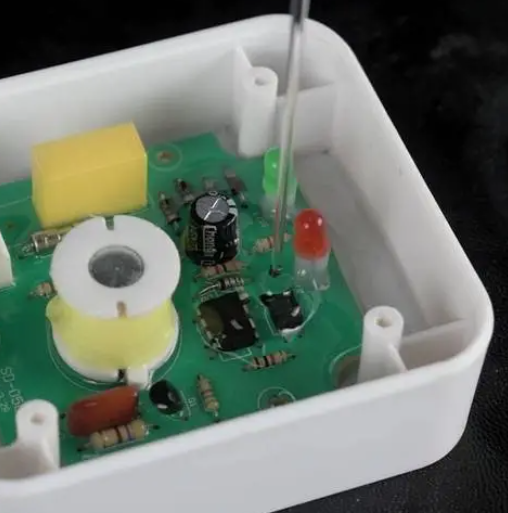

5. How to use silicone potting compounds?

5.1 Preparation of tools and materials

Before using silicone potting compound, you need to prepare the following tools and materials:

(1) Potting adhesive: Select the appropriate silicone potting adhesive according to the specific application scenario.

(2) Stirrer: it is used to stir the potting adhesive evenly.

(3) Coating tools: such as squeegee, applicator, etc., are used to coat the potting adhesive on the electronic products to be potting evenly to avoid air bubbles.

(4) Heating equipment: such as oven, heating plate, etc., are used to accelerate the curing of potting adhesive.

5.2 Operation steps

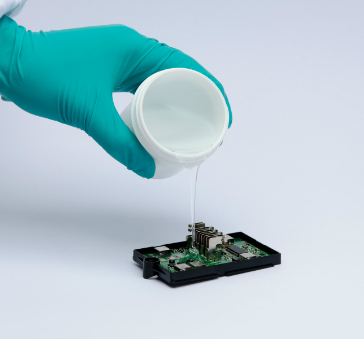

(1) Clean: it needs to clean the surface of potting electronic products and remove oil, dust, and other impurities.

(2) Coating: it needs to coat potting adhesive on the surface of electronic products evenly to ensure that the coating thickness is uniform, and has no air bubbles.

(3) Curing: you should put the coated electronic products into the heating equipment to heat so that the potting adhesive cures. According to the type of potting adhesive and electronic products to determine heating temperature and time.

(4) Inspection: After the potting adhesive is completely cured, check whether the performance and insulation of the electronic products meet the requirements.

5.3 Precautions

(1) When using silicone potting adhesive, pay attention to safety, and avoid contact with skin and eyes.

(2) Different types of potting compounds have different chemical properties and physical properties, and the appropriate potting compound should be selected according to the specific application scenario.

(3) In the heating curing, control the heating temperature and time to avoid overheating or overcooking.

(4) The silicone potting compound fully cured has good temperature resistance, performance, and insulation, but still needs to pay attention to avoid excessive bending or twisting of electronic components.

(5) When not in use, the potting compound should be stored in a cool dry place, avoiding direct sunlight and high temperature.

(6) If the catalyst is required, it should be added proportionally and stirred well.

(7) In the operation process, pay attention to keeping clean and hygienic, and avoid impurities or dust and other pollution.

6. How to make silicone potting compound performance better?

The silicone potting compounds is waterproof, has insulation and temperature resistance properties after cured, and can ensure the use of electrical components safety; Because of its thermal conductivity, you can avoid the electrical components' temperature being too high to avoid thermal expansion, and you can conduct the excess heat out; Its anti-vibration performance is good, you can ensure that the electrical components will not be collision, to reduce the chances of failure. Silicone potting compounds are widely used and can be applied to new energy, military, medical, aviation, shipping, electronics, automotive, instrumentation, power supply, high-speed rail, and other industries. How to improve the competitiveness of your products for typical applications?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry as well as more than 15 related patents and technical support. Our silicone raw material products can meet the demand for silicone potting compounds and support to provision of diversified customized solutions.