Many types of medical devices rely on adhesives for assembly. For medical device manufacturers, the decision to select an adhesive often requires extensive testing and validation to determine the adhesive's performance that can form a solid and good bond. This also requires medical adhesives to have specific properties.

Silicone adhesive is a one-component, translucent paste-like room temperature curing bonding adhesive, also called room temperature vulcanizing (rtv silicone). It has good adhesion to most metal and non-metallic materials, but also has excellent high-temperature resistance, and aging resistance. So why use silicone as adhesive in the medical field?

The selection of adhesives for medical applications follows the same process as for other applications, with criteria including special bonding substrate determination, strength requirements, load type, impact resistance, high-temperature resistance, low resistance to fluids, and processing requirements. Many medical devices require two other important criteria: sterilizability and low toxicity. Silicone adhesives have good biocompatibility, are non-toxic and non-irritant, do no harm to the human body, have a long service life, and can be widely used in the medical field.

Here’s some information about it:

- How to classify medical adhesives?

- What is a medical silicone adhesive?

- What are the requirements of medical silicone adhesives?

- What are the advantages of medical silicone adhesives?

- How to use medical silicone adhesive?

- How to apply medical silicone adhesive?

- How to make medical silicone adhesive performance better?

1. How to classify medical adhesives?

Medical grade adhesive is used as a medical device adhesive, can partially replace the surgical suture, can quickly stop bleeding, is biodegradable, can effectively reduce scarring and promote tissue regeneration, is widely used in the epidermis, subcutaneous tissue, blood vessels, heart, teeth and bone and other hard and soft tissue adhesive repair.

Common types of medical adhesives are:

1.1 Cyanoacrylate adhesives

Acrylate adhesives for a wide range of adhesive materials, have fast curing speed, especially with the plastic bonding performance. It is commonly used in conduit components, conveying pipe bonding, and polyolefin bonding.

1.2 Light-curing acrylate adhesives

It can be widely used in a variety of adhesive materials, has outstanding chemical resistance, and can be adjusted according to the requirements of the curing speed. It is commonly used in injection needle assembly bonding, anesthesia mask applications, heat exchangers, oxygenators, and delivery tube bonding.

1.3 Epoxy Resin Adhesives

Epoxy resin adhesive can be widely used in a variety of substrates, with outstanding heat resistance and chemical resistance, epoxy resin itself has a low shrinkage, good void-filling ability, and bonding properties. Epoxy resin-type adhesive is commonly used in a variety of potting adhesives, and injection needle assembly.

1.4 Polyurethane adhesive

It applies to a wide range of bonding materials, with excellent peel resistance, impact resistance, and weather resistance. Polyurethane adhesives are suitable for potting and device tip bonding.

1.5 Silicone adhesive

Different from other adhesives, silicone adhesives, and sealants have high peel strength, good heat resistance, and good elongation at break, silicone adhesives in the medical also have a wide range of applications.

Applying silicone sealant is commonly used to seal joints, but silicone adhesives are used to bond different materials, such as silicone substrate bonding and sealing, and extremely flexible base material surface coating.

2. What is a medical silicone adhesive?

Medical silicone adhesives bond at room temperature, these adhesives, have a high environmental rating and need to be over the industry FDA certification, and biocompatibility is good.

Usually, we can see these medical silicone products in hospital beds, such as medical silicone tubes, silicone balloons, baby soothes, and other products bonding.

3. What are the requirements of medical silicone adhesives?

Different from silicone sealants, for medical adhesives, the threshold will be higher, and more demanding requirements for research and development, but this is the advantage of silicone adhesives.

3.1 Anti-bacteria test

Because of the special nature of the medical industry, the requirements for adhesive materials will be more stringent, not only to have other common standards of the industrial sector, corrosion resistance, high strength, aging resistance, etc., there is a very important point is to be able to pass the test of anti-bacteria.

3.2 Low toxicity

Our most common medical adhesives are mainly used in disposable products, such as syringes, catheters, oxygenators, etc.; It will also be used in reusable devices, such as surgical instruments, diagnostic equipment, etc.; there are some implantable devices, such as pacemakers will also be used in adhesives. Medical devices are related to human health, and in the hospital is also the easiest to spread the virus place, so the use of medical devices is more rigorous. Therefore, many medical devices in addition to complying with a series of hospital regulations, but also resistant to sterilization and low toxicity.

3.3 Long service life

Adhesives used in medical devices need to be tested for their effects on viruses, cells, blood, and other systems. Because these medical devices or adhesives used to assemble medical devices are always in contact with the patient's exposed skin, systemic tissues, etc., so it is even more important to be careful. It follows that one of the most important roles of adhesives is to resist sterilization and disinfection, and most disposable and reusable medical devices need to be sterilized before they can be used. Some products (such as endoscopes, surgical instruments, etc.) may require more than one sterilization cycle, the adhesive must withstand these processes, without affecting the realization of the main function.

4. What are the advantages of silicone adhesives?

(1) Non-corrosive

It has no damage to the surface of the substrate to be bonded and potted;

(2) Adhesive properties,

It can be directly bonded to metal, glass, ceramics, a variety of plastics, and other materials without surface treatment;

(3) No pollution

It is safe for the environment before and after the curing of the glue, with no harm to the human body;

(4) Wide temperature range

The silicone adhesives cure at -60 ~ 200 ℃ and still maintain a good physical state;

(5) Weathering and aging resistance

Silicone adhesives have resistance properties to ultraviolet light, ozone, salt spray, and the effects of the atmosphere;

(6) Low curing contraction rate

The internal stress of silicone adhesives is small, has no effect on all kinds of products, and no shrinkage of the volume of the adhesive after curing;

(7) Easy and convenient to use

It can be extruded from the packaging container for direct use and can be cured at room temperature or heating, the use method is very convenient.

5. How to use medical silicone adhesive?

The method of medical silicone adhesives is very simple (cleaning, glue, pressure).

(1) First, it needs to clean the surface of the material which is bonded, and then coat glue (the thickness is less than 1mm evenly ) on the surface of the material.

(2) Then, you should squeeze tightly together the adhesive surface of the silicone with the glue of two materials, the pressure time can not be less than half an hour. You need to place it at room temperature for a day (24 hours) better the curing process.

(3) Notes: the bonding surface of the material should avoid oil and dirt, and tighten the lid to prevent the curing of the gel inside the tube after use.

6. How to apply medical silicone adhesive?

In modern medical research, as flexible adhesive, the medical silicone adhesives used for the human body can be compatible with the human body's tissues, with no toxic side effects on the human body

Silicone adhesive can bone grafting, repair organs, replace sutures, ligation closure, effectively stop bleeding, cover wounds, treatment of vesicles, and so on.

(1) Medical adhesive applications are mainly in hospitals, the beauty industry, etc., which have direct contact with the human body (Chinese medicine plasters, etc.) medical silicone tubes, silicone balloons, soothers, baby products bonding, or which need to be put into the human body (breast augmentation) cosmetic surgery and other aspects.

(2) In surgery, use silicone adhesive instead of suture, this operation is simple, rapid, and reliable, can reduce the patient's pain, promote the rapid recovery of the organism, and also reduce the scar.

(3) In dental treatment, the use of adhesive technology can be bonded, inlaid, closed, filled, anti-caries, beauty, and so on. The beauty of the adhesive and bonding technology such as rhinoplasty, and breast augmentation in the use of silicone and foam adhesives.

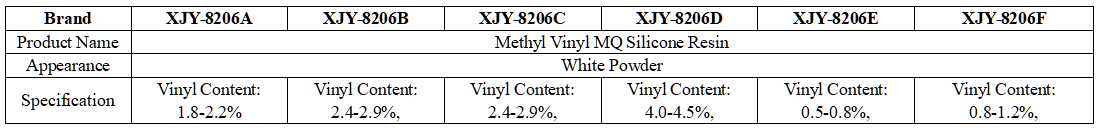

XJY-8206 Methyl Vinyl MQ Silicone Resin is a solid powder resin, that can be used as reinforcing filler for additive molding silicone rubber, and can be used in dentistry as a basic silicone caulk raw material with high transparency and high hardness.

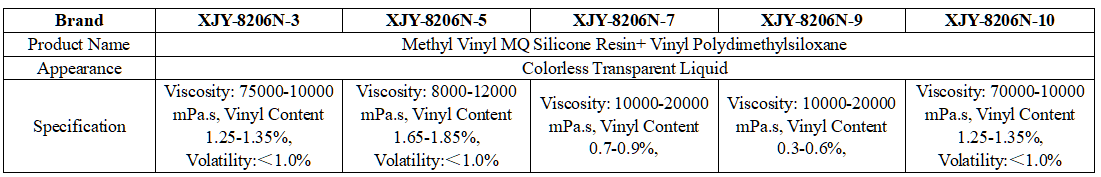

XJY-8206N Methyl Vinyl MQ Silicone Resin+Vinyl Polydimethylsiloxane is a colorless and transparent liquid resin composed of vinyl MQ silicone resin and vinyl silicone oil. It can be used in LSR liquid silicone rubber and other additives, also has good reinforcing and hardening properties, and is widely used in the medical field.

7. How to make medical silicone adhesive performance better?

Silicone adhesives have superior high and low-temperature performance; and good seismic performance; are not easy to deform; electrical insulation; superior electrical properties; excellent weather resistance, an outdoor service life of up to 20 years or more; environmentally friendly, many silicone products through the FDA's demonstration; silicone products are not flammable, combustion is not exothermic, virtually no hazardous substances released. Therefore, they can be widely used in the medical field as adhesives. How to improve the competitiveness of your products when purchasing silicone adhesives raw material?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry as well as more than 15 related patents and technical support. Our silicone raw material products can meet the needs of silicone rubber adhesive and silicone sealant and support the provision of diversified customized solutions.