As people's demand for sunscreen products in skin care routines becomes higher and higher, the skin’s surface effects they are expected to achieve are also diverse.

In reality, few sunscreen products can combine protection, skin feel, mildness, and stability. Generally, it's either too greasy, white, and muddy, clogging pores and trapping dead skin cells, or it doesn't have enough sun protection. it’s also not safe for sensitive skin, such as acne-prone skin. In order to solve these problems, silicone will be added to sunscreen. Although traditional sunscreens can block UV rays to a certain extent, they often have problems such as greasy skin feel and poor waterproof performance. The emergence of silicone materials provides new ideas for upgrading sunscreen products. Why add silicone to sunscreen?

Silicone not only can be used as silicone adhesive Silicone won’t clog pores, but it can also be a skin barrier to protect skin cells without pore clogging and improve the freshness and film-forming speed of sunscreen products; adding silicone can make the sunscreen have low viscosity, suitable evaporation speed, easy to spread, refreshing and non-greasy, and good emollient and texture. Silicone gel elastomers with a high-definition, refreshing feeling, excellent velvet feeling, powdery smooth feeling, and matte soft mist effect can make up for the greasy feeling on the skin's surface caused by sunscreen and at the same time, give the product an excellent sensory experience.

Here’s some information about it:

- What are the features of silicone?

- What is silicone sunscreen?

- Why choose silicone sunscreen?

- How to add silicone to sunscreen?

- How to make silicone sunscreen better?

1. What are the features of silicone?

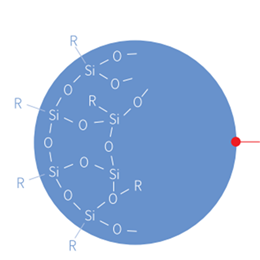

Silicone is an organic compound composed of silicon and carbon and has both inorganic and organic properties. In its molecular structure, silicon atoms and organic groups are combined with covalent bonds to form a stable chemical structure.

Compared with ordinary organic compounds, silicone has the following characteristics:

![]()

![]()

1.1 Thermal stability

Silicone remains stable at high temperatures and will not decompose or fail. This is very beneficial during cosmetic processing and consumption. Silicone materials are also chemically stable and can maintain their performance under a wide range of temperatures and acid- base conditions. This characteristic allows silicone sunscreen products to maintain a stable sunscreen effect in a variety of environmental conditions and is less likely to fail due to external factors.

1.2 Waterproofness

Silicone materials have a low surface tension and spread evenly over the skin's surface to form a continuous and uniform protective film. This protective film not only blocks UV rays but also prevents moisture loss while providing good moisturization to the skin. Silicone can form a protective film that prevents cosmetics from falling off and deteriorating when exposed to moisture. This is very important for moisturizing cosmetics.

1.3 Lubricity

Silicone can form a lubricating film, making cosmetics easier to spread and absorb on the skin, making the user feel more comfortable

1.4 Thickening

Silicones can increase the viscosity of cosmetics, making them easier to apply and use. At the same time, it can also improve the stability of cosmetics and extend their service life.

Because of silicone’s features, it can be used in many fields, like silicone gels for wound healing, and skin protectants.

1.5 Good biocompatibility

Silicone materials have very low skin irritation and good biocompatibility. This makes silicone sunscreen products in the use of the process can reduce the occurrence of skin allergies and other adverse reactions, improving the safety of the product.

2. What is silicone sunscreen?

Sunscreen silicone emulsion is a water-in-oil white paste made by emulsifying composite ultraviolet absorbers, silicone oil, high-grade fatty acids, and other raw materials. It can prevent the harm of medium and long-wave ultraviolet rays in the sun to human skin, and achieve the purpose of beauty and skin care. Purpose: After biological testing, it is non-toxic, non-irritating, and non-allergenic to the human body, and is suitable for preventing erythema, age spots, sunburn, or other skin diseases.

Because sunscreens are mostly used outdoors, the sunscreen ingredients can be spread continuously, while oil-soluble sunscreens stay in the oil phase. After application, the sunscreens are easily dispersed and discontinuous, resulting in a "window effect", thereby reducing the sunscreen effect. Therefore, it is necessary to use water-soluble sunscreen agents and add film-forming agents to enhance the waterproof and sunscreen effects of the formula.

Advantages of Silicones in Sunscreen Products

Silicone materials have multiple unique advantages in sunscreen products, making them ideal sunscreen formulation ingredients.

(i) Improved skin feel

Traditional sunscreen products often appear greasy and heavy due to the high content of sunscreen agents, while silicone materials can significantly improve this problem. Components such as volatile silicone oils and silicone elastomers have a light, refreshing skin feel, which reduces the stickiness of the product and provides a silky, moisturizing experience.

(ii) Enhanced waterproof performance

The hydrophobic film formed by the silicone film-forming agent can effectively prevent sunscreen products from dissolving or falling off in water, thus extending the duration of the sunscreen effect. This waterproof performance makes silicone sunscreen products especially suitable for outdoor activities and water sports scenes.

(iii) Improve formulation stability

Silicone emulsifiers and film-forming agents can enhance the emulsification stability of sunscreen products, preventing the formulation from delamination or precipitation. In addition, the chemical stability of silicone materials to maintain good performance in different environmental conditions.

(iv) Reduce the amount of sunscreen agent

Through the synergistic effect of silicones, the SPF value of sunscreen products can be enhanced with a reduced amount of sunscreen agents. This not only reduces product irritation, but also optimizes costs.

3. Why choose silicone sunscreen?

With climate change and the destruction of the ozone layer, the harm of ultraviolet rays to humans is becoming more and more serious, and people have increased their attention to ultraviolet rays. Silicones as synthetic polymers, have outstanding sun protection effects and can block ultraviolet radiation to protect the skin from damage. Silicone is often used to make sunscreen. It has a high sun protection index and can block multiple wavelengths of ultraviolet rays. Silicone is stable and waterproof and will not be washed off when swimming or sweating, so it is more suitable for outdoor activities.

4. What is the principle of silicone sunscreen?

Silicone is a class of polymer compounds with a unique chemical structure, the core structure of which is the silicon-oxygen bond (Si-O), and can be modified by different functional groups. In sunscreen products, silicone mainly works through the following mechanisms:

(i) UV absorption and reflection

Silicone materials can absorb or reflect UV rays to reduce their damage to the skin. Certain silicone resins and elastomers can absorb specific wavelengths of UV rays, thereby reducing the intensity of UV penetration of the skin. In addition, the film-forming nature of silicones allows them to form a uniform protective film on the surface of the skin, further reflecting UV rays.

(ii) Film-forming and water repellency

Silicone film-forming agents can quickly form a layer of hydrophobic film on the skin surface, which not only prevents UV rays from directly contacting the skin but also significantly improves the waterproof performance of sunscreen products. Studies have shown that the addition of silicone film-forming agent sunscreen products after washing can still maintain a high SPF value.

(C) synergistic effect

Silicone materials can also be synergistic with other sunscreen agents (such as organic sunscreens or inorganic sunscreens) to enhance the overall effect of sun protection. For example, the combination of silicone elastomers and organic sunscreens can significantly increase the SPF value while reducing the amount of sunscreen agents.

5. How to add silicone to sunscreen?

The silicone resin mixture can form a film on the skin, is washable, resistant to migration, and has a long-lasting effect. It also has a fast evaporation rate, forming a bright hydrophobic film, which is resistant to migration and has excellent skin adhesion. Silicone sunscreens generally have higher molecular polarity and are better compatible with highly polar oils. Adding phenyl silicone oil and alkyl silicone wax can increase the compatibility between oils in the oil phase system and improve the skin fit of the product. Therefore, silicone in sunscreen formulas can enhance the sunscreen and waterproof effects, provide refreshing and skin-friendly effects, and adjust various skin textures through silicon micro powder to meet the diverse needs of customers.

Specifically, there are the following aspects:

5.1 Refreshing effect - volatile silicone oil

Sunscreen agents with strong sun protection capabilities are usually in a solid state. When designing refreshing sunscreen formulas, liquid oil sunscreen agents with moderate solubility need to be combined with highly volatile silicone oil to provide a refreshing skin feel, especially in the W/ O formula system.

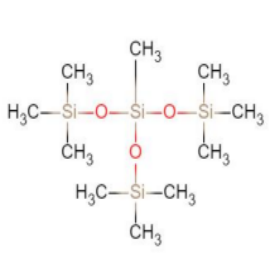

Volatile silicone oils (e.g., cyclodimethylsiloxane) have low viscosity and rapid evaporation properties that leave a thin protective film on the skin surface.

XJY-058 Methyl Trimethicone

It is a kind of MT structure methyl polytrimethylsiloxane. It is acyclic, colorless, and non-irritating. It has excellent volatility, is compatible with a variety of cosmetics, and has a refreshing and non-greasy texture. It can be used in sunscreen products and can replace D5 Cyclopentasiloxane.

5.2 Sun protection and waterproofing silicone film-forming agent

Use W/O system sunscreen, because most of the sunscreen is in the external oil phase, and the sunscreen ingredients can be spread continuously, while the oil-soluble sunscreen in the O/W system stays in the oil phase, and the sunscreen is easily dispersed and discontinuous after application, creating a "window" effect", thus reducing the effectiveness of sun protection.

Therefore, it is necessary to use water-soluble sunscreen agents and add film-forming agents to enhance the waterproof and sunscreen effects of the formula.

Silicone film-formers (e.g. trimethylsiloxysilicate) form a uniform, transparent film on the skin's surface, effectively preventing UV penetration. Such film-forming agents are not only water-resistant, but also improve the durability of sunscreen products.

XJY-8203/8205 Trimethysiloxysilicate ( Film Forming Agent )

It is a solid powdery resin that provides excellent film-forming properties, softness, and waterproof properties. It can be used in cosmetics and hair care products. Adding it to sunscreen can improve sun protection properties and improve smooth skin feel.

5.3 System stability - silicone emulsifier

Silicone emulsifiers are often used in W/O emulsification systems. Generally, emulsifiers with strong emulsifying ability have a relatively large molecular weight, large hydrophilic and lipophilic groups, and a thicker skin feel when used.

Silicone emulsifiers are used to build stable emulsion systems, especially in water-in-oil systems. They improve the stability of formulations while reducing the heaviness associated with emulsifiers.

Emulsifiers with relatively small molecular weights will have weaker emulsifying power and stability but will have a refreshing skin feel and need to be used together when designing formulas.

5.4 Skin feel adjustment - silicone micro-powder

The birth of powder raw materials provides sunscreen products with more skin feel styles. Commonly used powder raw materials include micro silica powder, which can improve the smoothness of the skin; and compound silica powder, which makes the skin feel softer and closer to the skin.

XJY-801 Polymethylsilsesquioxane

It is a type of solid powder with a true spherical shape and a narrow particle size distribution. Its chemical structure is a densely cross-linked cured resin with insoluble and infusible trifunctional components. It can be used for many skin care products sun protection, after-sun repair, etc.

5.5 Compatibility and skin fit - phenyl silicone oil, alkyl silicone wax

The molecular polarity of organic sunscreen agents is generally high, so when choosing oils, you should choose oils with medium to high polarity. Phenyl silicone oil and Alkyl silicone wax are polymers with a hydrocarbon-branched chain structure connected to the silicone oil chain.

A number of novel silicone materials (e.g., silica micropowders, phenyl silicone oils, etc.) have been used to further modulate the skin feel and performance of sunscreen products. For example, silica micropowders can enhance skin slip while phenyl silicone oils can improve the compatibility of oil-phase systems

It has good compatibility with highly polar oils. Adding phenyl silicone oil and Alkyl silicone wax can increase the compatibility between oils in the oil phase system and improve the skin fit of the product.

XJY-056-Phenyl Trimethicone

It has a high refractive index and can be used in personal care and hair care. It is soft and lubricating, antioxidant, has good compatibility with cosmetic ingredients and can increase the skin adhesion of sunscreen.

5.6 Slip property-silicone rubber elastomer

Silicone elastomers, such as polydimethylsiloxane crosspolymers, not only have good film-forming properties, but also provide a smooth skin feel. Their unique three-dimensional structure enhances the adhesion and rub resistance of sunscreen products.

XJY-804-M Silicone Gel / Silicone Rubber Elastomer

It is a type of silicone rubber elastomer gel dispersed in Decamethylcyclopentasiloxane system. The silicone elastomer is a regular sphere with excellent slippery properties. Due to the special structure of the elastomer, the product has excellent performance. The product is suitable for a variety of formulations, has excellent compatibility with other materials, and can be used for skin care, makeup and body care. In addition, this product has excellent film-forming properties and has good applications in the field of make-up.

XJY-804-W Silicone Spherical Elastomer

It is a true spherical silicone rubber elastomer aqueous dispersion with a solid content ranging from 30 to 90% (according to customer needs). It has excellent slippery properties and is mainly used in the personal care and cosmetics industries. Especially in sunscreen and liquid foundation, it has good performance and can improve the sun protection index and skin feel of the product.

6. How to make silicone sunscreen performance better?

Silicone sunscreen can give people a refreshing and non-greasy skin surface feel, provide hydrophobicity, and will not burden the skin; Silicone can also improve the ductility of sunscreen, reduce application resistance, and present a lighter film form. This prevents cosmetics from rubbing onto the face. How to improve the competitiveness of your products?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry and more than 15 related patents and technical support. Our silicone raw material products can meet the needs of silicone sunscreens and support the provision of diverse customized solutions.