The built-up roofs are a very important part of the house. In addition to good insulation and heat preservation, waterproof construction is also very important. If the roof is waterproofed, there will be no problem of seepage or leakage in the future. Among many kinds of materials, why choose silicone roof coatings?

The silicone roofing system can effectively prevent rainwater infiltration, protect the structural safety of the building, and extend the service life of the building. When choosing roof waterproofing materials, comprehensive consideration needs to be made based on factors such as the specific needs of the building, the budget, and the existing roof environment, in which it will be used. Silicone roof coating systems are suitable for a variety of roofs, such as polyurethane foam, metal roofs, commercial roof, and so on.

The silicone roof coating system has excellent waterproof performance, and can effectively prevent water infiltration, to protect the building and its internal facilities from water. Because silicone waterproofing materials use special chemical raw materials, it has good weathering performance, can withstand high and low temperatures, and UV rays, do not easily age, crack, or deform, and can extend roof life. Silicone waterproof material construction is simple, easy to master, and suitable for a variety of different shapes of buildings, reducing labor costs.

Here's some information about it:

- How to classify roof waterproof material?

- What is silicone waterproof coating?

- What are the features of silicone waterproof coating?

- How to use silicone waterproof coating?

- How to pay attention to silicone waterproof coating when used?

- How to make silicone waterproof coating?

1. How to classify roof waterproof material?

Waterproof coating, such as functional building materials for silicone roof coating systems, needs to be carefully considered, choose the wrong waterproof coating, the waterproofing effect is poor, costly, and laborious; heavy leakage aggravates, damage to the housing structure, resulting in greater economic losses.

It needs to choose the right material for waterproofing, different kinds of products applicable locations, and construction methods are not the same.

There are many roof waterproofing materials, commonly water-based asphalt waterproofing coatings, JS waterproofing coatings, and silicone waterproofing coatings.

![]()

![]()

1.1 Water-based asphalt waterproof coating

Water-based asphalt waterproof coating is an environmentally friendly coating, using water-based asphalt as the main raw material, widely used in construction, bridges, roofs, and other waterproofing areas. Its features include convenient construction, a wide range of applications, non-toxic odorless, etc., compared to traditional waterproof coatings, has a certain degree of ductility, elasticity, plasticity, resistance to cracking, resistance to penetration, and weather resistance, and has good temperature adaptability, simple operation, easy to repair, and routine maintenance.

![]()

![]()

1.2 JS waterproof coating:

JS waterproof coating is a certain proportion of organic polymer emulsion and inorganic powder uniform mixing, the formation of high-strength tough waterproof coating film. The advantage is that the product is a water-based coating with non-toxic, odorless, no air pollution. As the material has weak anti-ultraviolet ability, more suitable for basements, toilets bathrooms, and other indoors.

Construction requirements waterproof liquid material to be added in proportion to the powder, water machine stirring, and paint can be operated for a short time, condensation table dry, it can not be reused. When construction and multi-layer coating, each layer of coating thickness should be taken following the specified dosage, and to ensure that the paint and grass-roots level before leaving no air bubbles.

1.3 Silicone waterproof coating

Silicone coating is characterized by its silicone substances, so the product's anti-aging, anti-ultraviolet ability is excellent. It is also water-based environmental protection waterproof coating, safe, and environmentally friendly. However the disadvantage lies in the lack of adhesion, not alkali resistance, and poor abrasion resistance. Silicone waterproof can be applied to many roof materials, such as polyurethane foam, and metal roofs.

2. What is silicone waterproof coating?

Different from high solids silicone, it is a silicone rubber emulsion and its nano-composite emulsion is the main substrate, mixed with inorganic fillers and a variety of additives made of water-based environmentally friendly waterproof coatings.

Silicone waterproof coating can be used for new and old roofs, roofs, basements, bathrooms, swimming pools, warehouses, metal roofs, etc., cement mortar, concrete substrate, wood, ceramics, and other building materials have good adhesion and permeability, for the basement, toilet and other places of leakage repair has other waterproof materials can not be compared with the superiority.

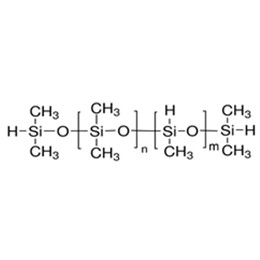

XJY-701 Polymethylhydrosiloxane under the action of metal salts catalyst, low temperature can be crosslinked into a film on the surface of various substances to form a waterproof membrane, and can be used as a waterproofing agent for metal, cement, marble, and other materials to be added to silicone waterproofing coatings.

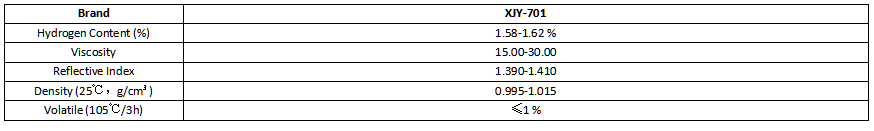

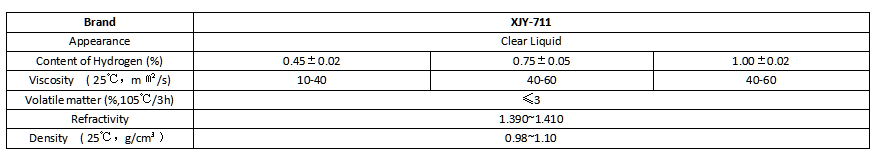

XJY-711 Hydride Terminated Methyhydrosilocane / Dimethylsiloxane Copolymer can be added to silicone coatings as a waterproofing agent for construction.

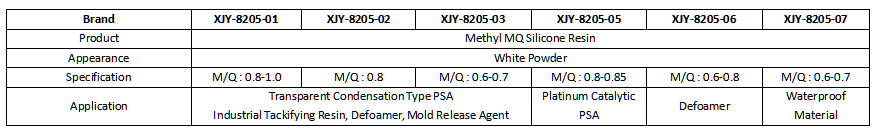

XJY-8205 Powder Series Methyl MQ Silicone Resin is a solid powder resin, this resin can provide excellent transfer resistance and water resistance and also can form a long-lasting film, long-lasting and durable, in the field of building materials that can be used as silicone waterproof coating.

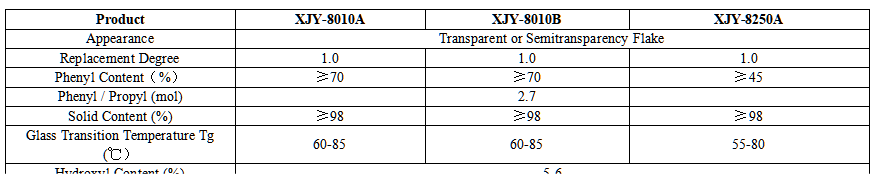

XJY-8010/8250 Flake Silicone Resin/XJY-83350 Polyester Modified Flake Silicone Resin has excellent weather resistance, ozone resistance, electric arc resistance, hydrophobic moisture resistance, salt spray resistance, mold resistance, and other properties. It can significantly improve the waterproof coating paint water resistance, temperature resistance, and other properties.

3. What are the features of silicone waterproof coating?

(1) Good overall film-forming properties.

Silicone waterproofing coatings are cured to form a continuous smooth surface layer of uniform integrity of a rubber-like elastomer, so made of the waterproof layer without lap joints. Used in shaped parts of the waterproof construction will be better.

(2) Good elongation.

Because the film is cured to form a layer of rubbery elastomer, the elongation is good and has a good tensile strength.

(3) Colorful.

Silicone waterproof coating belongs to a single-component waterproof coating and can be made of color coating, or custom colors for customers.

(4) Construction is convenient.

Whether using scraping, painting or brushing can be constructed, the grass-roots humidity requirements are not strict, so the same can be constructed on a wet surface or areas where ponding water. Silicone waterproof coating in the prohibition of open flame and complex shape of the construction site will be superior to other waterproof coatings.

(5) Green environment protection

Silicone waterproof coating is non-toxic and tasteless, easy to use and safe.

![]()

![]()

4. How to use silicone waterproof coating?

(1) Waterproof coating should be stirred before construction, do not feel free to add water.

(2) Brush or roller coating method of construction. The direction of the brush and stroke length should be consistent, each brush should be alternated evenly. The waterproof coating should be applied in layers.

(3) Each paint should be carried out after the previous one is dry (it is best to touch the coating with your hands, do not stick to your hands).

(4) Paving the carcass cloth, lap not less than 5cm. In the coating of the substrate reinforcement material, it is recommended to lay the substrate cloth at the same time as the coating. The matrix should be scraped flat to discharge air bubbles so that the coating can penetrate the matrix and complete coverage, there shall be no exposed tire.

![]()

5. How to pay attention to silicone waterproof coating when used?

5.1 Construction preparation

In signing the construction contract, clear construction scope, volume, and design requirements, make preparations, according to the design documents to prepare waterproofing project construction design or construction program, and technical briefing and safety education.

5.2 Grass-roots Acceptance and Cleanup

Coating construction of the grass-roots level should be flat, smooth, solid, and dry, the drainage slope should meet the design requirements, and corners should be obtuse or arc when the grass-roots level appears sanding, skinning, pockmarking, unevenness, and cracks, after treatment to meet the acceptance standards before construction. Clean up the debris left on the grass-roots level, use a broom or hair dryer to blow clean the floating dust on the surface of the grass-roots level, and the surface of the grass-roots level shall not have oil stains.

5.3 Brush grass-roots level treatment agent

Grass-roots treatment agent in accordance with the silicone waterproof coating: clean water = 1:2 ratio of mixing and stirring, in the waterproofing layer within the scope of the construction of the grass-roots level of uniformly coated treatment agent. Grass-roots treatment agents should be uniform, and thoughtful, with no bottom, and no accumulation. Grass-roots treatment agent after drying about 1H, you can carry out the next process.

5.4 Additional layer construction

Gutter, gutter, deformation joints, yin and yang corners, window wells, ventilation holes waterproofing after the pouring zone, and other designs have requirements of the weak parts of the additional layer construction. An additional layer of width and height shall not be less than 150 ~ 250mm. construction method for a cloth three coated, thickness of about 0.8mm.

5.5 Membrane waterproofing layer construction

Coated waterproofing layer construction generally uses thin coating multiple construction methods, that is, according to the coated waterproofing layer design thickness coating three times, four times, five times, or even six times to meet the thickness requirements, each coating surface drying 2H, and then subsequent construction. Coating film uniformity, no accumulation, flow, bottom dew, and film thickness are consistent. The thinnest part shall not be less than 80% of the design thickness. Tire reinforcement materials when there will be tire reinforcement materials soaked, are not dew-white

5.6 Membrane waterproofing layer sealing.

The coated waterproofing layer head part should be determined according to the design, the head of the application of silicone sealing material for crimping, crimping width of 10mm; can also be used to increase the coating brush several times (not less than two times) to achieve the head seal.

5.7 Protective layer construction

When the protective layer is made of fine sand, mica, vermiculite, and other loose materials, it should be evenly spread after the last coating; when using cement mortar and concrete protective layer, it should be made as an isolation layer first and then rigid protective layer, and reserve compartmentalized joints according to regulations.

5.8 Drenching or water storage test

The drenching test should not be less than 2h, water storage test not be less than 24h. storage height is determined by the design according to the height of the flashing and roof load. The water test process should be timely inspection, observation, and record.

![]()

6. How to make silicone waterproof coating?

Silicone waterproofing coatings formed by the waterproof layer have anti-cracking impermeable force, waterproof effect, the long service life of the overall film-forming good, after curing, the film forms a layer of continuous uniform integrity of rubber-like elastomers, thus making the waterproofing layer without laps and joints, the construction is more suitable for the construction of shaped parts; It is easy to construct, scraping, coating, brushing can be constructed on the grass-roots level of humidity is not stringent requirements in the construction of wet surfaces; Silicone waterproof coating is also both green and environmental protection, non-toxic and tasteless, maintenance costs are fewer. How to improve the competitiveness of your products?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry as well as more than 15 related patents and technical support. Our silicone raw material products can meet the needs of silicone waterproof coatings and support the provision of diversified customized solutions.

![]()