The rapid development of the new energy vehicle industry has brought new application areas. Whether it is a new energy vehicle or its charging pile, because it is different from the traditional automobile material requirements, is inseparable from the use of a variety of new functional adhesives, silicone adhesive which occupies a large proportion. Why choose silicone adhesive in the new energy vehicle charging pile?

New energy vehicle charging pile as a new energy vehicle "gas station", charging time is much longer than the traditional car refueling time, coupled with the continued surge in sales, range anxiety arises. In order to meet the new energy vehicle charging pile "fast charging" demand, the output power needs to continue to increase, the charging system heat flow density increase dramatically, and its system safety is facing a major challenge.

To solve this problem, the selection of potting materials is indispensable. In the choice of new energy vehicle charging pile, glue to be able to -40 ~ 150 ℃ extreme temperatures environment still maintains its excellent stability, aging resistance, impact resistance, waterproof moisture resistance, resistance to leakage, etc., and does not corrode other bonding materials, does not produce environmental pollution. Compared with other adhesives, silicone adhesives fully meet this demand.

The silicone adhesive in the new energy vehicle charging pile potting glue operation, the cured adhesive has excellent electrical properties, aging resistance, high and low temperature (-40 ~ 150 ℃), waterproof moisture, shock resistance, resistance to leakage, viscous, deep curing, and the bonding material two surfaces does not produce a corrosive effect and does not pollute the surrounding environment; It is in line with the relevant environmental requirements.

Here’s some information about it:

- What is silicone adhesive?

- How to classify silicone adhesives?

- What are the properties of silicone adhesives?

- How to apply silicone adhesives?

- How to make silicone adhesive?

1. What is silicone adhesive?

Silicone adhesive is a silicone material as the main body of the single-component, translucent paste-like room temperature curing silicone rubber or silicone resin adhesive, belongs to the high-performance elastomers, is a class of excellent performance, unique features, and a wide range of new materials. It has excellent resistance to heat and cold, aging, and electrical insulation properties, and most metal and non-metallic materials with good adhesion in the industrial setting.

The curing mechanism of silicone adhesive is absorbing moisture in the air, curing through a condensation reaction. The components of such adhesives include terminal hydroxy polydimethylsiloxane, methyl silicone oil, fillers, crosslinking agents, coupling agents, and catalysts.

In terms of application, silicone adhesives are widely used in electronics, electrical products, aerospace, automotive, household goods, healthcare, and other fields. In addition, it is also used in shoe-making, packaging, magnetic recording materials, and other fields.

2. How to classify silicone adhesives?

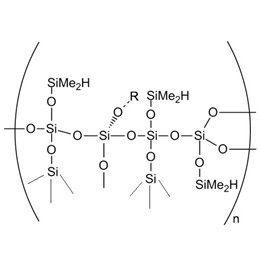

Silicone adhesives can be divided into two categories: silicone resin-based adhesives and silicone rubber-based adhesives.

The chemical structure of the two are different:

(1) Silicone-oxygen bond composed of the body structure of the main chain, at high temperatures can be further condensed into a high-strength crosslinked hard and brittle resin;

(2) Silicone rubber is a linear silicone-oxygen bond and is the main chain of the relatively high molecular mass of the elastomer. Relative molecular mass ranging from tens of thousands to over a hundred thousand, condenses into several cross-linked points of the elastomer in the role of the curing agent or catalyst.

It can also be divided into two categories, condensation and additive molding, additive molding is a cyanide-containing polysiloxane, with vinyl polysiloxane as the main material, in the role of the catalyst produced by the silicone adhesive.

3. What are the properties of silicone adhesives?

3.1 High-temperature stability

Silicone adhesives can maintain a low volatility and odor at high temperatures. This makes them ideal for high-temperature conditions, such as in automotive manufacturing, electronic equipment assembly, and heat treatment processes.

3.2 Weather resistance

Silicone adhesives have excellent weathering and UV resistance in outdoor environments. They are resistant to UV rays, high temperatures, humidity, and chemicals, and are therefore widely used in outdoor products, construction, and aerospace applications.

3.3 Bonding property

Silicone adhesives can bond with a variety of materials (including metals, plastic, rubber, ceramics, aluminum, etc.), and they can provide high-strength bonding, with very low surface tension and good flexibility.

3.4 Electrical insulation

Silicone adhesives have excellent electrical insulation properties and can provide reliable insulation and sealing in electronic and electrical equipment. They have good isolation of current and voltage and can effectively prevent current leakage and arc discharge.

3.5 Resistance to Chemical Attack

Silicone adhesives are resistant to corrosion and erosion by chemicals such as acids, alkalis, solvents, etc. This makes them ideal for use in the chemical industry and laboratories for sealing and fixing test tubes, pipes, and equipment.

4. How to apply silicone adhesives?

The application of silicone glue in new energy vehicle charging pile mainly includes the following four points:

4.1 Charging pile shell

A charging pile is generally fixed and installed on the ground or wall, district, public community, service area, bus station, underground parking lot, and outdoor parking lot. Its shell mainly plays the role of external protection and beautification, in addition to the need to protect the use of pre-transportation, the installation process may occur during the collision, but it also must be able to adapt to its use in the process of complex environment.

Silicone adhesive sealant has excellent temperature resistance, the use of temperature range can be up to -60 ~ 200 ℃. It also has excellent sealing adhesion, moisture resistance, shock resistance, weather resistance, aging resistance, and excellent adhesion to most metals, plastics, ceramics glass, and other materials.

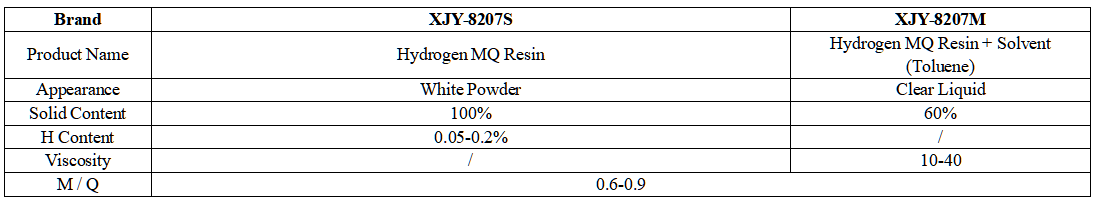

XJY-8207 S / M Hydrogen MQ Resin can be used as raw materials for silicone tackifiers used in silicone adhesive sealant.

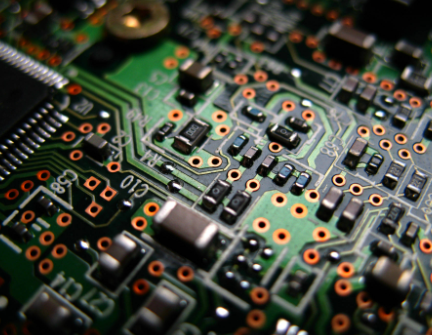

4.2 PCB circuit board

PCB circuit board is a key component of the electronic system, not only needs to be used in the charging pile, but new energy vehicles are also inseparable from it, and automobile safety is closely related to it, it is needed to pay special attention to the failure mode of the PCB in various situations, its performance requirements can be said to be harsh.

Single-component solvent-free silicone three-proof paint has many performances, such as low odor, excellent electrical insulation, temperature resistance, including fluorescent detection, can be thick layer coating, room temperature curing, or heating fast curing, meet HF, ROHS, UL94-V0 flame retardant.

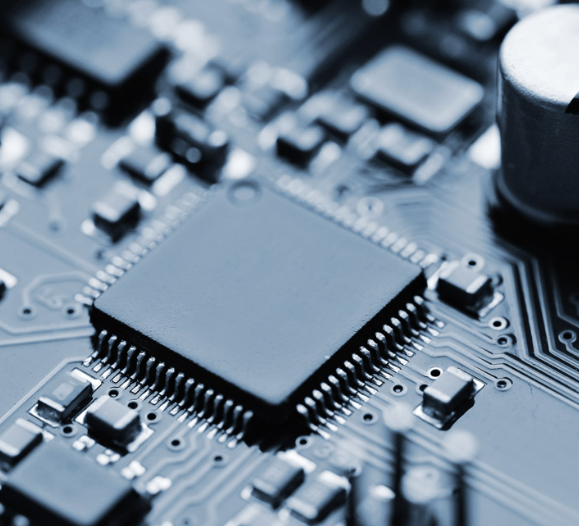

4.3 Electronic Components

Like PCBs, as an important component of internal control systems, they are not only used in charging piles but also in new energy vehicles. When working continuously, electronic components will generate a large amount of heat, if not for thermal conductivity, which will greatly affect the reliability and stability of the parts and even cause potential safety hazards.

Thermally conductive silicone gel is molded with the shape of the structure, with excellent structural applicability and structural components surface fitting characteristics and gap filling. It has good insulation voltage characteristics and temperature stability and is safe and reliable.

4.4 Inductor

Inductor adhesive is a kind of silicone used in inductors that mainly plays a role in fixing, the general function is to fix and cushion inductor parts, and another purpose is to solve the problem of heat dissipation and flame retardant.

Plus molding silicone thermally conductive potting adhesive can be room temperature curing, and can also be heated to accelerate curing. It has performances such as impact resistance, low viscosity, good leveling, easy to-penetrate the gap; moisture-proof, waterproof effect can be up to IP65 waterproof grade; good thermal conductivity, high flame retardant grade; heat and cold resistance, from -60 ~ 220 ℃ continuous operation, effectively extend the service life of the product.

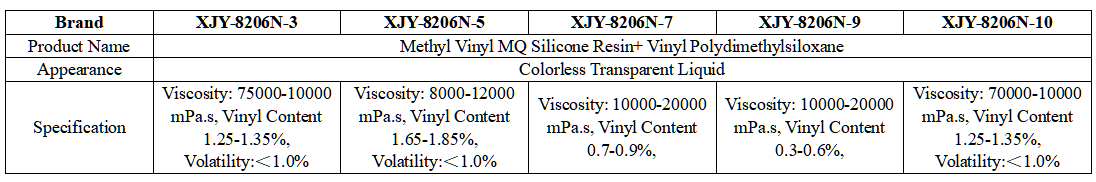

XJY-8206N Series Solution Methyl Vinyl MQ Silicone Resin It is a colorless and transparent liquid form resin, which consists of vinyl MQ silicone resin and vinyl silicone oil, and can be used for LSR, liquid addition molding silicone rubber, as well as another two-component addition adhesive.

5. How to make silicone adhesive?

Silicone adhesive is a class of one or two-component silicone adhesive, which can be cured at room temperature or under heating conditions. It is a class of environmentally friendly adhesive products, with superior electrical properties, bonding properties, temperature resistance, and weather ability, which is suitable for the electronics industry and industrial manufacturing field, and it is a very widely used and common electronic adhesive and sealant. How to find easy way to improve the competitiveness of your products?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry and more than 15 related patents and technical support. Our silicone raw material products can meet the needs of silicone adhesives and support the provision of diversified customized solutions.

![]()