The sink is a very important scrubbing equipment in the kitchen. If there is no sink in the kitchen or the quality of the sink is defective, it will stain causing mold, making your washing and scrubbing very inconvenient. The kitchen sink must be fixed with glue with a watertight seal performance. Silicone sealant can be used as a caulk tool, so why use silicone sealant for sinks?

Sealants are also used in many places such as toilet roots, countertops, wall gaps, window seals, etc. Cured sealant is very important in the field of home decoration. Apply sealant can solve many problems in life, but general sealants often create leaks easily.

Silicone sealant has excellent bonding performance and can be bonded to various substrates, such as glass, metal, ceramics, etc. Silicone sealant also has a watertight seal, permanently flexible and anti-mildew performance, can prevent secondary mold, and moisture seep, it is not prone to deformation and falling off in the performance environment of the kitchen sink; Silicone sealant has good aging resistance and long service life; silicone sealant is non-toxic, non-irritating, has good environmental performance.

Here’s some information about it:

- What is the best silicone sealant for sink?

- How to classify silicone sealants?

- How to choose silicone sealant?

- How to pay attention when using silicone sealant?

- How to use silicone sealant?

- How to make silicone sealant performance better?

1. What is the best silicone sealant for sink?

Sealant is used to seal and bond various joints or holes. During decoration, the gaps between building materials and furniture must be filled with sealant to prevent dust, liquid, etc. from entering the gaps and breeding bacteria and parasites, insects. In addition, the edges, corners, and joints are treated and covered by gluing to prevent the base material from being exposed and to correct the deficiencies in the surface decoration.

Choosing cheap and low-quality sealants to save costs often has incomplete product information, unpleasant odor, and many quality problems after use, causing losses that may far exceed the price of the sealant itself. Some glues or decoration materials contain toxic and harmful substances such as formaldehyde and toluene, which can endanger the health of you and your family.

Many types of glue can be used in home decoration: polyurethane, polysulfide, epoxy resin, silicone sealant, etc. Some of the glues contain substances harmful to the human body, such as Formaldehyde (carcinogens), Benzene, and Benzene series substances (carcinogens), etc.

Among many sealants, silicone sealants are relatively healthy and environmentally friendly because no toxic substances such as formaldehyde and toluene are introduced into the raw materials and production process of silicone sealants. Silicone sealants can stop mildew growth in sinks.

![]()

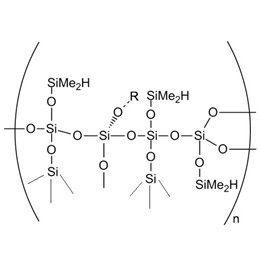

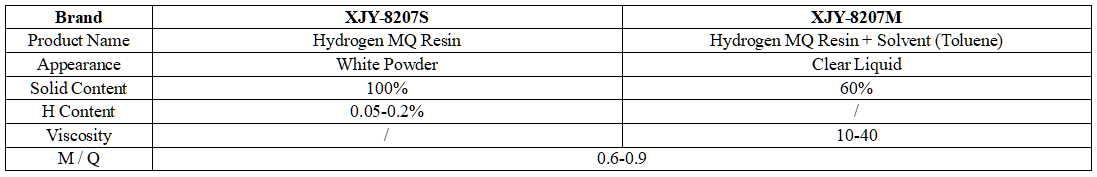

XJY-8207S/M Hydrogen MQ Resin can be used as a tackifier for silicone sealants.

2. How to classify silicone sealants?

2.1 Acid silicone sealant

Acidic silicone sealants have strong adhesion, can be used on aluminum alloys, ceramics, and glass, and cure quickly. The price is generally the lowest among all sealant types.

However, due to its acidic characteristics, it will be somewhat corrosive, and during the curing process it emits some pungent acetic acid smell that is harmless to the human body, so it is not the first choice for ordinary home decoration.

2.2 Neutral silicone sealant

Neutral silicone sealant is mainly suitable for surfaces such as masonry, aluminum, and paint. It is also a general seal. It is slightly more expensive than acidic sealant. It has a less irritating smell and a good sealing effect. It is not corrosive in itself. Neutral sealants are more suitable for use in homes than acidic sealants.

![]()

![]()

3. How to choose silicone sealant?

Although sealants are used in small quantities in the field of home decoration, not one kind of sealant can "go all over the world". Different sealants have different applicable occasions. If you choose the wrong material or use the wrong part, it will not have a good effect. Sealing, durability, beauty, and other functions.

So, how should families choose the right silicone sealant when decorating?

3.1 Neutral silicone sealant

It is suitable for bonding or caulking indoor doors, windows, integrated walls, wainscots, background boards, skirting lines, decorative lines, etc.

As caulk tool, these parts do not require high bonding strength and are mainly used for sealing and beautifying. When choosing a sealant, it is recommended to choose a neutral silicone sealant.

3.2 Mildew-proof silicone sealant

Such as edge sealing of shower rooms, sanitary ware, bathtubs, washbasins, sinks, bathroom countertops, kitchen countertops, and ceramic tile basements.

Due to the humid environment, the sealants used in these areas need to be the watertight seal. Ordinary waterproof sealants are prone to mold, blackening, and bacterial growth in such an environment, so mildew-resistant silicone sealants should be selected.

3.3 Weather-resistant silicone sealant

Sealing joints such as outdoor doors, windows, sunrooms, and roofs.

Considering that these parts are exposed to the outdoors for a long time, the structure is unstable, and the durability of the sealant is high. It is recommended to choose a weather-resistant silicone sealant for the curtain wall, which has good durability, strong displacement ability, no shrinkage, no cracking, and light resistance.

4. How to pay attention when using silicone sealant?

4.1 Usage:

One-component silicone sealant is ready for use. It can be easily knocked out of the glue bottle with a glue gun, and its surface can be trimmed with a spatula or wood chips.

![]()

4.2 Sticking time:

The curing process of silicone sealants develops from the surface inward. The surface drying time and curing time of silicone gel with different characteristics are different, so if you want to repair the surface, you must do it before the silicone surface dries. If color separation paper is used to cover a certain area, after applying the glue, it must be removed before the skin forms.

4.3 Curing time:

The curing time of silicone sealant increases as the bonding thickness increases. When bonded to glass, metal, or most woods, it has a peel strength of 20 lbs/in after 72 hours at room temperature. If the area where silicone sealant is used is partially or completely sealed, the curing time will be determined by the tightness of the seal. In an airtight place, it is possible to remain uncured forever. Increasing the temperature will soften the silicone. The gap between metal and metal bonding surfaces should not exceed 25mm. In various bonding situations, including sealed situations, the bonding effect should be comprehensively checked before the use of the bonded equipment.

4.4 Bonding:

Completely clean the metal and plastic surfaces to remove oil and dirt, and then rinse all surfaces with acetone except for the plastic. The rubber surface should be polished with sandpaper and then wiped with acetone. When using acetone please observe the precautions for using this solvent.

Apply silicone evenly on the surface of the prepared object. If you are bonding two surfaces, you can find a position on one side first, and then squeeze the other side with enough force to squeeze out the air, but be careful not to squeeze it out. Silicone glue.

Attention: Place the bonded device at room temperature until the silicone solidifies.

4.5 Seal:

When organic silicone is used for sealing, follow the same steps as above. Squeeze the silicone into the joint surface or gap to make full contact between the silicone and the surface.

4.6 Cleaning:

Before the silicone sealant starts to cure, it can be wiped off with a cloth or use mineral spirits. After curing, the cured sealant must be scraped off with a scraper or scrubbed with solvents, such as Xylene and acetone. If you want to replace old caulk, we also need to clean it.

5. How to use silicone sealant?

It will look perfect when you follow a line, and you can't pause. The force must be even, and it must be hit in place at one time to ensure a good result.

(1) First, you must be able to use a caulk gun;

(2) You need to determine the width of the glue, which is the width of the gap;

(3) You need to load the sealant cartridge, according to the width of the glue gap, and cut the glue nozzle of the sealant cartridge into a diameter slightly smaller than the gap with the utility blade;

(4) You need to do a good job of protecting both sides of the glued gap. Apply painter’s tape with 2-3CM on the glass, profiles, stones, etc. on both sides of the gap to protect the glass, profiles, stones, etc. on both sides. It is very convenient for correcting the glue in the gap;

(5) You need to master the speed of gluing and the speed of the caulk gun and move the glue gun evenly according to the depth of the gap;

(6) You need to trim the gluing area, find a spatula to smooth out the uneven areas, and fill the gaps where there were no gaps during gluing;

(7) After 48 hours, you need to remove the tape on both sides of the material to complete the construction.

![]()

![]()

6. How to make silicone sealants performance better?

Silicone sealant has the advantages of aging resistance, good electrical insulation, wide temperature range, and bonding performance, and is also permanently flexible and mildew resistant. It is widely used in the construction, automotive, and photovoltaic fields. Because of its wide temperature range, excellent UV resistance, and ozone aging resistance, it is mainly used as a sealing material for gaps, such as the sealing of doors, windows, building roofs, decorative panels, and gutters. How to make your silicone sealant more competitive?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry and more than 15 related patents and technical support. Our silicone raw material products can meet the needs of silicone sealants and support the provision of diversified customized solutions.