Silicone compounds have been used in industry since the 1960s, and have been developed on a large scale since the 1980s. They were used in non-aqueous systems in the past, but in recent years they have been focused on aqueous solutions. Silicone surfactants can excel in several applications. Why choose silicone surfactants?

Compared with traditional surfactants, silicone surfactants (anionic silicone surfactants and cationic surfactants) have higher surface tension and better permeability, so they can improve the wettability of the surface of objects more effectively. The molecular structure of silicone surfactants contains Si-O-Si bonds, which provide excellent temperature resistance. It can still maintain good surface activity under a high-temperature environment. Silicone surfactants are widely used in many fields, such as polyurethane leveling agents, coating auxiliaries, textile auxiliaries, wetting agents, agricultural chemicals, and so on.

The following six aspects of the silicone surfactants:

- What are silicone surfactants?

- What are the properties of silicone surfactants?

- What are the applications of silicone surfactants?

- What are the problems of silicone surfactants?

- How to solve the problem of silicone surfactants?

- How do silicone surfactants perform better?

1. What are silicone surfactants?

Silicone surfactants are generally made of siloxane as hydrophobic groups, Polyoxyethylene chain, Carboxyl, Ketone, Amino, Epoxy, and other polar groups as Hydrophilic groups, i.e., more than one polar group connected to the main chain of the base silicone oxygen. Silicone surfactants can be divided into the anionic silicone surfactant and the cationic silicone surfactant.

Silicone surfactants do not have the linear structure of many conventional surfactants but have a T-type structure, consisting of all Methylated siloxane skeleton, with one or more polyether tails.

2. What are the properties of silicone surfactants?

(1) Excellent ability to reduce surface tension

Silicone surfactants to soft Si-O bonds are the main; methyl and the three hydrogen atoms with which it is free to rotate require a larger space, increasing the distance between neighboring siloxane molecules, and the intermolecular forces are small table to be low tension.

(2) Excellent super-wetting properties

Silicone surfactants can not only reduce the interfacial tension of the oil/water interface but also in the low-energy hydrophobic surfaces (such as polystyrene surfaces) wetting expansion, this ability is called 'super-wetting' or 'super spreading', and can be used as wetting agent.

Because of the hydrogen bonding between oxygen and polar molecules, the force between molecules increases a spread into a monomolecular layer, aqueous siloxane lying on the polar surface "extended chain" configuration.

(3) Physiological inertness

Silicone materials have no toxic side effects or biosafety. Environmentally friendly features. Siloxane surfactants are also physiologically inert, so when used as cosmetics and detergents, they are very safe and do not cause environmental pollution.

(4) Ability to stabilize emulsion

Some grafted silicone surfactants can stabilize the emulsion in the presence of ethanol and organic solvents, which is not available in traditional hydrocarbon surfactants.

3. What are the applications of silicone surfactants?

(1) Cosmetics

Polydimethylsiloxane and polyether graft copolymer an important surfactants in the cosmetic industry, when the dosage reaches 0.15%~5% (mass fraction) in an aqueous solution, it can make the cosmetic surface tension drop, which is conducive to the diffusion of cosmetic products on the surface of skin and hair.

(2) Personal toiletries

In shampoo products, we use more quaternary ammonium compounds. This is because Polysiloxane surfactants have hydrophobic polysiloxane links, and positively charged quaternary ammonium salts have strong adsorption on the hair.

(3) Laundry detergents and finishing agents

Silicone surfactant itself has a certain degree of hydrophobicity and can be used as a water-repellent agent. Its polar groups are repositioned and non-polar methyl groups are neatly arranged in the outermost layer of the fiber.

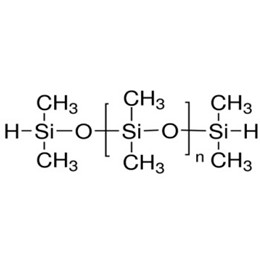

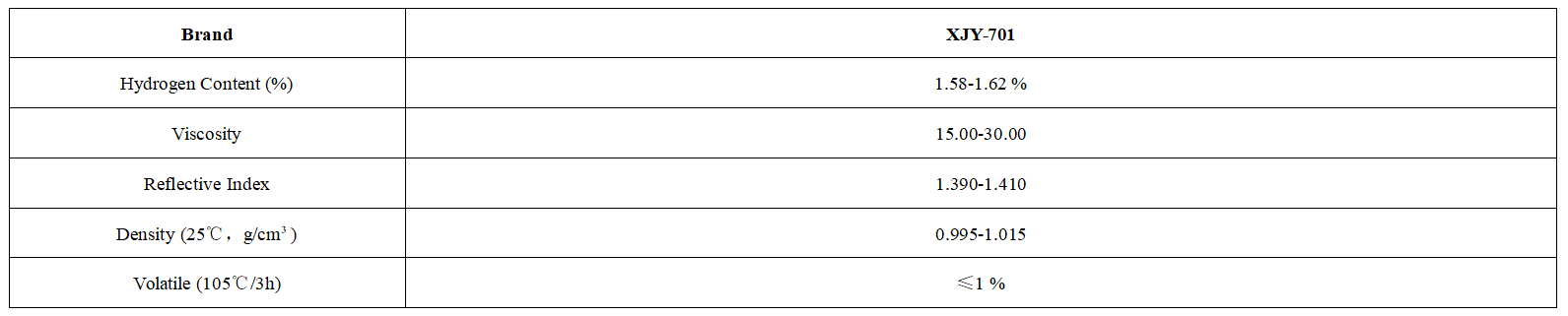

XJY-701 Polymethylhydrosiloxane

It can be crosslinked to form a film at low temperatures under the action of a metal salt catalyst, forming a water-repellent film on the surface of many kinds of substances, and can be used as a heavy water-repellent agent for fabrics.

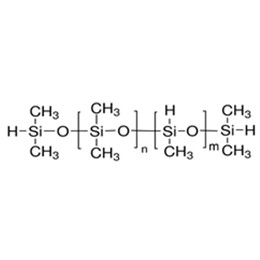

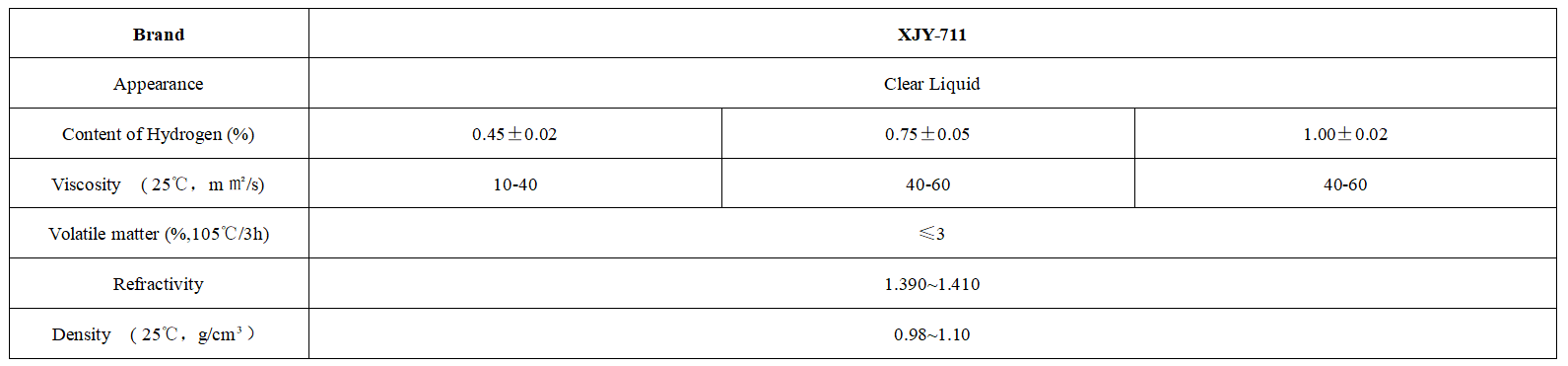

XJY-711 Hydride Terminated Methyhydrosiloxane/Drimethylsiloxane Copolymer

It can be used as a heavy-duty water repellent and finishing agent for fabrics after special formulation, and it can exert maximum water repellency.

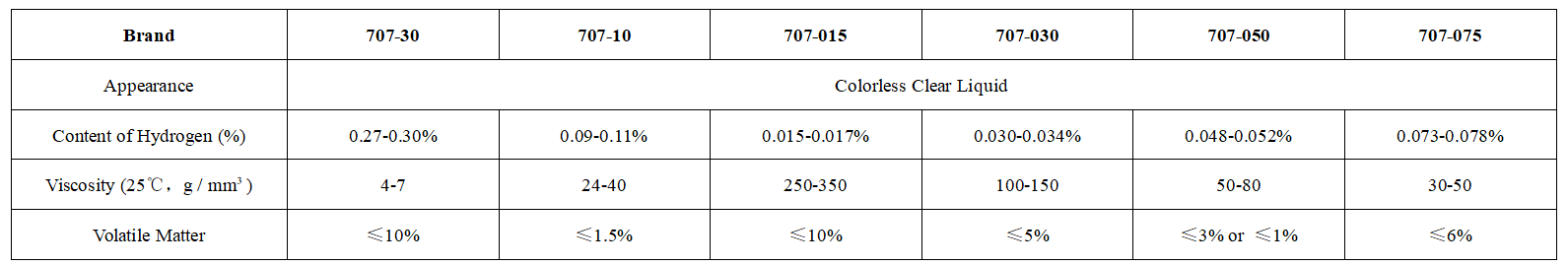

XJY-707 Hydride Terminated Polydimethylsiloxanes

It can be used as a heavy-duty water-repellent and softener for natural and synthetic fiber fabrics.

(4) Agriculture

Silicone surfactant enhanced spreading can be used as fertilizer additives to improve fertilizer utilization and reduce fertilizer waste by improving soil physical properties and promoting fertilizer adsorption and release. The application of silicone surfactants in fertilizers usually adopts the way of encapsulating fertilizer particles, so that they can continue to slowly release nutrients in the soil. At the same time, silicone surfactants can also reduce the loss of fertilizer in the soil, reduce the pollution of the environment, and play a role in environmental protection.

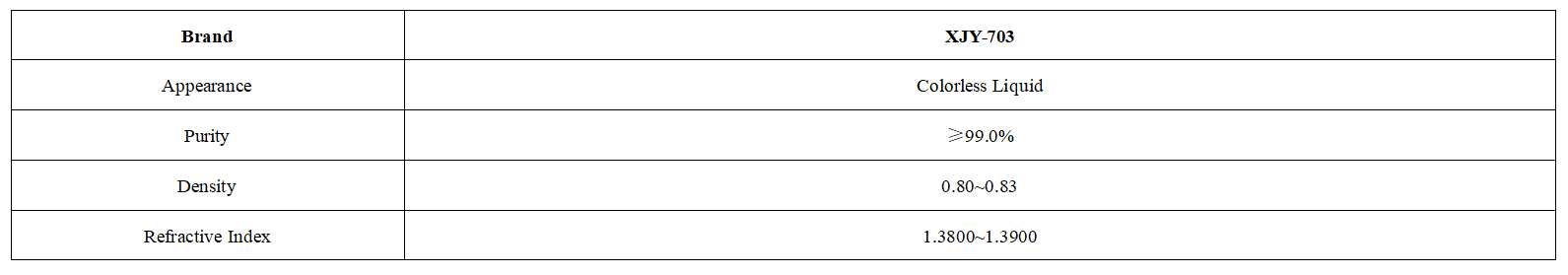

XJY-703 Heptamethyltrisiloxane

It is the base material for synthesizing polyalkyl epoxy-modified Heptamethyltrisiloxane, which is a kind of specific structural surfactant used in pesticide additives, coating auxiliaries, and also used in flexible polyurethane foam.

XJY-207 Polyalkyleneoxide Modified Heptamethyltrisiloxane

XJY-207 Polyether-modified heptamethyltrisiloxane-polyether-modified silicone oil is a commonly used silicone surfactant and is widely used in agriculture to improve the surface diffusion effect of pesticides, improve the diffusion performance, and thereby improve the effectiveness of drugs.

(5) Other applications:

Silicone oil can be used in cleaning and polishing agents because of its low surface tension, which can quickly and uniformly form a film on the surface of substances

The good compatibility of silicone products with the skin makes silicone-containing creams have special therapeutic effects on certain skin diseases. Silicone-containing ointments for burns and scalds can be made.

Silicone additives can cross-link with the amino and carboxyl groups on the surface of the leather to form a thin film, due to the presence of the film makes the surface of the leather glossy, waterproof, and breathable, and also can be the leather brightening agent.

4. What is the problem of silicone surfactant?

(1) The influence of the environment is suitable for use in neutral or weak acid, and weak alkali; strong acid and alkaline media lead to the destruction of carbon and oxygen chains.

(2) Silicone surfactants can significantly reduce surface tension compared to conventional surfactants, but have little synergistic effect on emulsification, dispersion, etc., and even have side effects.

(3) The hydrolytic stability of organosilicon surfactants is not high, and the Si-O-Si bond is easy to hydrolyze and condense, which leads to structural damage and disappearance of the performance of silicone surfactants.

5. How to solve the problem of silicone surfactants?

(1) Modification, such as the introduction of Polyether in Polysiloxane (combined with ethylene oxide, propylene oxide-based), especially the introduction of Polyethylene glycol ether, so that Polysiloxane can be soluble in water, and make it have good compatibility with cosmetic base materials, to solve the problem of silicone compounds are difficult to dissolve in water, not easy to emulsify.

(2) For the hydrolytic stability of solution four for the improvement of polyether, reduce the content of free polyethylene glycol, and closed-end hydroxyl; improve the molecular weight of lipophilic group, reduce the water solubility of silicone surfactants, the introduction of Si-Si or Si-C-Si in the main chain.

6. How do silicone surfactants perform better?

Silicone surfactants have many unique advantages and are widely used in the daily chemical industry. With the development of the fine chemical industry, it is believed that silicone surfactants will have a broader development space. How to improve the competitiveness of your products?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry as well as more than 15 related patents and technical support. Our silicone raw material products can meet the demand for silicone surfactants and support the provision of diversified customized solutions.