High-performance silicone resin production technology opens up a new route for low-cost high-performance silicone resin synthesis, compared with the traditional silicone resin production technology, the application of new technologies not only produces high-performance silicone resin products but also significantly reduces energy consumption and reduces the emission of organic solvents. Expanding the flexible use of these new technologies can also synthesize and improve a variety of types of high-performance silicone products (silicone rubber, pressure-sensitive adhesives, and so on). What are the classifications of silicone resins?

Silicone resins are classified into Methyl silicone resins, Phenyl silicone resins, and Methyl phenyl silicone resins according to the type of group attached to the side chain of the silicon atom. The following introduces Methyl silicone resins, Methyl silicone resins, Methyl Phenyl Vinyl silicone resins and their related components, and one-component room-temperature curing Methyl Phenyl silicone resins.

- What is silicone resin?

- What is the technological evolution of silicone resins?

- How to distinguish silicone resin?

- How to improve the performance of silicone resin?

1. What is silicone resin?

Silicone resin is a semi-inorganic and semi-organic type of polymer with -Si-O- as the main chain and organic groups in the side chain. Silicone resin is a body-type polymer, and with a number of reactive groups, these reactive groups further crosslink the reaction into the insoluble and non-melting three-dimensional structure of the curing product.

Compared with organic resins, silicone resins have good chemical resistance such as high temperatures resistance, UV radiation, weather aging resistance, water-repellent and moisture-proof, high dielectric strength, low dielectric loss, low viscosity, arc resistance, and irradiation resistance, and non-reactive.

General solution silicone resins are mainly used as heat-resistant coatings, weather-resistant coatings, and high-temperature-resistant electrical insulating materials based on polymers.

![]()

2. What is the technological evolution of silicone resins?

Among all kinds of silicone polymers, silicone resins are the earliest type of silicone products synthesized and applied. Compared with the high-speed development of silicone rubber's new and innovative technology, silicone resin's technological upgrading is relatively slow, and there are fewer major technological breakthroughs. About twenty years ago, due to the Aryl Heterocyclic high-temperature polymers of technological progress, a crowded part of the original belonged to the application of silicone resins, but the Aryl Heterocyclic heat-resistant polymers of solvent toxicity and harsh curing conditions limit the expansion of the application in recent years people began to attach importance to the research and development of silicone resins, silicone resins have a wide range of temperatures, aging resistance, and hydrophobic moisture resistance performance, such as outstanding advantages, signs indicate that the silicone resin is the earliest synthesized and applied a class of silicone products. The silicone resin has a wide temperature range, aging resistance hydrophobic moisture resistance, and other outstanding advantages, there are signs that silicone resin may also have a greater space for development in the future.

![]()

3. How to distinguish silicone resin?

3.1 Methyl silicone resin

(1) Synthesis of Methyl silicone resin from Methyl Chlorosilane

Methyl Chlorosilane as the main raw material for the synthesis of methyl silicone resin, due to the different structure and composition of silicone resin (silicone resin cross-linking degree, i.e., [CH3]/[Si]value), needs to be used separately in different synthetic process conditions.

When the synthesis of low R / Si ([CH3] / [Si] ≈ 1.0) methyl groups silicone resin, the main raw material monomer methyl trichlorosilane hydrolysis condensation reaction rate is quite fast, the reaction temperature must be strictly controlled not to exceed 0 ℃, but also need to be reacted in the composite solvent, and the reaction product at room temperature storage period of only a few days.

(2) Synthesis of Methyl silicone resin from Methyl Alkoxysilane

Methoxysilane Hydrolysis condensation reaction rate, can be controlled by changing the reaction conditions, methoxysilane can be synthesized from methyl alkoxysilane with different degrees of crosslinking of methyl silicone resin.

![]()

Medium degree of crosslinking ([CH3]/[Si] ≈ 1.2 ~ 1.5) of the commercial methyl silicone resin, most of the hydrolysis condensation reaction with methoxysilane produced: by the deacidification of refined Methyltriethoxysilane and Dimethyldiethoxysilane monomers and water mixed with a trace amount of hydrochloric acid or an appropriate amount of strong-acid-type cation-exchange resins (macroporous acid-type ion-exchange resins catalytic effect is better), the activated white clay (acidification treatment and drying) as the Acidification treatment and drying) as a catalyst, heating, hydrolysis reaction, to reach the end point, add an appropriate amount of hexamethyldisilazane to neutralize the catalyst hydrochloric acid, or filter out the catalyst ion exchange resin or active white clay to terminate the condensation reaction. The product obtained is an alcoholic solution of methyl silicone resin.

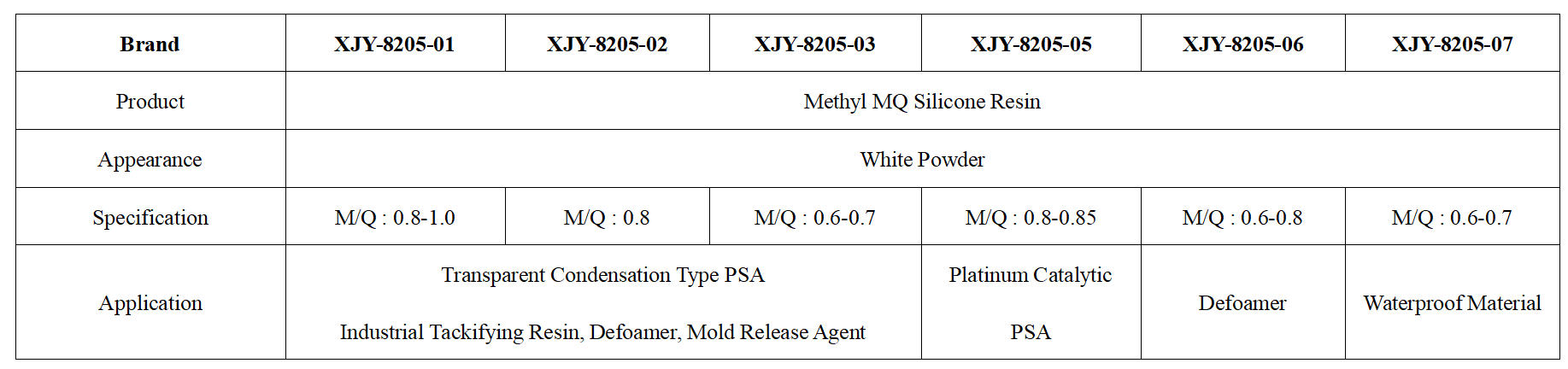

XJY-8205 Methyl MQ Resin

(Sodium silicate, reaction product with chlorotrimethylsilane and Isocobalt alcohol) It is the co-hydrolysis product of Tetraalkoxysilane (Q unit) and Trimethylalkoxysilane (M unit).MQ Resin is widely used in the fields of personal care, adhesives, defoamers, water repellents, etc., and it has good and high mold-releasing ability in the mold-releasing agent used for polyurethane processing.

3.2 Methyl phenyl silicone resin

The main raw materials for the industrial production of methyl phenyl silicone resin are Methyl Trichlorosilane, Dimethyl Dichlorosilane, phenyl Trichlorosilane, and Diphenyl dichlorosilane. Part or all of the monomer plus solvent toluene or xylene, according to the appropriate proportion of mixing, under the stirring of dropwise addition of water, control the temperature of the hydrolysis reaction, water washing to remove the reaction by-products of HCl (aqueous hydrochloric acid), hydrolysis of the silanol solution, and then evaporated out of part of the solvent into a condensed silanol, and then through the cold condensation or heat condensation reaction to produce silicone resin, and finally filtered, packaged, and get the finished silicone resin.

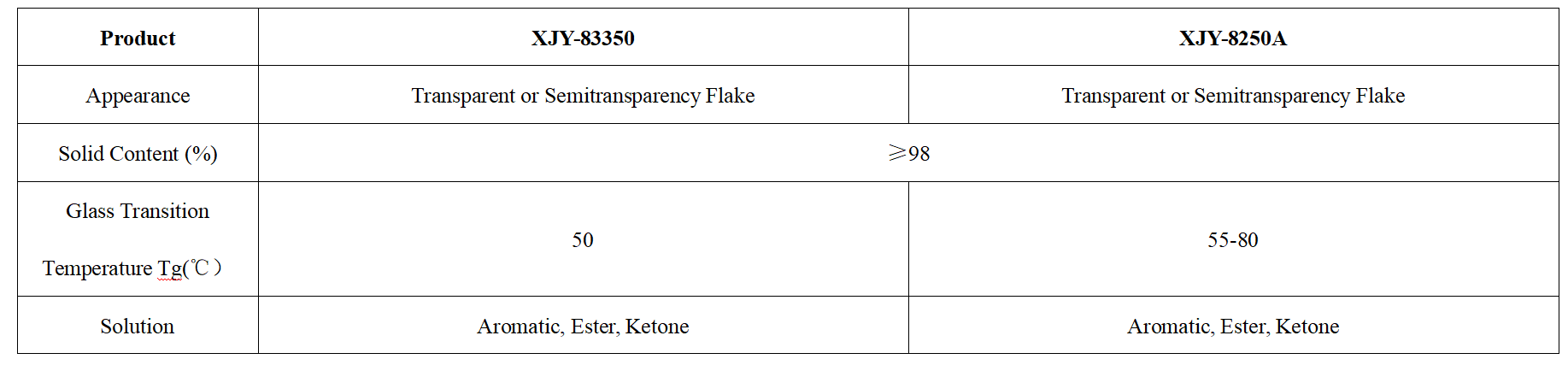

XJY-8250A Flake Silicone Resin is a methyl phenyl silicone resin with a hydroxyl functional group. XJY-83350 Polyester Modified Flake Silicone Resin is a polyester-modified methyl phenyl silicone resin intermediate. These two products can be used in high-temperature-resistant powder coatings and liquid coatings. The primary characteristic of the silicone resin is its excellent heat resistance, which hardly decomposes at 200°C or even higher, and can be used in the preparation of various heat-resistant paints with heat-resistant insulation levels up to H class. For example, the use of silicone resin as a base material, adding aluminum powder silver paint can be used at 400 ~ 600 ℃ under the use of long-term use, can be used for chimneys, steam pipes, exhaust pipes, gas installations, stoves, ovens, electric stoves, chemical equipment, boilers, engines, generators, electrical equipment, radiators and so on.

3.3 Methyl Phenyl Vinyl silicone resin and its related components

The production process of methyl phenyl vinyl silicone resin and methyl phenyl silicone resin is similar, but Methyl Chlorosilane and Phenyl Chlorosilane monomers are removed from the hydrolyzed raw materials, and then vinyl-containing silicone monomers such as methyl vinyl dichlorosilane and other vinyl-containing silicone monomers are added in an appropriate amount. The above-mixed monomers by hydrolysis, washing, and concentration, obtained by the concentrated hydrolysis of silanol, plus metal organic acid salt catalyst, reduced pressure heating condensation to a predetermined viscosity, or according to the gelatinization time to control the end of the condensation reaction, the production of Methyl Phenyl vinyl silicone resin.

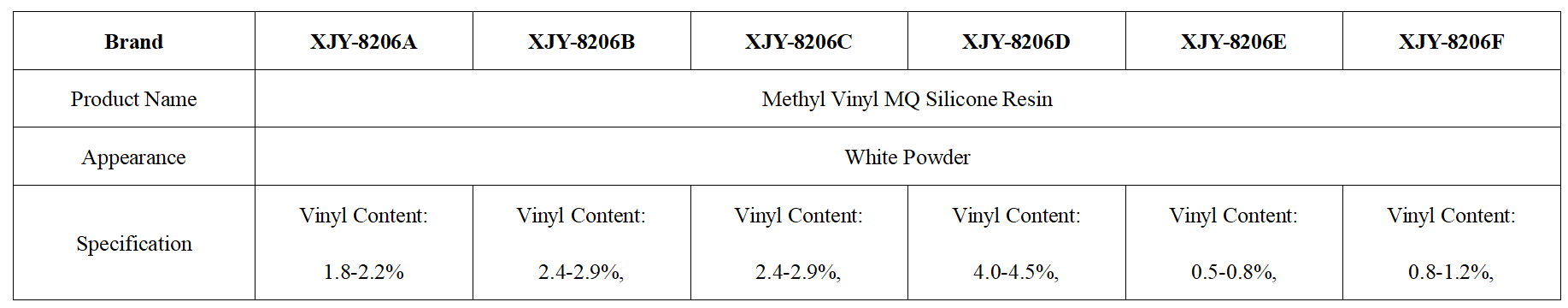

XJY-8206 Vinyl Methyl Silicone Resin is condensed from tetrafunctional siloxane (Q) and a functional methyl silicone (M), the molar mass is generally 2500-5000g/mol, and the molecular structure of the ratio of M and Q chain determines the structural properties of M resin.

Silicone polymers and silicone compounds made from VMQ materials can provide a wide range of physical properties such as temperature resistance, abrasion resistance, weathering resistance, resistance to permanent deformation in compression, and resistance to ultraviolet radiation. Moreover, they are harmless to humans, so this food-grade silicone can be used in the automotive, medical, and food industries.

Used as Methyl Phenyl vinyl silicone resin addition reaction crosslinking agent component of Methyl Phenyl hydrogen-containing Polysiloxane, usually for the degree of polymerization is not a large cyclic or linear polymer, they are made from methyl hydrogen-containing dichlorosilane by hydrolysis cyclization, or by methyl hydrogen-containing Dichlorosilane, Phenyl Trichlorosilane plus Trimethylchlorosilane Hydrolysis condensed and produced.

3.4 One-component room temperature curing Methyl Phenyl silicone resin

One-component Methyl Phenyl silicone resin retains the excellent performance of traditional Methyl Phenyl silicone resin, and at the same time, it has the advantages of single-package products that do not need to be mixed before use and can be cured quickly at room temperature.

One-component room temperature curing Methyl Phenyl silicone resin is a branched silicone polymer with multiple hydrolyzable reactive groups. After this silicone resin solution is coated onto the surface of the substrate, the polymer absorbs moisture from the air, the reactive groups are hydrolyzed and a cross-linking reaction of the polymer occurs until the coating film is cross-linked and cured.

![]()

The production of room temperature can be fast curing Methyl Phenyl silicone resin economic and practical technical route, which can start from the methyl Chlorosilane and Phenyl Chlorosilane, in the presence of organic solvents co-hydrolysis, the silanol mixture obtained by washing and acid removal, and then by nucleophilic catalytic condensation reaction, the preparation of a suitable amount of active silicone hydroxyl silicone resin pre-polymers, and then add the appropriate crosslinking agent and selective catalysts, and then further catalytic condensation reaction, the conversion reaction, and then add the appropriate crosslinking agent and selective catalyst. Then an appropriate crosslinking agent and selective catalyst, further catalytic condensation conversion reaction, to obtain the methyl phenyl silicone branched polymer with a number of hydrolyzable active groups. Finally, with the appropriate amount of stabilizers and other additives, add or subtract solvents to adjust the solid content, that is, the production of a high-performance one-component Methyl Phenyl silicone resin solution which can be quickly cured at room temperature.

4. How to improve the performance of silicone resin?

Under the guidance of chemical theory, through in-depth research and development of high-performance silicone resin production technology, it has been tested in production practice, the production of high-performance silicone resin products achieves the desired results in practical applications, high-performance silicone resin in the national defense and military supporting played an important role. How to improve the competitiveness of your products?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry as well as more than 15 related patents and technical support. Our silicone raw material products can meet the needs of the silicone resin field and support the provision of diversified customized solutions.