Cosmetics need to add film-forming agents in order to achieve “dryness”, “waterproof and anti-sweat”, and “long-lasting makeup” effects so that the product performance meets the needs of consumers. The cosmetic film-forming agent market has gradually occupied an important segment in the cosmetics industry. Why use TMS as a cosmetic film-forming agent?

It is a highly durable raw material with excellent water repellency, transfer reduction, and detergent washout resistance. It offers formulation flexibility. Cosmetics are evolving rapidly due to increased demand for quality of life, and products are constantly being updated. In order to create a flawless base and improve makeup application, it is necessary to add TMS film-forming agents to makeup products to improve their performance.

The following four aspects of the application of TMS in film-forming agents are introduced:

- What is a cosmetic film-forming agent?

- What is a silicone resin film-forming agent?

- XJY film-forming agent series?

- How to make film-forming agent performance better?

1. What is the cosmetic film-forming agent?

Cosmetic film-forming agents are generally polymers that form a film on the skin after application. This film protects the skin, increases the durability of the product, and improves the texture of the product.

According to the source and nature, they can be divided into silicone film-forming agents, acrylic resin film-forming agents, silicone acrylates, polyethylene copolymers, protein film-forming agents, copolymers of various types of hydrocarbons, and so on.

1.1 What are the advantages of film-forming agents in sun protection?

(1) Assist in enhancing SPF value and reducing the amount of physical sunscreen added;

(2) Enhance skin feel;

(3) Waterproof and sweat resistant;

(4) Abrasion resistance;

(5) Migration resistance.

1.2 What are the advantages of film-forming agents in color cosmetics?

(1) Quick drying and setting of foundation, mascara, eyeliner, etc;

(2) Helping to disperse color powder; improving gloss;

(3) Waterproof and sweat resistant;

(4) Wear-resistant;

(5) Migration resistance.

1.3 What are the advantages of film-forming agents in cream masks?

(1) Moisturizing:

The film-former can keep wet and stop water loss.

(2) Physical cleansing:

The use of film-forming agent tear-off masks when tearing off the surface of the skin is conducive to the removal of the gray layer, “dead skin” adsorption, to achieve physical cleansing, and exfoliation.

2. What is a silicone resin film-forming agent?

The film-forming and lubricating properties of silicone resins make the formed film comfortable and smooth to the skin and achieve the effect of breathability without smothering acne, which is quite popular in the cosmetic market.

2.1 What is the structure of silicone resin film-forming agents?

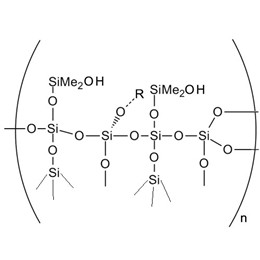

Structurally, silicone resin film-forming agents mainly contain silicon atoms and oxygen atoms as the basic elements, with a three-dimensional network structure of polymers. The basic structural units of silicone resin film-forming agents are the following four (M, D, T, and Q are used as shorthand symbols in the organosilicon chemical world):

2.2 What is the structure of MQ resins?

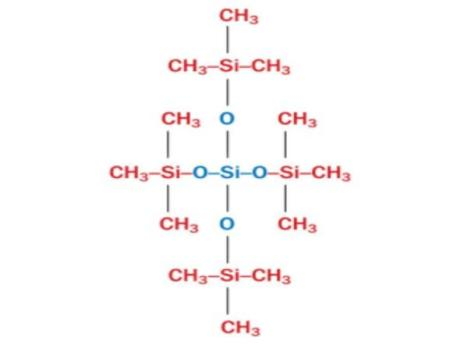

(1) MQ resins are composed of two monomers, M and Q. The INCI names for MQ resins are all [trimethylsiloxysilicate], and the expressive action of this polymer is determined by its exact structure.

The ratio of M to Q groups determines the structure of MQ resin and its application.

If the structure of MQ resin is abbreviated as MnQ, the simplest composition that can be envisioned is the following M4Q structure (M unit in red and Q unit in blue):

(2) It is generally recognized that MQ resin is a bilayer structure of compact spheres.

The core of the sphere is a higher density Q layer connected by Si-O-Si chains, and the shell of the sphere is a lower density M layer (R3SiO1/2), and the R groups of the MQ resin are all methyl groups.

The R on the spherical shell (M layer) is predominantly methyl, and when different R groups are introduced, a variety of different types are formed.

When R is all Methyl, it is called Methyl MQ resin, or MQ resin for short;

When R is all phenyl, it is called Phenyl MQ resin;

When part of R is phenyl (the rest is methyl), it is called Methyl Phenyl MQ resin;

There are also fluorine-containing MQ resins and Vinyl MQ resins.

3. XJY-Film-forming agent series

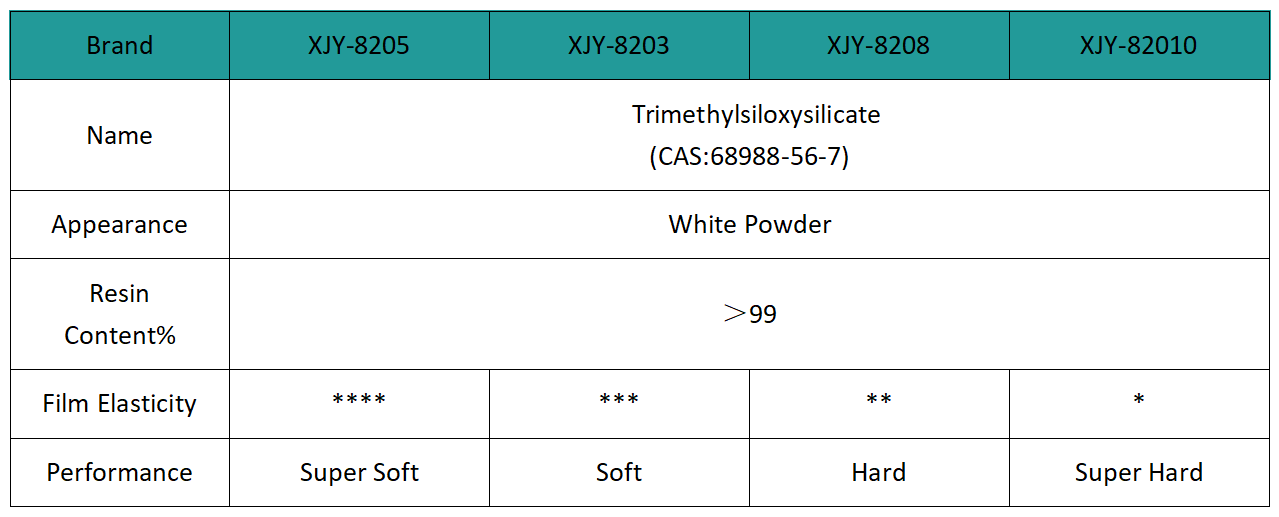

XJY's MQ resin is a siloxane polymer, which has a unique molecular structure, which makes the film-forming reticulation more powerful, waterproof, anti-sweat, and superior durability, and can be customized according to customer's different needs and product applications.

1、XJY-8203 Trimethylsiloxysilicate, MQ film-forming agent series can not only provide powder series but also provide silicone film-forming agent fluids dispersed in different carriers, bringing either refreshing or moisturizing or quick-drying unique performance, easy to use, no need to dissolve, to meet the needs of customers with different formulations.

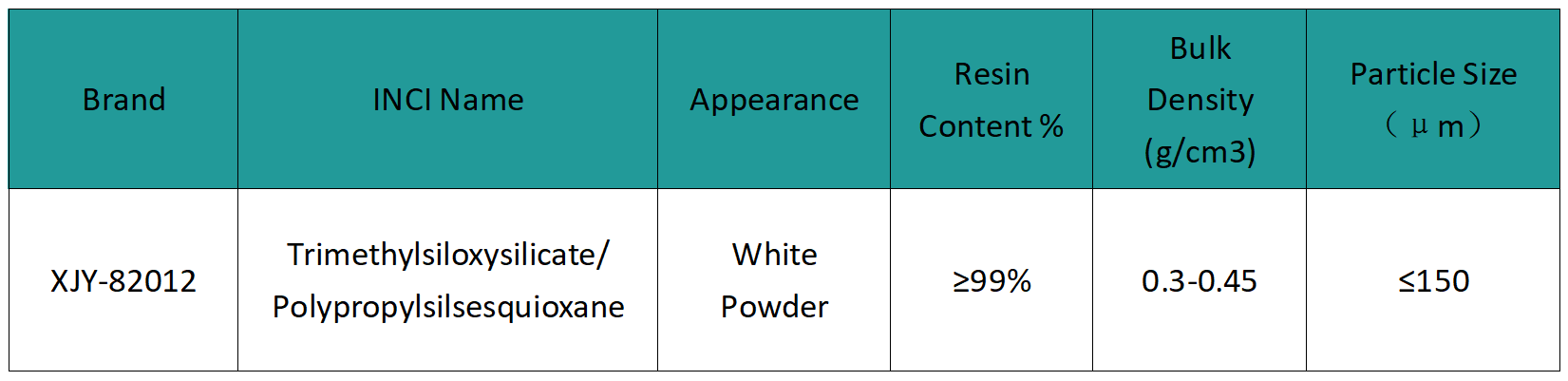

2、XJY-82012 Trimethylsiloxysilicate/Polypropylsesquisiloxane, has a free choice of solvent, and good formulation flexibility.

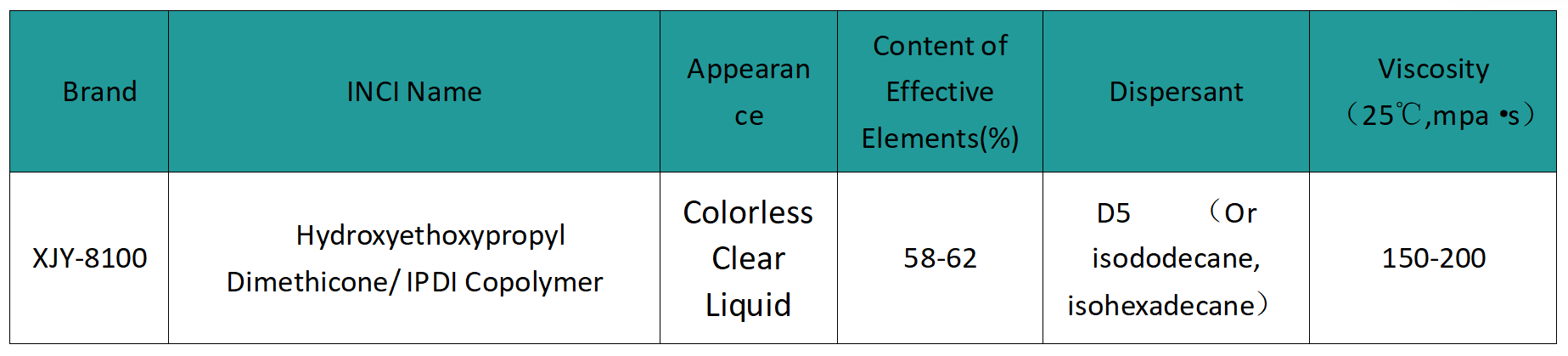

3、XJY-8100 Bis-Hydroxyethoxypropyl Dimethicone/IPDI Copolymer, this soft film-forming can provide a comfortable, non-tight experience; forming a breathable film, providing long-lasting moisturization, and good compatibility with most shading agents and color powders.

These benefits provide beauty formulators with more options and creative inspiration to help create high-performance differentiated foundations, sunscreens, and color cosmetics.

(1) XJY-8203 Trimethylsiloxysilicate TMS

XJY-TMS mainly contains monofunctional Si-O units (M units) and tetrafunctional Si-O units (Q units). Structurally, organic groups are attached to the silicon atoms, and it generally exhibit a dense three-dimensional spherical structure.

It is suitable for film-forming agents in various states and can be used in combination with super soft and hard films.

Functional Characteristics

Excellent hydrophobicity, film forming, and moisturizing properties, can be mixed with volatile silicone oil or polydimethylsilicone oil.

Good adhesion, migration, and wash resistance

Provide a matte, rich finish, and a soft, silky, non-greasy feel.

It can be used in accordance with the ultra-soft film and hard film with the use of a variety of different states of the film-forming agent adjustment

It increases the SPF value and reduces the amount of sunscreen, which optimizes the cost and is cost-effective.

Product Application

Soft film: sunscreen, cream, foundation, eye makeup, etc;

Medium film: lipstick;

Hard film (for styling): mascara, hair styling wax, nail polish etc.

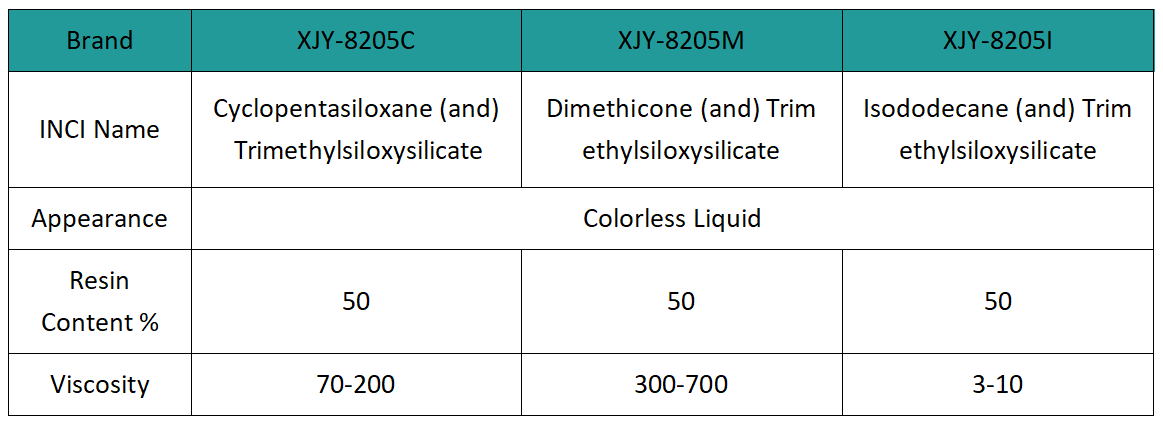

(2) XJY-8205 Series MQ Silicone Liquid Film Former

XJY - TMS also provides a series of silicone film-forming agent fluids dispersed in different carriers, which are recommended to be used in skincare, sunscreen, and color cosmetics to help the foundation, sunscreen, mascara, lipstick, bath products, etc. to hold makeup for a long period of time and to effectively increase the SPF value in the application of sunscreen, to provide a more comfortable skin feel, as well as resistance to oil, perspiration, and anti-migration properties.

(3) XJY-82012 MTQ silicone resin film-forming agent

The products are reaction products of MQ and TPD silicone resin, which can provide excellent transferability and water resistance to the product, and form a comfortable and flexible film.

Functional Characteristics:

Excellent transfer and wash resistance

Improve the color intensity of makeup, easy to formulate

Resistant to grease and wiping, improves gloss persistence

Increase SPF index

Comfortable skin feel, non-tacky and smooth to the touch

Application:

Cosmetics

Skincare products

Sunscreen

Hair care

(4) XJY-8100 MQ modified polysiloxane film-forming agent

It is a Polysiloxane polymer that forms a very thin soft film to improve adhesion, elasticity, and bonding. It can significantly improve durability, waterproofness, and serviceability after use, with a silky skin feel, good affinity with the skin, high ductility, and non-sticky and smooth characteristics.

Functional characteristics:

Good film-forming properties (super soft film), softness;

Excellent slipperiness lubricates the skin, non-greasy;

Good spreadability can improve the coverage of cosmetics;

Good water resistance

Polyurethane-modified film-forming agent with better adhesion than pure MQ resin.

Applications.

It can be used as lipsticks, lip glosses, and other kinds of products with long-lasting and waterproof performance.

It has a soft, silky touch, which can improve the durability of sunscreen products, reduce color differences, and maintain makeup.

It can reduce viscosity, used in moisturizing creams, face creams, and other personal care products.

4. How to make film-forming agent performance better?

In cosmetics, film-forming agents are widely used in cosmetics and personal care, such as foundations, lipsticks, mascaras, eye shadows, sunscreens, face masks, creams, and so on. They help these cosmetic ingredients adhere better to the surface of the skin, improving the durability, humidity resistance, and application of the products, as well as protecting the skin from damage caused by the external environment. How can we improve the competitiveness of finished products?

XJYsilicones has not only film-forming agent type MQ silicone resin but also a variety of other types of MQ resins, which can meet the needs of customers in different applications. XJY is one of the leading manufacturers of silicone resins in China, with more than 30 years of R&D and manufacturing experience in the silicone industry, It has long served many well-known brands at home and abroad, to meet the needs of the cosmetic field and can through cosmetic ingredient review, but also can be customized according to the needs of resin products.