In recent years, with the rapid development of electronic technology, the feature size of electronic devices has been drastically reduced from the micron scale to the nanometer scale, while the integration degree is increasing at a high rate of 40% to 50% per year. Currently on the market common thermal interface materials used in the electronics industry are thermally conductive silicone gel and so on. What is thermally conductive silicone gel?

Thermally conductive silicone gel is a gel state of the thermal conductivity of the material, through the silicone gel and thermally conductive filler composite together to form a thermally conductive silicone gel. It has a high thermal conductivity and low compressive deformation stress, and is easy to handle, allowing for continuous automated production for applications. It can solve the problem of poor performance reliability of thermally conductive silicone grease, play the role of thermally conductive gaskets, and in some performance aspects, better than thermally conductive gaskets.

The following 7 aspects of the application of thermally conductive silicone gel in the electronics industry:

- Why need to dissipate heat?

- What is the composition of thermally conductive silicone gel?

- What are the features of thermally conductive silicone gel?

- How is the oil permeability of silicone gel?

- What is the adhesion of the silicone gel?

- How to apply thermally conductive silicone gel?

- How to make silicone gel performance better?

1. Why need to dissipate heat?

The power loss in the operation of electronic devices is mainly converted into thermal energy, resulting in the rise in temperature of electronic equipment and thermal stress increases, seriously affecting the reliability and service life of electronic devices, so the need for heat sinks for this residual heat energy dissipated as soon as possible. In this heat dissipation process, thermal interfaces materials play a crucial role. Thermally conductive materials are mainly used to fill the micro-gaps and uneven surface holes generated when the electronic device is in contact with the heat sink, reducing the thermal resistance of heat transfer.

With the arrival of the 5G era characterized by high frequency and high speed and the maturation of 5G technology, various types of wireless mobile terminals such as smart wear, driverless cars, VR/AR, etc. are being vigorously developed, and the upgrading of hardware parts and components is occurring, resulting in a substantial increase in power consumption and a significant increase in the amount of heat generated; the antennae of 5G wireless mobile terminals have also reached 5~10 times the number of 4G wireless mobile terminals. 5G wireless mobile terminals also use new materials such as ceramic and glass shells that do not shield 5G signals, but the heat dissipation performance of these materials is weaker than that of metals, so materials with better thermal conductivity are needed. At the same time, the construction of 5G communication base stations also requires a large number of thermal interface materials to play a rapid heat dissipation. Therefore, on the one hand, the latest development of electronic technology has opened up a new field of application for thermal interface materials, making the role of thermal interface materials in various types of electronic products more and more important, and becoming an important material in the electronic heat dissipation project, and the use of the future will continue to increase dramatically; on the other hand, the continuous updating and upgrading of electronic products put forward brand new performance requirements and technological challenges for the thermal interface materials related to the industry chain.

2. What is the composition of thermally conductive silicone gel?

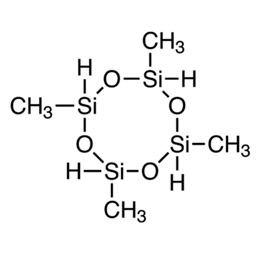

Silicone gel is a kind of liquid and solid together called “solid-liquid coexisting materials” Special silicone rubber, to polymer compounds constitute a network structure, with unique properties. Before curing, it is generally divided into A, and B two-component, catalyzed by platinum metal compounds, thermally conductive silicones resin matrix on the vinyl or propylene-based, and crosslinking agent molecules on the silicone hydrogen group reaction. The entire reaction vulcanizes as an addition reaction, producing no by-products and therefore no shrinkage. Thermally conductive silicone rubber is a straight-chain Polyorganosiloxane with a high molar mass (generally above 148,000 g/mol).

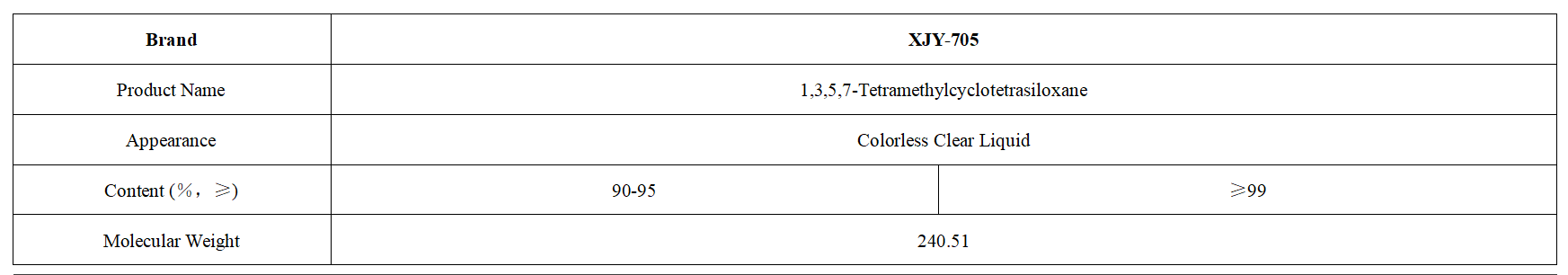

XJY-705 Tetramethylcyclotetrasiloxane TMCTS is a reactive organosilicon containing silicon hydrogen bonding, which can react with unsaturated olefins in an addition reaction, and can be used for the synthesis of room-temperature vulcanized silicone rubber.

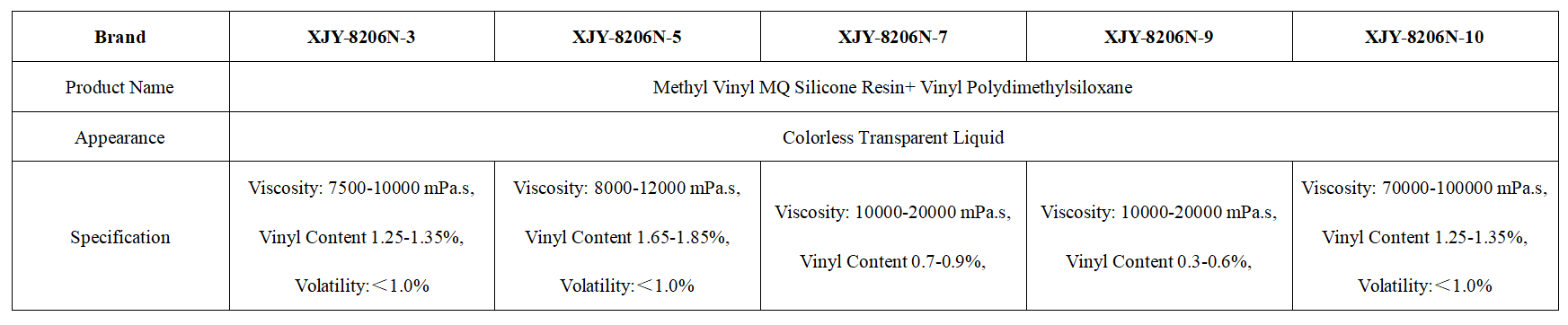

XJY-8206N Methyl Vinyl MQ Silicone Resin + Vinyl Polydimethylsiloxane is a colorless and transparent liquid resin containing methyl and vinyl groups, consisting of vinyl MQ silicone resin and vinyl silicone oil, which can be used for LSR liquid addition molding silicone rubber with low thermal resistance.

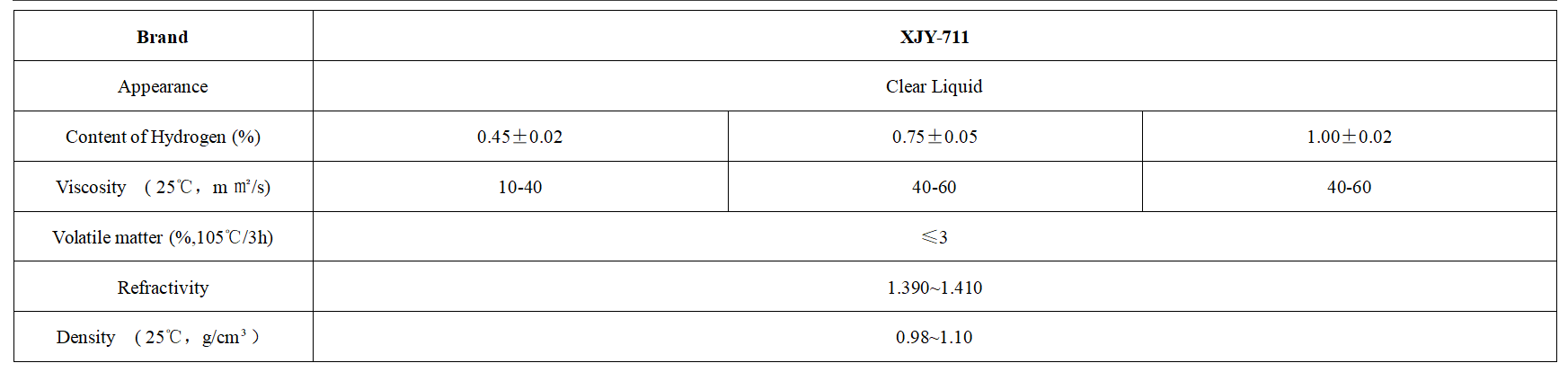

XJY-711 Hydrogen Terminated Methylhydrogensiloxane Dimethylsiloxane Copolymer is a colorless and transparent liquid, that can be used as a crosslinking agent of silicone rubber with excellent thermal conductivity.

3. What are the features of thermally conductive silicone gel?

R is usually Methyl, but in order to improve or enhance certain properties, it can also be introduced into other groups such as ethyl, vinyl, phenyl, and trifluoroaldehyde group, R′ is hydroxyl or alkyl, n represents the number of links. The main chain in the polysiloxane molecule is composed of Si-O-Si bonds, and its main properties are:

(1) Physical and chemical properties are stable, basically independent of temperature, can be used in the temperature range of 50 ~ 250 ℃, electrical insulation properties and resistance to high and low temperatures (-50 ~ 250 ℃) are excellent.

(2) Without primer or surface treatment agent, it can physically adhere to the surface of most common electronic devices or other materials, and there are no by-products or shrinkage during the curing process.

(3) The system is colorless and transparent, so it is easy to observe the internal structure of the potting component when used as a potting material. After curing in the semi-solidified state, many of the adherents have good adhesion and sealing performance, and excellent resistance to hot and cold alternating properties.

(4) Operable time is long, and it will not gel quickly after two-component mixing. Heating will promote curing, curing time can be flexibly controlled by adjusting the curing temperature. With good self-leveling, it is convenient to flow into the fine points between micro-components in the circuit.

(5) For different application scenarios, the gel can be flexibly adjusted for hardness, fluidity, curing time, and other properties, and can also be added to prepare silicone gel with flame retardant, and electrical or thermal conductivity.

(6) Good self-repairing ability, cracked by external forces, with the ability to automatically heal, and at the same time play a role in waterproofing, moisture, and rust.

4. How is the oil permeability of silicone gel?

In silicone gel vulcanization for the solid-liquid coexistence of the state, the crosslink density is low, so the production of thermal conductivity of silicone gel is prone to oil seepage problems, thereby contaminating the electronic devices, reducing the reliability of their long-time work, in order to improve the rate of thermal conductivity of silicone resins at the same time, we need to avoid the generation of oil seepage. Thermally conductive silicone gel crosslinking density, the greater the amount of oil seepage is smaller. This is because of the crosslinking density of the thermal conductivity of the silicone gel system, more silicone macromolecules react with each other and crosslink into a complete network structure system and mobility, and uncrosslinked resin basically does not exist, even if there is a trace of the existence of a complete network structure system in the unit volume of the formation of dense crosslinking points, the uncrosslinked resin in the movement and the network structure produces a larger coefficient of friction, preventing the uncrosslinked resin The flow of the uncrosslinked resin is hindered, thus reducing the amount of oil seepage.

5. What is the adhesion of the silicone gel?

In some applications, such as between the PET film of a battery module and aluminum alloy, there are certain requirements for the adhesion of thermally conductive silicone gels. Thermally conductive silicone gel adhesion performance is mainly related to the viscosity of the gel and the body strength, the viscosity of the gel determines the size of its adhesive strength in the bonding interface, and the body strength is determined by the gel itself is destroyed when the force required, which is usually referred to as the cohesive force of the gel. The size of the adhesion depends on the colloid produced by the interface of the adhesive force and the cohesive force of the body of the smaller. If the adhesive force of the colloid is less than the colloid itself is destroyed when the cohesive force is required, the occurrence of interfacial damage and the size of the adhesion depends mainly on the adhesive force of the colloid that viscosity; if the adhesive force of the colloid is greater than the colloid itself is destroyed when the cohesive force required, the occurrence of cohesive damage, the size of the adhesion depends mainly on the cohesive force of the body.

6. How to apply thermally conductive silicone gel?

(1)Avionics equipment

A type of avionics switch low-temperature data packet loss failure due to the original design of the use of thermally conductive gaskets for the local stress is too large. Compared with traditional dielectric materials such as thermally conductive silicone grease, thermally conductive adhesive, and thermally conductive spacer, thermally conductive silicone gel, as a new type of thermal interface material, has achieved better test results in a number of targeted tests such as high and low-temperature performance test, crash safety test, continuous vibration test, etc., and it can be applied to the production of avionics products.

(2) 5G electronic equipment

The use of the new thermally conductive silicone gel material can both enhance the conduction effect of thermal energy and realize the conduction of thermal energy. Compared with traditional heat-conducting materials, the use of new thermally conductive silicone gel materials in the application of electronic components can effectively improve the efficiency of signal propagation and promote the high-quality application of new thermally conductive silicone gel materials.

(3) Power battery

The vast majority of power batteries use lithium-ion batteries, which have the advantages of high energy density and long service life, but there are also major safety hazards. During normal driving of electric vehicles, the impacts that lithium batteries may endure include continuous vibration, large temperature changes, rain immersion, etc. In the case of battery failure and traffic accidents (e.g., collision, falling into a river), the impacts that the battery may endure include local short circuit, overloading, strong mechanical impact, immersion in water or other liquids, fire, etc. Therefore, in complex or even unexpected environments, the impacts that lithium batteries may endure are not as serious as those of other batteries, but they may be more serious. Therefore, maintaining the safe operation of Li-ion batteries in complex or even unexpected environments and protecting the safety of drivers and passengers in electric vehicles are the goals pursued by all parties. If the thermally conductive and flame retardant silicone gel is used to encapsulate the power battery cell, it can greatly improve the safety performance of the power battery pack, and the thermally conductive silicone gel can play the role of waterproof sealing, flame retardant sealing, heat dissipation and shock absorption and fixation.

7. How to make silicone gel performance better?

With the arrival of the high-frequency, high-speed 5G era, the integration of electronic devices, and the increase in the number of networked devices and the number of antennas, the power consumption of the equipment continues to increase, and the heat generation also rises rapidly. The new thermally conductive silicone materials with good thermal properties are also bound to become indispensable materials in strategic emerging fields and widely used in various fields. How to improve the competitiveness of your products?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry and more than 15 related patents and technical support. Our silicone raw material products can meet the needs of the electronics field and support the provision of diversified customized solutions.