After decades of development, the silicone materials used in coatings have not only been limited to silicone resin, with the development of the electronics industry, silicone rubber-based coatings and inks have also developed rapidly. To improve the performance of coatings, a variety of silicone and its secondary processed products are also widely used. What are the applications of silicone coating?

- Insulating materials

- Primary coatings

- Heat-resistant coatings

- Industrial maintenance coatings

- Hygienic Coatings

1. Insulating Materials

The first application technology of silicone resin as a coating was silicone-impregnated fiberglass cloth tape, which was used as a protective layer for wire insulation on navy submarines. Silicone resin is also mainly used in the impregnation of coils for H-class motors, the impregnation of fiberglass cloth for wire wrapping and slot insulation for H-class motors, the impregnation of fiberglass insulating sleeves, and mica tapes for insulation.

Therefore, pure silicone resin as an insulating coating is the oldest silicone product. The pure silicone resin produced by the old process has the advantages of high-temperature resistance, weather resistance, good insulation, and other general-purpose organic resins can not be compared, but there are also shortcomings such as high curing temperature, long curing time, poor adhesion, and sticking back at high temperature. With the development of science and technology and the development of new materials, silicone is not the only H-class insulating coating material, there are Polyimide and Polyester and other high-performance organic resins H-class insulating varnish.

Therefore, in order to adapt to the needs of the situation, silicone coatings must be developed for new processes, new technologies, new varieties, and new uses. Through the reform of the silicone resin production process and the use of organic resins and silicone resin cold splicing or copolymerization modification and other new technologies, silicone resin's three defects have been greatly improved, and silicone coatings application areas have also been expanded.

2. Primary coatings

The bonding force between the coating and the substrate includes mechanical bonding force, chemical bonding force, diffusion force, and dipole force. The size of the bonding force directly affects the adhesion of the coating.

Methods to improve the adhesion between the coating and the substrate are mainly: substrate grinding, sandblasting, reducing the construction viscosity of the coating, improving the construction temperature, improving the wettability of the substrate (using solvent wiping, corona, flame burning, oxidizing agent treatment, etc.), related to silicone is the use of silane adhesion promoters in primer.

Alkoxysilanes can improve the adhesion, fluidity, leveling, abrasion resistance, dispersion of pigment and filler, water resistance, and salt spray resistance of coatings and substrates, and it has been widely used in primer formulations for a variety of metals, concrete, and silicone-containing materials(which can be used in metal roofs or other silicone roof coating systems).

(1) Adhesion promoter

Alkoxysilanes (mainly various silane coupling agents) must be used as adhesion promoters at the interface between the coating and the substrate or between the sealant and the adhesive material to increase adhesion. The use of adhesion promoters as a primer is usually done by applying or spraying silane to the surface of the substrate after it has been formulated into a 0.5% to 5% ethanol or alcohol-water dilution.

In addition to increasing adhesion, the use of silane primers improves hydrophobicity, UV resistance, weathering resistance, thermal stability, surface activity, chemical resistance, and corrosion resistance. The selection of adhesion promoters needs to be matched with the organic molecules in the coating, and common adhesion promoters are matched with polymers.

(2) Anti-corrosion primer with rust

A kind of anti-corrosion coating with rust that can be used as a metal primer. When the metal surface rust removal is not complete, the coating can be used to brush directly on the metal surface, it has good adhesion.

The coating also has stabilizing, transforming, and physically encapsulating effects on rust, transforming the harmful rust into useful substances, thus improving the anti-corrosion performance of the whole coating. It is made of Alkyd resin as the film-forming material, adding antirust pigment and other additives. Adding a silane coupling agent can make the primer improve various indexes, especially covering power, drying time, salt water(or rain) resistance, and Acid and alkali resistance, which can be used as silicone roof coatings.

3. Heat-resistant coatings

As the main chain of silicone polymers is an SI-O-SI-O bond, the side base is organic, therefore, with both inorganic and organic properties, high temperatures resistance is better than most organic resins.

Metal filler has high thermal conductivity, and can transfer the heat on the coated substrate; in addition, due to the oxidation of silicone resin, metal particles, and silicone resin fusion, the formation of a stable structure containing a metal-siloxane bond similar to ceramic coatings.

If more reinforcing fillers (such as mica powder or wollastonite powder) are added to the formula, better thermal stability can be obtained. Even for silicone-modified organic resins or organic resin-modified silicone resins, the addition of pigmented fillers can greatly increase their heat-resistant temperature.

High-temperature resistant coatings with high-temperature resistant pigments or fillers are mainly used in chimneys, automobile mufflers and exhaust pipes, boilers, ovens, steam pipes, barbecues, stoves, heat exchangers, incinerators, wood-burning stoves, fireplace inserts and doors, space heaters, lighting fixtures and bulbs, portable oil stoves, kitchen stoves, and dryers in laundries.

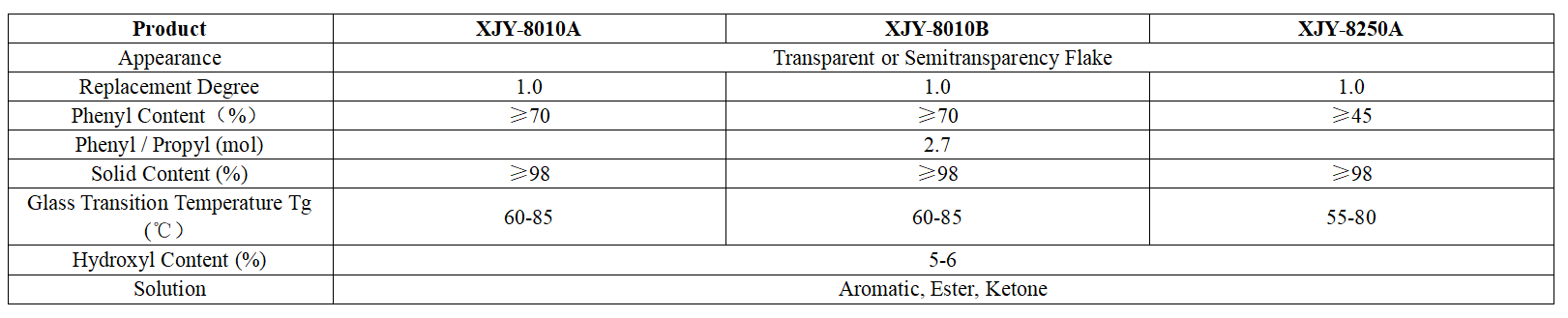

XJY-8010/8250 Flake Silicone Resin

It is a solid powder resin, that can provide excellent transfer resistance and water resistance and also can form a long-lasting film, long-lasting and durable, in the field of building materials that can be used as silicone coatings to prevent water vapor.

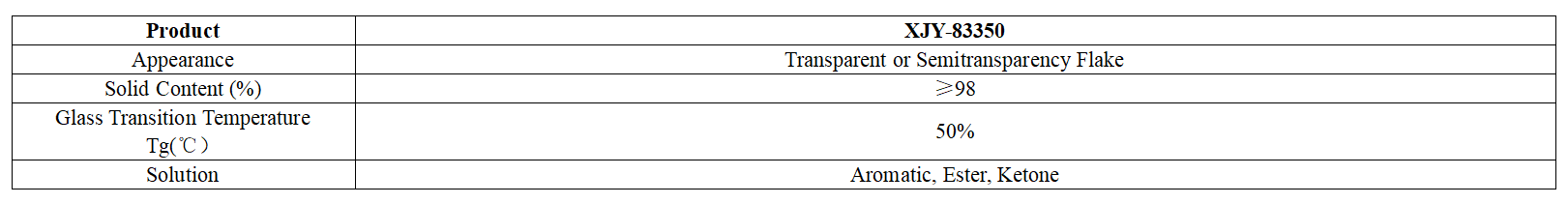

XJY-83350 Polyester Modified Flake Silicone Resin

It has excellent weather resistance, ozone resistance, electric arc resistance, Hydrophobic moisture resistance, salt spray resistance, mold resistance, and other properties. It can significantly improve the waterproof coating paint water resistance, temperature resistance, and other properties.

4. Industrial maintenance coatings

Industrial maintenance coatings are mainly used in industrial anticorrosion, home appliances, ships on the water part, furniture and coil and roof coating(existing roof), and so on. In the early years, taking into account the high cost of organic silicon, industrial maintenance coatings use more organic resin coatings. In recent years, due to the continuous increase in oil prices, the trend in the coatings market has been to reduce volatile organic compound (VOC) emissions and lower costs. Extending the service life of coatings is one of the ways to reduce VOC emissions and lower costs. Introducing silicones into organic resins is a good way to extend the life of coatings.

Market demands for control of coating emissions, control of total coating construction costs, and technological advances in coating performance have driven the development of silicone-organic resin composite coatings for industrial maintenance coatings. This is because efficient, long-lasting composite coatings reduce the additional cost of coatings.

5. Hygienic coatings

Food hygiene is essential for human health. In health care and food processing equipment need to meet the hygiene standards of the coating. The selection of new biocides is subject to multiple reviews, and the commercialization of new sterilants requires costly trials and cumbersome approval documentation; in contrast, prevention of microbial contamination can be achieved with easy-to-clean coatings, which can be done with much less hassle. The most commonly used sterilization method is UV irradiation; however, UV irradiation reduces the adhesion and abrasion resistance of organic resin coatings, and cleaning with friction-based cleaners and chemical disinfectants destroys the protective properties of the coating. If silicone is introduced into the coating, it can give the coating excellent UV resistance, hydrophobicity, low surface energy (20-22 mN/m), non-sticky and chemical detergent resistance, and extend the service life of the coating.

It applies to the Hydroxyl-containing Polymethylsiloxane, Polymethylphenylsiloxane composed of silicone anti-adhesive coatings (such as silicone light glaze), coated in aluminum, tinned iron plate, and other metal surfaces, after natural evaporation, high-temperature baking and curing of the film can be used as a food mold anti-adhesive coatings.

6. How to make the coating performance better?

Silicone application technology in coatings has developed from specialized, high-performance coatings to a wider range of fields. The application of silicone can improve the insulation, heat resistance, weathering, stain resistance, abrasion resistance, and other properties of coatings. How to improve the competitiveness of your products? If you have any questions please contact us (such as shipping costs and lead time).

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry as well as more than 15 related patents and technical support. Our silicone raw material products can meet the needs of the coating field and support the provision of diversified customized solutions.