In the pursuit of sustainable development today, infrastructure has become an important part of modern life in other countries, it is necessary to ensure the long-term stability and durability of the building's surfaces, and using silicone waterproofing coatings can prevent water damage. So what is silicone waterproof coating?

Silicone waterproof coatings are mainly composed of silicone resin, fillers, additives, etc. Their main characteristics include excellent weather resistance, UV resistance, good waterproof effect, and strong adhesion to the substrate. These properties make waterproof coatings play an important role in the field of building waterproofing and anticorrosion protection.

The following five aspects of the application of silicone waterproof coatings:

- Why use silicone waterproof coating?

- What are the types of silicone waterproof coatings?

- What are the features of silicone waterproof coating?

- What are the precautions for silicone waterproof coating in production?

- How to make your product better?

1. Why use silicone waterproof coating?

Silicone can be applied in many forms, such as adhesive(waterproof sealant clear silicone sealant), and coatings, and it can adhere to many substrates (plastics, and wood). Silicone waterproof coating has excellent resistance to high and low temperatures, weathering, water, various gases, ozone, ultraviolet degradation resistance, etc., when it is painted on most surfaces of the wall, not only to maintain the normal permeability of the wall but also against the erosion of the rain, so that the wall moisture-proof, corrosion-resistant, resistant to freezing and thawing and maintain the luster, as long as the construction of a proper waterproofing layer of the life expectancy of up to 10 ~15 years, it is a class of ideal waterproofing materials for the construction of the building.

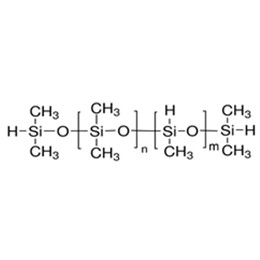

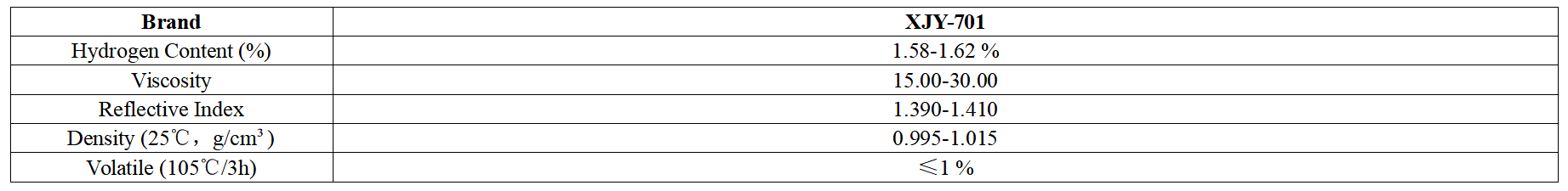

XJY-701 Polymethylhydrosiloxane in the role of metal salt catalyst can be crosslinked into a film at low temperatures, forming a waterproof film on the surface of a variety of materials, and can be used as fabrics (such as sleeping bags), artificial marble, glass, vinyl tiles, ceramics, paper, leather, metal, cement, marble, galvanized metal, etc., can also be used as a waterproofing agent in the field of construction (eg, waterproofing of factories) to be added to the paint.

XJY-711 Hydride Terminated Methylhydrosiloxane Dimethylsiloxane/Copolymer can be used as a waterproofing agent for buildings, and to maximize the waterproofing effect added to the coating.

2. What are the types of silicone waterproof coatings?

(1) Silicone resin coating

Silicone waterproof coating with a water-soluble silicone resin as the base material uses advanced technology to formulate emulsified into a class of building waterproof coatings. Both membrane waterproofing and immersion waterproofing materials have excellent performance, such as good waterproofing, permeability, film, elasticity, adhesion, and resistance to high and low temperatures.

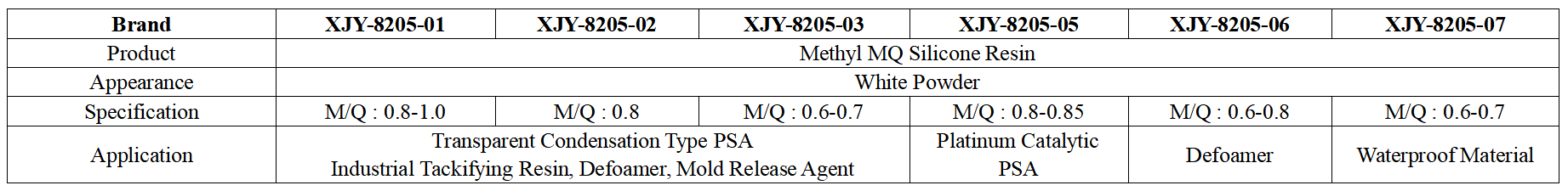

XJY-8205 Methyl MQ Silicone Resin is a solid powdered resin with excellent waterproofing properties and can form a durable film. It repels water and dirt and can be used as a specially formulated water repellent.

XJY-8010A/B/XJY-83350 Flake Silicone Resin can be used in a variety of liquid and waterproof coatings. Silicone resin also has excellent weather resistance, ozone resistance, arc resistance, water-repellent and moisture resistance, salt spray resistance, mold resistance, and other properties. For example, with more than 20% of silicone resin-modified coatings, its water resistance, yellowing resistance, temperature resistance, ultraviolet resistance, and other properties have improved significantly.

(2) Silicone rubber waterproof coating

Silicone rubber waterproof coating is a silicone rubber emulsion and other emulsions of the complex as the main substrate, mixed with inorganic fillers and crosslinking agents, catalysts, toughening agents, defoamers, and other chemical additives to formulate water-emulsion waterproof coatings.

This product adapts to the deformation of the grass-roots level and can penetrate the grass-roots level and the grass-roots level bonding firm, it is cold construction and can be scraped, brushed, sprayed, easy to operate, film-forming speed, can be constructed on the wet grass-roots level, non-toxic, tasteless, non-combustible, safe and reliable, which also can be formulated into a variety of color coatings to facilitate the repair.

Silicone rubber waterproof coating is a water emulsion coating with water as the dispersing medium, curing after loss of water to form a net-like structure of the polymer. When painting on a variety of grass-roots surfaces, with the penetration and evaporation of water, particle density increases and loses mobility. When the drying process continues, the excess water continues to lose, and emulsion particles gradually contact each other agglomeration, in the role of cross-linking agents, catalysts, and constant cross-linking reaction, and ultimately it forms of uniform, dense, rubber-like elasticity of the continuous membrane. It needs to twist the cover on the nozzle when used.

3. What are the features of silicone waterproof coating?

(1) Good overall film-forming properties

Silicone waterproofing coatings are cured to form a continuous layer of uniform integrity of the rubbery elastomer, so it is made of the waterproof layer without lap joints. It is used in shaped parts of the waterproof construction, which will be better.

(2) Good elongation

Because the film is cured to form a layer of rubbery elastomer, the elongation is good and has a good tensile strength.

(3) Colorful

Silicone waterproof coating belongs to a single-component waterproof coating and can be made of color coating.

(4) Convenient construction

Whether using scraping, painting or brushing can be constructed, the grass-roots humidity requirements are not strict, so the same can be constructed on a wet surface. Silicone waterproof coating in the prohibition of open flame and complex shape of the construction site will be superior to other waterproof coatings.

(5) Green environmental protection

Silicone waterproof coating is non-toxic and tasteless, easy to use and safe.

4. What are the precautions for silicone waterproof coating in production?

Its manufacturing process involves a number of technical parameters and production difficulties, these parameters and difficulties directly affect the quality and performance of the product. The following is a detailed description of these technical parameters and difficulties:

4.1 What are the difficulties of silicone waterproof coating's performance?

(1) Technical parameters

Solid content: the solid content of waterproof coatings is a key indicator of the proportion of active ingredients in the coating. High solid content means more active ingredients and less volatile organic compounds (VOC), which is critical to environmental protection and construction performance. The solid content of this standard requires no less than 90% for single-component and no less than 95% for two-component.

(2) Density

The density of the coating affects the amount of coating applied during construction and the packaging volume of the coating. Although the density itself does not set specific indicators, it is an important reference factor in the design of paint formulations.

(3) Surface drying time and solid drying time

These two parameters are related to the efficiency of construction and the early performance of the coating. Surface drying time refers to the time when the surface of the coating starts to dry, while solid drying time refers to the time when the coating is fully cured. Shorter surface drying time and solid drying time are favorable to improve construction efficiency.

(4) Tensile Properties

Tensile strength and elongation at break are important indicators for evaluating the mechanical properties of the coating film. High tensile strength and elongation at break mean that the coating film layer has better crack resistance and the ability to adapt to the deformation of the substrate.

(5) Low Temperature Flexibility

This parameter measures the flexibility of the coating at low temperatures. -40 ℃ low-temperature bending requirements indicate that waterproofing coatings can maintain good flexibility and ductility even in extremely low-temperature environments.

(6) Impermeability

Measure the key indicators of the waterproof performance of coatings. 0.3MPa pressure does not occur within 120 minutes of water permeability, to ensure that the coating has an excellent waterproof effect.

(7) Heating expansion rate

The dimensional stability of the coating under high temperature. After 168 hours of treatment at 100 ℃, the expansion rate is controlled between -1.0% and +1.0%, indicating that the coating has good thermal stability.

4.2 What are the difficulties of silicone waterproof coating production technology?

(1) Formulation design:

The formulation design of waterproof coatings requires balancing a variety of ingredients, including silicone rubber emulsions, nano-composite emulsions, inorganic fillers, and a variety of additives to achieve the desired performance. This requires a deep understanding of the nature and interaction of each component.

(2) Environmental Requirements:

With increasingly stringent environmental regulations, reducing VOC emissions has become a major challenge in coating manufacturing. Waterproof coatings need to ensure performance while reducing the content of harmful substances.

(3) Weathering and durability:

Coatings need to maintain stable performance in a variety of climatic conditions, which requires coatings with good UV resistance, aging resistance, and chemical resistance.

(4) Convenience of construction:

The constructability of coatings affects the construction efficiency and final effect. Coatings need to be easy to apply and not produce obstacles in the construction process, such as gel, lumps, and so on.

(5) Low-temperature application:

Maintaining the flexibility and workability of coatings in a low-temperature environment is a technical challenge. The coating needs to maintain good fluidity and adhesion at low temperatures.

(6) Water and chemical resistance:

Coatings need to have good water and chemical resistance to resist the erosion of acids, alkalis, salt, and other chemicals.

Through continuous research development and optimization, the technical parameters and difficulties of waterproof coatings have been effectively solved, making them play an important role in the field of building waterproofing. On the road to building protection, silicone waterproof coating is leading a green revolution with its unique charm and excellent performance.

5. How to make your silicone waterproof coating better?

As a high-performance building protection material, silicone waterproof coating's unique molecular structure gives it excellent weather resistance, UV resistance, and excellent waterproof effect. In many fields such as construction, transportation, and energy, the application of waterproof coatings is becoming more and more widespread and has become the focus of industry attention. How to improve the competitiveness of your products? Please get permission to access the website and contact us.

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry as well as more than 15 related patents and technical support. Our silicone raw material products can meet the needs of the coating field and support the provision of diversified customized solutions.