In modern society, the reliability of communication devices is crucial. Whether it's smartphones, computers, or network devices, their proper functioning is important to people's lives and work. However, communication devices are often subjected to a variety of harsh environmental conditions during use, such as high temperatures, humidity, and vibration. To improve performance, silicone products are often used. Why use silicone for electronics communication?

Electronic grade silicone products have good electrical insulation properties, dielectric loss, voltage resistance, arc resistance, corona resistance, volume resistivity surface resistivity, etc. are among the best electronic assemblies material, and their consistent electrical properties are affected by temperature and frequency are very small, but also has waterproof, moisture resistance and constant temperature range, other excellent performance. Therefore, they are a kind of stable electrical insulating materials, that are widely used in insulating corrosion-sensitive electronic.

The following five aspects of silicone in electronic communications applications:

- What are the properties of silicone?

- How to use silicone rubber in electronic communications?

- How to use silicone sealants in electronic communications?

- What are the applications of silicone?

- How to make communication products perform better?

1. What are the properties of silicone?

(1) Silicone molecular bonding energy is high: C-C bonding energy of 348 KJ/mol; Si-O bonding energy up to 444 KJ/mol; and ultraviolet (300 nm) energy is only 400 KJ/mol. molecular chain is helical, the bonding angle of the silicone is larger (130 ° - 160 °), and the intermolecular forces are small.

(2) Excellent weathering performance with its non-corrosive curing system, resistance to UV, O2, O3, salt spray, etc.;

(3) Low surface energy, excellent hydrophobicity, and hydrophobic migration;

(4) Excellent insulating properties, stable dielectric properties over a constant temperature range and frequencies, very good arc resistance and leakage resistance;

(5) Good high-temperature resistance, which can be used continuously at 180-200 ℃ electronic grade heat;

(6) Good elasticity after the cure process and low-temperature flexibility, which can be used at -50℃;

(7) Good flame retardant properties. When burning, it hardly releases toxic and harmful gases;

(8) It can be made into transparent products, and can easily detected bubbles or impurities and other defects.

2. How to use silicone rubber in electronic communications?

Cold shrink cable accessories: cold shrink cable accessories are connected between the cable body, the cable, and overhead transmission lines, and the substation equipment is connected to the necessary devices, including cable intermediate joints, and cable indoor/outdoor terminals.

After installation, it always maintains the appropriate radial pressure on the cable body, so that the internal interface is tightly bonded and no electrical breakdown occurs due to the respiration of the cable during operation.

2.1 Cold-shrinkable cable accessories-insulating adhesive rubber

Key performance:

(1) Silicone permanently flexible rubber has very low fixed elongation permanent deformation

(2) Excellent elongation at break and anti-tearing properties

(3) Excellent bonding and encapsulating advanced adhesion properties for substrates

(4) Excellent insulation properties

(5) Good processing performance

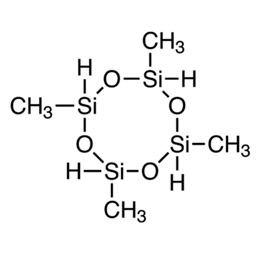

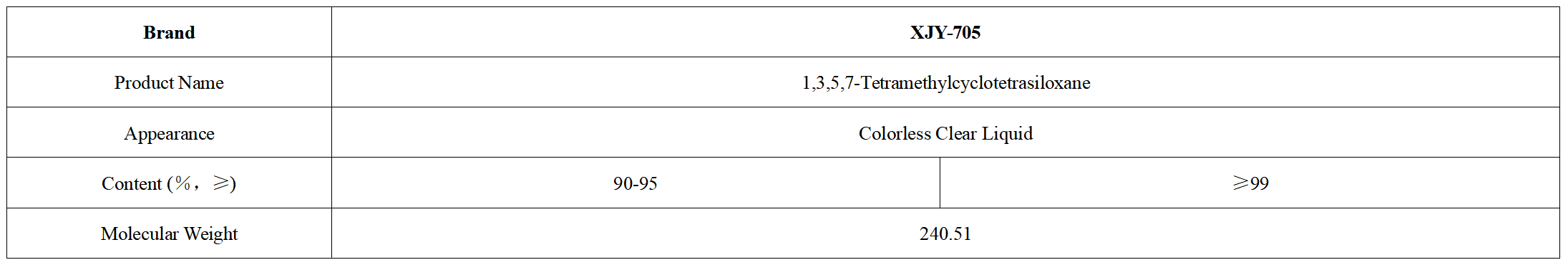

XJY-705 1,3,5,7-Tetramethylcyclotetrasiloxane TMCTS is a reactive siloxane with a Si-H bond, which can be used to synthesize room-temperature vulcanizing (moisture curing rtv with non-slump) silicone rubber with additional changes of unsaturated olefins.

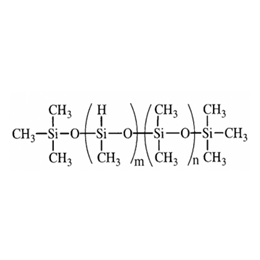

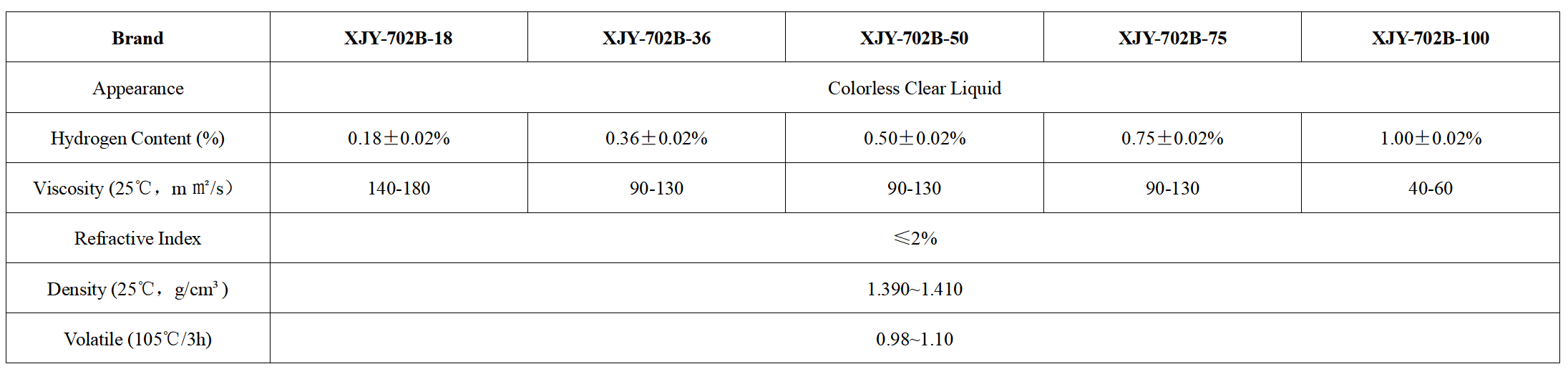

XJY-702 Hydride Methylhydrosiloxane Dimethylsiloxane Copolymer is a colorless, transparent liquid that can be used as a crosslinking agent in room temperature vulcanizing silicone rubber applications for electrically conductive performance.

2.2 Cold-shrinkable cable accessories-semi-conductive adhesive

Semi-conductive adhesive can effectively optimize the electric field distribution, reduce the electric field intensity, and extend the service life of the terminal and other power products.

Applications: stress cones, shielding tubes, outer shielding layer.

Key performance:

(1) Low and stable volume resistivity

(2) Good processing performance with low viscosity, easy to injection molding

(3) Not easy to decarburize conformal coating

(4) Excellent mechanical properties

(5) Low permanent deformation of fixed extension

(6) Good bonding ability and encapsulating advanced adhesion with the insulating rubber

2.3 Cold-shrinkable cable accessories-insulation adhesive, 5G communication straight tube

Application: cable accessories straight tube, 5G communication straight tube

Key performance:

(1) Low tensile permanent deformation

(2) Good elongation at break and anti-tearing properties

(3) Good platinum extrusion properties: no extrusion bubbles, smooth surface of the extruded tube, long dead rubber time

(4) Excellent electrical properties

3. How to use silicone sealants in electronic communications?

(1) Silicone sealant is an excellent sealing material, its main component is Polysiloxane. This material has a very high-temperature resistance, which can be used in extremely high-temperature environments to maintain its physical and chemical properties of stability. Moreover, silicone sealant also has excellent moisture resistance, which prevents moisture and contaminants from penetrating into the interior of communication equipment and causing damage. In addition, it can also effectively dampen vibration, to prevent external vibration on the normal operation of the equipment.

(2) In the manufacturing process of communications equipment, silicone sealant's successful application cases are numerous. For example, in the encapsulation of mobile communication base stations, silicone sealant is used to fix the antenna and is waterproof and dustproof. It can effectively protect the equipment from the external environment and improve the stability and transmission quality of communication signals.

(3) Another case is the application of fiber optic transmission equipment. Silicone sealant is used in the terminal encapsulation of fiber optic connectors to ensure reliable fiber optic connection and prevent signal attenuation. This is critical for long-distance fiber optic transmission and high-speed data transmission.

(4) In wireless network equipment, silicone sealant is widely used in radio frequency module sealing and protection. It can effectively isolate harsh environmental conditions, such as high temperature and humidity, to protect critical electronic component from damage.

The successful application of silicone sealant not only improves the reliability of communication equipment but also reduces the maintenance cost and failure rate of the equipment. Through the use of silicone sealant, the life of communication equipment is greatly extended, performance is more stable and user experience is better.

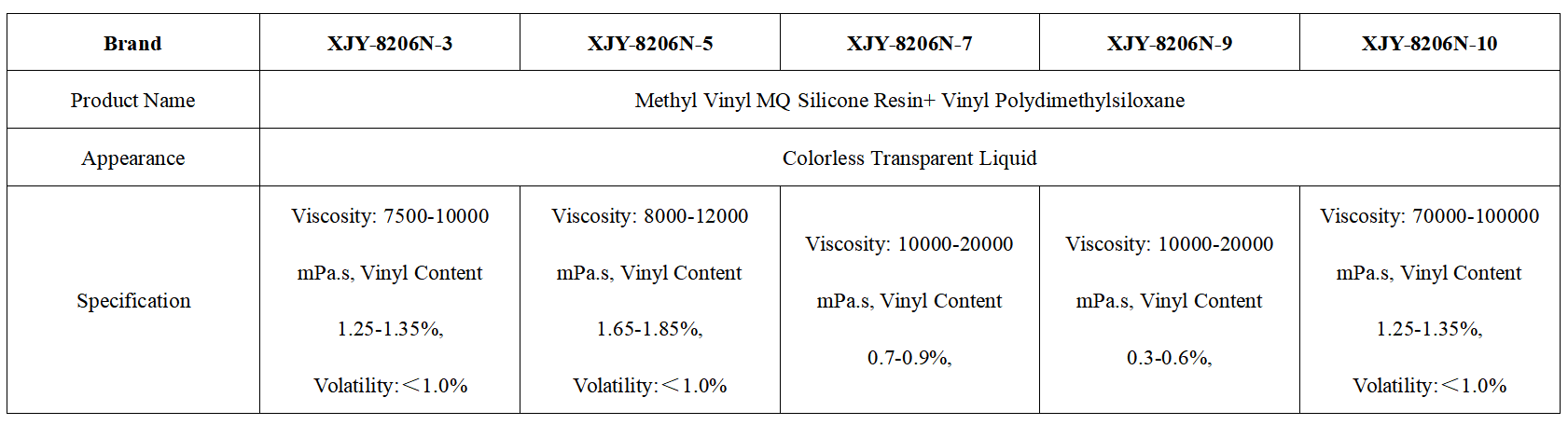

XJY-8206N Methyl Vinyl MQ Silicone Resin + Vinyl Polydimethylsiloxane is a colorless and transparent liquid resin, which is composed of vinyl MQ type silicone resin and vinyl silicone oil, and can be used for silicone sealant.

4. What are the applications of silicone?

(1) Automotive

Silicones can isolate extremely sensitive automotive electronic components. Silicones help protect the performance of electronic components at extreme temperatures from humidity, salt erosion, and other corrosive environments. Silicones help ensure the reliable operation of electronic components in airbags, brake systems, ignition, and transmission.

(2) Aviation and aerospace

Silicones can withstand the pressure and temperature limits necessary in aerospace. Silicone adhesives, sealants, and potting agents ensure that electronic components and systems function well.

(3) Communication

Silicones can seal, bond, and pot mechanical and electronic components in home and office equipment, including power transistor rectifier thermal switches. Auxiliary keyboards, keyboards, and copier rollers are made of silicone.

(4) Microelectronics and Microprocessors

High-purity silicon is critical for sensitive circuits. Advances in technology so that the processing capacity to increase, and reduce the size of the increasingly compact electronic modules on the thermal stability and moisture resistance to put forward higher requirements. Silicones meet the changing needs of microelectronic devices, components, assemblies, and systems for the integrated circuit packaging industry.

(5) Circuit Boards and Electronic Modules

Silicone for the finished circuit board or electronic module assembly and protection is critical. A variety of silicone materials from coatings, sealants, and gels can enhance the insulating properties of the material and chemical resistance, continuous protection, resistance to moisture, humidity, vibration, overheating, corrosion, and the effects of radiation. Sealants, adhesives, and primers can be easily manufactured with a variety of common materials including ceramics, reactive metals, and filled plastics. This facilitates aseptic and rapid mass production of electronic systems.

(6) Semiconductors

Silicones can pot and protect semiconductors, which are essential components of almost all electronic devices. High-voltage/power applications such as industrial motors, locomotives, and power supplies that require high-voltage switching; high-frequency communications such as cell phone base stations, satellites, and radar; high-temperature applications such as aircraft engines, oil drilling, and automotive electronics (including sensors for controlling fuel efficiency and emissions); semiconductors are required for the operation of all of these devices.

(7) Electricity and power supply

Power transmission depends on uncontaminated insulation to avoid costly and dangerous interruptions in the power supply system due to exposure to water, salt, sand, or industrial pollutants. Silicones provide high-voltage insulating coatings that protect wires, power, and communication cables. Silicone insulation ensures the safe, continuous transmission of high-energy power to underground and aboveground cables. Silicones' inherent durability extends material life and reduces maintenance and replacement costs.

5. How to make communication products perform better?

Due to the unique structure of silicone, both inorganic materials and organic materials, with low surface tension, low viscosity and temperature coefficient, high compression, gas permeability and other basic properties, and has high and low-temperature resistance, electrical insulation, oxidation stability, weather resistance, flame retardant, water-repellent, corrosion-resistant, non-toxic, tasteless and physiologically inert and other excellent characteristics, widely used in aerospace, electrical materials and electronic, and other industries, which Silicone is mainly used in sealing, bonding, coating, waterproofing, moistureproofing, etc. How you improve the competitiveness of your products ideally suited and specifically formulated?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry and more than 15 related patents and technical support. Our silicone raw material products can meet the needs of the electronics field and support the provision of diversified customized solutions.