From the market situation in recent years, the demand for pressure-sensitive adhesives has been maintaining rapid growth, especially with the rapid development of high-performance special-purpose pressure-sensitive adhesives, production and sales continue to rise sharply, and globally become the highest sales of pressure-sensitive adhesive varieties. With the continuous improvement of performance, it is predicted that the growth of this type of pressure-sensitive adhesive will continue to be the fastest. The traditional pressure-sensitive adhesives for packaging tapes are growing slowly and becoming less profitable as the market has matured and is nearing saturation. Why use silicone resins for PSA?

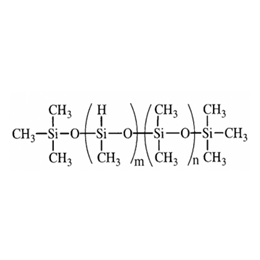

High-performance silicone pressure-sensitive adhesives are composed of elastic and flexible silicone rubber and silicone resin. Because the silicone-oxygen-silicone bond is more stable than the carbon-carbon and carbon-oxygen bonds in other organic pressure-sensitive adhesives, silicone pressure-sensitive adhesives have high resistance to humidity, chemicals, temperature, and excellent dielectric properties. Silicone pressure-sensitive adhesive is the highest temperature resistance of all pressure-sensitive adhesives. Its use of the temperature range is also the widest of all the repulsive adhesives, for 75-260.℃, and its short-term use of the temperature can even reach 300.℃.

The following four aspects of the silicone resin in the application of pressure-sensitive adhesive:

- What is the role of silicone resin?

- What are the advantages of silicone PSA?

- What is the application of silicone PSA?

- How to make silicone PSA better performance?

1. What are the types of pressure-sensitive adhesives?

Pressure-sensitive adhesive is generally divided into elastomer-type and resin-type pressure-sensitive adhesive.

Elastomer-type pressure-sensitive adhesives mainly include natural rubber pressure-sensitive adhesives, synthetic rubber pressure-sensitive adhesives, recycled rubber pressure-sensitive adhesives, SBS and SIS hot melt pressure-sensitive rubber;

Resin-based pressure-sensitive adhesive mainly polyacrylate, polyurethane, polyvinyl chloride, polyvinyl ether, silicone resins, etc., of which acrylic pressure-sensitive adhesive is used most, but silicone-type pressure-sensitive adhesive due to excellent resistance to high temperatures and aging performance, used to manufacture a variety of high-grade pressure-sensitive adhesive products.

2. What is the role of silicone resin?

(1) Excellent heat-resistant properties:

In early processes of preparation of silicone resins sodium silicate and various chlorosilanes were used as starting materials. It has a low dissolution index, can resist temperatures up to 450 ℃, and will not therefore produce secondary volatiles, can be used as a high-temperature adhesive, material coatings, and encapsulation material;

(2) Good water resistance:

Compared with organic resins, silicone resin has good water resistance, can prevent the penetration of silane and dispersant to the air, and can effectively block water; (3) good water resistance: silicone resin has good water resistance, can prevent the penetration of silane and dispersant to the air, can effectively block water.

(3) Good chemical resistance:

Silicone resin can react with acids, alkalis, salts, and other organic substances, which can prevent them from destroying its surface

(4) Antioxidant properties:

Due to the good antioxidant properties of silicone resin, can effectively prevent the heat generated by the combustion of the surface damage to the object

(5) Friction resistance:

Silicone resin has good friction properties, can effectively avoid unnecessary friction, and can prevent wear and tear.

XJY-301 Silicone Pressure-sensitive Adhesive

It is made of the specific structure of silicone resin and high molecular weight polydimethylsiloxane with the cooperation of organic adhesive, which is applied to specific scene conditions. Compared with natural rubber, it has high-temperature resistance, high stability, good electrical insulation, good transparency, high peel adhesion, and so on, and has a wide range of applications in the fields of industrial products processing, electronic processing, optical materials, health care and so on.

3. What are the advantages of silicone PSA?

Silicone pressure-sensitive adhesive is mainly used in the production of electrical and electronic adhesive tape and other uses that require temperature resistance.

(1) Silicone pressure-sensitive adhesive tape can withstand changes in cold and heat cycles, which is incomparable to other pressure-sensitive adhesives. In addition, it can also bond a variety of difficult-to-stick materials such as unsurfaced polyolefins, fluoroplastics, polyimide polycarbonate, and so on.

(2) However, although the main chain of silicone molecules Si-0 bond polarity, because of the geometric configuration of the molecular skeleton is helical, the dipole moments offset each other to eliminate the polarity of the bond, and thus the low polarity of silicone, resulting in poor adhesion properties, low cohesion strength, and so on. We have chemically modified its main raw materials, the introduction of new groups, increased the initial adhesion, improved the cohesive strength, and ultimately produced high-performance pressure-sensitive adhesive.

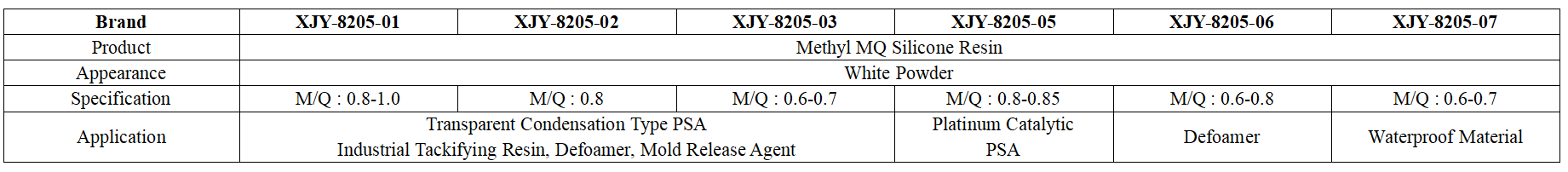

XJY-8205 Methyl MQ Silicone Resin Series is composed of silicone resin with methyl groups, with the characteristics of good thermal stability, good insulation, good UV radiation, non-reactive with other substrates, good hydrophobicity, water repellent, heat resistance, film-forming, adhesion, water repellency, aging resistance, resistance to ultraviolet irradiation, etc. It is suitable for pressure-sensitive adhesives and so on.

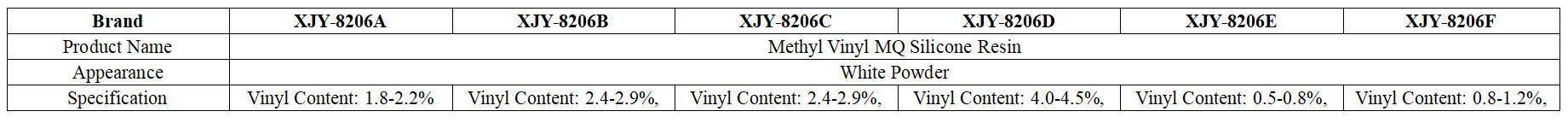

XJY-8206 Methyl Vinyl MQ Silicone Resin is a crosslinked semi-inorganic polymer with a highly crosslinked structure. Methyl Vinyl MQ Silicone Resin is a very unique class of organo-silicon polymer polysiloxane compounds with a double-layer structure in the form of a compact globule. It can be used for silicone hydrogen addition modification, highly transparent LSR, medical gels, isolate modifiers, PSA modifiers, and so on.

4. What is the application of silicone PSA?

With the development of industry, more and more industrial applications require more high-performance pressure-sensitive adhesive and high-performance pressure-sensitive adhesive, and its products are electronic industry, automotive industry, aerospace industry production lines important auxiliary materials. Silicone pressure-sensitive adhesive has a high resistance to moisture, chemical resistance, temperature resistance, and excellent dielectric properties, to meet the increasingly wide range of applications.

Silicone pressure-sensitive adhesive application areas are divided into the following key aspects of the introduction.

4.1 Electrical insulation tape

Silicone pressure adhesive has excellent electrical insulation properties and heat resistance and can be used as an H-class insulation material, with which to make polyimide, glass cloth, mica PTFE, and other substrates of electrical insulation tape.

(1) Bundle transformer:

In the transformer core wire and the insulation of the interlayer, the tape tightly adheres to the flange, comprehensive bundle transformer, when the line is used at high temperatures, the tape protects the end of the winding from vibration and protects the outer structure of the winding.

(2) Fixing electronic components:

Surface mount technology (SMT) is the technique of placing small electrical components on a printed circuit board. Adhesive tape and carrier adhesive tape to seal the sheet-like electronic components, the requirements of the adhesive heat aging resistance are good, coated with glue are; adhesive adhesion on the substrate in order to prevent the adhesive tape in contact with the guide rollers, the guide rollers left on the residual adhesive; have good adhesive properties, to ensure that the electronic components are firmly adhered to the adhesive tape. Silicone pressure-sensitive adhesive has high-temperature resistance, high adhesion, and no residual adhesive these properties can meet the requirements of its use.

(3) the application of the automobile industry: the wiring harnesses used in automobiles are almost all wrapped with electrical tape, on the one hand, to improve the insulation of the wiring harness; on the other hand, to prevent friction between the wiring harness and other parts of the car, as well as external substances on the corrosion of the wiring harness to improve the safety of the automobile operation.

4.2 Masking tape

In the printed circuit board plating, hot air leveling and wave soldering before the part that does not require plating or tin spraying with masking tape to protect up, this time the tape is required for the edge of the concave and convex part of the tight adhesion to prevent plating solution or tin penetration into the board, the tape's heat resistance, acid and alkali resistance, water resistance and chemical resistance and non-polluting printed substrate is essential.

4.3 Specialized tape for LED encapsulation

LED encapsulation process is the most critical process - injection, is a certain concentration of liquid epoxy resin glued into the mold shell and high-temperature curing process, it directly affects the quality of the finished product LED. Silicone pressure-sensitive adhesive tape used in the LED display encapsulation epoxy resin, not only protects the LED in the operation of the smooth, but at the same time can make the display panel high temperature curing to achieve the effect of flat, and in the removal of the tape, there will be no residual adhesive situation occurs, to ensure the quality of LED.

4.4 Protective film for cell phones

Intelligent devices: protective film

Application advantages: effectively prevents the screen from scratches and impacts during use.

The secret weapon of the cell phone screen protector: silicone resin

(1)With the rapid development of science and technology, people have higher and higher requirements for cell phone screen protection. Organic silicone resin plays an important role in cell phone screen protection film because of its excellent performance.

(2)The silicone resin used to make cell phone screen protection film is usually formed by combining with silicone rubber and other components of silicone pressure-sensitive adhesive. This pressure-sensitive adhesive has excellent adhesive properties, high and low-temperature resistance, chemical resistance and low dielectric properties, which are ideal for protecting cell phone screens from scratches and impacts.

(3)The specific applications of silicone resins in cell phone screen protectors are as follows:

Protective film substrate: silicone pressure-sensitive adhesive can be used as one of the substrates of the cell phone screen protection film, and PET and other film materials are used in combination to form a protective film with excellent protective properties.

Bonding layer: In the multi-layer structure of the screen protection film, silicone pressure-sensitive adhesive as a bonding layer, can firmly connect the various layers of materials, to ensure the integrity and stability of the protective film.

Anti-scratch layer: by adjusting the formula and process of the silicone pressure-sensitive adhesive, a protective film with excellent anti-scratch performance can be prepared to effectively protect the cell phone screen from scratches and abrasion.

The application of silicone resin not only improves the performance of the cell phone screen protector but also provides users with safer and more reliable protection.

4.5 Electrical Components Production

Electronic components such as capacitors, resistors, etc., due to the number of large, and small sizes, so an advanced production process should be used for pressure-sensitive adhesive tape, through mechanical equipment will be positioned after the component tape and carried out. To capitalize on capacitors, for example, silicone pressure-sensitive adhesive tape in the production of capacitors epoxy impregnation, high-temperature curing, printing in the row of stickers to fix the role of protection of capacitors, it requires the use of pressure-sensitive adhesive tapes, must be able to quickly fix the lead at room temperature, through the high-temperature operation does not shift, does not fall off, in order to carry out the performance test, etc. At the same time, if the capacitor is unloaded from the tape, the lead can not be left on the glue, so as not to affect the future 147 solder fastness. These heat-resistant properties, on the one hand, require glue in the positioning, braiding tape polymer chain segments easier to move, and can quickly wet the sticky material, on the other hand, requires glue in the high-temperature region when the polymer inter-chain force is strong, not easy to move to resist the high temperature caused by the heat of the polymer movement, to prevent the decline of the adhesion, therefore, high-performance pressure-sensitive adhesive in the production process of the assembly line is important.

4.6 Other

In addition, silicone pressure-sensitive adhesive tape can also be used in spacecraft high-temperature adhesive tape products, automobile manufacturing, shipbuilding, electrical insulation of generators and motors, an electronic combination of photolithography mask, flame and plasma spraying masking, electromagnetic interference, radio frequency interference shielding, chemical etching processing of the mask, gas shielding and chemical shielding, as well as ultra-high-temperature baking paint and powder coating and so on. Conclusion We use inexpensive water glass to prepare silicone resin, which greatly reduces the cost of raw materials and is suitable for industrial production. The time and proportion of hexamethyl disiloxane addition were controlled to prepare M Q silicone resin with a uniform molecular distribution. Through the introduction of phenyl, vinyl silicone resin to improve the system's temperature resistance, peel strength, and adhesion to the substrate.

5. How to make silicone PSA?

The first step in making pressure-sensitive adhesive is to choose suitable raw materials. Usually, the main components of pressure-sensitive adhesive include elastomer, tackifying resin, softener and antioxidant. Elastomer gives pressure sensitive adhesive good elasticity and adhesion, tackifying resin improves the adhesive force of the adhesive, softener makes the adhesive has when the softness, and antioxidant is dead long the life of the adhesive, these raw materials by discussing the strict screening and testing to ensure that its quality meets the requirements.

Next is the mixing process. Various raw materials are added to the reactor in a certain proportion, and mixed thoroughly by heating and stirring. This process is like a chemical magic, where different components interact with each other at high temperatures to gradually form a homogeneous mixture. The speed and time of stirring need to be precisely controlled to ensure that the raw materials are fully mixed to avoid localized inhomogeneity.

After the mixing is completed, the polymerization reaction stage is entered. Under a certain temperature and pressure, the molecules in the raw materials undergo a polymerization reaction to form a polymer. This process requires strict control of the reaction conditions, such as temperature, pressure, reaction time, etc., to ensure that the molecular weight and properties of the polymer meet the requirements. The polymerization reaction is the key link in the production of pressure sensitive adhesive, which determines the adhesive viscosity, elasticity and durability and other important properties.

After the polymerization reaction is completed, the pressure sensitive adhesive needs to be cooled and molded. The high-temperature adhesive is cooled to room temperature through a cooling device to make it into a solid or semi-solid state. The adhesive solution can then be coated onto various substrates, such as paper, plastic film, fabric, etc., to form different types of pressure-sensitive adhesive products according to different application requirements. The coating process requires precise control of the thickness and uniformity of the adhesive to ensure the quality of the products.

In addition, the pressure-sensitive adhesive products are quality tested and packaged. Through various testing means, such as adhesion test, tensile strength test, aging test, etc., to ensure that the performance of the products meets the standard requirements. Then, the qualified products are packed for storage and transportation.

6. Challenges

(1)Develop MQ silicone resin independently:

The base materials of silicone pressure-sensitive adhesive are mainly silicone rubber raw rubber and MQ resin, and the selection of these materials directly affects the performance of the final product. In order to obtain high adhesion silicone pressure sensitive adhesive, it is necessary to select silicone rubber raw rubber and MQ resin with excellent adhesion and cohesion.

(2)Formulation design

Formulation design requires precise control of the ratio of each component to achieve the desired thin-coat, high-adhesion effect.

The amount of curing agent added also needs to be precisely controlled to ensure that the product has adequate curing speed and strength.

By adjusting the formulation, its viscosity, fluidity, curing speed and other properties can be improved to better meet the needs of thin coating and high viscosity.

(3)Production process control

Adopt advanced production technology and management methods to ensure the batch stability of product performance.

7. How to make silicone PSA performance better?

Silicone pressure-sensitive adhesive generally refers to the use of silicone polymers as the main body of the pressure-sensitive adhesive, or the silicone polymer-modified acrylic and silicone-modified rubber-type pressure-sensitive adhesive. Compared with the traditional acrylic pressure-sensitive adhesive and rubber-type pressure-sensitive adhesive, it has excellent resistance to chemicals, water, oil, solvents, high temperature, low temperature, heat degradation, oxidative degradation, and other properties, and can be glued with a variety of difficult-to-stick materials such as non-surface-treated polyolefins (BOPP, PET, PE, etc.) fluorine plastics, polyimide, and polycarbonate. How to improve the competitiveness of your products?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry as well as more than 15 related patents and technical support. Our silicone raw material products can meet the needs of pressure-sensitive adhesive fields and support to provide diversified customized solutions.