As summer draws closer and closer and the intensity of UVB rays and UVA rays increases, to avoid early skin aging and skin cancer, broad-spectrum sunscreens have become an integral part of our daily skincare routine for broad-spectrum protection. However, after sweating with sunscreen, there is always a whitish nose or white sweat, which brings unnecessary embarrassment. Why do whiting after applying sunscreen it be white?

It is mainly related to the following factors:

1. The types of sunscreen

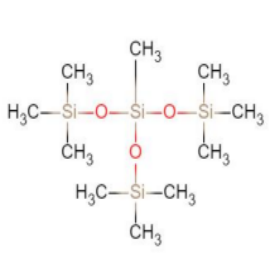

According to the sun protection factor, sunscreens are divided into organic sunscreens(chemical sunscreens) and physical sunscreen (mineral sunscreens). Physical sunscreens mainly include two kinds, Titanium Dioxide and Zinc Oxide.

The whitening problem of physical sunscreens is more common, especially when larger particle-size physical sunscreens are used. Zinc Oxide and Titanium Dioxide, due to their high refractive index, can form a noticeable white coating on the skin if the particle size is large. In addition, physical sunscreens may require the use of higher concentrations of physical sunscreens in order to achieve a higher SPF, which may also lead to more severe whitening. Titanium dioxide has a higher refractive index than zinc oxide and its whitening is more pronounced. So to avoid this, it should try to choose broad-spectrum sunscreen, followed by zinc oxide and finally titanium dioxide.

While physical sunscreens at the nanoscale level can reduce the whitening problem, if they are not formulated properly, the nanoparticles may aggregate and still cause whitening. Therefore, even nano-scale physical sunscreens may have some degree of whitening problems. So the dispersion problem for sunscreens is also the main reason, we can add dispersants such as Polyhydroxystearic acid, grind the sunscreens, and use dispersing slurries that the supplier well disperses to reduce this phenomenon. Secondly, we can tone the color of the sunscreen, such as using iron black, iron yellow, and iron red to reduce the skin's whiteness.

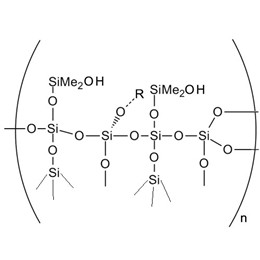

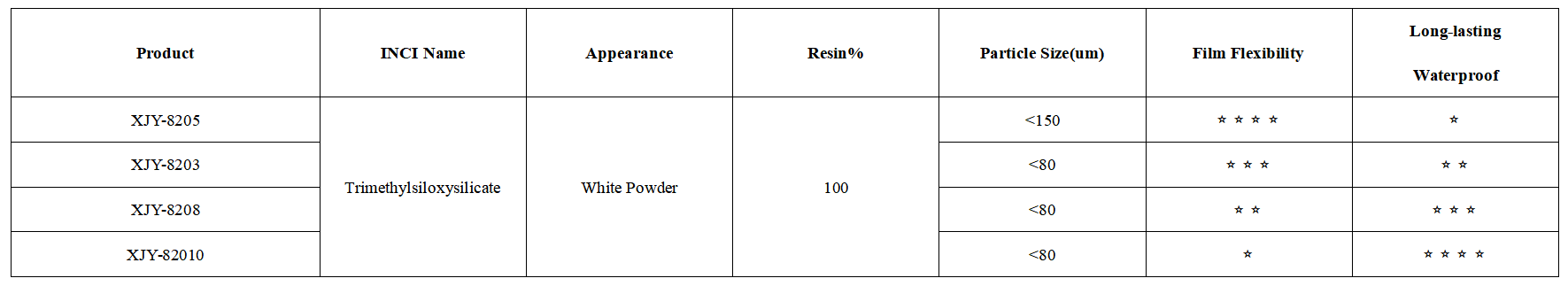

XJY-804M Silicone Gel

Compared to ordinary silicone gel, it has a better smooth skin feel, and excellent adhesion and can improve the sunscreen SPF and PA sunscreen index to a certain extent, so that can reduce the addition amount of sunscreen agent.

2. Waterproof performance of sunscreen

Sunscreen products on the market are mainly oil-in-water (O/W) type and water-in-oil (W/O) type, the main difference lies in their emulsification system and distribution of ingredients. In oil-in-water sunscreen products, water is the continuous phase, while the oil is dispersed in the water phase in small droplets form. This structure makes oil-in-water sunscreen products usually have a lighter texture, and easy to spread evenly, but at the same time may also lead to uneven distribution of sunscreen on the skin, which is easy to forms white traces on the surface of the skin, a phenomenon known as "whitening".

At the same time, it also leads to poor waterproof performance, sunscreen products are easily rinsed off by sweat, with sweat running down, resulting in whitening.

On the other hand, in water-in-oil (W/O) sunscreens, the oil is the continuous phase and the water is dispersed in the oil. This structure usually makes the sunscreen product have a thicker texture, and the oil phase can better carry and disperse the sunscreen agent so that it can be distributed more evenly on the skin; in addition, because the outer phase is oil, its waterproof performance is also improved, so W/O sunscreen products are relatively less prone to whitening.

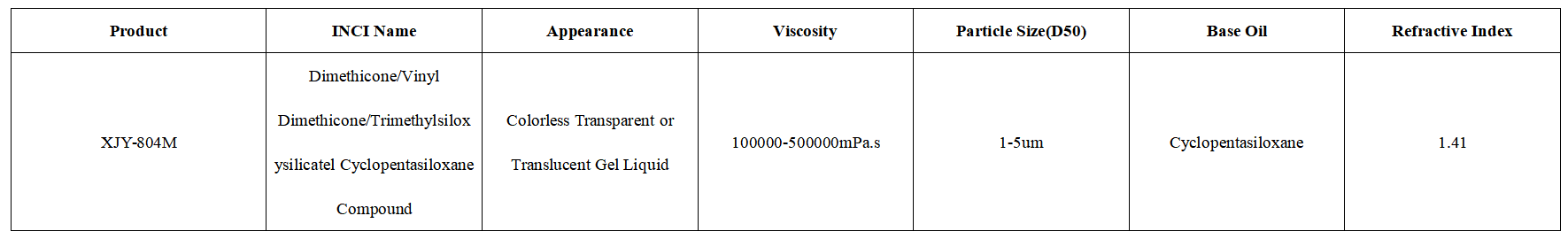

XJY-Trimethylsiloxysilicate(TMS)

XY-8203 TMS series mainly contains monofunctional Si-O units (M Units) and tetrafunctional Si-O units (Q units). Structurally, organic groups are attached to the silicon atoms, which generally show a dense three-dimensional spherical structure, and due to their unique structure, they can reflect and refract ultraviolet rays when sun exposure to a certain extent, thereby increasing the sun protection value to a certain extent. It can also be used as a film-forming agent to provide waterproof and sweatproof sunscreen with longer-lasting performance.

XJY-804M is also added with TMS film-forming agent, which is waterproof and sweatproof, and also has smooth and skin-friendly performance, improving the greasiness of the traditional silicone gels.

3. Total internal reflection

Lotus leaf is very waterproof, so it is easy to form white dewdrops, why does it cause this phenomenon?

The reason is that water molecules absorb light from the surrounding environment during the formation of dewdrops. Since water droplets are transparent, they reflect and refract light, causing all clight colors to be reflected, resulting in a white effect. This phenomenon is called "total internal reflection" which means that the light is reflected inside the water droplet without escaping, making the droplet appear white.

In addition, the surface of the lotus leaf has a special microstructure that increases the reflection and scattering of light from the droplets, further enhancing the white appearance of the dewdrops. This property of the lotus leaf, also known as "superhydrophobicity", allows the water droplets to form an almost perfect sphere on the surface of the leaf, which also helps to enhance the reflection and scattering of light.

In short, the dewdrops on lotus leaves are white mainly because the water droplets reflect all colors of light, and the special structure of the superhydrophobic surface of the lotus leaves enhances this reflection effect.

So, even if our sunscreen is very waterproof, when we sweat, beads of sweat will form on top of our skin (especially on top of our nose), and this bead of sweat structure will lead to total internal reflection, which will be aggravated by the fact that our sunscreen is usually added with sunscreen agents.

4. How to choose sunscreen?

Because most sunscreens are used outside to avoid the sun's harmful UV rays

, sunscreen ingredients can be spread continuously, while oil-soluble sunscreens stay in the oil phase, after application, sunscreens are easily dispersed discontinuous, resulting in a "window effect", thus reducing the effect of sunscreen. Therefore, it is necessary to match the water-soluble sunscreen agent and add a film-forming agent to enhance the waterproof and sunscreen effect of the formula.

Silicone structures are multifunctional ingredients that improve the formulation process by enhancing spreading, spreading evenly, and reducing the viscosity of the moisturizing and sunscreen ingredients to minimize the greasiness of oily skin and reduce dead skin cells, providing easy-to-feel benefits for consumers, enhancing the performance of the sunscreen, and providing a refreshing sensation on the skin.

The silicone resin mixture can form a film on the skin, long-lasting; it can form a film on the skin quickly, is wash-resistant, anti-migration, and long-lasting; it can be a faster evaporation rate, the formation of a bright hydrophobic film, and anti-migration, with excellent skin-feeling.

Organic sunscreen agent molecular polarity is generally higher, and high polarity grease compatibility is better, adding Phenyl silicone oil and Alkyl silicone wax can increase the compatibility between the oil phase system grease, and improve the skin-friendliness of the product. Therefore, silicone in sunscreen formulations can enhance the sunscreen and waterproof effect, provide refreshing, skin-fitting efficacy, and adjust a variety of skin feel through silicone to meet the diversified needs of customers's sensitive skin.

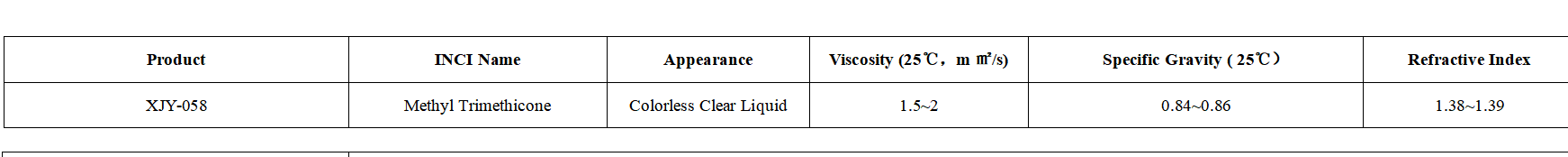

XJY-058 CYCLIC-FREE SILICONE FLUID

It is a methyl polytrimethylsiloxane with an MT structure. It is acyclic, colorless, and non-irritating. It has excellent volatility, is compatible with a wide range of cosmetics and hair conditioners, and has a refreshing, non-greasy texture on human skin, to keep the sunscreen active ingredients from being absorbed. It can be used in sunscreen products and can replace D5 Cyclopentasiloxane.

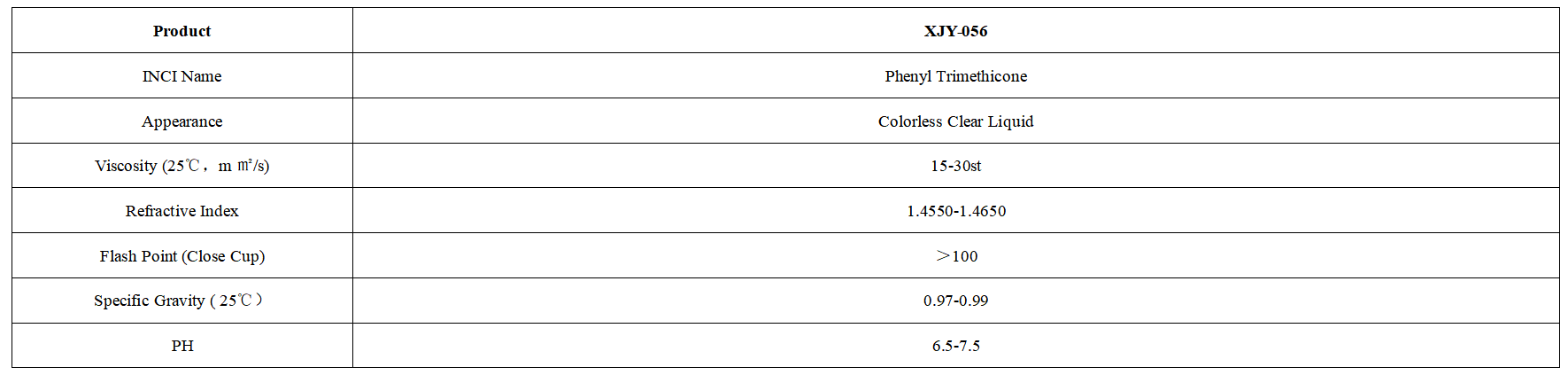

XJY-056 PHENYL-MODIFIED SILICONE FLUID

Silicone-based oil has a high refractive index and can be used in personal care and hair care. It is soft and lubricating, antioxidant, has good compatibility with cosmetic ingredients, and can increase the adhesion of the skin to sunscreen, making a skin barrier.

5. How to make sunscreen perform better?

Adding silicone can make sunscreen with low viscosity, appropriate evaporation rate, easy to spread, refreshing and non-greasy, and good texture; strong degreasing effect, highly efficient removal of facial oil; and excellent spreadability, and excellent slip on skin's surface. How to improve the competitiveness of your products?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry as well as more than 15 related patents and technical support. Our silicone raw material products can meet the needs of the color cosmetics field and support the provision of diversified customized solutions.