Adhesive can be the same or two or more homogeneous or heterogeneous parts (or materials) connected, cured with sufficient strength of organic or inorganic, natural or synthetic substances of a class, collectively referred to bonding agents. In recent years, more and more customers have used higher-performance silicone adhesives to enhance mechanical strength. Why choose silicone adhesive?

Silicone adhesive has excellent resistance to high and low-temperature performance, water resistance, corrosion resistance, atmospheric aging, and other characteristics, it can be made of silicone resin solution or silicone rubber, fillers, crosslinking agents, catalysts, and other additives with the mixing and become. It is applicable to metal, ceramics, glass, and plastic parts of the bonding and sealing, and can be adjusted to enhance the bonding mechanical strength, used in construction( household repairs).

The following 4 aspects introduce how silicone adhesive affects the bonding effect:

- How to evaluate the effect of adhesive?

- What are the factors affecting adhesive bonding?

- What are the advantages of silicone adhesive?

- How to make silicone adhesive performance better?

1. How to evaluate the effect of adhesive?

Usually, when we judge the bonding performance of the right adhesive and the bonded object, we will do the tensile test, and then according to the destruction of the adhesive layer determine whether the adhesive bonding of the material is good or bad. The destruction of the adhesive layer will only appear in the following four cases, namely, bonding damage, cohesion damage, cohesion interface mixing damage, and the destruction of the bonded material.

These four forms of destruction of the adhesive layer, the right side of the destruction of the adhesive, is our most desired effect. This is because it means that the strength of adhesive bonding is already higher than that of the adherend material itself, which means that the bonding strength of the adhesive must be able to meet the demand. Therefore, the bonded material destruction is the best form of destruction, which means that the adhesive has bonded the best.

![]()

The left bonding damage, that the glue layer and the bonded material appeared completely separated, so it can be considered that the glue and the bonded material surface can not be realized bonding, belonging to the bonding failure.

Cohesion damage and bonding damage, are both phenomena that should be overcome in practical applications. We should try to improve the adhesive force and cohesion, so that the two forces are equal in size, tend to be balanced, and you can get the best bonding strength, at this time there are both part of the bonding damage and part of the cohesion damage, which means mixed damage.

2. What are the factors affecting adhesive bonding?

(1) Molecular weight:

Polymer compounds have a low molecular weight, low viscosity, and good fluidity, conducive to infiltration, although the adhesion is good, the cohesion is low, and the final bond strength will not be high. The molecular weight is large, and the cohesion of the adhesive layer is high, but the viscosity increases, so it is not conducive to infiltration. Therefore, only molecular weights in a certain range have both good adhesion, but also have a larger cohesion to ensure that the bonding joint has a good bonding strength.

(2) Polarity:

Polymer compounds contain polar groups in the molecule, which is conducive to the bonding of polar polymer compounds; For non-polar polymer materials and polar polymer materials, the general bonding strength is not too high. This is due to the low surface energy of non-polar polymer compounds, it is not easy to form a good combination with polar polymer compounds, so the infiltration is not good, and can not be very good adhesion.

Non-polar polymer compounds and non-polar polymer compounds can produce good adhesion. It can be seen that the structure is similar to the better mutual solubility, is conducive to diffusion, easy to bond firmly. In addition, the strength and number of polar groups have a greater impact on the cohesion and adhesion of the compound.

![]()

(3) Spatial structure:

Polymer compounds often have side chains on the main chain of the molecule, which constitutes its spatial structure. In the spatial structure, the type of side chain has a greater impact on the adhesive strength.

(4) The treatment of the surface:

Whether the surface is clean, active, or inactive is the key to bonding solid or not. Materials in the processing, transportation, and storage process, will inevitably produce corrosion, oxidation, and oil and grey layer pollution, and these will directly affect the bonding. So usually before the dispensing of glue, it needs to be bonded according to the nature of the material to choose the appropriate surface cleaning treatment.

(5) Process impact:

Glue application, static environmental conditions, curing conditions, interface contact pressure, etc. are very important. Adhesive manufacturers of the TDS physical properties of the table are generally only responsible for their sample test conditions, and usually can not guarantee the specific product application to ensure that the same performance can be achieved, only as a reference. Therefore, in the development stage, it is important to put several parties together (glue factory, parts suppliers, customers), through the initial setting of process conditions, combined with adhesive bonding and durability testing, curing the process parameters before mass production.

![]()

3. What are the advantages of silicone adhesives?

(1) High viscosity: Silicone adhesive because of its unique molecular structure, has a high viscosity and adhesion properties that typically, can be in a variety of surfaces to maintain a strong fixation.

(2) Heat resistance: Silicone glue has excellent high-temperature resistance and can maintain its adhesive properties in high-temperature environments, long-term use will not deteriorate, so it is widely used in high-temperature environments in the manufacture of adhesive tapes.

(3) Corrosion resistance: Silicone glue has excellent chemicals corrosion resistance, and can effectively resist acid, alkali, water, and other corrosive substances, making it suitable for a variety of industrial environments.

(4) Oxidation resistance: Silicone glue has good oxidation resistance, long-term storage will not appear oxidation phenomenon, to maintain its original performance.

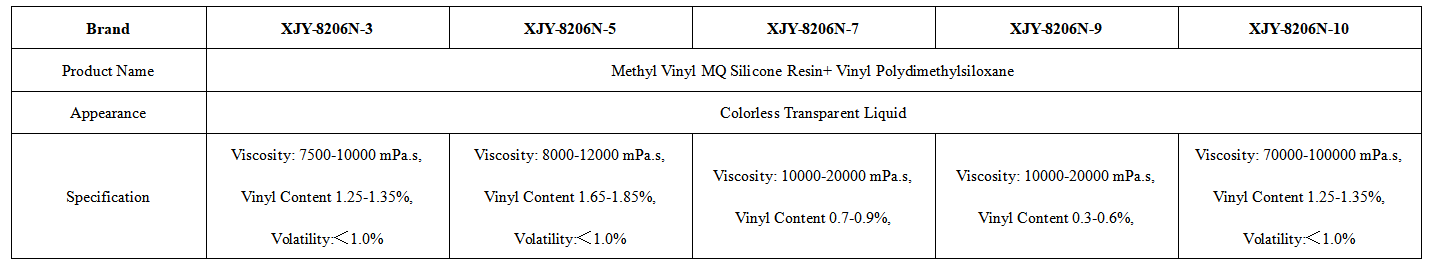

XJY-8206N Methyl Vinyl MQ Silicone Resin is a colorless and transparent liquid resin, consisting of vinyl MQ-type silicone resin and vinyl silicone oil, can be used for LSR, liquid additive molding silicone rubber, and can also be used for other two-component additive adhesives.\

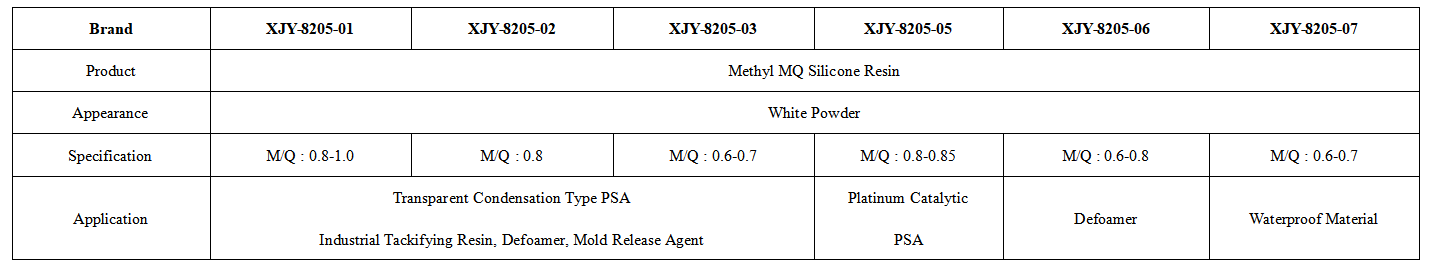

XJY-8205 Methyl MQ Silicone Resin is a solid powder resin, which can be used as reinforcing material for liquid silicone rubber. Adding MQ resin into potting adhesive can enhance the high and low-temperature resistance of sealant and prolong the service life of the sealant. XJY-8205M/M-02/M-03 silicone resin is an MQ solution, which is an important raw material for PSA.

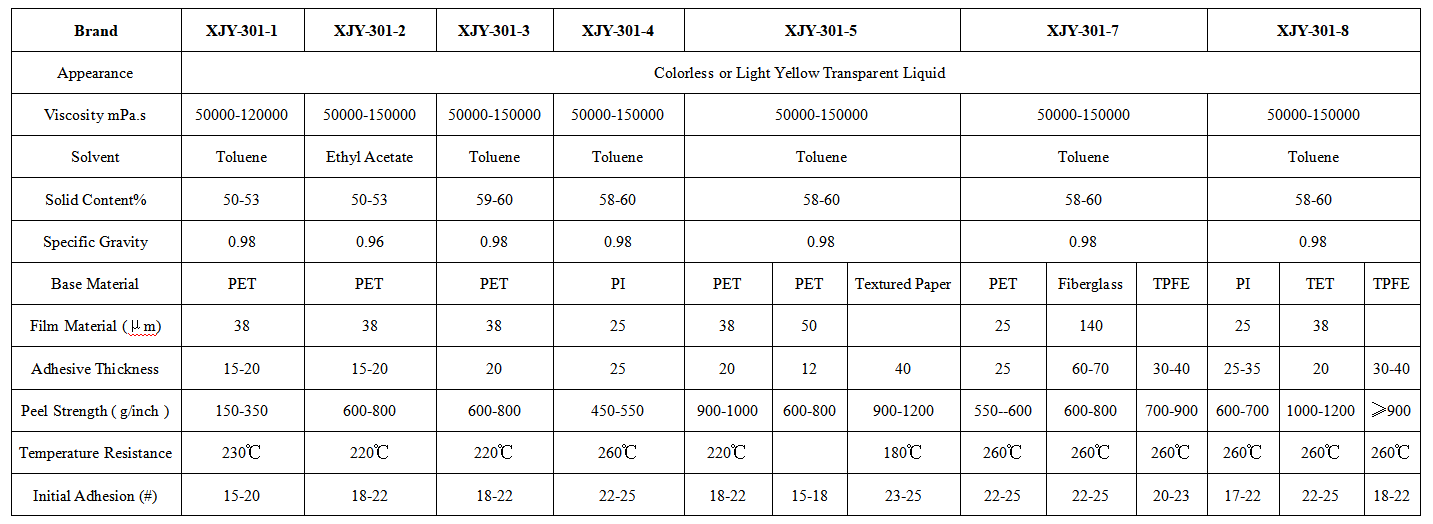

XJY-301 Silicone Pressure Sensitive Adhesive is made of the specific structure of silicone resin and high molecular weight polydimethylsiloxane with organic adhesive, which is suitable for specific scene conditions. Compared with natural rubber, it has high-temperature resistance, high stability, good electrical insulation, good transparency, peel adhesion, etc. It has a wide range of applications in industrial product processing, electronic processing, optical materials, health care, and other fields.

4. How to make silicone adhesive performance better?

Silicone adhesive is widely used in the silicone sealant, bonding, and fixing, etc. In the electronic and electrical industry, silicone adhesive is widely used in PCB circuit boards fixed, high-temperature resistant wires fixed, etc.; in the automotive manufacturing industry, silicone adhesive applications are more widely used, mainly in automotive sealing strips, glass joints, door tapes, and other parts of the car to ensure the safety of automotive performance. How to improve the competitiveness of your products?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry as well as more than 15 related patents and technical support. Our silicone raw material products can meet the needs of the silicone adhesive field and support the provision of diversified customized solutions. Anything please access the web site.