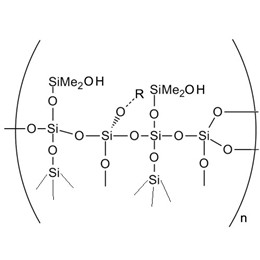

Silicone pressure-sensitive adhesive(silicone PSA) generally refers to the use of silicone polymers as the main body of the pressure-sensitive adhesive, generally, the main body of the liquid silicone rubber and MQ silicone resin mixed in a certain proportion.

The MQ silicone resin has a greater impact on the adhesive properties of the pressure-sensitive adhesive because the change in the molecular mass of the MQ silicone resin makes its body viscosity and cohesive strength change. When the molecular mass of MQ silicone resin is about 3000, the pressure-sensitive adhesive tape has the highest cohesive strength, good adhesive holding, high peel strength, and good thixotropy. (XJY-8205M Methyl MQ Silicone Resin Toluene Solution is an important raw material for silicone pressure-sensitive adhesives, which can improve the adhesive strength of the glue and increase the peel adhesion of the silicone PSA under light pressure.)

Next we are going to talk more about it:

- What is pressure-sensitive adhesive?

- Why choose silicone pressure-sensitive adhesives?

- What is the application of silicone pressure-sensitive adhesive?

1. What is pressure sensitive adhesive ?

Pressure-sensitive adhesives, at room temperature are dry, with dry viscosity and permanent viscous material, and can be peeled off from the surface of the bonded object, without residual traces of adhesive. When the pressure-sensitive adhesive in the appropriate, slow pressure, resulting in a viscous flow similar to that of the liquid, so that the pressure-sensitive adhesives and the surface of the object to be adhered to the close contact and flow into the surface of the adhesive pits and grooves, increasing the effective adhesive coated, thus generating a certain degree of bonding force. When the pasted pressure-sensitive adhesives products in the external force peeling, pressure-sensitive adhesives performance is similar to the nature of the elasticity, has a high peel adhesion, the greater the peeling speed, the higher the peeling strength.

Pressure-sensitive adhesives on the surface of the sticky material wettability can make it with the surface of the sticky material to the degree of molecular proximity, resulting in intermolecular forces, resulting in sufficient interfacial adhesion. Pressure-sensitive adhesive tape is the main use of pressure-sensitive adhesives form, such as double-sided tape, carpet tape, and so on. The main raw materials for pressure-sensitive adhesives are silicone adhesives, acrylic adhesives, and rubber adhesives.

2. Why choose silicone pressure-sensitive adhesives?

2.1 What are the advantages of silicone pressure-sensitive adhesives?

Compared with traditional organic adhesives like acrylic adhesive, and natural rubber adhesive, silicone adhesives have excellent resistance to chemicals, water, oil, solvents, high temperature, low temperature, heat degradation, oxidative degradation, and other properties, but also with a variety of difficult-to-stick to materials such as non-surface-treated polyolefin (BOPP, PET, PE, etc.) fluorine plastics, polyimide, as well as polycarbonate, such as adhesive bonding. (XJY-301-1 Silicone Pressure Sensitive Adhesive has excellent resistance to high and low temperatures.)

Silicone pressure-sensitive adhesives according to the vulcanization system can be two categories, peroxide vulcanization type and addition of molding. Due to advances in adhesive technology, compared with traditional pressure-sensitive adhesives, silicone PSA's excellent performance is profoundly expressed in its chemical resistance, extreme temperature stability, and dielectric properties.

Among all species, silicone pressure-sensitive adhesives to play performance of the critical temperature value almost makes it in any environment on earth can be used perfectly (high-temperature threshold: 300 ℃, low-temperature threshold: -75 ℃), in some of the environmental requirements of the high index, silicone PSA is almost no pressure. In addition, silicone adhesives can also bond a variety of difficult to adhere to materials, such as non-surface treatment of polyolefins, fluorine plastics, polyimide, and polycarbonate, such as ordinary pressure-sensitive adhesives can not be attached to the substrate, silicone pressure sensitive adhesives experimental results are satisfactory. (XJY-301-5 Silicone Pressure Sensitive Adhesive has high peeling force performance and good adhesion to low surface energy materials, and is compatible with many substrates .)

2.2 How to evaluate silicone pressure-sensitive adhesive quality?

Pressure-sensitive adhesives can be good or bad from the adhesive strength, drying speed, viscosity, solid content and PH value, and other five aspects to determine.

2.2.1 Adhesive strength

Pressure-sensitive adhesives, first of all, there must be enough adhesive strength, can stick adhesive parts and many substrates, and has a certain use. Industry to determine whether the pressure-sensitive adhesives, glue adhesive strength is qualified, can be two pieces of adhesive material along the adhesive interface tear, if found after tearing the adhesive material was destroyed, it proves that the adhesive strength is sufficient; if only the adhesive interface is separated, it shows that the adhesive strength is not enough.

2.2.2 Drying speed

According to the bonding process to choose the right pressure-sensitive adhesives glue. If the product is not suitable for the process, you can use pressure-sensitive adhesives water to add solvent dilution.

Generally can be used directly, machine assembly line coating production due to the speed, and more open thinning program, conducive to the coating of glue. At the same time the use of baking, tunnel furnace heating to speed up the solvent evaporation, and other methods to save time and cost.

2.2.3 Viscosity

Viscosity is the most important factor affecting the quality of adhesives. If the viscosity is too large, the coating is thicker, and the amount of glue consumption, drying slower, but also affects the adhesive on the surface of the adhesive wetting and penetration, which directly affects the adhesive strength; if the viscosity is too small, the coating is thinner, drying too quickly, prone to bonding and other problems.

2.2.4 Solid content

Is also one of the important factors affecting the quality of pressure-sensitive adhesives.The higher the solid content, the stronger the adhesive force, the faster the drying speed. Solid content also has a direct impact on viscosity and drying speed.

2.2.5 PH value

Synthetic resin adhesives are mostly weakly acidic, and will not have a negative impact on the bonding process. But water glass and starch adhesive alkaline, high alkaline will not only have a corrosive effect on the operators and equipment, and sometimes also corrosion of the sticky material, the formation of stains affecting the appearance. Therefore, when purchasing adhesives, we should consider the impact of pH value on the product.

3. What is the application of silicone PSA?

3.1 Industrial Application

Silicone pressure-sensitive adhesives can bond low surface energy surfaces due to their good resistance to high and low temperatures, chemical resistance, and low dielectric properties. This makes the silicone pressure-sensitive adhesive tapes tape widely used in industrial production in the form of splicing tape, electrical tape, plasma spraying tape, machining tape, and so on.

3.2 Electrical Application

Silicone pressure-sensitive adhesives and their tapes are generally used in the production and assembly of printed circuit boards (PCB). This requires pressure-sensitive adhesives not only to withstand high temperatures (270°C for a short time), and bond moist low surface energy interfaces but also to have lower dielectric properties. Since silicone PSA has good resistance to high-temperature damage and cohesion, it will not remain on the protected surface when it is torn off after high-temperature treatment.

Using PI film or textured paper as the substrate, coating cured silicone pressure-sensitive adhesives, mainly used in the wave soldering, reflow soldering, and soldering process of PCB circuit boards to shield and protect the gold fingers, as well as some electronic components insulation, such as mica tapes.

3.3 Electronic equipment

Silicone PSA is widely used to prepare protective films for the electronics industry, providing comprehensive protection for the transportation, manufacturing, and use of precision components.

In the field of wireless charging, pressure-sensitive tapes help to bond, fix and protect the module at receiving end and the transmitting end so as to make it play an energy-efficient role.

In the display field, the optical pressure-sensitive adhesive is used to bond various optical materials inside the screen to maintain optical transparency under high temperature and high humidity conditions to ensure the clarity of imaging.

Due to the high price of many smartphones, it becomes more and more important to protect their high-quality screen from scratch and impact in use. When the mobile phone leaves the factory, the manufacturer generally sticks a layer of film on the surface of the screen to prevent damage to the screen caused by scratches and bumps in the process of transportation or sale.

The silicone PSA has a wide range of applications in this thin and tough protective film. The protective film is usually a multilayer "sandwich" structure, and the specific properties of each layer of adhesive depend on its structure and chemical composition. Among them, the pressure-sensitive adhesive layer plays a key role.

3.4 Silicone release paper

In essence, silicone oil release paper can be regarded as a very thin layer of silicone rubber coating on the paper, and the silicone PSA has good adhesion to it.

The release paper splicing tape is made of silicone pressure-sensitive adhesives, which can be used to connect the broken ends of the previous roll and the next roll in the production process of the release paper, thereby reducing the number of downtimes and changing the paper, and improving the production efficiency and batch stability.

3.5 Other Application

Medical silicone PSA has developed rapidly in recent years. Because of their non-toxic, non-irritating, physiologically inert, wide temperature range, suitable adhesive strength, and drug permeability, they have been widely used in medical and percutaneous treatment system preparations. (XJY-301-2 Silicone Pressure Sensitive Adhesive is non-toxic and environmentally friendly, with no stimulation and harm to the human body, which can be used for environmental protection medical tapes.)

Silicone PSA has many applications and can be used as surface protection tape for automobiles, airplanes, mechanical parts, building reinforcement boards, household appliances, wood products, glass products, and plastic products. It can also be used for the wiring of transformer coils and electrical equipment.

The following XJY Silicone products data can be referenced:

XJY Silicones - the leading global supplier of Silicone pressure-sensitive adhesive

XJY Silicones, with more than 30 years of experience in silicone MQ resin and VMQ silicone production and R&D, we have a continuous silicone resin production line, also can customize the cost-effective products of silicone pressure-sensitive adhesive and its raw material silicone MQ resin to satisfy your specification requirements.