The medical use of silicone rubber was discovered very early and developed rapidly. The following is an introduction.

The medical properties of silicone rubber were discovered in 1945. In the 1960s, there were many reports on the application of silicone rubber as human implant materials and medical products. Especially the application of silicone rubber in pacemakers, and heart valves, not only made thousands of patients get a new life but also played a great role in promoting the development of other medical products.

In the 1960s and 1970s, many medical-grade silicone rubber products (silicone rubber breasts, knuckles, orbital base rests, tracheal intubation tubes, auricles, hydrocephalus drainage tubes, peritoneal dialysis tubes, bypass catheters with airbags, urinary catheters, etc.) were put into clinical application. The research on silicone rubber adaptive material has made great progress, and many functioned and serialized medical silicone rubber products have been put into medical industry clinical applications, high volume production.

Next, the application of silicone rubber in medical treatment will be described in detail:

|

Ⅰ. Characteristics and clinical applications of medical grade silicone rubber

1. Composition and properties of medical silicone rubber

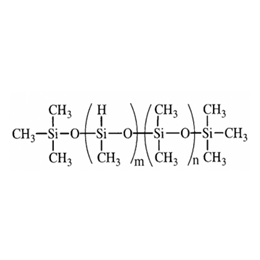

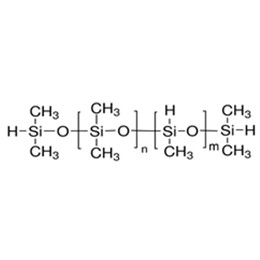

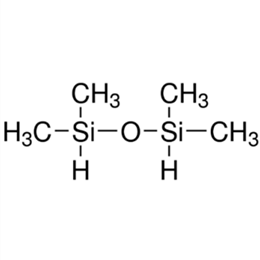

Silicone rubber belongs to one of the synthetic rubber, chemically known as polymethyl vinyl siloxane, and is made of dimethylsiloxane monomer and other silicone monomer polymerization under the action of acid or alkaline catalyst, the relative molecular weight is generally in 400,000 ~ 500,000.

The main chain of silicone rubber contains only silicon and oxygen atoms and is a long-chain siloxane structure. The side chains can access a variety of different organic substituents, which constitute different brands with different properties depending on the substituents. The common substituents are methyl, vinyl, phenyl, cyano, etc., or the introduction of other elements, such as fluorine, etc., to form methyl silicone rubber, methyl phenyl silicone rubber, and fluoro silicone rubber with different properties.

The introduction of different curative groups can improve the vulcanization, high or low-temperature resistance of silicone rubber. Silicone rubber is usually prepared from octamethylcyclotetrasiloxane with a small amount of cyclosiloxane containing vinyl or other organic functional groups as raw material, and obtained by ring-opening polymerization under the catalysis of potassium hydroxide or tetramethylammonium hydroxide as raw silicone rubber, after vulcanization and cross-linking to obtain an elastic polymer. Medical-grade silicone rubber is obtained by mixing raw rubber with silica, heating, and molding, and then cross-linking with cobalt 60 radiation. But it is different from food grade silicone rubber.

Some rubber compounds are very sensitive to specific chemicals and may cause irritation or infection when patients are exposed to them. However, medical silicone rubber will not, because medical polymer materials must meet the following requirements in addition to a broad range of strict control from raw materials to finished products: Chemically inert, non-erosive to tissue fluids; compatible with surrounding tissues, non-inflammatory, non-reactive with organisms, minimal foreign body reactions; Non-carcinogenic; does not cause allergic reactions, surface coagulation; implanted in the body, long-term use does not lose tensile strength, elasticity, and other mechanical properties; not deformed, can withstand the necessary sterilization measures; easy to process into complex shapes, etc.

Silicone rubber has excellent physiological characteristics, non-toxic, tasteless, High temperatures resistant, good biocompatibility, chemical resistance, no adverse effects in the implantation, biological aging resistance, high and low-temperature resistance, good permeability, and good mechanical properties, etc., in line with the requirements of medical polymer materials. In addition, silicone rubber has better oxygen and carbon dioxide transmission properties than other polymers, like silicone plastic, which is important for medical applications such as thin-film artificial lungs and contact lenses that require high gas permeability. Medical polymer products, it is the most widely used in artificial organs, surgical orthopedic products, and internal implants, extremely versatile.

2. Types and properties of human medical silicone rubber

There are currently four types of silicone rubber for human medical use:

1. Solid type: There are two kinds of soft and hard, milky white, opaque, hard like bone, soft medium-hard, elastic, and easy-to-process plastic.

2. Foam type (sponge type): fine pore sponge-like, soft, white, or yellowish, with greater elasticity and stretchability.

3. Film type: Transparent or translucent film, yellowish or milky white in color, with greater elasticity.

4. Liquid type: also known as silicone oil, a viscous liquid, yellowish color, or white latex.

Clinical applications of medical grade silicone rubber:

1. Solid-type medical silicone rubber can replace bone or cartilage as tissue filling or scaffolding material, so it can be made into artificial joints, and artificial tendons to repair the defects of limb joints and tendons. Plastic materials are mostly used as materials for repairing deformity defects in the face, ear, nose, etc.

2. Foam types of medical grade silicone rubber can replace human fat tissue to repair human facial subcutaneous tissue defect deformity, such as hemifacial atrophy.

3. Film types medical grade silicone rubber can be used as a substitute for tendon sheaths; an external intestinal fistula blocking piece is also made of this type of silicone, its role is to close the intestinal fistula in the intestinal cavity, not to make intestinal fluid leakage, keep the intestinal tract open, restore intestinal nutrition, reduce complications and simplify the treatment of intestinal fistula.

4. Medical grade liquid silicone rubber (medical grade lsr), also known as silicone oil, is a low viscosity transparent liquid, uses a coarse injection needle to inject silicone oil into the craniofacial depression deformity site, is easy to use, can be shaped, without hospitalization, can be treated on an outpatient basis. Allows multiple components to reduce costly depletion.

5. In addition, medical-grade silicone rubber is used clinically to make hydrocephalus drainage devices to treat hydrocephalus disease. It is made into a spherical artificial heart valve to replace the damaged mitral valve of the heart. As for silicone contraceptive ring, it has the advantages of safety, convenience, reliability, and longevity, silicone intravenous catheter, gastric tube, urinary catheter, etc., is lightly damaged, less irritated, and can be inserted in the relevant parts of the human body for a long time, and have been widely used in clinical practice.

Ⅱ. Application categorization of medical, pharmaceutical, and health industries

There are several aspects such as organ or tissue substitutes left in the human body for a long time, medical devices left in the human body for a short period of time, orthopedic medical devices, drug slow-release systems, and in vitro products, which are discussed below.

1. Long-term implantable human organs or tissue substitutes

Such organs or tissues include hydrocephalus drainage devices, artificial lungs, retinal implants, artificial meninges, larynxes, artificial fingers, palmar joints, artificial tympanic membranes, dental impressions and soft liners for the tissue surface of the braces, and artificial heart valve attachments.

1. The hydrocephalus drainage device was the first silicone rubber implant and the world's first silicone rubber hydrocephalus drainage device was produced in 1955 to drain hydrocephalus into the thoracic or abdominal cavity with excellent results; it is still successfully used in medical applications today, and silicone rubber is still the only medical grade materials used for this device today.

2. The excellent permeability of silicone rubber allows it to be used as an artificial lung, thus ensuring the smooth operation of thoracic cell organ surgical materials. The artificial lung membrane is made of polydimethylsiloxane and polycarbonate block copolymer (MEM-213), and the modified molded silicone rubber is a good oxygen enrichment material.

3. The world's treatment for retinal detachment is to implant a soft silicone rubber scleral sponge between the fossa bone and the wall of the eye to promote retinal reimplantation. These silicone rubber retinal implants mainly include ring ties, bad tie wheels, and composite artificial meninges made of room temperature vulcanized silicone rubber and nylon fabric, which can be used to repair traumatic cerebral dural injuries and dura caused by resection of tumors in the basal tip or infiltrated area of the dura. The composite artificial meninges are made of room-temperature vulcanized silicone rubber and nylon fabric.

4. The artificial larynx made of highly tear-resistant silicone rubber can replace the cartilage removed during laryngectomy, and the patient can quickly resume speech, eating, and breathing without abnormalities after surgery.

5. Silicone rubber artificial knuckles have been on the market since 1963 and have been implanted in thousands of patients in more than 90 countries worldwide over the last few decades.

6. In 1960, research on artificial tympanic membranes was initiated. Types I, II, III, and thin-film artificial tympanic membranes of the same thickness and size or framed thin-film devices have been developed to be applied to the perforated tympanic membrane to promote healing and improve hearing.

7. Room-temperature vulcanized rubber can be made into the soft liner of the denture base, molded, and bonded directly in the patient's mouth; no pressure and pain after use, and can enhance the retention force, this soft liner the elasticity of the gums, can effectively prevent the loosening and falling off of the denture, the development of artificial heart valve products began in 1964, researchers made artificial spherical mitral valve with silicone rubber, clinical application results show that the implantation of the product patients to restore normal heart function, and can be competent for general physical labor.

8. Since 1953, various materials have been used to make artificial tendons as permanent replacements for tendons. The artificial tendons must meet the following conditions: no foreign body reaction after implantation, high elongation, good flexibility, and bendability, no deformation, firm union with the recipient's tendon, and both the union and the tendon itself can withstand certain tension without breaking, no adhesion with the surrounding tissues, and easy sterilization. After screening a variety of materials, it was found that the feasibility of using silicone rubber tubes as artificial tendon materials to repair flexor tendons is greater; this is because the pseudo sheath formed by wrapping silicone rubber tubes can prevent adhesion between the recipient tendon and the surrounding tissues and enable the patient to recover function quickly.

2. Short-term retention of the human body of auxiliary medical device oems applications

Silicone rubber products as auxiliary medical equipment class in the human body for a short period of time left in the body, like high-consistency rubber for drug elution systems and long-term implant biomedical, usually made of injection molded or cut. To play a rehydration, rescue, drainage injection, anti-adhesion, or anti-bubble role, such devices include an intravenous cannula, urinary catheter, arteriovenous fistula tube, abdominal dialysis tube, contact glasses, blood vessels, pressure relief tube, chest drainage tube, menstrual cups, gastroscopy canola, otitis media ventilation tube, fluid introduction tube, and nasal cannula.

3. Key components of medical devices

These components include artificial heart-lung transfusion pump tubes, membrane artificial heart-lung machines, fetal suction devices, and artificial blood circulation devices.

4. Application in cosmetic and restoration

In the past 20 years, silicone rubber has been widely used in cosmetic and prosthetic surgery, such as repairing facial defects, treating defects in the external ear, performing cosmetic surgery on the skull and chest, and repairing internal organs, artificial breasts, etc.

5. Application in drug slow-release system

Applications in drug sustained-release systems include silicone rubber capsules, long-acting contraceptives, matrix-based drug sustained-release formulations, and skin-absorbable formulations.

In 1957, silicone rubber material began to be used as a wrapping material for controlled-release drugs. In the closed silicone rubber tube, the drug can be released slowly and a certain drug concentration can be maintained in the body for a considerable period of time. It is precisely this property of silicone rubber that is utilized for effective controlled release and slow diffusion of drugs through silicone rubber.

There are two main ways to use silicone rubber to control drug release: one is the encapsulation type, that is, the drug as the core, the external silicon rubber film encapsulation; this drug delivery method is equivalent to the polymer membrane capsule as a drug "warehouse", so also known as storage agents or membrane formulations. The second is the particle dispersion type, that is, the drug is dispersed in the form of particles in the silicone rubber matrix, which becomes smaller with the speed of drug release and the growth of time; but the manufacturing is relatively simple, only need to mix the drug and silicone rubber, molding can be.

XJY cleverly functions silicone medical to meet more application needs and is committed to providing more differentiated and innovative solutions for our customers. The following are the product expansions of XJY silicone materials in the medical field.

XJY-8206N VMQ Silicone Solution.

Highly transparent platinum-cured medical grade silicone rubber, widely used in medical catheters and other medical devices. The best choice for you.

XJY-8206 for Dental

The two-component additive silicone rubber system is increasingly used in the dental field, with the advantages of good elasticity, high precision, and stability, which can be used for various dental prostheses and precision casting dentures.

XJY-8206 VMQ Silicone resin

It has physical properties such as wear resistance, weather resistance, pressure resistance, UV resistance, etc., which can improve the performance of medical devices and effectively reduce medical costs, etc.

XJY Silicones - the preferred raw material supplier of medical-grade silicone rubber

XJY Silicones, one of China's leading Silicone MQ resin and VMQ silicone manufacturers, has 30+ years of R&D and manufacturing experience and 15+ related patents in the silicone industry, also can customize the cost-effective products for medical device manufacturers according to your molding process and specification requirements.

![]()