Liquid silicone rubber is an important medical grade silicone polymer material, mainly used in the medical industry of catheters. The aging proces drives the demand for medical-grade silicones, and the market requirement for high-end medical equipment is gradually expanding. In addition, the development of the medical beauty industry and artificial organs provides growth space in the proportion of medical silicones in medical polymer materials.

Medical grade silicone plays an important role in various body functions and is directly related to the absorption of minerals. There is an average of seven grams of silicon in the human body, which far exceeds other important minerals such as iron. Silicon is necessary for the human body and plays a very important role in maintaining normal metabolism.

Due to its inertness and excellent biocompatibility, silicone medical grade materials have unique and irreplaceable advantages in medical device applications, and they are being used by more companies in the medical applications field. From infusion tubing, cochlear implants, and prosthetics to orthodontic dental molds, wound care, etc., silicone materials are actively protecting human health in various forms.

Performance introduction

1.1 Biological Properties

Bioactive silicone is an essential nutrient for the human body. Silicone is an important element that constitutes human tissue and participates in metabolism. Silicone exists in every cell of the human body, as a support for cell construction, and at the same time, it helps the absorption of other important substances such as magnesium, phosphorus, and calcium. We can only continuously obtain silicons through food.

Scientists believe that silicone exists in the human body mainly in three forms:

- ①soluble silicone, 10% by weight,

- ②30% is present in various cell matrices,

- ③60% is used to synthesize protein.

This shows that our daily requirement for silicone is quite high. If you want to stay young for 5 years, 10 years, or even 30 years, it is especially important to consume 20-30 mg of silicone per day.

1.2 Temperature resistance

Silicone products are based on the silicon-oxygen (Si-O) bond as the main chain structure, the bond energy of the C-C bond is 82.6 kcal/mol, and the bond energy of the Si-O bond is 121 kcal/g in silicone Therefore, the thermal stability of silicone products is high, and the chemical bonds of the molecules are not broken or decomposed under high temperature (or radiation exposure). Silicone is not only resistant to high temperatures, but also low temperatures, and can be used in a broad range of temperatures. Whether it is chemical or physical properties, the change in temperature is very small so it can apply well in medical device manufacturing.

1.3 Weather resistance

The main chain of silicone products is -Si-O-, and there is no double bond, so it is not easy to be decomposed by ultraviolet light and ozone. Silicone has better chemical resistance, thermal stability, radiation resistance, heat resistance and weather resistance than other polymer materials. The service life of silicone in the natural environment can reach several decades. Therefore, medical-grade silicone rubber can last for a long time no matter for the human body or for medical devices.

1.4 Low surface tension and low surface energy

The main chain of silicone is very flexible, and its intermolecular force is much weaker than that of hydrocarbons. Therefore, it has a lower viscosity, weaker surface tension, lower surface energy, and stronger film-forming ability than hydrocarbons of the same molecular weight. This low surface tension and low surface energy are the main reasons for its many applications. like hydrophobicity, defoaming, foam stabilization, anti-sticking, lubrication, glazing and other excellent properties.

Medical Grade Silicone For body

2.1Maintain bone growth

Osteoporosis is one of the characteristics of human aging. As calcium is constantly lost from the major systems of the body, our bones become fragile, and simply taking calcium-containing nutrients is not enough to stop this threat and disease. Because the human body needs the help of organic silicon to absorb and utilize this inorganic calcium.

For osteoporosis, silicone can relieve pain and even restore the body's self-healing function. For postmenopausal women, osteoporosis is the most common disease, and the data show that the number of deaths caused by fracture has exceeded the sum of breast cancer, cervical cancer and uterine cancer.

Osteoporosis is usually caused by the loss of calcium around bone protein, resulting in the thinning of bones. Gradually, the nutrients in the bone matrix are also lost, resulting in the continuous expansion of cavities. Therefore, even within the normal pressure range, there is the possibility of bone fracture. Therefore, it is a very important repair method to mineralize the calcium in the human body into the bone. It is suggested that organic silicon should be properly supplemented every day to better precipitate phosphorus, magnesium and calcium into bones, especially for calcium absorption.

2.2 Connective tissue

Connective tissue is composed of collagen, elastin, mucopolysaccharides, carbohydrates, and other substances, and around these tissue cells, moisturizing mucus is needed to help. With them, it is possible to make the tissue cells elastic and energetic, the same that prevents aging.

Studies have found that silicones account for a large proportion of these mucus macromolecules, which act as a "glue" to hold collagen together. So if there are enough silicones in the body, more collagen will be held together and, on a macro level, people and organs will become younger.

As the body ages, various connective tissues lose nutrients and become stiff, causing the body's tissues to decline as they too do not receive sufficient nutrients. Silicones can help slow down the degeneration process of these connective tissues.

2.3 Promote hair growth

Hair is the most natural beauty ornament. In addition to protecting the human scalp, healthy hair is also an attractive asset. Silicones have been found to contain 90 micrograms of silicone per gram of hair, which is close to 100 micrograms per gram of bone. Silicones are an important factor in the growth and strength of hair.

Medical Grade Silicone rubber

Silicone elastomer can be used as an ideal medium for specific drug delivery, including low consistency elastomer, liquid silicone rubber, solid silicone rubber and skin adhesive; The full range of products can be customized to meet the specific requirements of the implant or transdermal drug delivery applications.

The making of a dental impression is the first process in prosthodontics. Its quality and clarity are directly related to the final prosthodontic effect. Silicone dental impression materials can be rapidly vulcanized by adding room temperature silicone technology and make use of the advantages of high hydrophilicity and high thixotropy brought by the special spacing process so that users can obtain high-precision impression and replica in the shortest time.

Silicone is used to produce medical-grade silicone materials for various medical catheters (such as urethral catheters, gastric tubes, laryngeal mask tubes, peristaltic pump tubes, fluid reservoirs and other special tubes), as well as organic silicon materials for injection molding medical devices, perfusion medical devices, dental glue and other special requirements.

|

Infusion Tube |

Artificial Cochlea |

Orthodontic Dental Mold |

Wound Care |

Related Products

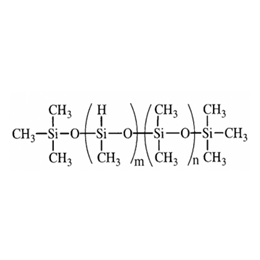

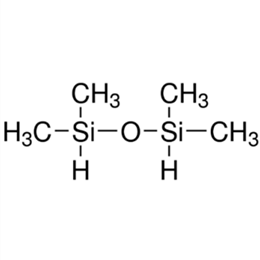

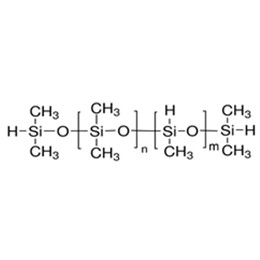

4.1 XJY-706 1,1,3,3-Tetramethyldisiloxane

4.2 XJY-8206 Methyl Vinyl VMQ/VMQ silicone resin

1. Excellent heat resistance and low-temperature resistance, can be used in the temperature environment of -60 ℃ to +300 ℃.

2. It has moderate flexibility and is resistant to aging and ultraviolet radiation.

3. It has good water repellency and excellent isolation performance.

XJY Silicones-First choice raw material supplier of silicone defoamers

| XJY Silicones, one of China's leading Silicone MQ resin and VMQ silicone manufacturers, has 30+ years of R&D and manufacturing experience and 15+ related patents in the silicone industry, also can customize the cost-effective products for medical device manufacturers according to your molding process and specification requirements. |