Film-forming agents are the core ingredient in cosmetics and the key point for base makeup and sunscreen products. The soft skin feel and toughness, its affinity with the skin, breathability, anti-sweat, and oil-control properties, and compatibility with the primer ingredients are crucial to the presentation of the final makeup effect, comfort, long-lasting continuous covering performance, and the avoidance of scrubbing. How to classify cosmetic film-forming agents?

There are five main types of film-formers commonly used in cosmetics:

- Protein Film-formers

- Acrylic Film-formers

- Polyethylene Copolymers

- Silicone Polymers

- Silicone Acrylates.

The following parts will describe film-forming agents in detail:

- What is the film-forming agent?

- How to classify film-forming agents?

- What are the water-soluble film-forming agents?

- What are the oil-soluble film-forming agents?

- How to classify film-forming agents according to efficacy?

- What are the applications of film-forming agents?

- How to improve the performance of film-forming agents?

1. What is the film-forming agent?

It's a polymer that forms a film on the skin, hair, or nails after drying with a silky feel, moisturizing, sunscreen, anti-sweat and waterproof, styling, and other effects.

2. How to classify film-forming agents?

(1) Solubility:

- Water-soluble

- Oil-soluble

(2) Source and nature:

- Silicone film-forming agent

- Acrylic resin film-forming agent

- Silicone acrylate

- Polyethylene-based copolymers

- Protein film-forming agents

- Copolymers of various hydrocarbons

- Hard film

- Soft film

Silicone resin film-forming temperature is different, soft film film-forming temperature is low, hard film film-forming temperature is high, generally soft film skin feel will be better, but the surface will have some viscosity, which can be compounded with the hard film to achieve a better coating feel and low viscosity, non-stick cup technology.

3. What are the water-soluble film-forming agents?

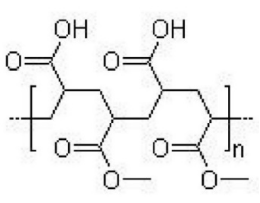

(1) Acrylates: Representative of the market, it has transparent and shiny film (increases waterproof + wear resistance)

- Acrylic acid (ester) copolymer and Styrene/acrylic acid (ester) copolymer:

It is a white powder form, which has very high hydrophobicity and water resistance, dispersion of color, and can form thin films;

- Acrylic copolymer emulsion:

Flowing liquid, water binding properties, easy dispersion of the aqueous phase, good water resistance, faster drying, into a soft film with gloss and hardness

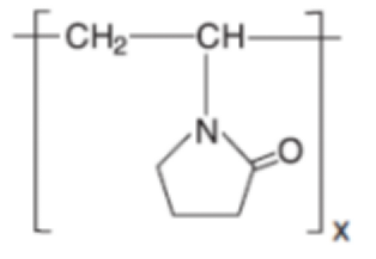

(2) Polyvinylpyrrolidone (PVP)

The higher the X, the higher the molecular weight, it will be more viscous with stronger adhesion. When adding in the carbo system carbo needs to be neutralized before adding.

It is in white powder form and can form a hard, glossy transparent film, it has a high molecular weight, and no need for neutralization for discontinuous film.

(3) Polyvinyl Alcohol (PVA)

It is in white powder form or granule form, which can form a hard film.

4. What are the oil-soluble film-forming agents?

(1) VP/hexadecene copolymer

Features: It is a viscous liquid with good water resistance.

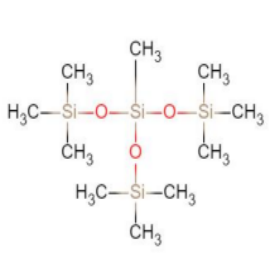

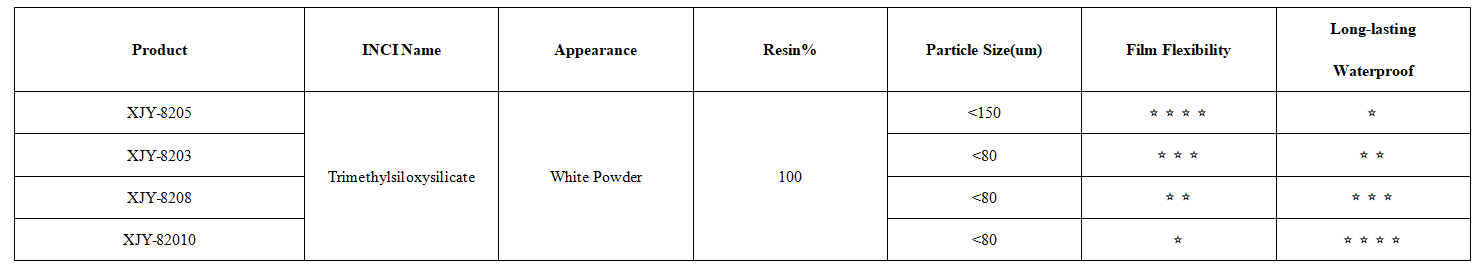

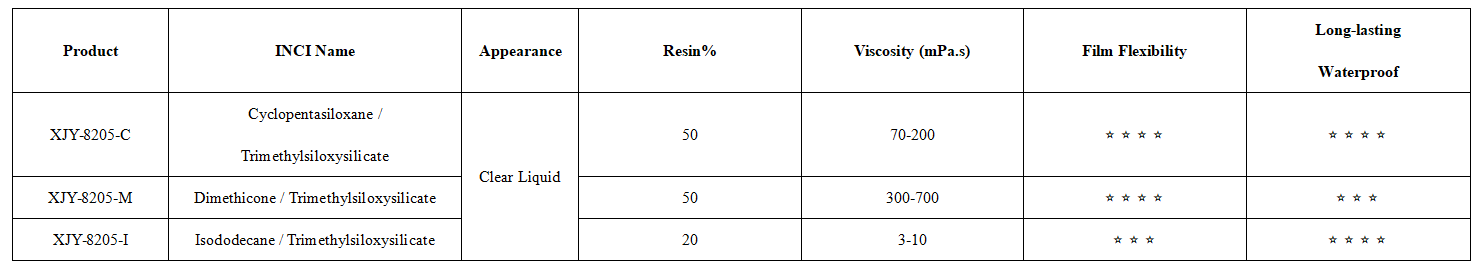

(2) Trimethylsiloxysilicate (MQ resin)

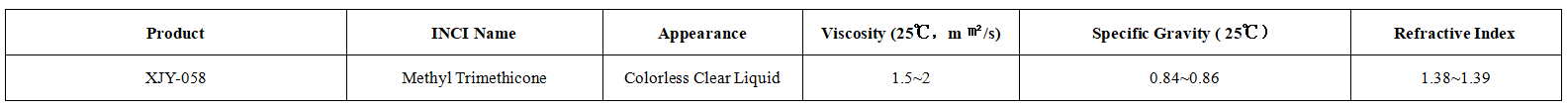

XJY Silicones can provide both powder and liquid forms of film-forming agents with a soft touch, and excellent water resistance and can be used in a variety of skin care formulations.

XJY-TMS is in white powder form, can form a waterproof film, prevents the coagulation of powder in the formula, and keeps the product free-flowing.

XJY-TMS also offers a range of silicone film-forming fluids dispersed in different carriers, recommended for use in skin care, sun protection, and makeup products, to help foundation, sun protection, mascara, lipstick, and other long-lasting makeup.

(3) Acrylic acid (ester) / Polydimethylsiloxane copolymer

Features: It is a colorless transparent or light yellow liquid, and can form a continuous waterproof membrane.

5. How to classify film-forming agents according to efficacy?

(1) Waterproof type:

- Wax resin film layer

- Small candle tree (EUPHORBIA CERIFERA) wax

It has film-forming, high hydrocarbon content, which is suitable for lipsticks, foundations, and other products.

Good formulation of the film

- The high content of Hydrocarbon

- Methyl Hydrogenated Turpentine

- Dimethicone Alcohol Stearate

(2) Skin-feel conditioning type

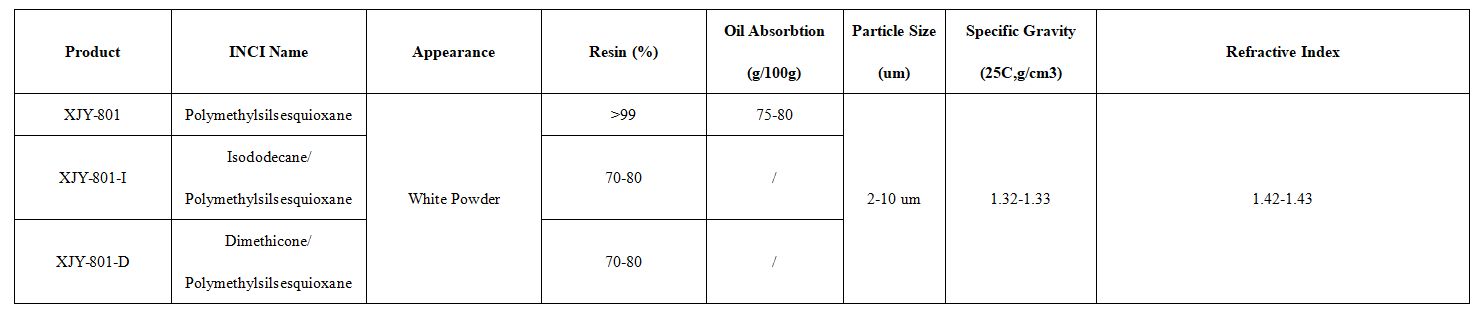

- Polymethylsilsesquioxane

XJY-801 Spherical Silicone Resin Powder are kind of insoluble non-melting trifunctional component of dense cross-linked curing resin. All of these resins have an excellent touch to the skin and can result in excellent performance benefits by different grades of particle sizes when incorporated into a variety of facial lotions and cosmetic formulations.

- Polyurethane Series - Natural Sustainable Related

- Polyurethane-1: It forms a hard film, 1.5%-3%, slightly white solution, somewhat matte, weak film-forming sensation, 2% is a bit white, no more than 2% is recommended.

- Polyurethane-11: It forms a hydrophilic smooth film, the coating has excellent skin-friendly properties and a soft finish, natural makeup before the smooth makeup film

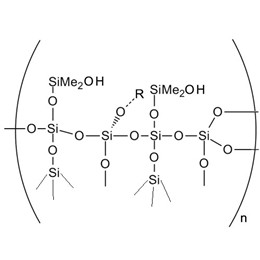

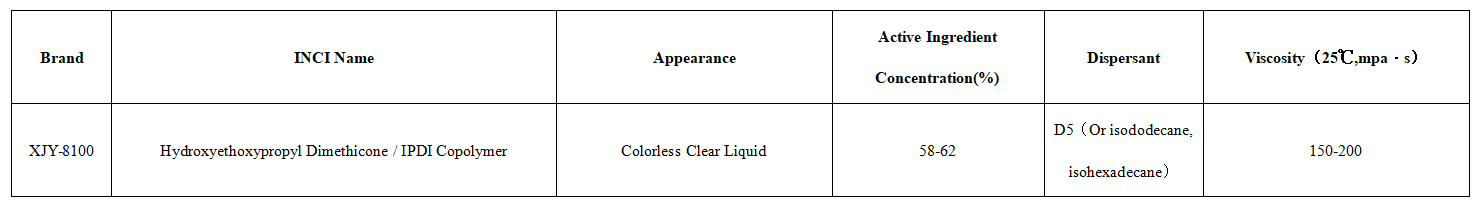

- XJY8100-Bis-HydroxyethoxypropylDimethicone/IPDl Copolymer

It is a Polysiloxane polymer that forms a very thin soft film to improve adhesion, elasticity, and bonding. It can significantly improve durability, waterproofness, and appliques after application. It has a smooth skin feel, good affinity with skin, high ductility, non-tacky, and smooth character.

- Volatile Silicone Oil

XJY-058 Methyltrimethylsiloxane is a methyl polytrimethylsiloxane with an MT structure. It is acyclic, colorless, and non-irritating. It has excellent volatility, is compatible with a wide range of cosmetics, and has a refreshing, non-greasy texture. It can be used in sunscreen products and can replace D5 Cyclopentasiloxane.

(3) Migration-resistant type

- Trimethylsiloxysilicate

It is a polymer with a three-dimensional network structure composed of silicon and oxygen atoms as the basic elements and can be dispersed by different solvents to form pre-made raw materials.

(4) To make granules/hydrogels/oil gels

- Hydrogel film

- Oleogel film

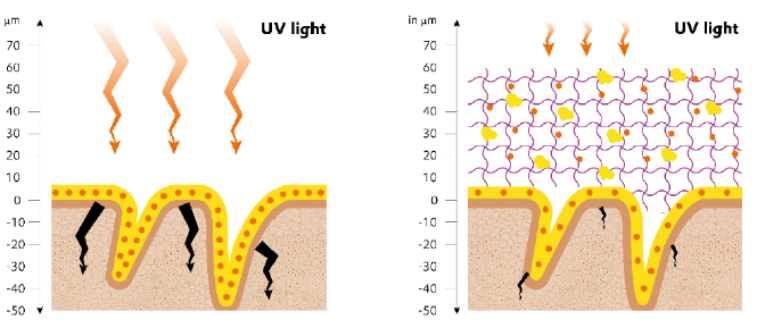

(5) Enhance sun protection

- Polyvinyl alcohol

With higher film formation, light will not leak down; so that the sunscreen can be dispersed more evenly.

(6) Adhesion type

- Polyvinyl acetate, Polyvinyl alcohol

- With Film-forming, adhesion to hair and sebum, low irritation.

(7) Anti-pollution type

It has pollution protection and a skin barrier effect; Its recommended addition is 0.5%-5%, Ph:3-9; and it dries at 100℃ for 3h to obtain a highly resistant, appearance that is transparent, and the film is easily removable.

(8) Firming

- Polyacrylate Crosspolymer-6

- Sodium Polystyrene Sulfonate

- VP/VA copolymer (vinylpyrrolidone/vinyl acetate copolymer)

6. What are the applications of film-forming agents?

(1) Creams and creams + water-soluble film-forming agent

It has breathable film that adheres to the skin's surface and prevents moisture loss.

It can adjust the skin feel and increase the silky, smooth, slippery feeling, keeping the skin smooth.

(2) Sun care, foundation, bb cream, etc. + oil-soluble film-forming agent

Waterproof protective film has waterproof, sweatproof, and anti-pollution, hair care applications.

It can assist in enhancing SPF value, and reduce the amount of physical sunscreen. added

It can enhance the skin's feel.

(3) Physical cleansing

- Face wash: adding Polyvinylpyrrolidone to increase the drawing viscosity of the product.

- Tear-off mask, exfoliating, adding products from the PVP series or Polyvinyl Aalcohols.

(In tear-type mask film, tearing off the surface of the skin is conducive to the gray layer, "dead skin" and other adsorption to remove, to achieve physical cleansing, and exfoliating role)

(4) Makeup

- Foundation, mascara, eyeliner, etc., fast-drying, styling decorative cosmetics

(Film-forming agents in mascara can give the product moisturizing, sunscreen, anti-sweat waterproofing, styling, the application of more acrylic resin film-forming agents, polyvinyl alcohol, polyvinyl pyrrolidone, silicone acrylate, water-soluble oil-soluble both, to play a waterproof film-forming effect.)

- Helps to disperse color powder

- Improves gloss

- Abrasion resistance; anti-migration

- Sweat and water-resistant

- Nail polish

Resin-based products are generally used in nail polish or other special products, due to the use of oil-based UV light therapy nail polish needs to use UV lamps and a certain degree of pollution to the air, so the development of water-based environmentally friendly nail polish, mainly polyurethane and acrylic resins, easy to apply, environmentally friendly, easy to tear off, non-toxicity, but film-forming is relatively poor, can be achieved through the film-forming auxiliaries dipropylene glycol monomethyl ether (DPM), propylene glycol mono butyl ether (PNBEE) and polypropylene glycol mono butyl ether (PNBEE), which can be used for the production of nail polish. However, the film-forming property is poor, which can be improved by film-forming additives such as dipropylene glycol monomethyl ether (DPM) and propylene glycol monobutyl ether (PNB).

7. How to make film-forming agents perform better?

The main function of the film-forming agent is to moisturize the skin by forming a uniform film, the film-forming agent is a polymer material, and after use, it can form a film on the surface of the skin to fit the skin, and it can effectively prevent the outside more than the size of the film holes in the material to enter the skin, so there is also the effect of the outside world to isolate the pollutants. How to improve the competitiveness of your products?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry and more than 15 related patents and technical support. Our silicone raw material products can meet the needs of the color cosmetics field and support the provision of diversified customized solutions.