Hair care and hairdressing have become an indispensable part of people's daily lives in terms of work and interpersonal communication, and it is very important to pay attention to daily care and protection of hair type from damage. The basic principle of hair care is to attach hair care ingredients to the surface of the hair cuticle, lubricate the surface layer of the hair, and reduce friction, thus reducing the chance of hair damage caused by external forces such as combing. In addition, the protective film formed by the conditioning ingredients prevents or slows down the loss of moisture within the hair. Why prefer silicone in hair products in the market?

Silicone-free hair products can damage our hair cuticles, causing worse hair fall and coarse hair; dandruff can also increase, and now and then you get an itchy scalp too.

Silicones naturally have low surface energy, high gas permeability (breathability), and excellent thermal stability. As a result, silicone-based hair products outperform many carbon-based materials in reducing interfiber friction, increasing softness, imparting hydrophobicity (water repellency), and all the characteristics of healthy, non-destructive hair, providing a plethora of benefits for hair care: ease of tangling, smoothness, shine, frizz control, protection, UV and color protection, repair of damage, and shorter drying times.

Let’s talk more information about it:

- What is silicone resin?

- What are the properties of silicone resin?

- How to synthesize silicone resin?

- How does silicone resin improve hair products?

- What are the advantages of silicone in hair products?

- What about silicone oils used in hair products?

- Is silicone good for hair?

- XJY Silicones- Silicone hair products preferred raw material supplier

1. What is silicone resin?

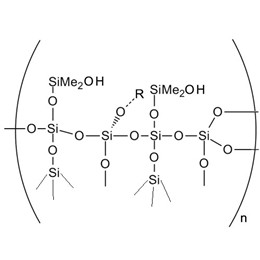

Silicone is a new type of special polymer synthetic material with many varieties, excellent performance, good safety, and wide application. At present, all kinds of silanes, siloxane intermediates and silicone oils, silicone rubber, silicone resins, silicone emulsions, and silane coupling agents, and other products made from them have been widely used in the electronic, construction, automotive, textile, light industry, cosmetics, medical care, food, and other industries, and has played a positive role. So far, silicone products that have been successfully developed for use in cosmetics and personal care products include Dimethylpolysiloxane, Methylphenylpolysiloxane, Polyether-modified silicone oils, Alkyl-modified silicone oils, silicone resins, silicone-treated powders, and other series.

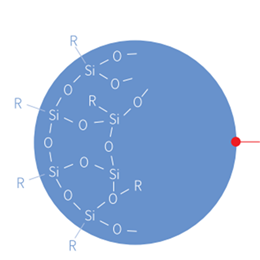

Silicone resins have better heat resistance and lower surface energy than general polysiloxanes, and they are used in a wide range of applications. Polymethylsilsesquioxane-type reticulated silicone resins are soluble in volatile solvents of cyclic silicones or hydrocarbon compounds, and this solution is easily coated on the substrate and then dried to form a thin film, which produces a non-tacky feeling, which has hydrophobicity and durability. The silicone is used in personal care products to provide very little lubrication and softening, a smooth feeling, and a drier feeling film compared to DPMS of the same viscosity, and the various products formulated with it do not leave a noticeable lubrication on the skin.

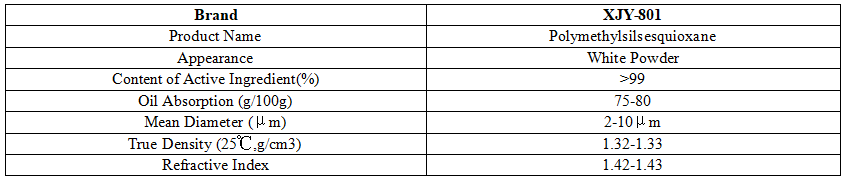

XJY-801 For Personal Care Polymethylsilsesquioxane is a kind of insoluble, non-melting, trifunctional component of dense crosslinked curing resin with excellent properties of low surface tension that easily diffuses to form a protective layer on the surface, and can be used as a solvent, conditioner, delivery agent, and moisturizer in hair product.

2. What are the properties of silicone resin?

Silicone resin has both Si-O-Si inorganic components, and organic groups of typical semi-inorganic polymer structure features, which make it both inorganic and organic double performance of special polymer materials, with the performance that other materials can not be replaced

(1)First of all, silicone resin has good resistance to high and low temperatures. Temperature range of about 100-400℃, its properties change very little in this range and can be used as high and low-temperature resistant coatings.

(2)Secondly, silicone resin has excellent electrical properties, excellent electrical insulation, an electrical breakdown temperature of 90-98Kv / MM, and excellent dielectric properties, in a wide range of temperatures, humidity, and frequency range to maintain stability, widely used as a motor impregnation paint and silicone insulating varnish, the use of the temperature of 180-200℃ and even up to 250-300℃ can be used as an insulating sealing material for electronic components, encapsulation materials.

(3)In addition, silicone resin has high chemical stability; at 25℃, silicone resin paint film in 50% sulfuric acid nitric acid, and even concentrated hydrochloric acid for more than 100 hours, and to a certain extent for chlorine has good resistance, can be used as a protective coating.

(4)Finally, silicone resin also has excellent water-repellent and moisture resistance, outstanding heat resistance, radiation resistance, transparency, and high mechanical properties.

3. How to synthesize silicone resin?

(1)Hydrolysis polycondensation

Silicone polymers are generally classified into three types of main chain structures. The first is a polymer with a silicone-oxygen bond as the main chain called Polyorganosiloxane. Secondly, the polymers with Si-Si bonds as the main chain structure are called Polysilanes. Third, the main chain structure of the polymer is composed of silicon and carbon, metal, and other heteroatoms, called Polyorganohaisosilane. Organic polysilanes are the most important class of silicone polymers, which are mainly produced by hydrolytic and non-hydrolytic condensation of silica-functional silanes.

(2)Emulsion polymerization

Emulsion polymerization is a polymerization reaction in which the monomer and water are configured into an emulsion under the action of an emulsifier, and an initiator is added to carry out the polymerization reaction at a certain temperature. The system is mainly composed of four basic components: monomer, water, emulsifier, and initiator. Emulsion polymerization methods are divided into intermittent, semi-continuous, continuous, top emulsification, and seed emulsion polymerization methods according to the process used and according to the nucleation mechanism are divided into micelle nucleation, homogeneous nucleation, and droplet nucleation.

4. How does silicone resin improve hair products?

Silicone resin micro powders obtained by hydrolysis polycondensation and silicone resin emulsions obtained by emulsion polymerization had significant improvement effects on the dry and wet combing performances of hair products.

(1)After using the hair product with silicone resin micronized to treat hair, the dry and wet combability of hair was effectively improved, indicating that the lubricity and excellent dispersibility of silicone resin micronized powder can reduce the friction between the hair strands, and provide a smooth feeling for the hair.

XJY-8203/8205/8208/82010 Trimethylsiloxysilicate TMS Film Forming is a series of solid silicone resin powders that have been specially developed to provide film-forming and softening effects. It can be added to clarifying shampoo, hair styling products, conditioners, etc. to meet different needs based on its unique properties.

(2)Hair products with silicone resin emulsions can also significantly improve the wet and dry combability of hair. The improvement in dry combability of hair was more pronounced for each sample formulation and the difference between each other in reducing hair friction was not significant. Its application was also generally superior to the sample formulations prepared by hydrolysis polycondensation. This is caused by the relatively uniform particle size distribution of silicone resin emulsions prepared by the emulsion polymerization method, which is ideal for the improvement of hair combability.

5. What are the advantages of silicone in hair products?

5.1 Color Protection

Silicone helps prevent color loss and fading in permanently or non-permanently dyed hair. Some color pigments simply remain in the outer layer of the hair scales and are washed out when the hair is rinsed. Because of their spreading properties, silicones help the pigments to penetrate further into the hair and thus have a long-lasting color-stabilizing effect. By forming a waterproof protective film, the silicone also prevents the color from being washed out.

5.2 Thermal protection

Hair dryers and heat styling tools heat the hair, making hair hydrated become dry and eventually causing hair to split and break. Silicones conduct heat very slowly, so the protective film of silicone that forms on the surface of the hair helps to minimize the evaporation of moisture and heat damage caused by reduced moisture. Silicones also help to flatten hair scales, resulting in a smoother, softer, and more aesthetically pleasing appearance.

5.3 Hair Strengthening

The film-forming properties of silicones also protect the hair from damage caused by the external forces of combing. Silicones help seal hair scales and prevent moisture from penetrating and evaporating from the hair cortex, thus maintaining optimal moisture levels for hair strength. Silicone films also add strength to hair that is frizz-prone, naturally fine, and prone to damage.

6. What about silicone oils used in hair products?

Silicones have been widely used in hair care products since the 1970s. They enhance performance in a wide range of products such as clarifying shampoo (standard and sulfate-free), rinse-off and leave-in conditioners, hair masks, hair oils, shine sprays, moisturizing oils, and more.

The conditioning and moisturizing agents added to the clarifying shampoo and hair products currently sold on the market are mostly silicone-based materials, especially Polydimethylsiloxane(water-soluble silicones), Emulsified Silicone Oils, Polyether-modified silicone Oils, Phenyl silicone oils, and so on, which are most widely used. They can bring good moisturizing and slippery effects for clarifying shampoo and hair products, and can effectively improve the combing performance of hair.

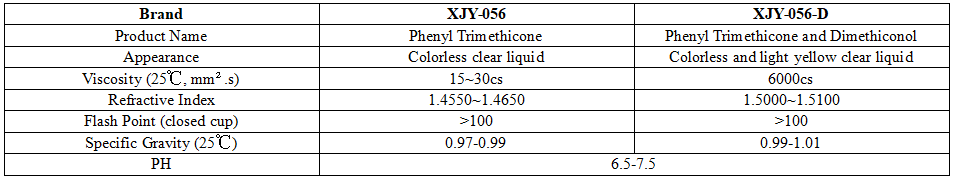

XJY-056 Phenyl Trimethicone (PHENYL MODIFIED FLUIDS) is a transparent phenyl silicone oil known for its high refractive index, which improves the gloss and softness of hair care products. It can be used in personal care products to formulate a wide range of products, including hair care, and helps improve the texture and spreadability of formulations.

6.1 What are the properties of silicone oil in hair products?

People found that the hair often dry frizz, and oil can solve this problem, so people began to use animal and vegetable natural oils for hair lubrication, to reduce the hair damage when combing. However, the hair is always oily and easy to get dust and other problems. The use of silicone oil has solved these problems.

The "silicon" contained in shampoos is not a silicon monomer but refers to Dimethicone. This is a sealant that mainly smoothes the hair. Since the 1950s, silicone oil has been used in personal care products; since the 1970s, it began to be commonly used in shampoos and hair care products.

(1)Silicone oil is viscous and ductile and has a moisturizing and smoothing effect on hair. Hair grows from hair follicles in the scalp and is composed mainly of keratin, with many unevenly spaced scales on each hair. Scales can buckle when damaged, which increases friction between hairs, causing them to tangle together, and more friction exacerbates the damage to the scales. When you wash your hair, the silicone oil in the shampoo adheres to the voids in the scales, filling in the surface of the hair shaft, and the hair feels soft to the touch. Especially on the often permed and dyed, more serious damage to the scales of the hair, the role is more obvious. Because the silicone oil is attached to the hair shaft to fill the damaged and open scales.

(2)Silicone oils also have sealing properties, forming a protective layer that keeps the moisture content of the hair stable - compared to shampoo-only hair, conditioner-applied hair loses less moisture in low humidity conditions and prevents the hair from absorbing too much moisture in high humidity conditions. Hair strands that are too wet or too dry can cause difficulty in combing and changes in hairstyle.

7. Is silicone good for hair?

Silicone in hair care products does not clog follicles, it only forms a film on the hair. There are hundreds of silicones, and different silicones perform well in different areas. Different silicones will either form a film or emulsify into a foam in the presence of water, depending on the properties of the medium. And silicone oils can make hair soft without affecting its health. There are questions about silicone-containing shampoos remaining on the scalp and clogging pores, which can cause folliculitis, hair loss, and other problems. In fact, silicone is not bad for your hair shaft.

(1)First of all, the possibility of silicone oil remaining on the scalp and clogging the pores is very low. Silicone oil is a macromolecular material, and will not be absorbed by the hair follicle, and shampoo containing silicone oil component is very small, for less than 1%, in the role of cleaning anionic surfactants under the action of a large number of water rinsing basically will not be left on the hair shaft.

(2)Secondly, silicone oil is safe to use in cosmetics. At present, there are a large number of studies in the European Union and the United States to show that the safety of cosmetics under the conditions of use is reliable. The Cosmetic Ingredient Review (U.S. CIR) expert panel concluded that silicone oil is not irritating to the skin. Although it forms a hydrophobic film on the skin, it is at the same time breathable.

Solution:

In the use of conditioner, hair film, which contains more silicone oil hair care products, as long as the application of the hair away from the scalp can be one end of the hair shaft, first, you can save the amount; secondly, the root part of the hair scales Damage is very little, basically do not have to take care of; thirdly, if you are rubbed in the root of the hair, not only greasy but also lead to the hair heavy collapsed.

8. XJY Silicones - Silicone hair products preferred raw material supplier

Silicone plays many roles in hair care products, such as preventing ultraviolet rays, protecting hair structure and color; providing cell protection and anti-aging; protecting hair from dryness and brittleness caused by hair dyeing and perming and hair loss, and protecting hair from damage due to pollution, sunlight, weather, sports and other damage to the hair. Silicone resins and silicone oils are widely used in hair care products, how to make your products more competitive in the market?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry and more than 15 related patents and technical support. Our silicone resins and silicone oils can provide customized solutions according to your application requirement specifications (hair care products).