Light diffusing agents are microspheres developed by cross-linking and grafting functional groups using polymer polymerization technology. In the traditional inorganic light diffusing agent and organic diffusing agent, why silicone light diffusing agent is widely used in the market?

The traditional lampshades are made by adding inorganic additives, such as barium sulfate, and silicon dioxide. When adding these inorganic nanoparticles, the light will be through the surface of the tiny particles for countless times light refraction to achieve light diffusion. But after all, the light is unable to enter the penetration of inorganic molecules, the loss of light energy is very large, and the brightening effect is not enough, it can only change the softness of the light.

The silicone light diffusing agent has the characteristics of both inorganic type light diffusing agent and organic type light diffusing agent, with low specific gravity, good lubricity, low volatility, high-temperature resistance, etc., in the Polycarbonate (PC), Polyphenylene Sulfide (PS), Polymethyl Methacrylate (PMMA) and other transparent resins with excellent light diffusion properties, while having a good balance of impact strength, haze, and light transmission.

There’s more information to talk about:

- Definition of light-diffusing agent

- What is silicone light-diffusing agent?

- What is the chemical principle of silicone light-diffusing agents?

- What are the advantages of silicone light-diffusing agents?

- What are the influencing factors of silicone light particle’s use effect?

- What are the applications of silicone light diffusion agents?

- XJY Silicone - Silicone light diffusing agents preferred raw material supplier

1. Definition of light-diffusing agent

1.1 What are light-diffusing agents?

The light-diffusing agent is a substance that scatters light. It can be added to PC, PVC, PS, PMMA, PET, epoxy resin, and other transparent resins, as well as LED (light-emitting diode), to increase the scattering and transmission of light, to cover up the light source and blinding light source at the same time, and make the whole resin emit a softer light.

In short, it allows light to no longer travel in a straight line, but to be scattered in all directions, making the light look softer and more three-dimensional. When light enters the light diffusing agent, due to the inconsistency of the refractive index of the light transmission medium or the catalyst, the light cannot travel in a straight line but will be reflected, refracted, and scattered many times, and eventually scattered in all directions, producing a natural, soft diffuse light effect.

1.2 How to classify light-diffusing agents?

There are mainly inorganic light-diffusing agents and organic light-diffusing agents:

(1)Inorganic light-diffusing agents mainly include nano-barium sulfate, calcium carbonate, silicon dioxide, and other inorganic light-diffusing agents. Inorganic light diffusing agents are solid balls of micro-beads from a microscopic point of view, the inability of light to pass through this solid sphere affects the transmission of much of the light, and only some of it passes through refraction, thus affecting brightness or light transmission. To do the lampshade requires a light transmission rate of more than 50%, so an inorganic light diffusing agent can not be selected.

(2)Organic light diffusing agents mainly include silicone-type and acrylic resin type. Organic light diffusing agents cause a small loss of light energy, the light diffusion at the same time basically does not affect the brightness of the light. Silicone light diffusing agents have superior light transmittance, the use of silicone light diffusing agent itself the refractive index of the material and the refractive index of the substrate of the difference in light refraction, light refracted many times through the substrate of the light becomes bright and soft, and the material of the transmittance of the impact of the small, it is a good choice to do the lamp lampshade and other optical material.

2. What is a silicone light-diffusing agent?

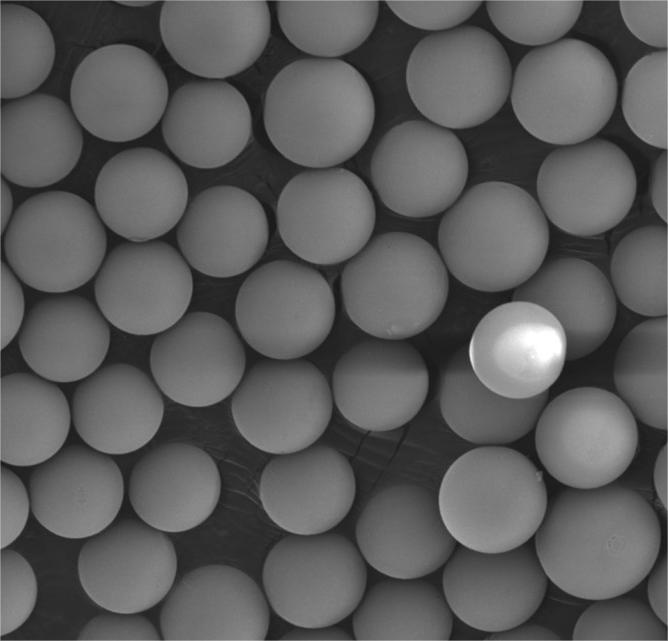

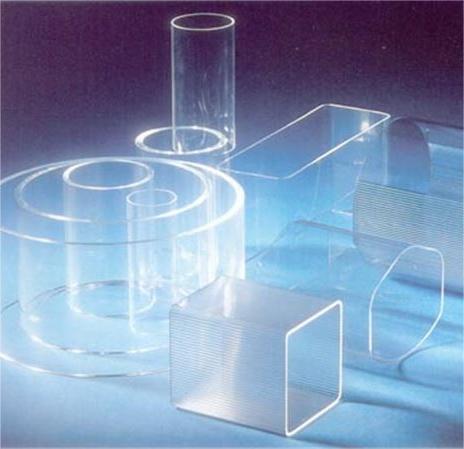

Silicone light diffusing agents are silicone resin microparticles (containing spherical resin particles with multiple pits on the surface) with excellent transparency and optical properties, and light diffusing film that satisfies good light diffusion and high light transmission in a balanced manner even when scattered light is observed at a certain position, and they are a kind of additives that can be used to improve the performance of plastics, rubbers, and coatings and are widely used in backlighting of liquid crystal displays, transmittance, lighting equipment, and light display panels. It can be widely used in the backlight of liquid crystal displays, transmissive screens, lighting apparatus, lamps and lanterns, and so on.

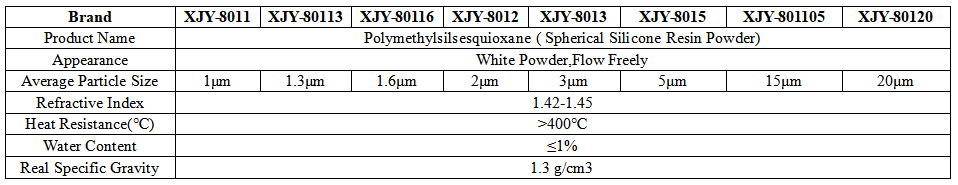

XJY-801 Polymethylsilsesquioxane takes Methyltrimethoxysilane as raw material, and acid as catalyst, firstly hydrolyzes the reaction, conducts condensation under alkaline conditions, and condenses and crystallizes into spheres. After high-temperature maturation and other processes, a solid product is finally obtained. It can provide a good optical performance balance of transmittance, haze as well as diffusion effect, widely used in high-end transparent PC lamps, lampshades, lightboxs, flat-panel LCD light diffuser plates, etc.

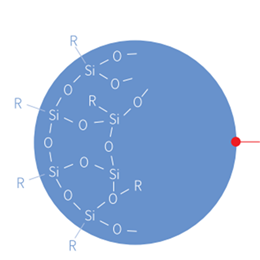

3. What is the chemical principle of silicone light-diffusing agent?

Silicone light diffusing agent belongs to the organic class of light diffusing agents and is a silicone-oxygen bond connection, a three-dimensional structure of the polymer microsphere. This light diffusing agent is a white powder, added to different materials in the resin, which will be a fine transparent glass sphere uniformly dispersed in the matrix, through the refractive index differences with different substrates, the light source penetrating refraction, changes the route of the light, to achieve uniform light and the purpose of light transmission. At the same time to meet the needs of the haze value and light transmittance.

4. What are the advantages of silicone light-diffusing agents?

(1)Compared with inorganic light diffusing agents, silicone light diffusing agents have good compatibility with the base resin, good dispersion, low specific gravity, low water absorption, excellent hydrophobicity, high light transmittance, and high haze value.

(2)Compared with the traditional Polymethyl Methacrylate(PMMA), Polystyrene microspheres(PS)organic light diffusing agents, silicone light diffuser has a good light diffusion effect, good weather resistance, UV resistance, non-yellowing, and excellent heat resistance. In the processing temperature range of the substrate material, no deformation, and sphericity remains intact, while other types of organic light diffusing agents due to low heat temperature are easy to heat deformation, which leads to an unsatisfactory light diffusion effect.

(3)The silicone light diffuser material is microscopically transparent and spherical, so it provides superior light transmittance, and at the same time, due to its extremely low refractive index of 1.43 (compared to acrylics of about 1.50 and styrene of about 1.55), the light diffusing agent material has high transmittance of light and high haze.

5. What are the influencing factors of silicone light particle’s use effect?

5.1 Particle size

Under the conditions of the same type of material and the same amount of light diffusing agent of the silicone microspheres particle size distribution, the smaller the particle size of the silicone microspheres is, the more the number of particles is, the more times the light is deflected, the greater the diffusivity is, and the higher the haze is. In other words, to obtain the same haze, the additional ratio of the silicone microspheres' light diffusion particles can be reduced, which can reduce the cost. However, the larger the number of light diffusion particles in the silicone microspheres, the lower the light transmittance. Therefore, it is necessary to determine the amount of light-diffusing agent to be added according to the silicone light-diffusing agent with different particle size distribution and the change in haze and light transmittance. However, if the particle size is too small, the particle size distribution is difficult to control, which leads to a decrease in transmittance under the same haze condition. If the particle size and particle size distribution are proper, the transmittance and haze can reach a higher value at the same time. At the same time, the better the regularity and finish of the particles, the better the haze and transmittance. Particle size is generally around 1-5 microns.

5.2 The refractive index of the material itself

Haze refers to the deflection of light when passing through the interface of two materials with different refractive indexes, resulting in diffusion. Therefore, the greater the difference in refractive index between materials, the greater the deflection angle of light after passing through, and the higher the efficiency of haze generation. The refractive index of the substrate and the diffusing agent should not be too large or too small. When the relative refractive index of the diffusing agent is between 0.91-0.97 and 1.03-1.09, the transmittance is better. If the relative refractive index is too small, the difference between the two refractive indices is not significant and scattering is not obvious. Too large a difference in relative refractive index will cause total reflection to occur, reflecting light back into the interior without effective export.

For example, the refractive index of PS and PC is 1.59, the refractive index of PMMA is 1.49, and the refractive index of silicone microspheres is 1.42~1.45, so the amount of silicone microspheres light diffusion agent required to achieve the same haze of PS and PC It is much less than that of PMMA. This is why the amount of PMMA light diffuser added is 2-3 times more than that of silicone microspheres.

5.3 Material thickness and shape

The light diffusion materials on the market mainly come in two forms: lamp panels and bulbs. The lamp panels are conventionally divided into 1mm, 1.5mm, and 2mm thicknesss. Although the materials may be the same, the amount and particle size of silicone microspheres' light diffusion agent required is different.

Taking standard 2μm silicone microspheres light diffusion particles, with a certain amount of addition, the 1mm light diffusion plate is closely arranged in the thickness direction, and it is impossible to exceed 1000μm / 2μm = 500 silicone microspheres light diffusion particles at most. Moreover, the material itself needs to be bonded between the particles. The 1.5mm and 2mm light diffusion plates can arrange up to 750 and 1000 light diffusion particles of silicone microspheres. Therefore, in comparison, the haze and light transmittance will deviate from each other. In this case, the appropriate amount of light diffusion agent of silicone microspheres should be determined by combining the haze and light transmittance, by using smaller diameter silicone microspheres' light diffusion particles to compensate for light deflection. For example, using 1.5μm silicone microspheres' light diffusion particles to prepare the 1mm thick board, can also achieve a good haze.

However, as far as the bulb is concerned because the lamp bead is far away from the lampshade, the haze requirement will be reduced. In addition, the bulb has a large reflected light area and strong reflection ability, so the light loss is very low, and the light is transmitted. The rate is high. Therefore, a relatively small amount of addition can achieve better light transmittance and haze. Generally, PC materials are added by 0.3~0.5%.

5.4 Spherical regularity

The more spherical silicone microspheres light diffusing agent particles, the more the light deflects on the surface of the sphere, and the more regular reflection angles. Therefore, the prepared light diffusing material has higher haze, better use effect, and lower addition.

5.5 Particle concentration

With the increase of light diffusion particles, the number of light scattering in the diffusion plate increases, backscattering increases, the free range of photons becomes smaller, and the haze increases, but the transmittance rate decreases. In order to ensure a high transmittance and haze, the additional amount of reasonable light diffusion material concentration is within 2%.

6. What are the applications of silicone light-diffusing agents

6.1 Highly transparent matting powder

Silicone light diffusion agent spherical micro powder added to the coating, which can form tiny unevenness on the surface of the coating film. As the tiny unevenness has a scattering effect on light, it can play a good matting effect.

6.2 Hand feel modified agent

Compared with inorganic powders, silicone light diffusing agents are easier to disperse, not easy to precipitate, have better adhesion and delicate feel when combined with coatings, and can form the surface of a more advanced sense of the coating.

6.3 Powder surface modification

Silicone light diffusing agents have strong friction-charged properties, so after dry mixing, it will be rapidly dispersed on the surface of plastics, organic powders, pigments, ceramics, inorganic powders, metal powders, and other particles, orderly mixing with uniform attachment to the surface of powder particles. Due to the formation of this orderly mixing, It improves the mixing characteristics, fluidity, and formability of powder molding, and can be used as an additive for coloring agents and carriers, and as an additive for ceramic molding.

6.4 LED industry

LED silicone light diffuser products are mainly used in PC, PMMA, PS, ABS, PVC lampshades, lamps, hoses, light diffusion plates, LED light-emitting resins, electronic display boards, digital tubes, dot matrix, lampshades, light boxes, advertising boards, light-emitting letters, cosmetic bottles and so on. It's significantly better than traditional light diffusion materials in solving the problem of glare in LED products; enabling the energy-saving advantages of LED lighting to be further strengthened; responding to the industrial policy and market trend of energy saving and emission reduction; making it possible for LED to enter homes and offices on a large scale

6.5 Plastic industry

Adding silicone light diffuser agents to Polycarbonate (PC), Polymethyl Methacrylate (PMMA), and other transparent plastics, increases the light scattering and transmittance of transparent plastics, the transparent resin emits a softer, more beautiful, and more elegant light while blocking out light sources and blinding light sources, achieving the comfortable effect of translucent opacity.

7. XJY Silicone - Silicone light-diffusing agents preferred raw material supplier

Silicone light diffusing agents are based on alkoxysilanes (such as Methyltrimethoxysilane, Phenyltrimethoxysilane, etc.) as raw materials, after hydrolysis, condensation crosslinking reaction to generate Polysilsesquioxane microsphere products, with high light diffusion efficiency, low additive amount, excellent thermal stability, widely used in various fields, has a higher market prospect. So how to make your products occupy the market quickly?

XJY Silicone is one of the leading manufacturers of silicone MQ resins and VMQ silicone in China, with more than 30 years of R&D and manufacturing experience in the silicone industry and more than 15 related patents and technical support. Our Polymethylsilsesquioxane is available in customized solutions according to your application requirement specifications (light diffusing agents).