Photovoltaic (PV) renewable energy has emerged as the core driver for achieving global green transformation and reducing carbon emissions, entering a new era of rapid development in recent years. As the scale of PV power plant construction and applications in complex environmental conditions expand, the industry’s technical requirements for the performance of encapsulation materials and backsheet adhesives continue to rise. The selection of high-quality resin materials not only directly impacts the initial performance of solar modules but also determines the stability, durability, and efficiency of power generation. High standards for heat resistance, strong adhesion, weathering, and long-term safety are setting new benchmarks for the reliability of such applications, especially for modules expected to last more than “25+ years.”

Silicone resins, with their unique chemical structure and physical properties, demonstrate exceptional advantages in the encapsulation and backsheet adhesive applications of high-end photovoltaic modules. There are different types of silicone resins, such as MQ, MDT, and Q-type, and the type of resin—determined by its molecular structure and functional groups—affects its suitability for specific applications in encapsulation, coatings, adhesives, and water repellents. Certain types of silicone resins offer specific advantages for encapsulation and backsheet adhesive applications in photovoltaic modules, such as enhanced durability, flexibility, and compatibility with various substrates. These resins serve as key binders and coatings for module layers and offer compatibility with diverse materials, providing a robust foundation for the high efficiency and ultra-long lifespan of photovoltaic systems.

There are six aspects to introducing silicone resin in the optical industry:

- What are the requirements for the photovoltaic industry?

- What is the role of back sheet adhesive?

- What are the characteristics of silicone resin?

- What are the application advantages of silicone resins in photovoltaic module encapsulation?

- What is the application of silicone resin in backsheet adhesives?

- How to enhance the performance of silicone optical resins?

1. What are the requirements for the photovoltaic industry?

According to statistics from authoritative institutions such as the International Energy Agency (IEA) and the China Photovoltaic Industry Association (CPIA), global photovoltaic installed capacity exceeded 1,200 GW in 2023. In such a large-scale industry, PV modules need resin encapsulants and adhesives that provide durability and high-temperature range stability. However, the industry faces challenges such as “limited land resources, high environmental pressure, and intense product price competition.” Efficient, durable, and harsh-condition-adaptable module encapsulation technologies—aided by state-of-the-art silicone resins and organic resins—are urgently needed in these applications.

Scenarios like ground-mounted plants, residential rooftops, BIPV, and exposure to desert, tidal flats, or high-humidity climates place the following demands on encapsulation and backsheet adhesives:

(1) Long-term resistance to high temperatures, low temperatures, humid heat, UV radiation, and outdoor weathering;

(2) Resistance to extreme climatic challenges such as salt fog, acid rain, dust storms, and ice/snow with low viscosity loss; advanced silicone resins help reduce viscosity loss under these extreme conditions.

(3) Extremely low water vapor permeability and excellent electrical insulation properties—directly related to the surface properties and water repellency of the silicone resin;

(4) Strong, durable adhesion and interface compatibility with films, glass, and other materials;

(5) The industry continues to overcome the limitations of traditional materials like EVA and POE by introducing new, high-performance silicone resins—these non-reactive cross-linked resins, combined with tailored methyl groups or vinyl groups, offer a “deep protective barrier”.

To meet the evolving needs of the photovoltaic industry, it is essential to use high-performance materials and follow best practices. This approach ensures optimal results in module performance and longevity.

2. What is the role of back sheet adhesive?

A typical photovoltaic module is composed of five layers: “glass/adhesive film/solar cell/adhesive film/back sheet.” The core components include the encapsulation adhesive film and the back sheet adhesive. Such adhesives and encapsulant films are carefully selected for their cure kinetics, curing temperatures, and compatibility. It is important to check compatibility and review technical data sheets before application to ensure proper performance and safety.

(1) The encapsulation adhesive film is primarily used to sandwich the solar cells between the glass and back sheet, achieving multiple functions such as sealing, insulation, cushioning, and protection, which require a stable resin backbone to prevent yellowing and ensure durability under UV and high temperatures.

(2) The backsheet adhesive/encapsulation adhesive not only provides physical functions such as bonding, mechanical load-bearing, waterproofing, and dustproofing, but also determines the long-term stability and safety “lifeline” of the module during outdoor operation. Silicone resin is more resistant to heat, weathering, and chemical attack than many competing resins, epoxy, or acrylate options.

(3) If the sealing material lacks sufficient aging resistance, it is highly prone to failure modes such as “micro-cracks, delamination, PID, moisture penetration, short circuits, erosion, and yellowing,” which affect the color, power generation performance, and product lifespan.

3. What are the characteristics of silicone resin?

Silicone resin is a cross-linked polymer material with a Si-O-Si backbone and numerous organic groups surrounding it, typically methyl groups, providing hydrophobic water repellent properties. The three-dimensional network structure is highly cross-linked, and the spacing between the “O” atoms in the backbone is relatively wide, imparting a “balanced rigidity and flexibility” characteristic—a signature advantage over sodium silicate or epoxy-only coatings. Silicone resin can be used in liquid form. In addition, vinyl groups present in silicone resins can undergo addition reactions, often catalyzed by platinum, to achieve crosslinking and curing at moderate temperatures. When preparing or modifying silicone resins, it is important to measure the correct quantities of each component to ensure optimal performance and consistent results.

(1) Extremely high thermal stability, heat resistant (glass transition temperature >200°C, capable of withstanding short-term high temperatures >350°C);

(2) Strong corrosion resistance, hydrolysis resistance, resistant to acid, alkali, salt, ozone, and UV radiation without decomposition;

(3) Excellent insulation properties (resistance at the 10¹⁴Ω·cm level, capable of withstanding voltage breakdown without carbonization);

(4) Low surface energy, hydrophobic and oleophobic, water repellency crucial for preventing moisture penetration during contact and operation;

(5) Adjustable viscoelasticity and flexibility, resisting cracking under wind loads, temperature stresses, or mechanical stresses thanks to the networked resin structure;

(6) High light transmittance and resistance to yellowing (color stability), with minimal absorption loss across the solar spectrum (especially the visible spectrum);

(7) Can undergo various chemical modifications to enhance adhesion, cure reaction, and interface compatibility with multiple substrates such as glass, films, backsheets, and silicon wafers.

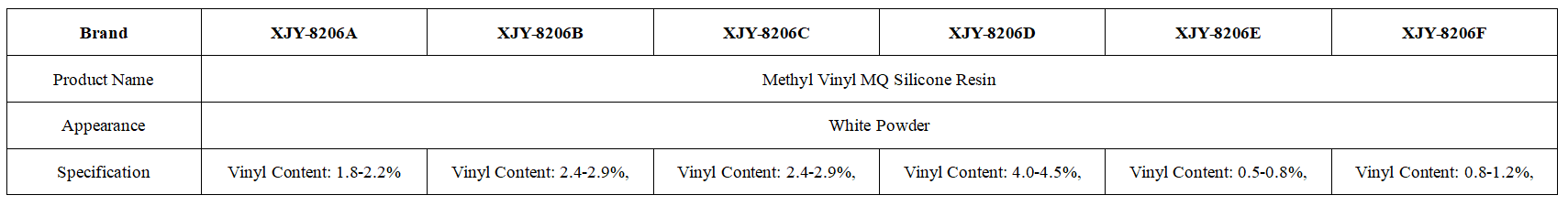

XJY-8206 Methyl Vinyl Siloxane Resin

It is made from the polymerization of tetrafunctional siloxane (Q) and monofunctional methyl siloxane (M). Silicone polymers and silicone compounds made from VMQ materials provide a wide range of temperatures, abrasion resistance, weathering, compression coagulation resistance, resistance to ultraviolet radiation, and other physical properties, and can be used in electronic and electrical appliances, LED, and other industries.

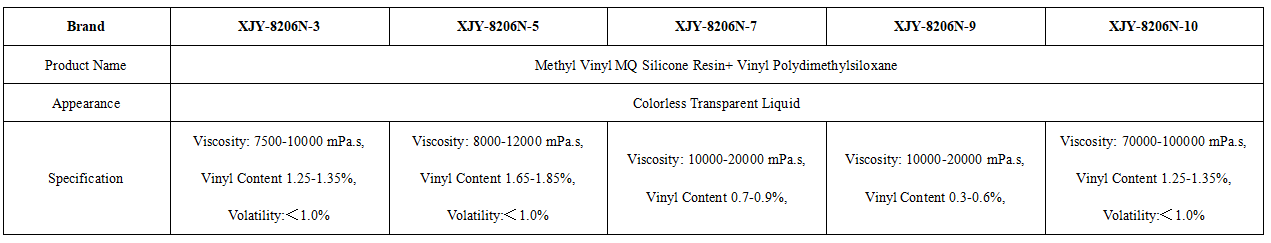

XJY-8206N Series Solution Methyl Vinyl MQ Silicone Resin

It is colorless and transparent and is composed of vinyl MQ silicone resin and vinyl silicone oil. It can be used for LSR(optical liquid silicone rubber), liquid additive silicone rubber, and can also be used for other two-component additive adhesives.

For best results, always follow the manufacturer's recommended procedures and guidelines for mixing and curing to ensure optimal product performance.

4. What are the application advantages of silicone resins in photovoltaic module encapsulation?

(1) Superior weather resistance and environmental adaptability

Silicone resins have a long-term operating temperature range of -60°C to 200°C, maintaining stable properties under high and low temperatures. This far exceeds the endurance of typical epoxy resins or acrylate pressure-sensitive adhesives in challenging locations—polar regions, deserts, and coastal climates. Importantly, silicone resins maintain their stable properties over extended periods of time, even when exposed to fluctuating environmental conditions.

5. What is the application of silicone resin in backsheet adhesives?

(1) Resists environmental corrosion and ensures internal stability

The backsheet is the “final barrier” of the module, directly determining its airtight protection and moisture barrier. Using organic silicone resin backsheet adhesive forms a robust, non-permeable, long-lasting adhesive layer with outstanding heat resistance and water repellency, blocking the intrusion of external moisture, dust, and pollutants, thereby reducing potential issues at the source. When preparing silicone resin adhesives, it is important to use a bottle to accurately add and mix solvents or additives, ensuring the proper formulation and optimal performance of the adhesive.

(2) High bonding strength, supporting the entire lifecycle

Silicone resin has excellent compatibility with various backplate materials such as TPT, TPE, fluorinated films, polyester films, and co-extruded films, effectively resisting air and ion corrosion.

(3) The back sheet adhesive remains flexible long-term with uniform stress distribution, maintaining bonding strength under wind loads, drops, relocation, etc., thus reducing the risk of water ingress or short circuit due to back sheet cracking or adhesive failure.

(4) Compatible with various back sheet materials and structural designs

Silicone resins demonstrate strong adaptability to double-glass, single-glass, multi-busbar, high-density modules, flexible modules, and other novel structures;

Supports fully automated industrial processes including dispensing, roller coating, spraying, hot pressing, and injection molding, significantly reducing manufacturing costs and enhancing quality stability.

(5) Enhances module safety and reliability

Silicone backsheet adhesive is high-voltage resistant, insulating, and non-carbonizing, ensuring long-term safety redundancy even under lightning or voltage surges.

The adhesive film contains no flammable parts, reducing fire risk and thermal runaway, thus improving intrinsic reliability for customers.

Solvent-free, halogen-free, and low-odor (odor), compliant with green market certification standards for global customers in the EU, SE Asia, etc.

6. How to enhance the performance of silicone optical resins?

Compared to traditional EVA, POE, and PU materials, organic silicone resin achieves over 95% light transmittance, outperforming conventional encapsulation adhesives (90-93%), with excellent temperature range endurance (-60°C to 200°C), superior heat resistance, UV and weathering stability, and minimal aging or yellowing. They also show resilience against mechanical fatigue, with superior electrical insulation, low moisture uptake, enduring vapor barrier properties, and flexibility and hardness. Silicone resins also excel in environmental certification, are solvent/halogen/heavy metal-free, and can be cured with modern curing approaches tailored for compatibility with new module materials and films.

XJY Silicone is one of China’s leading manufacturers of silicone MQ resins and VMQ silicones, with more than 30 years of R&D and manufacturing experience in the silicone resin industry, holding over 15 related patents and technical support. Our silicone resin raw material products meet the needs of the organic silicone optical field and provide diversified, batch-to-batch customized solutions for qualified industrial customers.

![]()