With the rapid development of the “beauty economy,” smart skincare, and healthy makeup, the cosmetic industry has entered a high-tech, precision-driven era, from formulation ingredients to product innovation. Today’s consumers no longer focus solely on basic makeup effects and skin feel; they place greater emphasis on product longevity, protective properties, safety, comfort, and technological content. Why are silicone cosmetic products popular?

Among various functional ingredients, silicone ingredients such as organic silicone powder film formers have sparked a materials revolution across multiple categories such as foundation, sunscreen, long-lasting makeup, and skincare, thanks to their unique molecular structure, exceptional skin feel, and outstanding performance. Silicones play an increasingly significant role in many beauty products due to their ability to enhance the texture and longevity of cosmetics and their synergy with other key ingredients like glycerin and moisturizing agents.

There are six aspects to introducing silicone film agent:

- What is the definition of silicone powder film-forming agents?

- What are the chemicals of silicone film-forming agents?

- What are the requirements for a film-forming agent in the cosmetics industry?

- What are the advantages of silicone powder film-forming agents?

- What are the applications of silicone film formers in cosmetics?

- What are the market trends of silicone in cosmetics?

1. What is the definition of silicone powder film-forming agents?

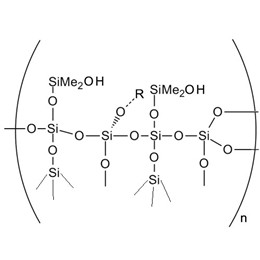

Silicone powder film-forming agents typically use spherical cross-linked polymethylsilsesquioxane, polymethylphenylsilsesquioxane (PMPSQ), and siloxane copolymer resins as their core structure, with multi-level cross-linked siloxane bonds. These silicone ingredients are produced through physical or chemical processes into ultra-fine powders. Their particles are predominantly spherical or near-spherical in shape, with a uniform particle size distribution, highly hydrophobic nature, and are colorless or slightly milky white. These silicone products are formulated to suit the needs of a broad array of skin types and are found in many popular skin care products. Their unique properties stem from their innovative chemical structure and inorganic-organic hybrid nature, often working together with fillers and other functional additives to optimize product performance on the body and face.

XJY-8203 / 8205 Trimethylsiloxysilicate is a series of solid silicone resin powders. These silicone resins have been specially developed to provide film-forming and softness effects. It can provide excellent water repellency and resistance to detergent/ water wash-off, and a flexible film with a smooth and comfortable touch on the surface for many skincare products.

![]()

2. What are the chemicals of silicone film-forming agents?

(1) Highly cross-linked Si-O-Si frameworks ensure excellent heat resistance, chemical inertness, and mechanical strength after film formation;

(2) Adjustable organic groups (such as methyl, phenyl, or alkyl) enhance compatibility with oils and cosmetic ingredients and tactile properties;

(3) A loose structure with a large specific surface area provides excellent dispersibility, spreadability, and lubricity;

(4) Particle size can be adjusted (typically 0.5–10 microns) to meet different formulation requirements, positively regulating the smooth feel and optical properties of the product.

Scientific research shows that the interaction of silicone’s siloxane bonds and the presence of both inorganic silica and organic functional groups creates a network that helps repel water and forms a distinct protective barrier on the skin’s surface. At the same time, this structure is breathable and allows oxygen to reach the skin, helping preserve comfort and skin health.

3. What are the requirements for a film-forming agent in the cosmetics industry?

The primary function of cosmetic film formers is to create a soft, uniform protective film on the skin’s surface, achieving goals such as long-lasting makeup effects, water and sweat resistance, protective encapsulation, and enhanced moisturization. With the rise of functional, long-lasting, and comfortable cosmetics, film formers are increasingly subject to higher demands:

(1) Long-lasting makeup effects—preventing makeup from smudging and ensuring high skin adhesion

(2) Superior water resistance — waterproof, sweat-resistant, suitable for outdoor/sports scenarios (hair care products like water-resistant conditioners and shampoos also benefit from silicone use)

(3) Ultimate skin feel — “bare-skin” lightweight, no film sensation, non-irritating, non-comedogenic

(4) Safety and non-irritating — low allergenicity, non-pore-clogging, certified by EU and other safety standards (medical grade silicone is even used for sensitive and post-procedural care and is less likely to worsen acne compared to some other occlusive agents)

(5) Compatibility with diverse matrices — compatible with silicone-based, oil-based, and water-based systems, and works synergistically with key ingredients such as moisturizers, emollients, glycerin, and SPF agents.

(6) Environmental sustainability trend — clean beauty, organic cosmetics, “green ingredients” aligning with market trends

Traditional organic film-forming agents (such as acrylic, polyester, polyurethane, etc.) face limitations in terms of smooth feel, durability, and green safety. Silicone cosmetic powder film-forming agents, with their exceptional ability to form robust films, high molecular structure, and ultra-fine powder physical properties, offer formulators and brands a new solution.

4. What are the advantages of silicone powder film-forming agents?

(1) Exceptional Skin Feel and Adhesion

The spherical micro-particle structure of silicone powder film formers significantly reduces the friction coefficient of formulations, delivering a “dry, lightweight, and non-greasy” skin-friendly experience. The low surface energy of silicones ensures smooth and lubricious application, enabling products to achieve popular makeup effects such as “invisible pores, matte blurring, and natural luster.” This smooth feel is a hallmark of silicone cosmetic formulations that often combine with fillers and humectants like glycerin for enhanced performance.

(2) Long-lasting Makeup Retention and Superior Water Resistance

Cross-linked silicone film-forming agents rapidly form a dense, continuous, transparent film. The high-strength silicone bonds resist hydrolysis, ensuring makeup remains durable and smudge-free even in extreme conditions such as high temperatures, sweating, or rain. This makes them particularly suitable for high-performance products like long-lasting foundations, waterproof sunscreens, and long-wear makeup. Silicones play a major role in water-resistant beauty products because the film they form resists moisture loss and slows the tendency for water to evaporate from the skin, helping maintain optimal moisture balance.

(3) Strengthened skin barrier protection

The silicone resin film layer effectively blocks direct contact with external dust, PM2.5, heavy metal particles, and volatile organic compounds, protecting the skin from environmental irritation; it also maintains a “breathable” state, preventing acne and clogged pores. The breathable property allows adequate oxygen flow, which is essential for skin vitality, while controlling occlusion so as not to worsen acne or irritation. Some variants, like dimethicone, are commonly used to treat scars and wrinkles due to their ability to enhance the skin’s healing environment.

(4) Excellent compatibility and formulation flexibility

Silicone powder has a stable structure and can be easily dispersed with various silicone gels, volatile silicones, plant oils, organic polymers, and other cosmetic ingredients in multiple formulations such as lotions, creams, foundation, pastes, and sprays, without clumping, migrating, or separating oils.

(5) Superior optical control and skin tone correction

Silicone powder exhibits excellent light scattering and diffuse reflection properties, effectively correcting minor imperfections and softening fine lines to achieve a soft-focus, matte, and natural highlight makeup effect. This is particularly critical for cushion foundation and other similar skin care products that aim to perfect the surface of the skin.

(6) High safety, environmental friendliness, and formulation flexibility

High-purity organosilicon is an inert, non-volatile, low-allergenic material certified by international cosmetic safety standards (REACH, RoHS, etc.), making it safe for the high-end cosmetic industry and even infant skincare products. These silicone products are increasingly favored in clean organic cosmetics thanks to their environmentally friendly properties and safety, and are less likely to block the natural oxygen flow to the skin or lead to dryness by holding in moisture so that it doesn’t evaporate too quickly.

5. What are the applications of silicone film formers in cosmetics?

(1) Base makeup products (foundation/cushion/loose powder)

Foundation products have extremely stringent film-forming requirements, needing to maintain makeup longevity, control oil, and prevent smudging while also being powder-free and wrinkle-free. Silicone cosmetic powder film formers help foundations form films quickly without stickiness, achieving a high-end makeup effect of “smooth, translucent, and soft-focus,” particularly suitable for long-lasting, matte, and natural-looking series. Dimethicone and similar silicone ingredients are commonly used in such formulas for their spreadability and finish, along with key ingredients like glycerin to improve comfort on the body and face.

(2) Sunscreen and skincare products

Modern sunscreen formulas generally aim for “high SPF protection + lightweight breathability + water and sweat resistance.” Silicone powder film-forming agents form films quickly, offer excellent water and sweat resistance, help sunscreen agents adhere effectively to the skin, enhance SPF longevity, and do not clog pores, making them suitable for sensitive skin types and daily skincare routine needs. Their compatibility with other key ingredients—such as physical UV filters, antioxidants, humectants like glycerin, and fillers—results in more effective and comfortable skincare products.

(3) Long-lasting makeup (lipstick/eyeshadow/eyeliner, etc.)

Silicone film-forming agents have excellent compatibility with high-molecular-weight color pigments, pearlescent agents, and wax-based systems, imparting makeup products with superior anti-transfer, smudge-proof, color-fast, and long-lasting hydration properties. They are crucial for innovative makeup products such as lipstick and lip gloss that do not transfer to cups, long-lasting eyeliner that resists smudging, and highly pigmented, long-lasting eyeshadow and blush. They are also found in certain hair care products like hair masks and conditioners to provide a smooth feel and protection.

(4) Functional skincare products

Silicone powder film-forming agents enhance the protective film of repairing and soothing lotions and serums, reducing transepidermal water loss. This ability to limit water loss and preserve hydration makes them a key element in moisturizers, emollients, and barrier-repair treatment serums. They coordinate with key ingredients that prevent moisture from evaporating quickly and ensure the right balance between occlusiveness and breathability so as not to worsen acne or lead to other sensitivity outcomes. In addition, topical silicone options are used in medical tissue and scar treatment.

(5) New hybrid innovative beauty products

“Skincare + makeup” cross-category products continue to grow, such as lotion-based sunscreen, cushion-based complexion correction, moisturizing concealer, and long-lasting setting spray. Silicone use in these formulated systems delivers enhanced compatibility, flexibility, and healing-support properties, fulfilling diverse market needs and making full use of advanced key ingredients—from oxygen-permeable silicones to moisture-locking glycerin and other advanced fillers.

6. What are the market trends of silicone in cosmetics?

(1) Global demand for silicone-based film-forming agents in the high-end cosmetics market continues to rise

According to data from multiple international industry consulting firms, the global market for tech-driven beauty products centered on silicone ingredients is growing at a compound annual growth rate exceeding 10%. Among these, powder-based film-forming agents are rapidly increasing their market penetration in sectors such as makeup and sunscreen. Leading brands in Japan, South Korea, Europe, and the US are increasingly adopting high-performance silicone products to enhance product value and consumer reviews, integrating more targeted fillers and key ingredients to optimize results on the body and face.

(2) Clean beauty and “oil-free, fragrance-free, and hypoallergenic” formulas are gaining popularity

In Europe, the US, Japan, and even China, the trend toward green formulas is driving the widespread replacement of polyacrylic acid and synthetic esters with silicone cosmetic materials (especially solvent-free powders) to meet consumer demands for health and safety.

(3) Personalized customization and formulation innovation are accelerating

With the emergence of demands for medical-grade silicone skincare, light medical-grade protection, and skincare-makeup fusion, silicone-based powders, with their high ability to deliver targeted treatment and healing support, have become the preferred raw material for high-end new cosmetic industry products.

7. How to Select Silicone Film Formers?

Silicone powder film formers are experiencing a boom in the cosmetic industry. Their unique properties, excellent skin feel, and superior safety and environmental attributes will continue to drive product upgrades in mainstream categories such as foundation, sunscreen, color cosmetics, and functional skin care. As green beauty and tech beauty converge, innovative silicone raw materials will also become a key driver of differentiated growth for major brands. How to enhance product competitiveness? Seek products where the synergy of silicones, key ingredients like glycerin, and gentle fillers is backed by research—to ensure the barrier supports breathable, optimal oxygen flow to skin without promoting excessive occlusion that could worsen acne or accelerate water loss via evaporation.

XJY Silicones is one of China’s leading manufacturers of organic silicon MQ resins and VMQ organic silicones, with over 30 years of R&D and manufacturing experience in the silicone industry, as well as more than 15 related patents and technical support. Our silicone raw material products can meet the needs of the cosmetics industry and support the provision of diverse customized solutions.

![]()