As global lifestyles, consumer attitudes, and environmental awareness continue to evolve, the demand for functional textiles with waterproof, stain-resistant, and oil-repellent properties is steadily increasing. Why use silicone waterproof agents for textiles?

In recent years, with the introduction of international conventions governing the regulation of persistent organic pollutants such as PFOS and PFOA, “fluorine-free waterproofing agents” have emerged as a core technological direction for the textile industry's green transformation. As a new generation of green waterproofing additives, fluorine-free silicone waterproof agents have gained significant attention across various sectors—including textile brands, public utilities, and even defense and military industries—due to their exceptional hydrophobic properties, excellent ecological compatibility, and high formulation flexibility. In addition, they offer the versatility seen in many construction and household projects where sealant, silicone sealant, and caulk are needed to fill gaps, seal cracks, and create a long-lasting waterproof seal, often working as a reliable rubber adhesive on a wall, around a bathtub, or other sensitive areas that experience significant pressure.

There are eight aspects to introducing silicone waterproof agent:

- What is the demand in the Fabric Waterproofing market?

- What are the properties and principles of silicone resin?

- What are the advantages of fluorine-free silicone waterproofing agents?

- What are the applications of silicone waterproofing agents in textiles?

- What is the comparison between silicone waterproofing agents and traditional waterproofing agents?

- What are the market Trends of Fluorine-Free Waterproofing Agents?

- What are innovation cases and green certification of silicone waterproofing agent?

- How to choose Silicone waterproof agents?

1. What is the demand in the Fabric Waterproofing market?

(1) Market Demand Drives Dual Upgrades in Functionality and Ecology

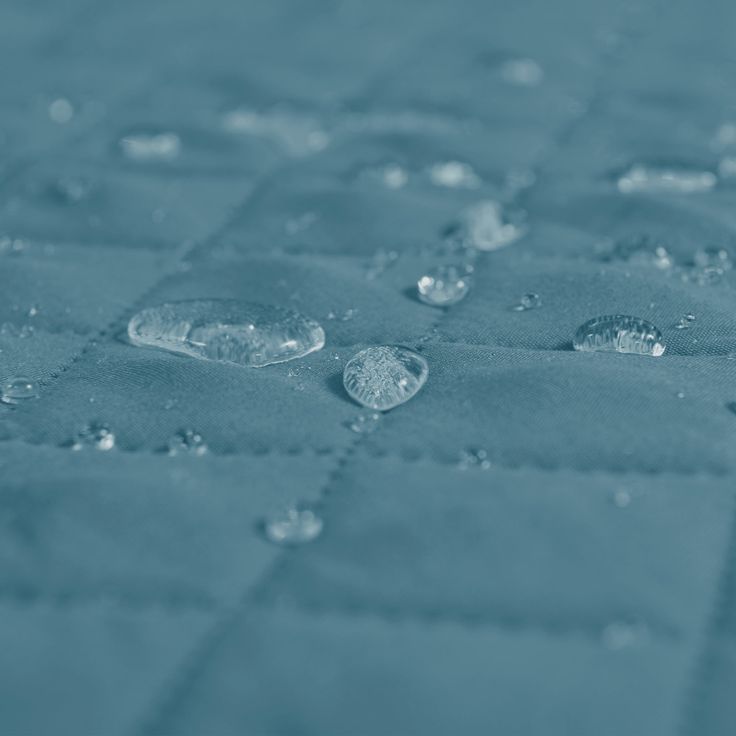

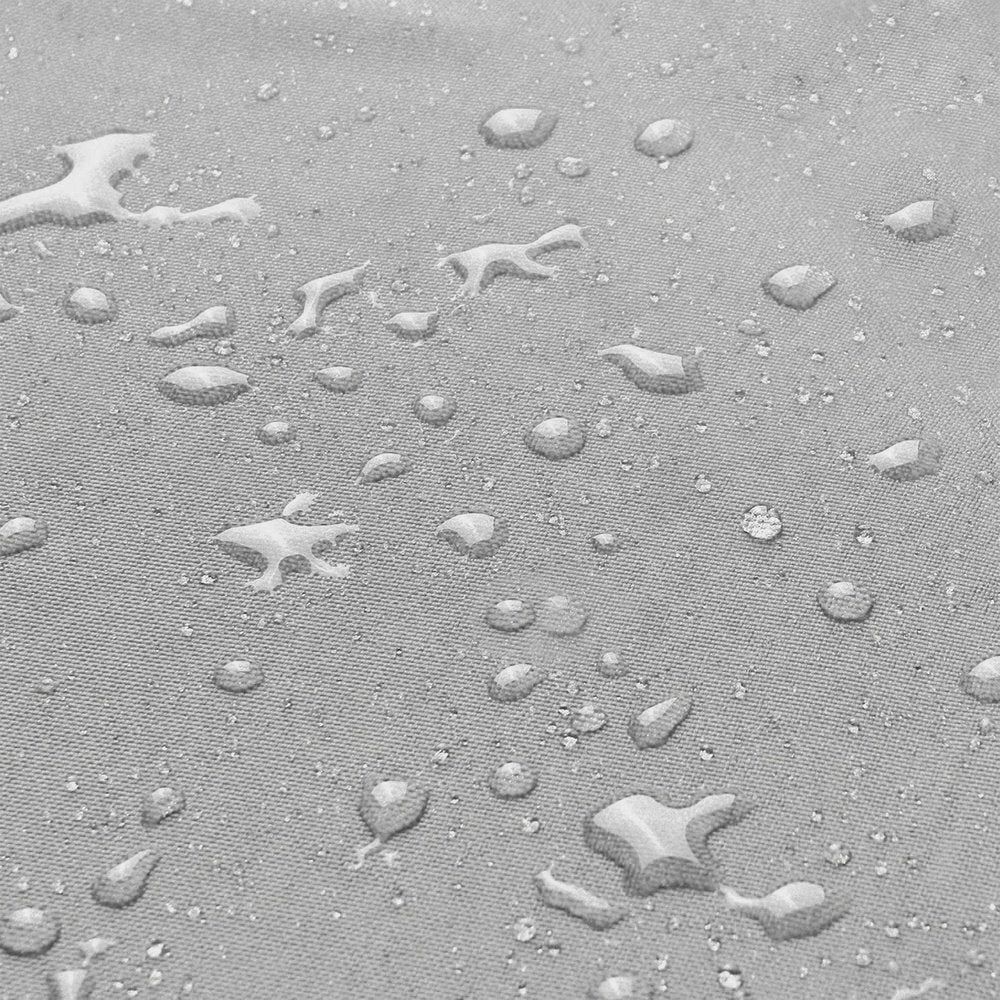

Waterproof functionality has become a standard feature for textiles such as clothing, home textiles, outdoor gear, and industrial filtration materials. Beyond water resistance, stain resistance, and moisture penetration prevention, users now demand higher standards for fabric feel, breathability, and washability. Especially in high-standard sectors like sports and outdoor gear, children's products, and medical protective gear, environmental friendliness and low allergenicity have become key differentiators in brand competition.

(2) Historical Evolution of Fabric Waterproofing Technology

Early Technologies: Primary wax-based, aluminum soap, and paraffin wax impregnation treatments provided some waterproofing but lacked durability.

Fluorocarbon Waterproofing Agents: Since the 20th century, fluorocarbon waterproofing agents synthesized from perfluorooctanoic acid (C8) and perfluorohexanoic acid (C6) have become mainstream, offering high efficiency and longevity but posing long-term risks to the environment and human health.

Emergence of fluorine-free waterproofing agent technology: This includes organosilicon-based, alkyl-modified polyurethane, aliphatic polymers, and nanomaterials. Among these, silicone-based materials stand out for their safety and high performance, gradually occupying a central position for both textiles and applications where a flexible and mildew-resistant sealant is desired, such as in bathroom or marine environments. For example, a silicone-based rubber adhesive or caulk applied at the wall-bathtub junction can resist pressure and prevent leaks even as materials expand, shrink, or dry over time.

(3) Regulations and green certifications drive fluorine-free upgrades

Major global markets have imposed bans on the use of PFOS and PFOA. Environmental standards such as Europe's OEKO-TEX, bluesign, and REACH require textiles to restrict or even prohibit the use of fluorinated waterproofing agents, creating significant market opportunities for fluorine-free materials.

2. What are the properties and principles of silicone resin?

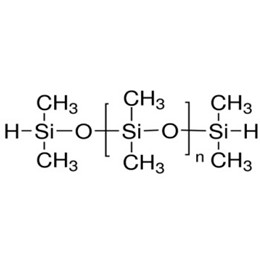

(1)Basic Structure of Silicone Resins

Silicone resins are a class of macromolecular materials with a siloxane backbone and different organic groups (such as methyl, ethyl, phenyl, etc.) as side chains. Their typical structures are generally [(RSiO1.5)x], [(R2SiO)x], or copolymerized with Q units. The Si-O-Si backbone of the molecule is highly stable, while the organic groups in the side chains can be adjusted to control flexibility, hydrophilic/hydrophobic balance, and affinity with fabrics. Silicone’s adhesion and bonds to various substrates, including plastics, metals, glass, and fabrics, have made it a preferred sealant for applications far beyond textiles—especially when a rubber adhesive is needed in high moisture or pressure environments.

(2)Basic Waterproofing Principles of Silicone Resin

Low Surface Energy Principle: The methyl side groups of silicone resin molecules impart extremely low surface energy, making it difficult for water droplets to spread on the fiber surface, thereby creating a distinct lotus effect (Lotus Effect), much like the effect achieved by a high-quality silicone waterproof agent applied as a bead along a surface—even in scenarios such as sealing a bathtub seam or a wall with consistent pressure from daily use.

Dense Film Structure: Silicone resin forms a uniform, dense nanoscale hydrophobic film on the surface of fibers or fabrics, providing high-durability waterproof and stain-resistant performance.

Customizable Molecular Structure: By modifying the chain length, crosslink density, and incorporation of special functional groups in silicone molecules, personalized waterproofing, softness, and wash resistance can be tailored for different fabrics.

(3) Environmental characteristics

Silicone itself contains no volatile organic fluorine, has no bioaccumulation properties, and does not release PFAS or its degradation intermediates during the degradation process, meeting the current EU and international standards for green waterproofing. Most silicone waterproof agents maintain excellent hydrophobicity even after multiple washes or wet conditions, greatly reducing the frequency of secondary finishing and resource consumption. This is true both for industrial use and for household use in waterproof sealant roles such as in bath, tile, and window areas where water, soap, grease, or dirt are present. Properly chosen silicone-based solutions also tend not to shrink or crack after they dry, maintaining performance in the long term.

3. What are the advantages of fluorine-free silicone waterproofing agents?

(1) Environmental Safety: Practicing Green Chemistry Principles

Fluorine-free silicone waterproof agents do not contain persistent organic pollutants (PFOS/PFOA, PFHxS, etc.), are safe for humans, and pose no accumulation hazards to aquatic and terrestrial environments. These sealant products are also mildew-resistant and do not promote the growth of mold in warm, humid conditions along bath or marine surfaces. In addition, their rubber-like elasticity allows them to withstand pressure along a bathtub or wall joint.

(2) Superior Hydrophobic Performance and Long-Lasting Lotus Effect

The waterproof membrane layer, centered on methyl silicone resin, has extremely low surface energy (<22 mN/m). Water droplets encountering the treated fabric form high contact angles, roll off, and exhibit strong “self-cleaning” properties. Resistance to liquid contamination (e.g., coffee, juice, oil stains) is also enhanced. This property is akin to how waterproof sealant and caulk are used to fill gaps and prevent water and moisture from penetrating surface joints, reducing the risk of water damage, even in fluctuating temperatures that might make other materials shrink or crack as they dry.

(3) No compromise on breathability and handfeel

Unlike traditional fluorinated agents, silicone-based waterproofing agents have larger molecular sizes, forming a dense membrane without obstructing the fabric's micro-pores. They have minimal negative impact on the fabric's skin-friendliness, softness, and breathability, making them ideal for high-end functional apparel and special occasion requirements.

(4) Excellent durability and compatibility

Silicone molecules can be further combined with emulsion-type auxiliaries/softeners/antimicrobial finishers through cross-linking, block copolymerization, and other technologies to impart “multi-functional” properties to the fabric. They exhibit outstanding heat resistance, UV resistance, and wash resistance, maintaining durable waterproof and stain-resistant effects even after washing. Similarly, the flexibility and heat resistance of 100 silicone-based sealant white allow creating a highly reliable seal along window or door frames or as a trailer sealant. These products maintain their rubber adhesive properties once fully dry and resist shrink-induced gaps under pressure.

(5) Wide Adaptability to Fabric Types

Suitable for various textile systems, including cotton, polyester, nylon, wool, hemp, composite, and non-woven fabrics, it can be used in industrial finishing processes such as calendering, immersion, and spraying. When finishing with silicone waterproof solutions, particularly for outdoor or marine applications, ensure to use the proper instructions for an even coat and bead.

(6) Low-foam, easy to use

High-quality organic silicone fluorine-free waterproofing agents are primarily low-viscosity, low-foam products, suitable for modern textile production lines such as automated sizing, impregnation, and filtration. They reduce mechanical damage, save energy, and lower maintenance costs. In applications such as bath sealant or window caulking, a caulk gun can be used to apply sealant, followed by shaping the desired bead size with a gloved finger or a tip attachment after you cut the nozzle to the right width. A quality rubber adhesive will retain flexibility and not shrink excessively after it dries.

4. What are the applications of silicone waterproofing agents in textiles?

(1)Functional clothing

High-end waterproof garments such as raincoats, windbreakers, jackets, down jackets, and workwear can meet excellent waterproofing and stain-resistant requirements when treated with fluorine-free silicone waterproof agents, while also making the garments lighter, more durable, and more comfortable against the skin.

(2) Outdoor Gear and Sports Equipment

Tents, sleeping bags, backpacks, sports shoes, fishing gear, and high-end fabric sportswear treated with fluorine-free silicone resin waterproofing agents can withstand complex weather conditions, ensuring the longevity and protective performance of outdoor gear. Even exposed seams benefit from a waterproof seal created using sealant or caulk to prevent leaks and water damage.

(3) Home Textiles

Sofa covers, curtains, tablecloths, bedding, and other items treated with silicone finishing not only prevent tea, juice, and oil stains from penetrating but also reduce bacterial growth, enhancing home hygiene and cleaning convenience. These fabrics are easy to clean and resist grease and dirt, similar to a moisture-blocking sealant used in kitchens or baths, and, when used for sealing bathtub or wall joints, a rubber adhesive ensures a continuous waterproof barrier under high pressure and does not shrink after it dries.

(4) Industrial Textiles

Special industrial fabrics such as filter cloths, medical protective materials, agricultural cover films, and construction protective fabrics have increasingly stringent requirements for durability, flame resistance, and liquid repellency. Fluorine-free waterproofing agents based on organosilicon resins provide industrial materials with more stable and long-lasting performance support, much like silicone waterproof sealant is relied on in construction for its cured strength and weather resistance.

5. What is the comparison between silicone waterproofing agents and traditional waterproofing agents?

Compared to traditional fluorine-containing waterproofing agents (such as C8, C6, C4), fluorine-free silicone waterproofing agents offer several significant advantages. They provide excellent waterproofing performance with a pronounced lotus leaf effect. Although their oil resistance is average, it can be improved through formulation adjustments. In contrast, fluorinated agents deliver outstanding oil and stain resistance in addition to water repellency.

Environmentally, fluorine-free agents are eco-friendly and pose no risk of persistent pollution, while fluorinated products carry a high environmental risk due to the potential generation of harmful substances like PFOS and PFOA. In terms of durability, fluorine-free silicone agents maintain strong waterproofing even after repeated washing, whereas fluorinated agents may leach pollutants over time despite their relatively good durability. For hand feel and breathability, fluorine-free agents leave fabrics soft and breathable, while fluorinated ones may feel slightly stiff or form a film-like texture.

Regulatory-wise, fluorine-free agents comply with current regulations in the EU, US, and Asia-Pacific regions, whereas many new regulations now ban or strictly limit the use of fluorinated waterproofing chemicals. As a result, fluorine-free silicone waterproofing agents are emerging as a more sustainable and compliant alternative.

Silicone solutions, like household bath sealant, are available in diverse oz and fl oz pack sizes, making them convenient to purchase for any project from textiles to construction. For best results, remove any old caulk or old sealant, clean the surface thoroughly, and use backer rod for gaps larger than 1/4 inch before applying and creating a smooth, continuous bead. Wipe off excess with a damp cloth or gloved finger. Always allow the rubber adhesive or caulk to fully dry before exposing it to water or pressure, so the seal does not shrink or lose integrity, especially around a bathtub or vertical wall.

6. What are the market Trends of Fluorine-Free Waterproofing Agents?

(1)Market Size Continues to Grow

According to analysis by leading global market research firms (such as Grand View Research and Marketsandmarkets), the global market size for fluorine-free fabric waterproofing agents is projected to expand at a compound annual growth rate (CAGR) exceeding 10% by 2030. Asian and European/American apparel giants have already massively shifted to fluorine-free materials, marking a new trend in industry upgrading.

(2) Key Policies and International Certifications Driving Adoption

European Market: Green certification systems such as OEKO-TEX, bluesign, GOTS, and ZDHC strongly recommend fluorine-free silicone waterproof products.

Chinese Standards: Standards such as the “Technical Specifications for Ecological Safety of Textiles” (GB/T 18885) restrict or prohibit the use of fluorinated chemicals.

Global apparel brands (such as Patagonia, ZARA, H&M, and Uniqlo) have committed to phasing out C6 and higher fluorinated finishes by 2025, thereby driving the comprehensive upgrade of upstream fluorine-free auxiliary materials. For additional information about silicone and other sealant options, consult the manufacturer’s instructions for specific application and compatibility with textiles or surface materials.

(3) Accelerated technological innovation

Independent or blended organic silicon fluorine-free waterproofing agents are continuously being introduced, with synergistic solutions such as “organic silicon + polyurethane” and “organic silicon + nanotechnology” emerging in large numbers.

Functional upgrade types: Integrated products with functions such as waterproofing, fireproofing, anti-static, and self-cleaning are increasingly available.

(4) Enhanced Consumer Awareness

Environmental protection and health have become key reference criteria for consumers when selecting high-end apparel and home textiles, with concepts like “NO-FLUORINE” and “PFAS-Free” deeply ingrained in public consciousness.

7. What are innovation cases and green certification of silicone waterproofing agent?

(1) Innovation Cases

Leading domestic and international sports brands have already pioneered the application of fluorine-free silicone waterproof agents in jackets, running apparel, and professional sports equipment, achieving exceptionally positive market feedback.

A well-known textile company has adopted fluorine-free waterproofing agents from Jiangxi Xinjia Yi New Materials, which have passed OEKO-TEX ecological certification, and are now mass-produced for the North American and European markets, achieving an excellent balance of waterproofing, lightweight, and skin-friendly properties.

(2) Green Certification

Silicone fluorine-free waterproofing agents have obtained multiple international authoritative certifications, including REACH (EU Chemical Registration), OEKO-TEX Standard 100, and assessments of human health and environmental impact, gaining recognition and favor from major global brands.

8. How to choose Silicone waterproof agents?

Methylphenyl silicone resin is increasingly applied in key industries such as electronics, construction, automotive, and new energy, driving steady growth in market demand. The accelerated industrialization of emerging economies and growing demand for environmentally friendly and sustainable materials present new growth opportunities for the methylphenyl silicone resin market. Products like inner foil seal and foil seal for packaging, or silicone waterproof and sealant for textiles and construction, underline the importance of adaptability, flexibility, and adhesion. How to Enhance Product Competitiveness? Choosing a high-quality silicone rubber adhesive ensures the product will not shrink or lose adhesion after it is dry, and provides outstanding performance even under pressure in demanding settings such as a wall-to-bathtub joint.

XJY Silicones is one of China's leading manufacturers of organic silicon MQ resins and VMQ organic silicones, with over 30 years of R&D and manufacturing experience in the organic silicon industry, as well as over 15 related patents and technical support. Our silicone raw material products can meet the needs of various industries and support the provision of diversified customized solutions.

![]()