Defoamers are food additives that have low surface tension during food processing and inhibit the generation of foam or control foam that has already been generated. Defoamers are used in a wide range of industrial applications, such as the pulp and paper industry, petroleum industry, wastewater treatment, metalworking fluids, printing and dyeing industry, paint industry, detergent industry, rubber latex industry, daily chemical industry, food industry, and paints coatings industry.

The food industry often requires mixing, fermentation, cooking, and other operations, these processes are prone to generate a large number of air bubbles. Why use silicone defoamer in the food industry?

Silicone defoamer has good heat resistance and low-temperature resistance, the viscosity of silicone oil is 200 ℃ above the gradual increase, but the silicone-oxygen bond will not decompose; silicone is non-toxic, non-polluting, physiologically inert, environmentally friendly substances; silicone has excellent weathering, durability and aging resistance, and can be used in any environmental conditions to play its role; silicone defoamer can effectively control foam to improve the taste and quality of food.

Here’s some information about it:

- Why is defoaming necessary in the food industry?

- How to classify food defoamer?

- What is the role of food defoamer?

- What is silicone defoamer?

- What are the features of silicone defoamers?

- How to apply silicone defoamer in food applications?

- How to pay attention when using silicone defoamer?

- How to make silicone defoamer performance better?

1. Why is defoaming necessary in the food industry?

Food foaming is due to mixing and ventilation has a relationship, another reason is that the food contains a large number of protein raw materials such as, peptone, corn syrup, soybean meal, yeast powder these are very easy to produce foam.

The harm of food foam:

(1) Foam will affect the taste of food.

(2) Too much foam will easily overflow, resulting in a waste of materials and an increase in the chance of bacteria.

(3) In serious cases, the respiration of bacteria will be hindered, leading to the destruction of bacteria.

(4) Excessive foam will lead to a reduction in the amount of material to be canned.

In the production of food, there are indeed many problems, such as juice processing producing a lot of foam, then the filling of the same problem. If the filling of a time, it is certainly not enough to fill, if the number of times, one is to increase the operation of the machine, increasing production costs; Secondly, the foam overflow to the mouth and body of the bottle, may cause mold contamination, thus affecting the quality of the product.

Another example, one step in the process of making tofu is to boil soy milk. Soymilk has a lot of protein and some saponins. They all have surface activity and can form a lot of foam when heated and stirred. Soymilk contains a considerable amount of protease inhibitors. If it is not inactivated, it will inhibit protease activity and affect the body's digestion and absorption of protein. Saponins have a bitter flavor, and higher levels can lead to nausea and vomiting. The temperature at which a large amount of foam is formed is only about 70 or 80 degrees, which is not hot enough to deactivate protease inhibitors and saponins. If not defoamed, the large amount of foam generated will make it difficult for the temperature to continue to rise.

To summarize, it can be said that the foam produced in the production not only affects the smooth running of industrial production but also affects the quality of the product, in addition to reducing the use of the equipment area and increasing the consumption of processing time.

We want to eliminate the foam method of mechanical defoaming and chemical defoaming two kinds, mechanical defoaming is to break the foam with the help of mechanical force, or with the help of pressure to make the foam rupture, the method does not need to add other substances, saving raw materials, reducing the chance of pollution of the chemical reagents, but the method requires a certain amount of equipment and power, and can not be eliminated to the root cause of the foam factors. Chemical defoaming is to add defoamer, the method and mechanical defoaming compared to save time and effort, small investment, quick results.

2. How to classify food defoamer?

Antifoams are substances used to reduce surface tension and eliminate foam during food processing. Foam is a non-homogeneous dispersion system in which insoluble gases enter the liquid under the action of external forces, and a large number of bubbles are formed, which are separated from each other by the liquid. Foam is a thermodynamically unstable system that has a tendency to shrink its surface area and burst on its own. Natural defoaming takes a long time, so the need to use a defoamer to achieve rapid defoaming to meet the requirements of food processing and production.

There are many kinds of defoamers, and their compositions are very different.

(1) Alum:

Alum is a kind of antifoam agent, it is mainly through the combination with the free acid in the protein that forms water-insoluble precipitation so that the bubble disappears. It is commonly used in candies, jellies, beverages, and other foods.

(2) Yeast Extract:

Yeast extract is a natural ingredient extracted from yeast, which is commonly used in foodstuffs such as beer, beverages, and milk. It is mainly used to control foam by releasing carbon dioxide from gaseous yeast.

(3) Gelatin:

Gelatin is also a kind of antifoam agent, it is mainly by combining with the free acid in the protein to form an insoluble precipitate, so as to achieve the effect of antifoam. It is commonly used in candy, jelly, drinks, and other foods.

(4) Silicone:

Silicone-based oil is a colorless, odorless, dilute oily liquid that can be used safely within the range of food dosage. It is mainly through the low surface tension that the effect of defoaming is commonly used in cakes, bread, cream, and other foods.

3. What is the role of food defoamer?

Food defoamer is a special kind of defoamer, mainly used in the food and beverage manufacturing industry, for eliminating and controlling air bubbles generated in the process of food industry and preservation. Its role and uses mainly include the following aspects:

(1) Improve the taste: In the production of some foods or beverages with soft texture, the bulging air bubbles will make the texture rough, and the defoamer can reduce the number and size of the air bubbles, thus improving the texture and making it softer.

(2) Improve the quality: In the production of some advanced, high-quality foods and beverages, it is necessary to ensure that there are no air bubbles and voids inside the finished product, defoamer can reduce the size and number of air bubbles, thus reducing the air bubbles and voids and improving the quality and performance of the product.

(3) Improve production efficiency: In some food processing with high process requirements, such as dairy products, beverages, etc., a defoamer can prevent the generation and disturbance of air bubbles, making the production process more stable and efficient.

(4) Extend the shelf life: In some perishable foods and beverages, such as fruit juice, beer, etc., the prolonged presence of air bubbles and air will promote the propagation of microorganisms and oxidation, so that the quality of the food decreases, defoamer can reduce the air bubbles and voids, and slow down the corruption and deterioration of food.

In short, food defoamer can improve food production efficiency, improve the taste of food, improve food quality, extend the shelf life of food, and other roles and uses.

4. What is silicone defoamer?

Antifoam agent is mainly composed of active ingredient, emulsifier, carrier and emulsifying additives, of which the active ingredient is the most important core part, playing the role of breaking the bubble and lowering the surface tension; emulsifier is the active ingredient dispersed into small particles, in order to better dispersed in the oil or water, better defoaming effect. The carrier in the defoamer accounted for a large proportion of the surface tension is not high, mainly play a role in supporting the medium, is conducive to the effect of defoaming and defoaming, can reduce the cost; emulsifying additives are to make the emulsification effect better.

Silicone defoamers are mostly liquid compound products. An antifoam agent is an additive whose function is to control foam formed by the material in the production process. Silicone antifoam agent has chemical properties, such as inert, stable physical properties, and no biological activity.

4.1 What kinds of silicone defoamers?

(1) Food-specific polysiloxane resin

Silicone antifoam agents generally include polydimethylsiloxane and so on. Silicone defoamers have poor solubility, fast defoaming speed, and good foam suppression at room temperature.

Dimethicone is the main body, containing less than 15% SiO2, and the product is the aqueous systems, with its emulsified products, others can be used directly with oil-based products, the dosage control 0.05g/Kg or less, such as defoaming occasions including fermentation and sugar, silicone - glycol copolymer suitable for fermentation process foam suppression.

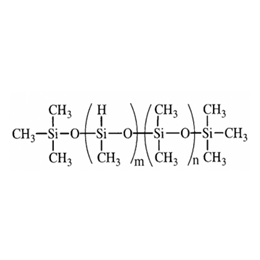

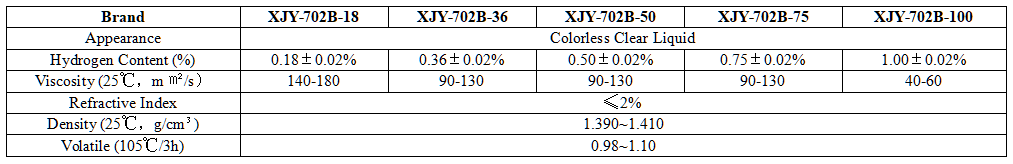

XJY-702 Methylhydrosiloxane / Dimethylsiloxane Copolymer is non-toxic and tasteless, with active genes, under the action of the catalyst, can be reacted with the double bond, hydroxyl, and other groups, it is a leveling agent, antifoam agent, water-soluble silicone oil and other products such as the basic raw materials.

(2) Silica

That is the body-type defoamer, commonly known as "silicone grease" or "silicone paste" in our practical application, usually composed of Polydimethylsiloxane and silica two main constituents through certain processing technologies. The defoamer with Polydimethylsiloxane as the substrate is an ideal class of defoamer in the antifoaming system. This kind of antifoam agent is an important part of the current emulsion-type antifoam agent.

(3) MQ silicone resin

MQ silicone resin is a kind of silicone material born by changing the structure of silicone resin, which can effectively improve high-temperature resistance, defoaming, and foam inhibition.

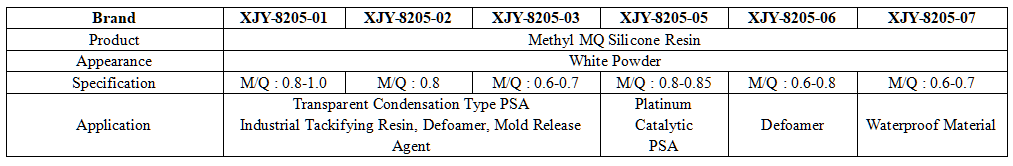

XJY-8205 Methyl MQ Resin is a solid powdered resin that provides excellent transfer resistance, good defoaming, and foam inhibition properties and can be used as an aqueous systems antifoam agent.

As a silicone defoamer, it also has a wide range of applications and is increasingly emphasized by various industries. In the chemical industry, paper, coatings, food, textiles, pharmaceuticals, and other industrial sectors, silicone antifoam agent is an indispensable auxiliary in the production process, it is not only able to remove the foam on the liquid surface of the production process media, thereby improving filtration, washing, extraction, distillation, evaporation, dehydration, drying and other processes of separation, gasification, liquid discharge, and other effects, to ensure that all types of materials containers, the handling of the capacity of the container.

4.2 What is the principle of defoamers?

(1) Foam is a dispersion system in which gas is dispersed in liquid; the gas is the dispersed phase, and the liquid is the dispersing medium, and a stable state is formed due to the fact that the gas is insoluble in surfactant. After the formation of bubbles, due to the intermolecular action of the foaming system, the hydrophilic and hydrophobic groups are adsorbed by the bubble wall, forming a regular arrangement, with its hydrophilic group toward the water phase and hydrophobic group toward the bubble, thus forming an elastic film on the interface of the bubbles, which is very stable and not easy to rupture under normal conditions. At the same time, the foam is a thermodynamically unstable system, under the action of gravity constantly undergoing the downflow of the liquid film, evaporation, rupture, as well as the foam liquid film between the discharge, infiltration process.

The reason for defoaming is mainly divided into two aspects: easy to spread, adsorption of defoamer molecules to replace the foaming agent molecules, the formation of a poor strength of the film; in the process of spreading defoamer molecules to take away the neighboring surface layer of part of the solution, so that the foam liquid film becomes thin, foam stability is reduced, easy to be destroyed.

(2) Foam exists inside the liquid because the gas surface adsorption of surface-active substances, resulting in a reduction of surface energy and the formation of energy-stabilized system and caused; silicone antifoam agent is the principle of changing the distribution of surface-active substances on the surface of part of the bubble state, thereby changing the surface tension caused by the change of the internal pressure of these bubbles and merged into the other bubbles, the formation of a larger volume of bubbles, but also cause new imbalance and new merger. This merger of large bubbles is finally pushed out of the liquid by buoyancy, which is a defoaming process; the presence of bubbles on the surface of the liquid under the action of gravity, the bubble film will gradually become thinner and finally rupture, silicone antifoam agent is to accelerate the thinning and rupture of the process.

5. What are the features of silicone defoamers?

Silicone defoamer (for food) is a common food additive, also known as food-grade silicone oil. It is mainly made of Polydimethylsiloxane and has the following properties:

(1) Foam inhibition and elimination: Silicone defoamers are effective in controlling foam and eliminating foam formation in both aqueous systems and oily systems, helping to reduce foam generation during food manufacturing and processing.

(2) High-temperature resistance: Silicone defoamer can be extremely stable under high-temperature conditions and is not affected by heat.

(3) Good dispersion: Silicone defoamer can be uniformly dispersed in the food without precipitation or stratification.

6. How to use silicone defoamer in food applications?

(1) Food processing: In baking, brewing, jam-making, and other food processing techniques, silicone defoamers can effectively defoam, prevent foam overflow, and improve production efficiency. It is generally used in the processing of water-soluble food with stable performance and a good defoaming effect.

(2) Sugar industry: The honey after the fermentation needs to add calcium carbonate for neutralization, the neutralization process will produce foam, which needs defoamer to defoam.

Different from the manufacture of MSG, the sugar manufacturing process adopts the concentration and crystallization method, defoamer is a commonly used industrial auxiliary in the sugar manufacturing process, and the defoamers used are: polyglycerol fatty acid esters (such as N-type), sucrose fatty acid esters, polyethers (such as PPE), and organosilicone (such as F-type), and so on. Because organosilicon defoamer has good effect of defoaming and foam inhibition in the process of sugar cooking, the surface tension of syrup can be reduced by a large margin, and it can also accelerate the settling speed of sugar crystals and improve the filtration performance of syrup, so the organosilicon defoamer is the most widely used antifoamer in the sugar industry at present.

Antifoam agents used in the production of cane sugar are vegetable oils, swine oils, sucrose fatty acid esters, polyglycerol fatty acid esters (N-type antifoam agent), silicone compounds, etc. The proteins, colloids, and other substances in the sugar solution are not suitable for the production of sugar but can be used in the production of sugar. Proteins, colloids and lipids and other surface-active substances in the sugar solution are easy to mix with air and produce foam in the conveying process, resulting in bubbling boxes, bubbling tanks, running sugar, etc., which affects the yield and quality of sugar, adding silicone antifoam agent is the simplest and most direct way to solve this problem.

In the sugar production process due to mixing, flow, transportation and other operations, so that the sugar solution mixed with air, resulting in a large number of bubbles, resulting in the loss of sugar loss, loss of raw materials, operational difficulties, while increasing energy consumption, affecting the economic benefits of the plant. Generally there are two methods to eliminate foam: one is the mechanical defoaming method, and the other is chemical defoamer. Silicone defoamer has the advantages of improving production efficiency, increasing economic benefits, accelerating the rate of evaporation and crystallization, and reducing the viscosity of the syrup, etc. In sugar production, organosilicon chemical defoamer is a commonly used method of eliminating foam.

(3) Fermentation industry: Grape juice and so on will produce gas and foam in the fermentation process, which will affect normal fermentation. A defoamer can effectively defoam to ensure the quality of wine production.

During the fermentation process, many foams are generated because of stirring and fermentation, and the foams bring a lot of unfavorable influences and factors to the processing of wine, such as causing “liquid escape”, charging reduction and so on, and these unfavorable factors further affect the yield and quality of wine products, and the defoamer is the simplest and most economical way to inhibit the foams.

With vegetable oil, lauric acid, dehydrated sorbitan monostearic acid, cinnamic acid, oleic acid and other fermentation antifoam agent to do large consumption, anti-foaming effect is not ideal; to polydimethylsiloxane as the main body of the silicone antifoam agent used in food fermentation with good results, the fermentation capacity increased, the yield increased; in the silicone antifoam agent, the role of the top cover of the fermentation tank can be in the working period has been closed, thereby reducing the oxidation of brewing liquid, increasing wine cleanliness. The top cover of the fermenter can be kept closed during the working period under the effect of silicone defoamer, thus reducing the oxidization of the brewing liquid and increasing the cleanliness of the wine; due to the reduction of oxidization, the physical and chemical stability of the wine is very good under the condition of denaturation of part of the proteins, and the wine is no longer turbid; the organosilicon defoamer makes the adherence degree of the yeast powder on the wall of the tank low, and at the same time reduces the work of cleaning afterward.

The determination of the original concentration of beer is not affected by the defoamer, which can effectively reduce the testing time, improve the success rate of the experiment, and reduce the labor intensity of the inspectors.

(4) MSG production

The fermentation process of MSG belongs to aerobic fermentation, which produces a large number of bubbles in the process, and the production of bubbles will reduce the yield, inhibit the respiration of the bacteria, and reduce the acid production rate of the bacteria. An antifoam agent is the most economical and simple way to inhibit foam. Antifoam agents used in the production of MSG usually have vegetable oil defoamer, polyether defoamer, silicone defoamer, but vegetable oil defoamer storage is not good, easy to deteriorate, acid value increases, and the application of less, the current polyether defoamer, silicone defoamer in the MSG fermentation industry is more widely used.

Silicone defoamer used in an MSG fermentation tank, the results show that this silicone composite defoamer is better than the current use of vegetable oil defoamer, no effect on the bacterial species, the dosage is less, the defoaming speed is fast, defoaming ability is strong.

As silicon refers to a class of special materials with Si -O -Si backbone organic groups, is the simplest polymer, namely polydimethylsiloxane (silicone rubber), these properties ensure that the silicone will carry a group migrated to the gas-liquid phase interface within the bubble, silicone and silicone copolymer is a high polymerization of materials, polydimethylsiloxane, they can be combined to produce a variety of have a control of the role of foam control agent with the function of antifoam.

(5) Dairy industry: Adding silicone antifoam agents can avoid the production of foam in dairy products, such as milk, cream, ice cream, and so on.

(6) Beverage industry: Silicone defoamer can prevent carbonated drinks, fruit juice,s and other aerated drinks from producing excessive foam.

(7) Other food: Silicone defoamer is also commonly used in chocolate production, edible oils, and fats processing.

7. How to pay attention when using silicone defoamer?

Defoamer is divided into industrial grade defoamer and food grade defoamer. added to the food of silicone defoamer is not harmful to the human body of food grade defoamer, so you can rest assured of its consumption. However, as a food additive, it is necessary to control the maximum dosage, and adding too much can be harmful to the human body.

The silicone defoamer production process needs to comply with the relevant production norms and standards to ensure product quality and safety. In terms of safety information, silicone defoamers are considered to be safe under reasonable conditions of use. However, the following precautions should still be taken when using them:

(1) Reasonable dosage: It should be used following the regulations for the use of food additives and should not exceed the maximum permitted dosage.

(2) Storage and transportation: The Silicone defoamer should be stored in a dry, ventilated place, avoiding contact with oxidizing agents and strong acids and alkalis.

(3) Avoid misuse: Silicone defoamer belongs to food additives and should not be consumed directly.

(4) Pay attention to allergies: People who have allergic reactions to silicone should avoid contact and eating food containing silicone defoamer.

In general, the application of silicone defoamer in the food industry is safe and reliable, but the use of reasonable use in accordance with regulatory requirements.

8. How can silicone defoamer perform better?

The active silicone defoamer is similar to the non-polar group, and it does not associate with water or substances containing hydrocarbon or polar groups and is extremely stable; silicone defoamer has a higher defoaming effect than other organic defoamers; silicone defoamer is inert to the general substance, will not be chemically reacted with the foaming material. Silicone defoamers can be used in many industrial applications, such as the petroleum industry, pulp and paper industry, and metalworking fluids. How to improve the competitiveness of your products?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry, as well as more than 15 related patents and technical support. Our raw silicone products can meet the needs of silicone defoamers and support the provision of diversified, customized solutions.