With the progress and development of modern science and technology, as one of the most commonly used polymer raw materials, liquid silicone is increasingly used in the healthcare and medical industry due to its biocompatibility and other excellent properties. So why choose liquid silicone rubber for medical?

Relative to liquid silicones, solid silicone has no fluidity and is a transparent material, its molding needs to add the vulcanizing agent to accelerate the vulcanization molding time, and open mold casting molding. Solid silicone is generally used in household goods, industrial miscellaneous parts, automobile parts, and so on.

Liquid silicon rubber(LSR) has good biocompatibility, no irritation to human tissues, very few reactions to the body, good physical and chemical properties, and can maintain its original elasticity and softness when contact with body fluids and tissues, which will not be degraded and also is a stable inert material. Liquid silicone rubber(LSR) is generally used in baby products, kitchen supplies, and medical supplies. As a versatile material, liquid silicone rubber(LSR) material can be in direct contact with the human body and used in medical and food-grade products.

Here's some information about it:

- What is liquid silicone rubber?

- What are the properties of liquid silicone rubber?

- What are the advantages of liquid silicone rubber for medical?

- How to apply liquid silicone rubber in the medical field?

- How to make medical liquid silicone rubber products?

1. What is liquid silicone rubber?

Liquid silicone rubber (LSR) is a non-toxic, heat-resistant, highly resilient flexible thermoset material. Relative to solid high-temperature vulcanized silicone rubber, it is a liquid versatile elastomer and has good fluidity, fast vulcanization, low viscosity, and a fast curing process, which is safer and more environmentally friendly. It can be produced by injection molding in a large number of rapid and repetitive mechanical production.

Compared with traditional materials, the liquid injection molding process has the advantages of a short liquid silicone rubber molding cycle, high degree of automatic molding, low vulcanization temperature, no by-products in the vulcanization process, high product precision, long service life, etc.

Liquid silicone rubber(LSR) also has excellent properties, such as degree of resistance to tearing, resilience, resistance to yellowing, thermal stability, and heat-resistant and anti-aging properties. Liquid silicone rubber is mainly used in baby products, medical products, and electronic products (keypads).

![]()

XJY-8206 Methyl Vinyl MQ Silicone Resin is mainly used in high transparent and high hardness silicone rubber and can be used as an additional filler for LSR two-component liquid silicone rubber that can be injection molded.

![]()

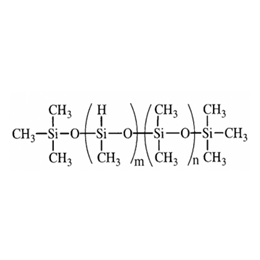

XJY-702 Methylhydrosiloxane, Dimethylsiloxane Copolymer is non-toxic and odorless, containing active Si-H groups. It can react with double bonds and hydroxyl groups under the action of a catalyst and can be used as a cross-linking agent of additive liquid silicone rubber.

![]()

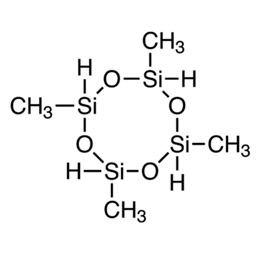

XJY-705 Tetramethylcyclotetrasiloxane TMCTS is a kind of reactive siloxane with Si-H bonds, which can react with unsaturated olefin, and can be used as a special cross-linking agent for additional molding of liquid silicone rubber.

![]()

2. What are the properties of liquid silicone rubber?

(1) Good solidification: Liquid silicone can be cured quickly at high temperatures, thus ensuring production efficiency.

(2) Good stability: The molecular structure of liquid silicone rubber is stable, it is not easy to produce chemical reactions with external substances and has very good chemical inertia.

(3) Biocompatibility: The application of liquid silicone rubber parts in medical products can be divided into in-vitro application and in-vivo implantation, its biocompatibility advantage is obvious and will not produce other adverse reactions.

(4) High precision: The shrinkage rate of liquid silicone rubber is less than one-thousandth of a percent, and no low molecules are released during the cross-linking process, so the replicated products have high precision and can meet the precision requirements of medical products.

(5) Excellent chemical resistance and high-temperature resistance: Liquid silicone rubber has good corrosion resistance to acids, alkalis, solvents, and other chemicals, and can be used stably for a long time in harsh environments; It also can maintain its elasticity and stability at extremely high temperatures, and can usually withstand temperatures as high as 200°C or more.

(6) High tensile and high tear resistance: Different from traditional thermoplastic injection molding, liquid silicone rubber molding can turn over the mold more often and is not easy to deform.

3. What are the advantages of liquid silicone rubber for medical?

Liquid silicon rubber has the properties of being non-toxic, soft, transparent, temperature-resistant, light-resistant, chemical-resistant, insulation, etc. After extensive testing, liquid silicone rubber has been proven to have excellent compatibility with human tissues and body fluids. Compared to other elastomers, liquid silicone materials are resistant to bacterial growth and will not stain or corrode other materials.

Liquid silicone is also colorless and odorless, which can be formulated to meet the stringent requirements of the FDA. The material can be sterilized by a variety of methods, including steam autoclaving and ethylene oxide sterilization, to achieve sterility for medical products.

Liquid silicone rubber has the ability to be easily fabricated into complex shapes, and its waste-free liquid injection molding processing mode makes it easy for companies to process and suitable for high-volume molding production. Its practicality and excellent characteristics make LSR materials ideal for use in medical devices from the outset. Medical-grade silicone products have high technical content, high added value, efficient liquid silicone rubber molding process, and considerable economic benefits.

4. How to apply liquid silicone rubber in the medical field?

Liquid silicone rubber has many properties such as durability, low viscosity, chemical and temperature resistance, and flexibility. Medical grades of liquid silicone are temperature resistant, easy to sterilize, and compatible with a wide range of medical devices and accessories such as implantable devices, fluid-fed bottles, dialysis filters, vibration-resistant sealed housings, drug delivery devices, and oxygen mask instruments. In addition, wearable medical devices are becoming increasingly sought after, leading to increased demand for liquid silicone.

Liquid silicone is particularly suitable for the medical market as it offers shorter cure times, lower curing temperatures, and higher consistency to medical device manufacturers. Since it is well suited for automation, it can limit contamination in cleanroom manufacturing operations. Compared to high-consistency rubberized silicone, liquid silicone also offers improved purity and biocompatibility

The range of products and applications for liquid silicone is expanding, especially in the medical use end market.

4.1 Medical Liquid Accessories

Medical liquid silicone accessories materials can be used as ordinary rubber processing methods, such as extrusion, and injection molding. But it's key to choose the material delivery between liquid injection molding and thermoplastic injection molding. In medicine, silicone products for contact with the human body have very high requirements, it has high technical content, low cost, and high value-added to use liquid silicone rubber parts as medical materials.

Liquid silicone medical accessories also have many unique properties, such as good physiological inertia, resistance to body fluids corrosive speed, aging resistance in harsh environmental conditions, and the human body does not cause urinary tract infection.

Medical Silicone Equipment Accessories Silicone Ventilator Mask

![]()

![]()

![]()

![]()

Medical Silicone Lenses Medical Silicone Connecting Tubes

4.2 Medical silicone products

Liquid silicone products have many excellent properties, cold and high-temperature resistance, weak acid and alkali resistance, and harmless, non-toxic, tasteless, excellent resilience, non-deformation, and other characteristics. They can be used at -50 ℃ to 250 ℃, can satisfy special requirements, have excellent insulating properties, and can be used to disinfect the ethylene oxide directly in high-temperature conditions.

![]()

Silicone Drainage Tube

(Silicone drainage tube is widely used as a treatment for hemothorax, pneumothorax, pyothorax, and other diseases. The silicone drainage catheter is inserted into the chest cavity at one end of the drainage tube, and the other end is connected to a water-sealed bottle which is lower than its position. Fluid and gas are discharged from the chest cavity so that the lung tissues can expand again and restore their function.)

![]()

![]()

Silicone Balloon Silicone Gastric Tube

5. How to make medical liquid silicone rubber products?

Liquid silicone rubber is particularly well suited to the medical market because it offers medical device manufacturers shorter cure times, lower curing temperatures more durable elastomer, and greater consistency. It is well suited for automation, it can limit contamination in cleanroom manufacturing operations. Compared to high-consistency rubberized, silicone liquid rubber also improves purity and biocompatibility. How to make your product stand out in the market?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry and more than 15 related patents and technical support. Our silicone MQ resin raw material products can meet the demand for liquid silicone rubber products for medical and support the provision of diversified customized solutions according to your lsr molding process.