In textile printing and dyeing production, many sections will produce foam. Foam production is not conducive to the accurate measurement of materials, which will cause waste of raw materials and products, prolong the production cycle, and affect the quality of the product, so that the production capacity of the enterprise has been greatly restricted, and more serious, it can cause environmental pollution and safety accidents triggered by the production.

In order to control foam, textile printing and dyeing enterprises focus on chemical additives, thus defoamer is introduced into the printing and dyeing industry and widely used in the textile printing and dyeing industry, weaving, dyeing, sewing, and other processes. So why use silicone defoamer in the textile industry?

Silicone defoamers have advantages that other types of defoamers do not have in foam control, such as excellent defoaming and foam inhibition, low addition, cost-effectiveness, long-lasting, low reactivity, good system compatibility, a wide range of temperatures, and PH use. In addition, silicone defoamer also has other characteristics of silicone polymers, such as excellent heat resistance, significant hydrophobicity, good abrasion resistance, and non-sticky performance, modified by organic groups of silicone and has excellent hydrophilicity and antistatic properties. At the same time, it is soft, smooth, and has good resilience.

Here's some information about it:

- What is silicone defoamer?

- What are the performances of silicone defoamer?

- What are the test methods for silicone defoamer?

- What are the types of textile defoamers?

- What is the role of textile silicone defoamer?

- What are the advantages of textile silicone defoamers?

- How to apply textile silicone defoamer?

- How to make textile silicone defoamer?

1. What is silicone defoamer?

Antifoaming agents are a kind of additive agent, whose function is to eliminate the foam formed by the material in the production process, to control foam, antifoam agent has various categories, such as mineral oil antifoam agent, polyether antifoam agent, high carbon alcohol antifoam agent, silicone antifoam agent. Because mineral oil antifoam agents' defoaming ability is poor, polyether antifoam agents' inhibition ability is good but defoaming is poor, high carbon alcohol antifoam agents' defoaming ability is good but inhibition is poor, the current application in many industrial processes is the most silicone antifoam agent.

The main component of silicone antifoam is called silicone oil, silicone oil at room temperature is a non-volatile oily liquid, which is insoluble in water, animal and vegetable oils, and mineral oils, or solubility is very small, it can withstand both high and low temperatures. It's chemical properties are inert and physical properties are stable, which has no biological activity.

Silicone antifoam agent is made of silicone oil as the basic component, with a suitable solvent, emulsifier, or inorganic filler formulated through a special process. It is suitable for textile slurry, high-temperature dyeing; industrial water treatment; metalworking fluids; pulp and paper; food processing; mud defoaming in petroleum mining; water-based aqueous systems coatings, and other various industrial applications that require a long time of foam inhibition and fast defoaming, which are effective in many demanding industrial applications.

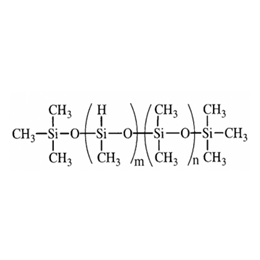

XJY-702 Methylhydrosiloxane, Dimethylsiloxane Copolymer is non-toxic and odorless, containing active Si-H groups. It can react with a double bond and hydroxyl groups under the action of a catalyst and is used as the basic raw material of foam stabilizers, antifoam agents, water-soluble silicone oil, and other products.

![]()

2. What are the performances of silicone defoamer?

Silicone antifoam has three functions: foam breaking, defoaming, and foam inhibition.

The advantages of silicone defoamers lie in their excellent defoaming performance and stability. They can eliminate various types of foam in the production process, including foam generated by high-speed mixing, foam generated in the stationary state, and foam generated by the interaction between liquid droplets. At the same time, they are also able to maintain stability in a variety of different media, such as water, organic solvents, and acids and alkalis.

3. what are the test methods for silicone defoamer?

(1) The compatibility of the silicone antifoam

Adding the silicone defoamer to the defoaming system, stirring, and observing the compatibility rate of the silicone defoamer in the liquid. If the defoamer has good compatibility, it will not affect the product.

(2) Silicone antifoam performance.

Adding the silicone defoamer to the defoaming system and observing the speed of foam elimination in the liquid. If the foam is eliminated quickly, the quality of the silicone defoamer can be judged.

(3) The foam inhibition time of the silicone antifoam

Adding silicone antifoam agent in the defoaming system, and observing the foam inhibition time and re-foaming time during the normal operation of the product, you can judge whether the antifoam agent has the role of foam inhibition or foam inhibition. Lasting judgment of the quality of the silicone defoamer.

(4) Whether the silicone antifoam will affect the product.

After adding the silicone defoamer to the defoaming system, observe whether the original product will be affected by the defoamer, such as quality, appearance, and operating procedures. A defoamer not affected is a good-quality silicone defoamer.

![]()

4. What are the types of textile defoamers?

Due to the large number of industrial textile additives, there will be a large number of foam generated during processing, making production operations inconvenient, reducing production capacity, product quality decline, and affecting the normal operation of the industry. Therefore, the textile industry needs to eliminate these foams in a timely manner. It is the more effective and economical method to use textile printing and dyeing defoamer to eliminate harmful foam in the textile industry.

4.1 Mineral oil defoamer

In the oiling process of acrylic production, in order to facilitate the operation, usually adding the oil agent, and the oil agent will produce a large number of foam in the process of production and transportation, resulting in the waste of resources and pollution of the surrounding environment, a large number of foam will be surrounded by the head of the fiber crimping, resulting in the heat of the crimping motor can not be emitted in a timely manner, resulting in damage to the motor.

However, mineral oil is a kind of petroleum product, that will produce a certain amount of environmental pollution in its production and use of the process, especially water pollution. At the same time, mineral oil is a non-renewable resource, and its use will also increase energy consumption and environmental pressure. Although mineral oil defoamer can effectively eliminate foam, in some special circumstances, the defoaming effect may not be as good as other defoamers. For example, in high temperatures, high salinity, acidity, and alkalinity extreme environments, the defoaming effect of mineral oil defoamer may be affected.

4.2 High-temperature defoamer

When polyester fabrics are spray dyed at high temperatures, in order to achieve even dyeing, the fabrics have to run at high speed in the machine. If the foam exists, it is very easy to cause uneven dyeing and dyeing spots and other phenomena, adding high temperature resistant and shear-resistant defoamer to the dyeing solution, so that the foam is eliminated quickly in a short time. However, its defoaming ability is poor with low bubble breaking and the use of temperature restrictions.

4.3 Silicone defoamers

Textile slurry foam will bring great difficulties to the sizing operation, sizing quality is also affected. Therefore, it is necessary to add a small amount of antifoam agent to control foam. And because the cause of sizing foam has physical foam and chemical foam. So the nature of the foam is more complex, we generally use silicone emulsion-type defoamer for defoaming, its applicability is strong, can take a long time to continue to inhibit foam, reduces our costs. It can also meet the requirements of printing paste, and printing paste has a good match, defoaming at the same time does not affect the smoothness of the printing paste and the surface of the smooth and flat, to avoid the production of "fish-eye", "shrinkage" and other issues.

XJY-8205 Methyl MQ Silicone Resin is solid powder resin with excellent defoaming and foam inhibition properties, which can be added to the solvent to make silicone defoamer. The silicone defoamers full line also have the advantages of non-toxicity and environmental protection.

![]()

5. What is the role of textile silicone defoamer?

The textile printing and dyeing industry is a production process involving many links, including slurry preparation, printing, dyeing, finishing and other links, in the processing course, contacts a variety of dyes and additives. These additives especially wetting agents, washing agents, penetrating agents, antistatic agents, leveling agents, and other surfactants with the property of reducing the surface tension of the slurry play a very big improvement in the slurry on the surface of the fabric spread and the slurry on the warp penetration.

However the low surface tension of the slurry in the mechanical vibration makes it easy to foam, foam will make the liquid and fabric contact surface reduction, processing uneven phenomenon occurs, and the tension affects the manufacturing and product quality. In the fabric dyeing and finishing processes, foaming is a difficulty in the refining, bleaching, dyeing, and rectification process. Because of foaming, fiber or fabric is difficult to fully penetrate, so the disposal results reduce the disposal time extension, but also cause stains and other quality problems. Therefore, silicone defoamer is widely used in textile printing and dyeing industry.

![]()

6. What are the advantages of textile silicone defoamers?

Textile silicone defoamer has three major advantages.

(1) Low surface tension

The surface tension of silicone oil is lower than the surface tension of the dyeing solution, Dimethicone with medium viscosity has a surface tension of 20-21mN/m², while the water tension is 76mN/m², so the silicone antifoam agent surface tension is low and thus the defoaming ability is relatively strong, so it is widely used.

(2) Stable performance

Silicone defoamers have stable defoaming performance, and they can withstand high temperatures of 150 ℃, under this temperature, they can still be stable defoaming and foam suppression, and it is chemically inert, which will not affect the nature of the aqueous solution of dyestuffs, it will not react with the dyestuffs, pastes, and other auxiliaries, and it will not affect the quality of the products.

(3) Good defoaming effect and low addition amount

Silicone defoamers have a fast defoaming speed, and a good ability to inhibit foam regeneration, one-thousandth of the additive amount can achieve a good defoaming effect, and the low dosage is conducive to textile manufacturers to control production costs.

7. How to apply textile silicone defoamer?

Silicone defoamers in textile printing and dyeing has a wide range of industrial applications:

(1) In the paste preparation process, the use of silicone defoamer can reduce foam generation and improve the permeability and color fixation rate of the paste;

(2) In the printing process, the use of silicone defoamers can reduce the foam generated in the printing process, improve the quality of printed products;

(3) In the dyeing process, the use of silicone defoamer can reduce the dyeing process of foam generation, and improve production efficiency.

Silicone-based defoamers can reduce the surface tension of the textile liquid, preventing the formation of air bubbles, and thereby improving the quality of spinning and weaving. In addition, it can also improve the dye dispersion and sizing effect, and improve the softness and gloss of the yarn. In short, the silicone antifoam agent is widely used in the textile printing and dyeing industry to improve production efficiency and product quality and reduce production costs.

![]()

8. How to make textile silicone defoamer?

Silicone defoamer is widely recognized by the industry because of its low cost, low dosage, wide range of applications, chemical inertness, non-polluting, and other advantages. It not only has a strong defoaming effect, low surface tension, low volatility, non-toxic, non-polluting, physiologically inert, and other characteristics but also has high-temperature resistance, strong alkaline resistance, and other properties. It can quickly dissolve in water, can be used alone, and can also be used in conjunction with other treatment agents; It has good stability, no emulsion breaking and oil drifting phenomenon, and no precipitate generation. How to make your products more competitive in the market?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry and more than 15 related patents and technical support. Our silicone raw material products can meet the demand for silicone defoamers and support to provide diversified customized solutions.