The high-voltage power cable transmission system is the main form of future mega-city power transmission to urban centers but also is the major way of the current hydroelectric power plant power transmission. So why use silicone rubber in high-voltage cables?

Early high-voltage cable insulation body material mainly used EPDM rubber, the rubber material insulation, and aging resistance are excellent, however, the hardness makes it difficult to install the attachment.

Silicone rubbers have excellent electrical insulation, heat resistance, cold resistance, and water repellency; It has a wide range of extreme temperatures, which can be used long-term at -60 ℃ (or lower temperature) to +250 ℃ (or higher temperature).

It has excellent physiological inertness and thus can be molded, calendered, liquid injection molding, and extruded with low energy consumption, which can meet the requirements of customers for the installation and maintenance convenience and operation safety of high-voltage cable accessories and is also increasingly used in high-voltage cable accessories.

Here's some information to talk about:

- What is silicone rubber?

- How to classify silicone rubber?

- What are the performances of silicone rubber?

- How to apply silicone rubber in high-voltage AC cables?

- How to make high-voltage cables with silicone rubber?

1. What is silicone rubber?

Silicone rubbers are rubbers whose main chain consists of alternating silicon and oxygen atoms, with two organic groups usually attached to the silicon atom. Ordinary pure silicone rubbers consist mainly of silicone-oxygen chain links containing methyl and a small amount of vinyl. The introduction of phenyl can improve the high and low-temperature resistance of silicone rubbers, and the introduction of Trifluoropropyl and cyano can improve the temperature and oil resistance of silicone rubbers.

Silicone rubber has good low-temperature resistance and can still work at -55℃. After the introduction of phenyl, up to -73 ℃. Silicone rubbers's heat resistance is also outstanding, can work for a long time at 180 ℃, can withstand a few weeks or longer, and still have an elasticity slightly higher than 200 ℃, which has instantaneous resistance to high temperatures of 300 ℃ or higher. Are silicone rubbers recyclable? Uncontaminated silicone rubbers can be sometimes ground and reused, it is low-cost to reuse silicone rubber products.

Because of its useful properties and ease of production and forming, silicone rubber compounds can be found in many products, including voltage line insulators, food storage products, apparel, electronic devices, medical devices, implants, silicone sealants, etc.

2. How to classify silicone rubber?

Silicone rubber is classified in many ways, usually according to the form before curing is divided into solid silicone rubber and liquid silicone rubber; according to the vulcanization temperature is divided into room temperature vulcanized silicone rubber, high-temperature vulcanized silicone rubber.

2.1 High-temperature vulcanized silicone rubber

High-temperature vulcanized silicone rubber refers to the process of polysiloxane into heat-cured elastomer after high-temperature (110-170 ℃) vulcanization molding. It mainly uses high molecular weight polymethyl vinyl siloxane as raw rubber, mixed with reinforcing filler, vulcanizing agent, etc., and vulcanized into elastomer under heating and pressure. Reinforcement of silicone rubber is mainly various types of silica, which can increase the strength of the vulcanized rubber dozens of times. Sometimes to reduce costs or improve the performance of the rubber material and give the vulcanized rubber a variety of special properties, but also to add a variety of additives.

![]()

2.2 Room temperature vulcanized silicone rubber

The difference between room-temperature vulcanized silicone rubber and high-temperature vulcanized silicone rubber mainly lies in that it is a small molecular weight polysiloxane as the base rubber, under the action of crosslinking agents and catalysts and room temperature or slightly heated can be vulcanized into elastomers. Room temperature vulcanized silicone rubber consists of base rubber, crosslinking agent, catalyst, filler, and so on. The packaging form can be divided into single-component and two-component two kinds.

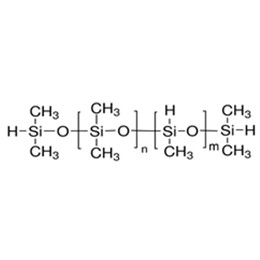

XJY-705 Tetramethylcyclotetrasiloxane TMCTS is a kind of reactive silicone containing silicone-hydrogen bonding, it can undergo additive change with unsaturated olefin, which can be used to synthesize room-temperature vulcanized silicone rubber.

![]()

2.3 Additive molding liquid silicone rubber

Additive molding liquid silicone rubber is mainly based on Polydimethylsiloxane containing end vinyl as the base rubber, Polydimethylsiloxane containing Dimethyl links and Methyl Hydrogen links as the crosslinking agent, and platinum complexes as the crosslinking catalyst made of rubber. Under the action of the catalyst, the rubber material is subjected to an addition reaction at room temperature or under heating, and a silicone rubber with a reticulated structure can be obtained.

![]()

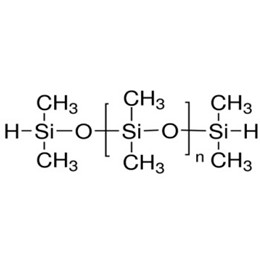

XJY-707 Hydride-terminated Polydimethylsiloxane, because of the molecular structure containing active hydrogen atoms, can be synthesized through the silicon-hydrogen addition reaction of copolymer polymer and can be made into a series of active silicone oils. It can be used as the chain extender of liquid silicone rubber.

XJY-8206N Methyl vinyl VMQ silicone series is a colorless transparent liquid resin that has methyl and vinyl groups, which is composed of vinyl MQ silicone resin and vinyl silicone oil, it can be used for LSR liquid addition molding silicone rubber.

![]()

2.4 Solid silicone rubber

Solid silicone rubber is composed of a special blend of raw silicone rubber and high-purity silicon powder, thus combining the properties of both inorganic and organic rubbers. Generally, silicone rubber can be cured using a platinum-catalyzed cure system, a condensation cure system, a peroxide cure system, or an oxime cure system.

3. What are the performances of silicone rubber?

Silicone rubber arises from the convergence of hydrolyzed Dimethyldichloromethylsilane and Methylbenzenedichloromethylsilane, and its molecular backbone consists of Si-O bonds. Due to the unique molecular structure of silicone rubber, the silicone polymers have the following performance characteristics:

(1) Electrical isolation

Silicone rubber is a saturated non-polar material, which has a very high resistivity, and excellent electrical insulation. The change of electrical insulation property is very small in the moisture, frequency changes, temperatures rise, it is not easy to burn in the arc discharge, even if the combustion, the generation of silica is still an insulator. At the same time, the silicone rubber material has excellent corona resistance and arc resistance.

(2) Heat and cold resistance

Silicone rubber molecular main chain Si-O bond energy is very high, so its heat resistance is good. Under high-temperature conditions, its performance retention rate is high. At 150 ℃, the tensile strength of silicone rubber is much higher than that of general-purpose rubber, while silicone rubber is resistant to high-temperature compression. As the silicone rubber Si-O-Si bond length is longer, the bond angle is large, flexible, and good, weak intermolecular forces, so the low-temperature resistance of silicone rubber is also very superior, which still maintains good elasticity at -60 ℃ ~ -70 ℃.

(3) Weather resistance

The silicone rubber main chain has no unsaturated bonds, and the Si-O-Si bond is very stable on oxygen, ozone, and ultraviolet light, so it does not require any additives and has excellent weather resistance. Its physical and mechanical properties do not change much when exposed to ultraviolet rays and wind and rain for a long time. When corona discharges in the ozone, organic rubber aging fast, but silicone rubber has little effect.

(4) Hydrophobicity

The silicone rubber molecular chain of negative electronegativity is small, and the hydrogen bonding energy is small, which can produce a special surface performance that a lot of materials do not stick and has excellent hydrophobicity.

Silicone rubber also has a unique hydrophobic mobility, when outdoor silicone rubber products after the appearance of dirty, internal small molecules can diffuse to the outer surface, and diffuse to the surface of the dirty layer, so in the case of dirt and moisture, the surface can still maintain a very high resistivity.

XJY-711 Hydrogen Terminated Methylhydrogensiloxane Dimethylsiloxane Copolymer is a colorless transparent liquid, it can be used as a crosslinking agent for the application of silicone rubber.

![]()

4. How to apply silicone rubber in high-voltage AC cables?

The extensive use of silicone rubber materials in the power cable industry is an important basic condition for the improvement and enhancement of power cable products. In the high-voltage cable accessories, silicone rubber insulation materials are mature, which is mainly used in outdoor terminals, GIS terminals, as well as joints on prefabricated stress cones and terminated outer insulating sleeves.

![]()

4.1 Application in cable termination

Two applications of silicone rubber in high-voltage cable terminals are as follows:

(1) Composite terminal insulation sheath tube

The application of silicone rubber composite sleeve overcomes shortcomings that the porcelain sleeve terminal is bulky and inconvenient to install and explosion, with light-weight, easy installation and excellent explosion-proof and other advantages, to ensure the safety of the surrounding personnel and equipment, in large cities with dense population and equipment, silicone rubber composite casing explosion-proof characteristics are particularly important.

(2) The core component of the terminal is a prefabricated silicone rubber stress cone.

Silicone rubber stress cone has excellent anti-aging performance, no stress relaxation in long-term use, and no significant change in electrical performance, which ensures the service life of the stress cone. On GIS terminals, silicone rubber stress cones are used in conjunction with epoxy inner cone insulators, using a spring-loaded compression device to solve the interface insulation; at the same time, silicone rubber stress cones are used to solve the stress concentration in the electric field. Together they form a standardized cable interface with high-voltage GIS switches, transformers, and so on.

4.2 Application in the indirect connector in cables

Silicone rubber in high-voltage cable indirect head is one of the applications of the overall prefabricated type structure of the joint. Silicone rubber overall prefabricated joints are the stress cone, high-voltage shielding tube, joints to enhance the insulation, and outer shielding layer using high-quality silicone rubber molded into a whole. Due to the good elasticity and low hardness of silicone rubber, the overall prefabricated joint has good interface characteristics with the cable. When installing on site, it just needs to expand the overall joint prefabricated parts over the cable insulation, and then pull it to the marking place after the fixture is installed, which simplifies the installation process and guarantees the installation quality.

High-voltage flexible DC transmission is the current solution to solve the long-distance large-capacity transmission channel and new energy scale utilization of large-scale grid interconnection under mainstream technology. With the development of flexible DC transmission technology, DC cables as the key equipment are also developing, with which the manufacturing level and voltage resistance level of high-voltage DC cable accessories are also improving. The application of silicone rubber is the same in high-voltage DC cable accessories and AC cable accessories, mainly used in the manufacture of prefabricated stress cones and terminal outer insulation sleeves.

5. How to make high-voltage cables with silicone rubber?

Silicone rubber has good insulating properties, aging resistance, sealing properties, and adhesion is also good, high strength, long-term use will not have any problem in the temperature range of -50℃ to +250℃, which is the ideal material for high-voltage cable accessories, how to make your products more competitive in the market?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry and more than 15 related patents and technical support. Our silicone raw material products for methyl silicone rubber can meet the needs of all kinds of electronic and electrical equipment, and support the provision of diversified customized solutions.