After decades of development, with the continuous development and innovation of science and technology, in order to improve the performance of coatings, a variety of functional additives have been widely used. Most of the additives used in coatings are surfactants, which reduce the surface tension of gas-liquid, liquid-solid, or gas-solid interfaces to achieve the effect of leveling, defoaming, dispersing, and improving adhesion. Then why use silicone additives for paints and coatings?

Changes in the silicone content and relative molecular mass of the silicone molecule can change the compatibility range of the additive with the coating binder systems, thus affecting the dispersion state of the additive in the system.

Silicone compounds have very low surface tension and high surface activity, which can be used to improve the productivity of coatings, and surface modification and prevent various paint film flaws. Silicone paint additives are important varieties of coating auxiliaries with multiple benefits and a wide range of applications in the coating system.

According to the different coating systems corresponding to the leveling, feel, re-coating, wetting, moisture resistance, and other performance requirements, silicone paint additives can be divided into silicone wetting agents, leveling agents, defoamers, adhesion promoters, wear-resistant auxiliaries, and so on, which are widely used in producing paints, coatings, printing inks, primers, powder, overprint varnishes and etc.

Here's more information about it:

- What are the types of silicone additives?

- Silicone additives as coating leveling agents

- Silicone additives as coating defoamers

- Silicone additives as substrate-wetting agents

- Silicone additives as wear-resistant additives

- Silicone additives as coating resin modification

- Silicone additives as adhesion promoters

- How to make silicone coating additives?

1. What are the types of silicone additives?

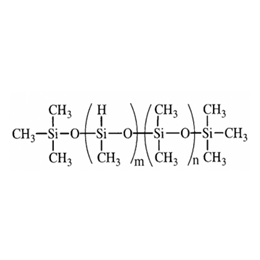

Silicone additives for coating systems are divided from the chemical composition, including silane and silicone oil. Silane is mainly some small molecule compounds, mainly used in coatings as adhesion promoters, crosslinking agents and dispersants, etc; Silicone oil additives are mainly composed of modified silicone oil, by adjusting the relative molecular mass of the additives, the type and content of the modified group R and the type of functional group of the end group, you can get a variety of different properties of the additives.

![]()

2. Silicone additives as coating leveling agents

(1) What are silicone coating leveling agents?

The structure of the leveling agent for coatings generally consists of two parts: chain segments compatible with the system and chain segments incompatible with the system and with a low surface tension. During the paint film-forming process, due to the separation and migration of the incompatible chain segments with low surface tension, the silicone paint additives will spontaneously migrate to the surface of the coating system to form a single molecule film, thus providing a uniform surface tension for the system and eliminating the various surface defects of the various paint film flaws caused by the surface tension gradient. Some- times a rather pronounced deformation of the surface texture can occur. The coating shows non-optimal flow–often described as orange peel.

Silicone leveling agent is an important class of coating leveling agents, in general, low relative molecular mass (<5,000) of Polydimethylsiloxane can be used as leveling agents. At present, the widely used silicone leveling agent in coatings is a variety of modified silicone oils, according to the different types of modification, mainly have Polyether modified silicone oil, Polyester modified silicone oil, Phenyl modified silicone oil, Alkyl modified silicone oil, Phenyl alkyl co-modified silicone oil, and Alkyl-polyether co-modified silicone oil, etc., Polyether modified silicone oil can be adjusted in a wide range due to its structure, its performance can cover many different requirements, which is the main variety of silicone leveling agent at present.

XJY-701 Polymethylhydrosiloxane is a kind of high molecular weight organic synthetic material with a general chemical structure, which can be used as a coating leveling agent.

![]()

(2) How to choose a silicone leveling agent?

When the leveling agent needs to be used in a high-temperature system (such as baking paint), due to the low decomposition temperature of Polyether, it easily decomposes in the process of use, which will cause some surface defects of the paint film, such as poor recoating, shrinkage and so on, then it is necessary to choose the modified silicone oil which contains high-temperature resistant groups (such as Alkyl-modified silicone, Phenyl-modified silicone, and Polyester-modified silicone, etc.), in comparison, the Alkyl-modified silicone oil, in addition to the leveling effect, also has a good anti-foaming effect, but its compatibility is not good, usually not suitable for varnish. Phenyl silicone fluids and polyester-modified silicone fluids are more compatible and are suitable for use in high-temperature varnish systems while providing excellent compatibility and heat stability. With the development of technology, recently appeared some silicone and acrylate combination of leveling agents, this kind of leveling agent at the same time combines the advantages of the two, both excellent pre-flatting and post-flatting effects. According to the different chemical structures, it can be divided into Acrylate modified silicone leveling agents (silicone is the main chain, acrylate is the side chain) and silicone-modified acrylate two types, and silicone-modified acrylate leveling agents can not only provide the leveling effect but also can incidentally provide with the effect of stain resistance.

3. Silicone additives as coating defoamers

As a defoamer for coatings, it is usually necessary to have a very low surface tension than the application system, and at the same time is incompatible with the application system. Silicones are widely used as raw materials for coating defoamers due to their low-polarity structure and incompatibility with most coating resin systems.

Usually, the relative molecular mass (10000~100000) of Polydimethylsiloxane can be used as coating antifoam agents, at present, this kind of antifoam agent is widely used in heavy corrosion and other systems. To improve the defoaming efficiency, you can also add some silica as a synergistic component. In addition, due to the high antifoaming efficiency of silicone, it has good results in a very low amount of silicone paint additives, in order to facilitate the addition, silicone antifoam agent is usually made into a lower concentration of the solution to adapt to the needs of the actual production.

XJY-702 Methylhydrosiloxane/Dimethylsiloxane Copolymer can react with double bond, hydroxyl, and other groups under the action of a catalyst, which is the basic raw material of leveling agent, defoamer, water-soluble silicone oil, and other products. In addition to the characteristics of Dimethicone, this product can produce addition and cross-linking reactions due to the presence of active hydrogen.

![]()

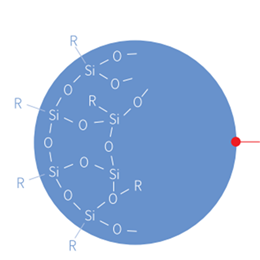

XJY-8205 Series Silicone Methyl MQ Resin is a solid powder resin having good defoaming and anti-foam performance and can be added into the solvent to be defoamer.

![]()

In waterborne coating systems, due to the high polarity of waterborne resins, conventional Polydimethylsiloxane has limited compatibility with the system and is difficult to use directly as a defoamer agent. It is usually necessary to modify Polydimethylsiloxane with Polyether, especially in the application of high-gloss systems. Usually, the higher the degree of polyether modification, the better the compatibility, but the defoaming effect will also decline, generally, it needs to be based on the ease of defoaming the system, to select the appropriate proportion of modification, in order to meet the conditions of defoaming ability, the lower the silicon content the better.

4. Silicone additives as substrate wetting agents

In a water-based system, because the surface tension of water is too large, the substrate (especially low surface tension substrate) of the rapid wetting is more difficult, so in the water-based coating system, the use of substrate wetting agents is particularly important. Silicone substrate wetting agents are widely used in waterborne coating systems due to their wide applicability.

![]()

Substrate wetting agent is actually a special class of Polyether-modified silicone oils, whose relative molecular mass is usually very small. Since the rapid wetting of the substrate is a dynamic process, and in accordance with the principles of physical chemistry, the wetting agent's principle of action is to reduce the surface tension of the system by rapidly migrating to the surface of the system, so as to achieve the effect of substrate wetting. According to the viewpoint of molecular kinematics, the migration speed of molecules depends on the relative molecular mass to a large extent, and the smaller the relative molecular mass is, the faster the migration speed is. Therefore, the relative molecular mass of the smaller Polyether-modified silicone oil is often used as substrate wetting agent for aqueous systems.

Further research found that as a substrate-wetting agent Polyether-modified silicone oil is used in aqueous systems. Due to its special structure, the silicone chain can be fully extended, stretching a large number of -CH3 to the outside, thus greatly reducing the surface tension of the system. Usually high relative molecular mass of Polyether-modified silicone oil in an aqueous system can only reduce the surface tension to 25~26N/ m, and small molecules of the substrate wetting agent can usually reduce the surface tension to 22N/m below, the lowest can be 20~ 21N/m. Such a low surface tension, so that the addition of substrate wetting agent of aqueous coatings can be wetted to most of the substrate with a low surface tension, and even wetting of PTFE substrate. At the same time, because the substrate wetting agent can reduce the surface tension of the aqueous system to a very low degree, the substrate wetting agent can give the system good anti-cratering performance and atomization effect during spraying.

![]()

Due to the small relative molecular mass of the substrate wetting agent, its silicone chain segment is very short, so it can not give the paint film surface smoothness (usually from the long silicone chain segment). When the slipperiness of the paint film is required, the substrate wetting agent is usually used with a high-relative molecular mass silicone leveling agent, which is also the difference between the substrate wetting agent and the ordinary silicone leveling agent.

5. Silicone additives as wear-resistant additives

For systems requiring wear resistance, in addition to improving the crosslink density from the resin perspective, adding additives is also a common method. Commonly, there are ultra-high relative molecular mass silicone microspheres, ultra-high relative molecular mass silicone emulsions, and silicone nano modifiers.

Ultra-high relative molecular mass wear-resistant silicone microspheres have a slightly cross-linked structure inside the dispersion of high relative molecular mass Polysiloxane, microscopically is microspherical. After joining the system, it will ultimately be oriented on the surface of the paint film arrangement, forming a layer of polysiloxane film, thus providing the system with excellent slipperiness and surface abrasion-resistant effect. In the water-based coating system, in addition to silicone microspheres, ultra-high relative molecular mass silicone emulsion is also a commonly used class of wear-resistant additives, which are usually obtained by the polymerization of silicone emulsions, the viscosity of the internal phase is extremely high, the relative molecular mass can be up to millions and added to the system, after the formation of the film, it can be formed on the surface of the ultra-high relative molecular mass of the silicone layer, thus improving the wear-resistant effect of the paint film.

XJY-801 Polymethylsilsesquioxane PMSQ can be used as wear-resistant modification material to improve lubrication, scratch resistance, dispersion, and hydrophobicity; Polymethylsiloxane powder is suitable for coatings and inks with high heat resistance and solvent resistance, with good toughness and scratch resistance. It is easier to disperse, less likely to settle, and has better adhesion when combined with coatings. It has a particularly delicate touch and can form a higher grade of surface coating.

![]()

6. Silicone additives as coating resin modification

Silicone materials usually have some special properties, such as surface smoothness, wear resistance, weather resistance, low-temperature flexibility, and other properties, when adding some silicone elastomers materials with reactive functional groups as modifying additives, which can be introduced into the resin system of silicone chain segments, so as to introduce the excellent performance of silicone materials into the coating system.

Silicone materials for resin modification have various functional groups and are usually silicone polymers with reactive groups at both ends. Silicone materials with carbon hydroxyl groups usually have better reactivity with Polyurethane materials, and can be used for modification of Polyester or polyurethane resins; Silicone materials with epoxy groups can be used for modification of Epoxy resins; Silicone materials with Acrylate double bonds at both ends can be used for modification of cured rubber; Silicone materials with Acrylate double bonds can be used for synthesis of silicone modification emulsions; Silicone materials with Amino groups can be used as silicone-modified polyimide resin synthesis for some high-end applications; silicone materials with Carboxyl groups can be used as powder coating resin modification and participate in the reaction.

7. Silicone additives as adhesion promoters

Silane adhesion promoters have been widely used in solvent-borne coating systems with substrates of glass, ceramics, zinc metal, iron metal, cured rubber, and some plastic systems.

![]()

The Alkoxy group in silane reacts with a small amount of water in the system to generate the silicon hydroxyl group, which reacts with the hydroxyl group on the surface of the substrate to form a strong adsorption layer, and the R group contained in the silane contains reactive groups (amino, epoxy, methacryloyl, etc., for different resin systems) can be chemically bonded with the resin system during cross-linking, which provides strong bridging effect between the resin and the substrate, thus greatly improving adhesion. Same as the solvent-borne coating system, silane can still be used as an adhesion promoter in water-borne coating systems when applied to glass, ceramics as well as some metal and plastic substrates.

However, unlike the solvent-borne system, since the water-borne system takes water as a dispersing medium, silane adhesion promoter which is usually applicable to solvent-borne systems will be hydrolyzed too quickly and become ineffective when it is added to the water-borne system, so it can only be added at the construction site. Silanes suitable for waterborne coating systems were developed based on the characteristics of waterborne coating systems. By adjusting the size of the R group in the silane structure, the hydrolysis speed of the silane is affected by the site resistance effect of the R group, so that the hydrolysis cycle of the silane can be synchronized with the use cycle of the waterborne coatings, and the storage stability of the waterborne coatings is improved.

8. How to make silicone coating additives?

Silicone coating additives are a kind of chemical additives widely used in the coating industry at present. It has unique properties and versatility that can significantly enhance the performance and quality of coatings, and also protect the coating surface from various environmental factors. So how to choose silicone additives to make your products more competitive in the market?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry as well as more than 15 related patents and technical support. Our silicone raw material products can meet the needs of various application additives for coatings and support the provision of diversified customized solutions.