The light diffusers market is currently showing positive development. With the rapid development of LED lighting, optoelectronic products, liquid crystal displays, and other industries, the market demand for light diffusers, as key materials, continues to grow. According to industry analysis, the market size of light diffusers has grown steadily over the past few years and is expected to maintain a steady growth trend in the coming years. Silicone technology innovation and the continuous expansion of application areas will further promote the development of the light diffusion market. What are silicone light diffusers?

Silicone light diffusers are light diffusers consisting of polymer microspheres with a three-dimensional structure linked by silicone-oxygen bonds. Silicone light diffusers are pure white powder in appearance. Compared with traditional light diffusers, they have the advantages of good chemical stability, high refractive index, good heat resistance, non-volatile, high light diffusion efficiency, etc., and they have a broad application prospect in the fields of cosmetic, electronic products, LED light appliances, strip light, and coatings.

The following six aspects of the application of silicone light diffusers:

- What are the types of organosilicon light diffusers?

- What are the characteristics of silicone light diffusers?

- How is the silicone light diffuser compared with other materials?

- What are the applications of silicone light diffusers?

- How to affect the transparency of the film?

- How to make silicone light diffusers better performance?

1. What are the types of silicone light diffusers?

Silicone diffuser is mainly divided into three types: silicone-inorganic hybrid light diffusers, silicone microsphere light diffusers, and organosilicon polymer light diffusers.

(1) Silicone-inorganic hybrid light diffusers are made of silicone and inorganic materials, and have excellent chemical stability and optical properties;

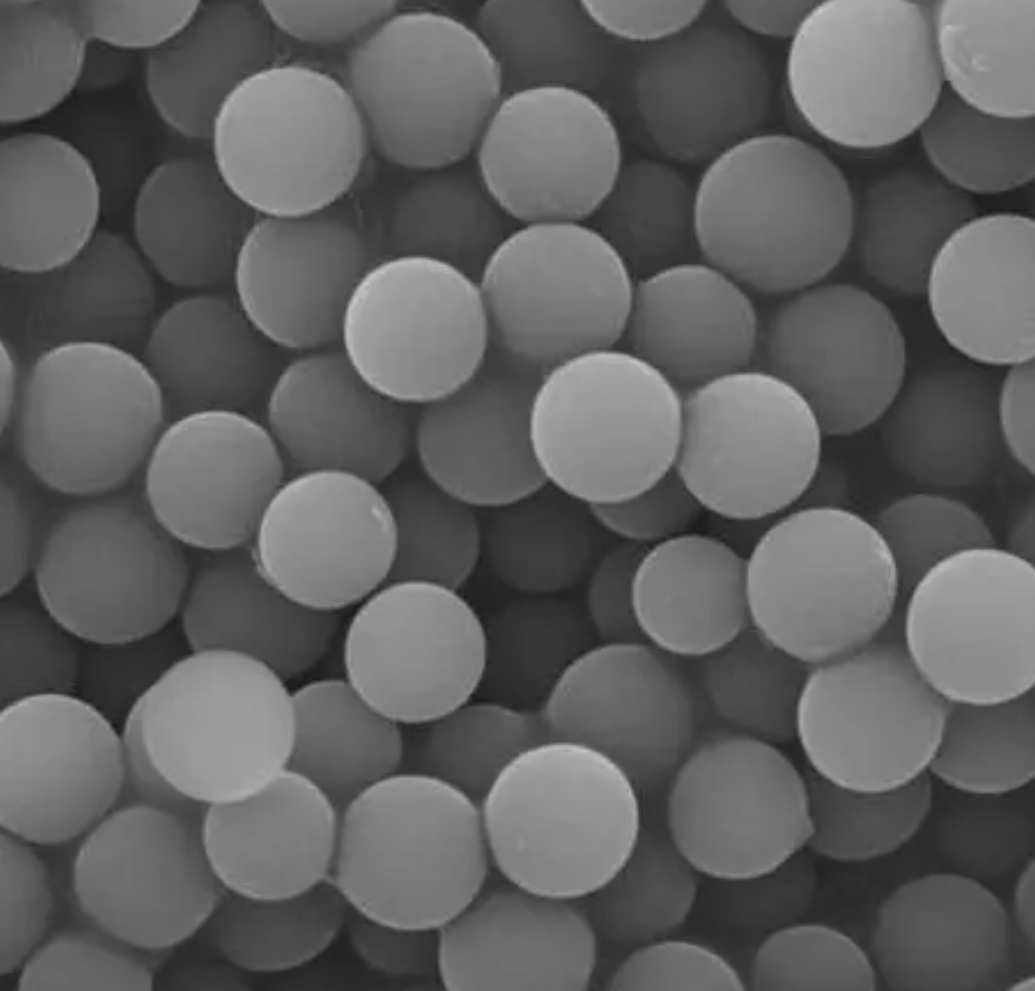

(2) Silicone microsphere light diffusers made of organosilicon microspheres as raw materials, mainly used in the preparation of high-efficiency light diffusion materials;

(3) Silicone polymer light diffusers are made of light-diffusing particles and silicone polymers as raw materials, which are the most widely used silicone light diffusers.

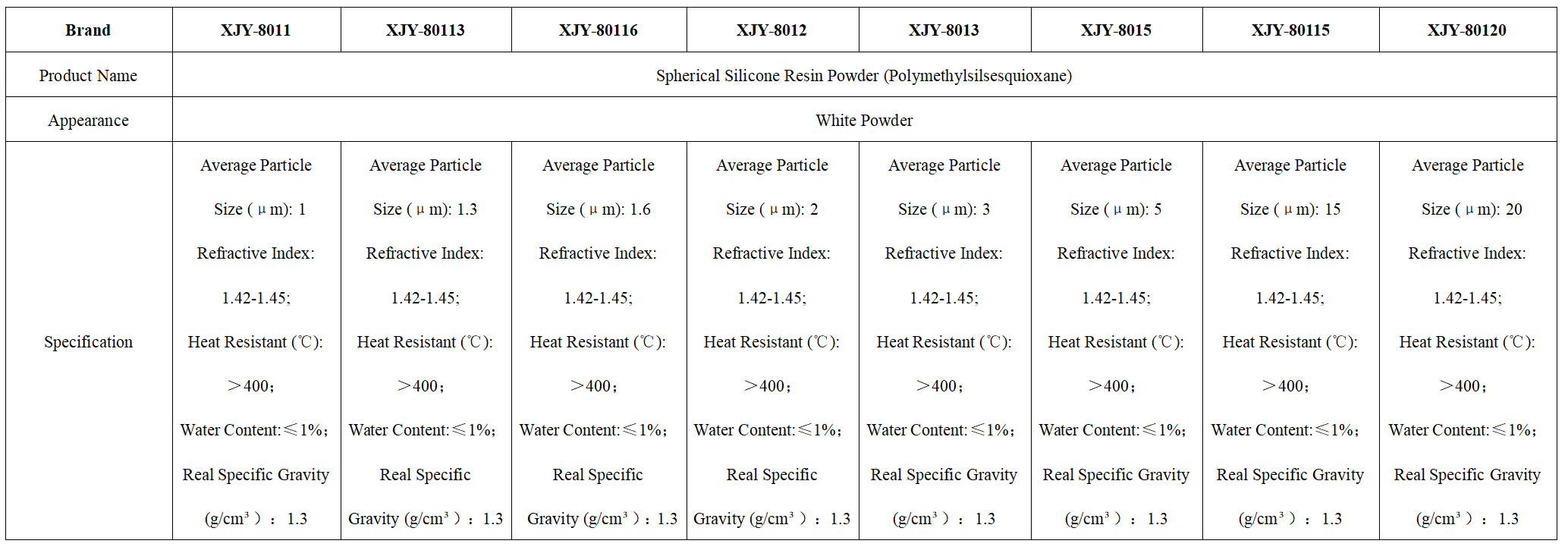

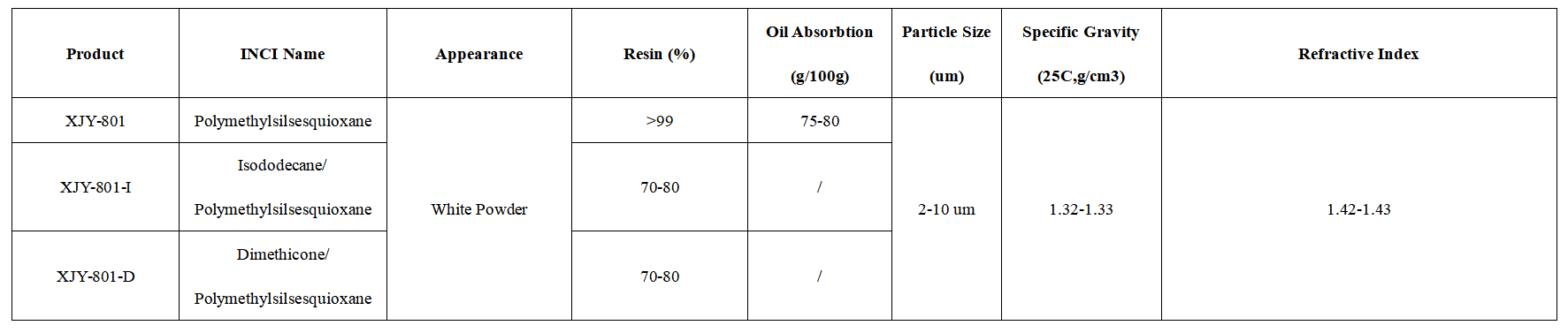

XJY-801 Polymethylsilsesquioxane ( Spherical Silicone Resin Powder) as raw material, acid as catalyst, first hydrolysis reaction, condensation under alkaline conditions, and then condensation crystallization into spherical. Its particle size distribution can be customized. After high-temperature maturation and other processes, the solid product is finally obtained. It can provide a good balance of optical performance in terms of transmittance, haze, and diffusion effect, and is widely used in high-end transparent PC lamps, lampshades, light boxes, flat-panel LCD light diffusion panels, and so on.

2. What are the characteristics of silicone light diffusers?

Silicone light diffusers are a kind of polymer microspheres connected by silicone-oxygen bonds with three-dimensional structures. It usually exists in the form of pure white, regular spherical micro-powder, with good transparency and shape stability. The main role of silicone light diffusers is through their special structure and light scattering properties, the original straight line propagation of light into the material in different directions of the random propagation of light, thus improving the material's light transmittance and light diffusion effect.

3. How is the silicone light diffuser compared with other materials?

(1) Compared with inorganic light diffusers, silicone light diffusers have higher diffusion efficiency, good compatibility with the matrix resin, good dispersion, small specific gravity, low water absorption, water-repellent hydrophobicity, light transmission, and uniformity of light more balanced.

(2) Compared with traditional acrylic light diffusers, it has high light diffusion efficiency, low additive amount, excellent heat resistance, high brightness, and can maintain ideal light transmittance.

(3) Excellent heat resistance and high-temperature resistance, making the service life of lamps, light boxes, lampshades, and other products longer.

(4) It can be customized production, for different light diffusion and light transmittance balance requirements, to provide different specifications of the pure silicone system of high-efficiency light diffusion agent.

4. What are the applications of silicone light diffusers?

Silicone light diffusers have broad application prospects in many fields.

(1) In the field of cosmetics, organosilicon light diffusers can increase the dispersibility, anti-breakage, and filling properties of cosmetics, and are more widely used in lipsticks and powders;

XJY-801 Polymethylsilsesquioxane

It is a polymer formed by times half siloxane methyl siloxane, methyl times half siloxane is dense crosslinking curing resin insoluble, non-melt, with three functional components. Polymethylsilsesquioxanes are silicone round particles that can be used in many skincare and cosmetic applications because the main chain of all these silicone resins consists of repeating units of silicone, elemental silicon, and oxygen, which provide excellent tactile sensation on the skin, and typical particle sizes of different grades can yield excellent performance advantages when incorporated into a variety of lotion and cosmetic formulations.

(2) In the field of electronic products, they are mainly used in the manufacturing process of backlight modules, with tablet PCs and smartphones as their downstream products;

(3) In the field of lighting appliances, it can be used in the manufacture of LED lamps, which can effectively reduce glare and the phenomenon of light spots. With the growing demand for applications in the future, the silicone light diffusion agent industry will continue to accelerate the pace of development.

5. How to affect the transparency of the film?

5.1 Scattering effect

When silicone light diffusers are added to the film, a layer of concave-convex structure will be formed on the surface of the film. This structure causes light to scatter inside the film, thus spreading the light in multiple directions. While this scattering effect helps to improve the optical uniformity and light transmission properties of the material, it also reduces the transparency of the film to some extent. Especially in large-area transparent conductive films, this effect is more pronounced.

5.2 Why will silicone diffuser transparency be reduced?

The reduction of transparency is mainly due to the light inside the film caused by multiple scattering and reflection. When the light enters the film and encounters the concave and convex structure formed by the silicone light diffuser, multiple scattering, and reflection will occur, resulting in part of the light not being able to pass directly through the film, thus reducing the transparency of the film.

5.3 How to minimize the impact on film transparency?

(1) Appropriate amount of additives

The amount of additives added is an important factor affecting film transparency. If the amount of additive is too much, it will cause a significant reduction in transparency. Therefore, when adding a silicone light diffusion agent, need to strictly control the amount of additive, generally recommended to add no more than 10%. At the same time, you can also choose a relatively high transparency of the silicone light diffusing agent varieties to further minimize the impact on the transparency of the film.

(2) Appropriate treatment

Appropriate treatment to modify and smooth the surface of the silicone light diffusers can also reduce its impact on film transparency. For example, surface treatment and spray modification can be carried out to make the organosilicon light diffusers more evenly distributed in the film and reduce the scattering effect.

5.4 Application to Specific Fields

Although organosilicon light diffusers can reduce the transparency of the film, in some specific areas, this effect is acceptable and even beneficial. For example, in organic solar cells, a highly transparent conductive layer is needed to collect charge, and the addition of an appropriate amount of silicone light diffusers can help improve the photoelectric conversion efficiency of the cell. In addition, silicone light diffusers can also be used for self-cleaning, anti-reflection, etc., to improve the overall performance of the film.

6. How to make silicone light diffusers better performance?

As a high-performance light diffuser, organosilicon light diffusers are widely used in many fields (LED lights, LED strip light, aluminum channels), and can reduce hot spots. In the future, with the maturity of technology development and the decline in production costs, the market share of organosilicon light diffusers will increase. How to improve the competitiveness of products?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry as well as more than 15 related patents and technical support. Our silicone raw material products can meet the needs of the light diffusion field and support the provision of diversified customized solutions.