With the increasing development of automotive electronics technology, automotive electronic equipment occupies an increasingly important position in modern automobiles. Choosing the right sealant for automotive electronics is crucial because electronics are the most critical part of the car. If the electronic equipment fails, it will have a serious impact on the normal operation of the vehicle. Therefore, it is crucial to choose a reliable sealant to protect these devices. Why use silicone sealants for automotive electronics?

Silicone sealants offer excellent adhesion, high and low-temperature resistance, weather ability, water repellency, electrical properties, and chemical resistance due to their unique molecular structure. These characteristics have led to the widespread use of silicone sealants in automotive applications such as lamp sealing, especially in high-end models that are not used on porous surfaces.

The following four aspects of the application of silicone sealants:

- How to choose a suitable sealant?

- What are the features of silicone electronic sealant?

- What is the application of silicone sealant in automotive electronics?

- How can silicone sealant performance be improved?

1. How to choose a suitable sealant?

(1) You need to choose a sealant with high adhesion and high sealing properties. This sealant should be able to firmly adhere to a variety of surfaces, including metal, plastic, and glass. In addition, it should be able to resist a variety of environmental factors, such as high and low temperatures, moisture, and UV rays.

(2) You need to consider the durability of the sealant. Automotive electronics need to be able to stand the test of time, so you need to choose a sealant that will last. This means that you need to choose a sealant that has been rigorously tested and proven to ensure that it will protect your car electronics for a long time.

(3) You need to consider the safety of the sealant. The sealant should be a safe and reliable product that does not pose any risk to your health. Therefore, you need to choose a sealant that has been rigorously tested and certified to ensure that it will not release harmful substances.

To summarize, choosing the right sealant for your car's electronics requires considering its adhesion, durability, and safety. By carefully comparing different products and brands, and referring to the advice of professionals, you can choose a sealant that best suits your vehicle to ensure that your automotive electronics can function properly.

2. What are the features of silicone electronic sealants?

Silicone electronic sealant is a kind of sealant made of one-component silicone material elements, with the following features and advantages:

(1) High and low-temperature resistance: silicone electronic sealant has excellent high and low-temperature resistance, which can be in -50 ℃ to 200 ℃ extreme temperatures range to maintain stable performance, to meet the automotive electronic equipment on the temperature requirements of the harsh conditions.

(2) Sealing performance: silicone electronic sealant has excellent sealing performance, and can effectively prevent moisture, dust, and other external substances from the erosion of electronic components, blocking dust and fine particles into the motor control unit, maintaining internal cleanliness, to avoid dust caused by circuit short-circuits or failures, to protect the stable operation of electronic equipment. Automotive motor control unit is usually exposed to humid and rainy environments, the use of glue for sealing can effectively prevent water vapor from entering the interior, thus reducing the risk of electronic components moisture.

(3) Seismic performance: the car's driving environment is complex, due to uneven road surface caused by bumps in the case of sometimes occur, silicone electronic sealant can increase the structural stability of the motor control unit, reduce the vehicle driving process due to vibration and impact generated by the loosening and damage.

(4) Chemical resistance: silicone electronic sealant has strong chemical resistance, and can resist the automotive environment of acids and alkalis, oils, and other chemicals erosion, to maintain the long-term stability of the equipment.

(5) Insulation properties: silicone electronic sealant has excellent insulation properties, can effectively isolate electronic equipment, and provides reliable insulation protection.

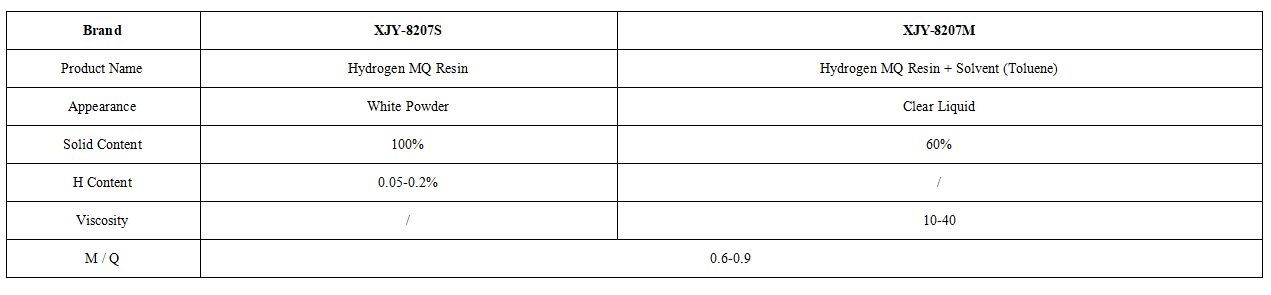

XJY-8207 S/M Hydrogen MQ Resin can be used as a silicone sealant tackifier to improve the performance of clear silicone sealant so that it has excellent adhesion.

3. What is the application of silicone sealant in automotive electronics?

Silicone electronic sealant has a wide range of applications in the field of automotive electronics, including but not limited to the following aspects:

(1) New energy vehicle battery pack:

The rise of new energy vehicles has led to the rapid development of battery technology, and one-component silicone electronic sealant can be used as a key material for battery pack encapsulation, to protect the battery module from moisture, vibration, and pollutants.

(2) Body electronic control unit (ECU) sealing:

ECU as one of the cores of the vehicle's electronic system, needs to be well protected by sealing. One-component silicone electronic sealant can be used for ECU shell sealing to resist moisture and dust erosion.

(3) Automotive lamps and lanterns sealed:

Automotive lamps and lanterns usually need to withstand harsh environments, and one-component silicone electronic sealant can provide excellent sealing performance, to protect the lamps and lanterns inside the electronic components from water vapor, vibration, and temperature changes.

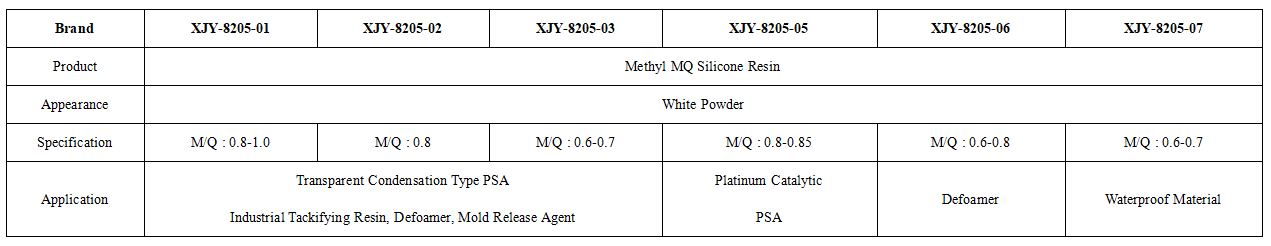

XJY-8205 powder series Methyl MQ Silicone Resin is a solid powder resin, which can be used as a reinforcing material for liquid silicone rubber. Adding MQ resin to the potting compound can enhance its resistance to high and low temperatures and prolong its service life, which is suitable for a wide range of materials and applied to various electronic components within the power supply, including PCB boards.

(4) Automotive radar, camera protection:

With the rapid development of intelligent driving technology, automotive radar cameras and other sensory equipment in automobile applications are becoming more and more common. These devices need to be protected by sealing to prevent the interference of moisture and pollutants. One-component silicone electronic sealant can provide reliable protection to ensure the stable operation of the intelligent driving system.

4. How can silicone sealant performance be improved?

As one of the materials to protect and seal the key components of electronic devices, silicone electronic sealants( silicone adhesive) in the field of automotive electronics applications are gradually gaining widespread attention. With its excellent performance and versatility, this material plays an important role in the field of automotive electronics and has great market potential, used on other materials surface aluminum. How to improve the competitiveness of products?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry as well as more than 15 related patents and technical support. Our silicone raw material products can meet the needs of the automotive field and support the provision of diversified customized solutions.