The medical silicone fluids market has continued to grow in recent years, mainly due to its wide range of applications in the healthcare sector. Medical silicone oil plays an important role in various aspects such as ophthalmic surgery, lubrication of medical devices, and drug carriers due to its high purity, high consistency, biocompatibility, and long-lasting properties. With the continuous progress of medical technology and the aging population trend, the market demand for silicone oil in the medical industry is expected to expand further. At the same time, the market competition is also increasingly fierce, enterprises need to strengthen technological innovation and product differentiation to enhance their competitiveness. What is medical silicone oil?

Medical grade silicone oil is a colorless clarified oily liquid; odorless or almost odorless, tasteless. Medical silicone oil is extremely soluble in trichloromethane, ether, or toluene, and insoluble in water and ethanol. It is an organosiloxane liquid and its derivatives are specially used in the medical field. It serves a variety of functions such as lubrication and defoaming in medical devices. Medical silicone oil is widely used in medical operations, pharmaceutical preparations, and personal care products, such as ophthalmic surgery, gastroscopy, silicone adhesives, scar repair gel, etc. It is favored for its mild, pure, and non-irritating properties to the skin. Its production and application are subject to strict quality standards and specifications.

The following 5 aspects of the application of medical silicone oil:

- What is the role of medical silicone oil?

- What are the standards for medical silicone oil?

- What are the characteristics of silicone?

- How is silicone oil used in medicine?

- How to make silicone oil performance better?

1. What is the role of medical silicone oil?

Medical-grade silicones are used for diagnosis, prevention, and treatment of disease or lubrication, and defoaming function in medical devices. Broadly speaking, the cosmetic silicone oil used for skin care and beauty care also belongs to this category. Commonly used medical silicone oil, such as polydimethylsiloxane, etc., the use of its defoaming properties, can be made to treat abdominal distension of flatulence tablets and the treatment of pulmonary edema aerosol, but also in abdominal surgery as the prevention of intestinal adhesion of anti-adhesion agents, in gastroscopy as a gastric defoamer and some medical surgical instruments lubricant. Medical silicone oil is required to be produced in a clean environment, with high purity, no residual acid and alkali catalysts, and low volatile matter, and is now mostly produced by resin method.

(1) It can be used as a lubricant and polishing agent for tablets, capsules, tablet granulation, tablet pressing, coating, and other processes, bright, anti-adhesive, and moisture-proof; controlled-release preparations, especially the coolant of the drops;

(2) It can be used as a suppository mold release agent; and can be used in the traditional Chinese medicine extraction process of defoamer;

(3) Its surface tension is small and can change the surface tension of bubbles so that they rupture.

2. What is the standard of medical silicone oil?

Medical silicone oil is a commonly used medical material, widely used in medical devices, medical instruments, medical supplies, and other fields. In order to ensure the quality and safety of medical silicone oil, all countries have formulated corresponding standards and norms. The following will introduce some common medical silicone oil standards.

(1) Purity standard

The purity of medical silicone oil is an important index, usually required to reach more than 99.9%. High-purity silicone oil can reduce irritation and damage to the human body and improve the safety and reliability of medical devices.

(2) Viscosity standard

The viscosity of medical silicone oil refers to its fluidity performance, which is usually expressed using Sylvester degree (cSt) as a unit. Different medical devices and applications require different viscosities of silicone fluids, so it is necessary to choose the appropriate viscosity grade according to the specific needs of use.

(3) Biocompatibility standards

Medical silicone fluids are in direct contact with the human body, so their biocompatibility is an important consideration. National standards require medical silicone oil in the body does not produce toxicity, irritation, and allergic reactions, and will not cause damage to human tissues and organs.

(4) Temperature resistance standards

Medical silicone oils usually need to be disinfected and sterilized at higher temperatures, so their temperature resistance is also an important indicator. The standard requires medical silicone oil to maintain stability and reliability within a certain temperature range.

(5) Stability standard

Medical silicone oil needs to maintain stability during long-term storage and use, without decomposition, oxidation deterioration, and other phenomena. Standards require medical silicone oil for a certain period to maintain its physical and chemical properties do not change.

In addition to the above aspects of the standard, there are some other standards that also need to be considered, such as the color, smell, and appearance of medical silicone oil. All these criteria are to ensure the quality and safety of medical silicone oil and protect the health and interests of patients.

In practice, medical silicone oil also needs to comply with the requirements of the laws and regulations of various countries and regions, different countries on the standards and norms of medical silicone oil may be different, so the production and sales process needs to be adjusted according to the requirements of the specific country and region and comply with.

3. What are the characteristics of silicone?

Silicone material is a synthetic polymer with a unique chemical structure and physical properties. It has the following characteristics:

(1) High chemical stability:

Silicone materials can remain stable in extreme environments such as high temperatures, low temperatures, and strong acids and alkalis, and it is not easy to have chemical reactions.

(2) Physiological inertia:

Silicone has good compatibility with human tissue, is non-toxic, non-irritant, and can be safely used in the human body.

(3) Low surface tension:

Silicone has a low surface tension, with good lubricity and anti-adhesion.

(4) Strong aging resistance:

Silicone has a long service life and can remain stable in the natural environment.

(5) Good biocompatibility:

Silicone and human tissue have good compatibility and can be safely used in the human body.

4. How to use silicone oil in medicine?

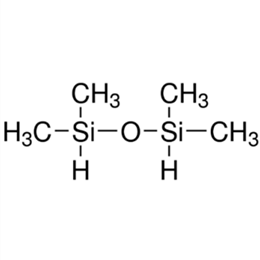

Tetramethyldisiloxane is synthetic organic chemistry, and soluble in organic solvents such as aromatic/petroleum hydrocarbons, but insoluble in water. It is a versatile silicone intermediate, usually used as a silicone capping agent. Because of the reactive hydrogen atoms in the molecular structure, copolymer polymers can be synthesized through hydrogenated silylation reactions to make a range of reactive silicone fluids with a variety of functional groups.

Tetramethyldisiloxane has a wide range of applications in the medical field, mainly in the following areas:

(1) Pharmaceutical packaging and protection

Tetramethyldisiloxane is an important raw material for the manufacture of silica gel, which is often used as a moisture-proof and anti-deterioration material in pharmaceutical packaging due to its excellent adsorption properties. This helps to maintain the stability and effectiveness of drugs and extend their shelf life. liquid silicone rubber also can be used in it.

(2) Infusion and blood collection

Tetramethyldisiloxane or its related products (e.g. medical silicone oil) can reduce the immune response to the body and the deterioration of the condition during infusion and blood collection due to its low osmotic pressure and non-irritating properties to the tissues, which improves the safety and comfort of the medical process.

(3) Drug synthesis and preparation

Tetramethyldisiloxane also plays an important role in drug synthesis. For example, it has been used to successfully synthesize pharmacologically important inhibitor drugs such as cagliflozin (Invokana) and dagliflozin (Farxiga). The development and application of these drugs have provided new treatment options for diabetic patients.

(4) Medical Device Lubrication

High purity and lubricity: Because tetramethyldisiloxane or its derivatives (e.g., medical silicone oils) have high purity and good lubricity, they are often used in the lubrication of medical devices to reduce friction between the devices and body tissues, to reduce patient discomfort, and to improve the efficiency and safety of the use of medical devices.

(5) Other medical applications

Widely used in cosmetics, tetramethyldisiloxane also exhibits antioxidant, antibacterial, and anti-inflammatory properties. These food-grade silicone properties make it potentially useful in the medical field as well, such as for the improvement and treatment of skin sensitivity, dryness, and other problems.

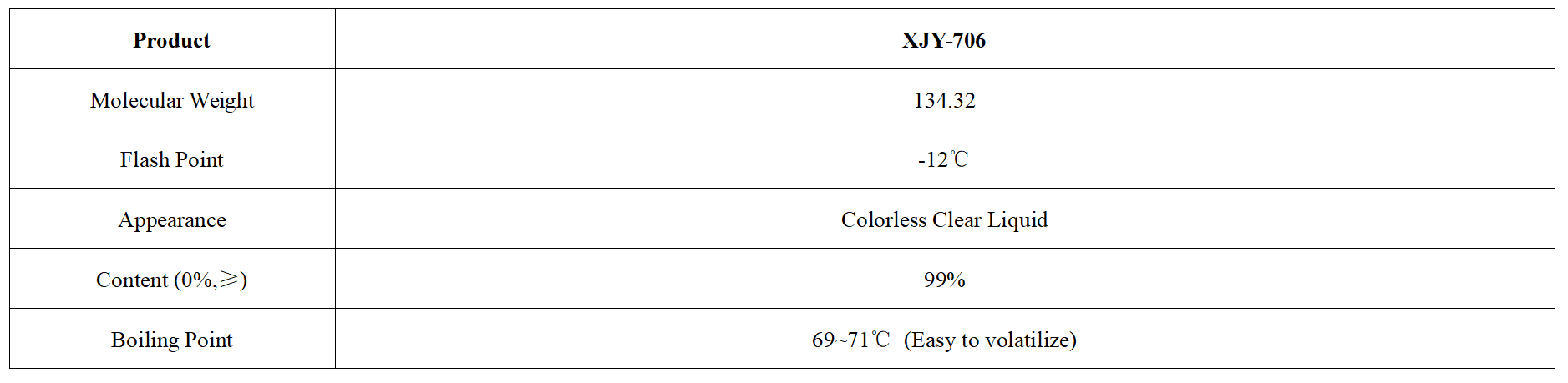

XJY-706 1,1,3,3-Tetramethyldisiloxane

It is a widely used silicone intermediate, usually used as a silicone capping agent and also can be used as a pharmaceutical-grade raw material for pharmaceutical intermediates.

5. How to make silicone oil perform better?

Silicone oils are widely used and important in the medical grade materials field, silicone adhesive and silicone rubber(high-consistency rubber) also can be used. Their high purity, non-toxicity, good biocompatibility and chemical stability make silicone oils ideal for medical device manufacturing, pharmaceutical formulations and personal care products. How to improve the competitiveness of your products?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry as well as more than 15 related patents and technical support. Our silicone raw material products can meet the needs of the medical field and support the provision of diversified customized solutions.