In recent years, we are increasingly using lightweight and easy-to-process silicone products in our lives. With technological advances and the continuous expansion of application areas, the market size of silicone continues to expand. In the long run, with the recovery of the global economy and the rise of emerging markets, the demand for silicone is expected to grow further. What is silicone?

Silicone belongs to the synthetic rubber in the special rubber, which is divided into solid and liquid according to the form. Liquid according to the vulcanization temperature is divided into room-temperature vulcanization type and high-temperature vulcanization type. The basic structural unit of silicone products is composed of silicone-oxygen chain links, and the side chain is connected to various other organic groups through silicon atoms. Therefore, the structure of silicone products contains both “organic groups” and “inorganic structures”, this special composition and molecular structure sets the characteristics of organic and inorganic functions in one.

The following is an introduction to the use of organic silica gel from 4 aspects:

- How to classify silicone?

- How safe is silicone?

- What are the recommendations for using silicone?

- How to make silicone perform better?

1. How to classify silicone?

Silicone is a common material. Usually, people commonly known as silicone are divided into two main categories: inorganic silicon gel and silicone.

(1) Inorganic silica gel is mainly obtained by acid condensation and precipitation of sodium silicate without carbon atoms. It forms interconnected pores has a huge surface area, and is generally used as a desiccant, adsorbent, and catalyst carrier, and has a wide range of applications in industrial fields such as wastewater and waste gas treatment.

(2) In our daily life, the common silicone is mainly silicone polymers, silicone polymers's chemical structure are mainly based on silicone-oxygen bonding to form the main chain, in the silicon atom connected to other groups. As its molecular chain is mainly composed of heteroatoms, the formation of the material has good flexibility and elasticity, properties, and processing methods are close to rubber, so it is also called silicone rubber.

![]()

Silicone rubber is often used as a substitute for rubber in the field of daily use. In the construction, electrical, medical food, and other industries (such as silicone sealants) have been widely used. In medical applications, silicone products will have food contact and even human-body contact performance.

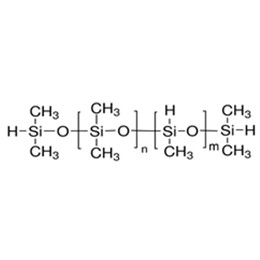

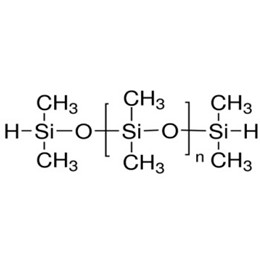

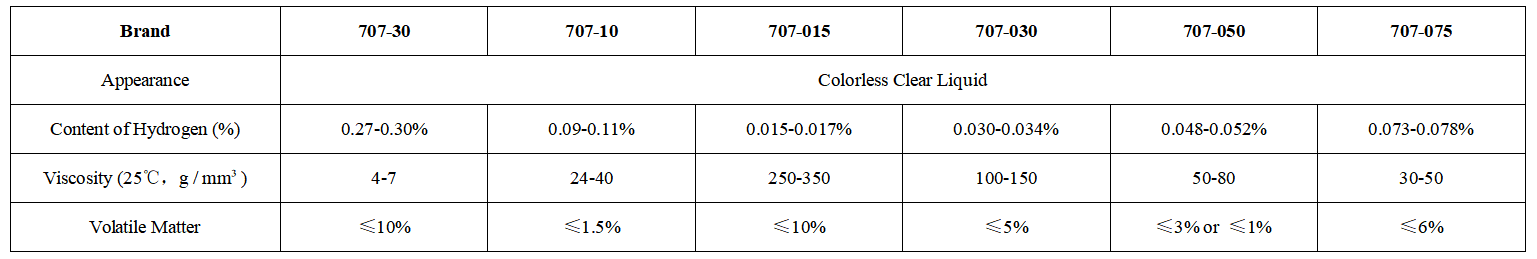

XJY-707 Hydride terminated Polydimethylsiloxane

As the molecular structure contains active hydrogen atoms, it can be synthesized through the silicon-hydrogen addition reaction of copolymer polymers and can be made into a series of active silicone oils. It can be used as a chain extender for liquid silicone rubber.

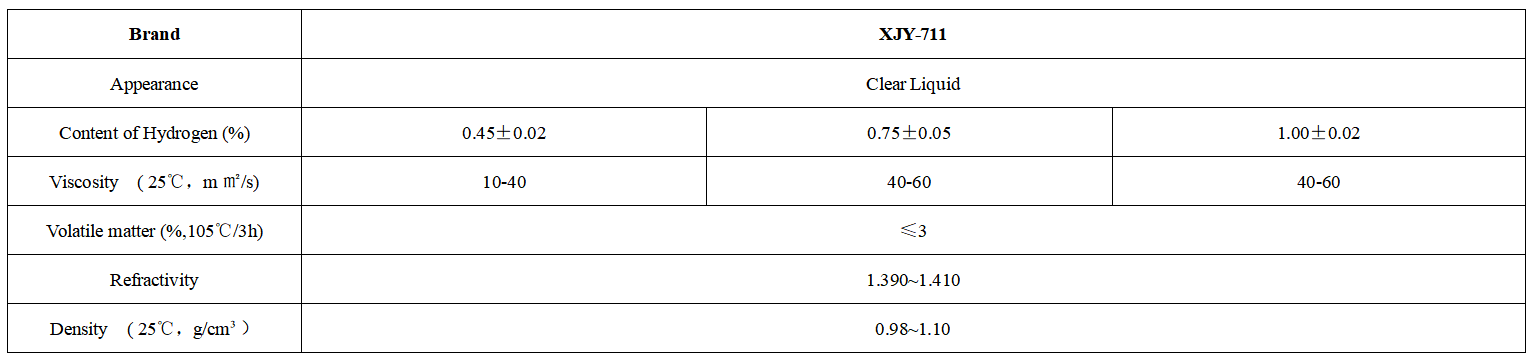

XJY-711 Hydrogen terminated Methylhydrogensiloxane Dimethylsiloxane copolymer

It is a colorless transparent liquid and can be used as a crosslinking agent of silicone rubbers.

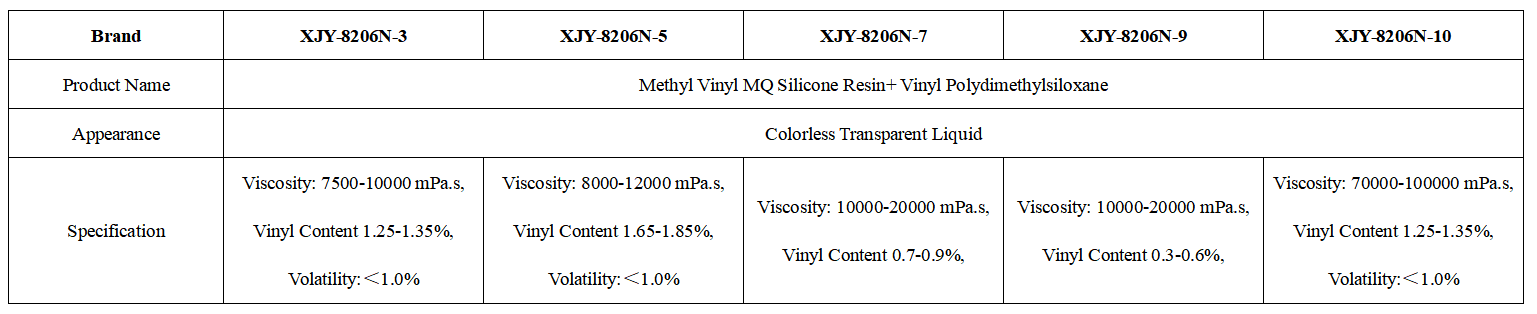

XJY-8206N VMQ Solution Series Methyl Vinyl MQ Silicone Resin + Vinyl Polydimethylsiloxane

They are colorless and transparent liquid silicone resins of methyl and vinyl composed of vinyl MQ silicone resin and vinyl silicone oil, which can be used for LSR liquid additive molding silicone rubber.

2. How safe is silicone?

2.1 Safety of silicone itself

For plastics, silicone, and other polymer materials, its safety is mainly reflected in several aspects.

(1) The first is the material itself, the material itself must be non-toxic, and physiologically inert even during the curing process.

(2) In addition, the material should also have chemical stability, and corrosion resistance, and not be easy to decompose, to prevent the production of harmful substances. A counter-example is polycarbonate. Currently, the most widely used polycarbonate for bisphenol A polycarbonate, the use part of the unreacted bisphenol A monomer may be migrated from the material, this substance will affect the children's metabolism as well as growth and development, so it is not suitable for children's products.

(3) Compared with ordinary plastics, the safety of silicone is obviously much higher. Silicone's molecular chain is mainly dominated by silicone-oxygen bonds, and the incidental groups are mainly methyl and other non-reactive groups. Therefore, the nature of silicone is very stable, not easy to decompose, there is no physiological activity, does not participate in the metabolism, and there is no toxic effect on the human body.

Biocompatibility testing of medical silicone tubing has shown that human tissue reacts very little to it, and even in the case of implantation, it does not cause foreign body reactions. Because of this, people feel comfortable allowing silicone to come into contact with the human body during medical procedures, even when it is used for blood delivery or implanted into the body. The physiological inertness of silicone makes it widely used in medical treatment.

![]()

2.2 Safety in use

In addition, we are concerned about the stability and weather resistance of the material in daily use. Especially when food-grade materials are used as containers, we often need to heat and sterilize them. So whether the material can withstand high temperatures, or whether it will produce harmful substances in the heating process is a very important indicator. It can be said that among polymer materials, silicone has excellent heat resistance. This is because the silicone main chain skeleton is composed of alternating silicon atoms and oxygen atoms, with similar properties to quartz and other inorganic materials, and can be regarded as a kind of semi-inorganic and semi-organic substance, so it inherits some of the inorganic properties of high-temperature resistance. Silicone can generally be used at 200 degrees Celsius, without worrying about the material decomposition or the production of harmful substances, and can be repeatedly heated. This is the reason why some containers such as frying spoons, milk bottles, and lunch boxes can now be manufactured using silicone.

![]()

3. What are the recommendations for using silicone?

Silicone is a safe and reliable polymer material. As silicone is more and more appearing in life.

(1) Selecting food-grade silicone

In daily life, people often judge the material by its appearance and odor, and even some misunderstandings. Because of some historical reasons, a considerable part of people think that silicone or plastic with color must be recycled materials, unhealthy and inferior products. But in fact, as daily necessities, it is very normal to have color for aesthetic or other functions. As ordinary people choose silicone supplies, the simplest thing is to see whether the material is food-grade.

The relevant standards for food-grade materials, specifically stipulate the raw materials that can be used in silicone products as well as the production process, which excludes a significant portion of silicone products with health risks. In addition, the food-grade material standards also emphasize the so-called migration test. In the migration test, the silica gel will be immersed in ethanol or other solvents, which requires that the color and turbidity of the immersion solution should not change after the test and that the various substances in the immersion solution, such as heavy metals and nitrosamines, should not exceed the specified values. Therefore, regardless of the color of the silicone, as long as it meets the standards of food-grade materials, there is no need to worry about the leaching of harmful substances.

![]()

(2) Pay attention to the environment

Any kind of material has its specific scope of use and environment, silicone is the same. In the process of use, first of all, we should pay attention to the use of temperature should not exceed the permissible value, to avoid burning silicone products. At the same time avoid the use of gasoline, strong acids, and other organic solvents or corrosive substances on its soaking. This will not only avoid the production of harmful substances but also enhance the service life of silicone, to ensure the safety of the process of use. At the same time the new production of silicone products, due to the molding and mixing process will undergo a short period of high-temperature treatment, there may be a slight odor, which is normal. It is recommended that after boiling and cleaning or natural ventilation for a few days, waiting for these odors to disappear, you can use it normally.

Relative to ordinary polymer materials, silicone's safety is better. In daily life, as long as attention is paid to the selection of quality-assured food-grade materials while paying attention to the use of the environment, the safety of silicone can be guaranteed.

4. How to make silicone perform better?

Silicone has temperature resistance, weather resistance, electrical insulation properties, physiological inertia and chemical properties, and low surface tension these are excellent properties, so it has a very wide range of applications. It is not only used as a special material in aviation, cutting-edge technology, and military technology sector, but also used in all sectors of the national economy, its application has been expanded to: construction (such as silicone sealant), electrical components and electronic, textile, automotive, machinery, leather and paper, chemical and light industry, metal and paint, medicine and health care, and so on. How to improve the competitiveness of products?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D to produce silicone products in the silicone industry and more than 15 related patents and technical support. Our silicone raw material products can meet the needs of the silicone field and support the provision of diversified customized solutions.