Silicone defoamer is more important in the chemical industry, coatings, textiles, and other industries, and in the industrial processes used, silicone resin defoamer should pay attention to the method precautions, What are the precautions for silicone defoamer?

- What is an antifoam agent?

- What are the advantages of silicone defoamers?

- What are the classifications of silicone defoamers?

- How to apply silicone defoamer in the production process?

- How to store silicone Howdefoamer?

- What is the dilution method for silicone defoamer?

- How to make silicone defoamer perform better?

1. What is an antifoam agent?

An antifoam agent is a chemical substance used to suppress or eliminate surface foam generated during the manufacturing process. These foams are formed by the dispersion system of a gas in a liquid, in which the gas as a dispersed phase is separated by a continuous liquid medium. Since foam is a thermodynamically unstable system whose elimination significantly reduces the free energy of the system, defoamers are required to control it.

The mechanism of the defoamer is that it can reduce the surface tension in the foam system, thus contributing to the thinning of the liquid film discharge. When an antifoam droplet enters the foam film, the film rapidly thins and ruptures because the surface foam tension of the contacting part of the film decreases while the surrounding surface tension remains constant. This process will extend to the antifoam agent droplets across the liquid film, and due to the film contraction and fracture, ultimately realize the foam rupture and elimination.

2. What are the advantages of silicone defoamers?

Silicone defoamer is one of the many defoamers, due to its excellent performance and wide range of applications, it has been widely recognized as the ideal and most promising defoamer. It is even more effective when used in combination with hydrophobically modified silica particles, thanks to the interfacial activity of the solid particles, the so-called Pickering phenomenon, which makes it easier for defoamer droplets to enter the bubble film. The advantages of silicone defoamers include their excellent stability, high efficiency to foam control, and environmental friendliness.

(1) Wide range of applications

Due to the unique chemical structure of silicone, it is neither soluble in water or liquids containing polar groups, nor compatible with hydrocarbons or organic substances containing hydrocarbon groups. This makes the food-grade silicone defoamer suitable for both aqueous system defoaming, but also applicable to oil systems, so that in many areas can play its foam control role.

(2) Low surface tension

The surface tension of medium viscosity silicone oil is about 20 to 21mN/m, much lower than water (72mN/m) and other common liquids. This characteristic makes the silicone defoamer can more effectively reduce the surface tension of the foam system.

(3) Strong defoaming ability

Silicone defoamer can not only quickly break the existing foam, but also effectively inhibit the foam generated again. The dosage is very small, only one-millionth of the weight of the foam system can produce a significant defoaming effect. The common dosage range is (1~100)×10-6 (i.e. 1~100ppm).

3. What are the classifications of silicone defoamer?

According to the physical form, silicone antifoam agents can be divided into pure silicone oil, silicone oil solution, silicone cream and silicone oil emulsion, and silicone resin five types. Among them, pure silicone oil-type defoamers often use small surface tension polydimethylsiloxane, suitable for lubricating oil and oil extraction, oil refining or cracking hydrocarbon heavy oil, and other processes of defoaming.

(1) Pure Silicone oil

Low-viscosity methyl silicone oil easily forms small droplets dispersed in the foam to play the role of antifoam, but the solubility of the large results in a lack of continuity; high-viscosity silicone oil, on the contrary, solubility is small but long continuity. Mixing the two can realize both defoaming and foam inhibition. In addition, polymethylphenylsiloxane is suitable for defoaming ethanol, while polysiloxanes containing ethyl or propyl groups are suitable for defoaming coatings and inks.

Although the surface tension of fluorinated silicone oils is slightly higher than that of methyl silicone oils, their solubility in hydrocarbons is lower. As a result, fluorinated silicone fluids excel in defoaming non-aqueous systems. On the other hand, the surface tension of polydimethylsiloxane and its interfacial tension with water are also key factors affecting the antifoaming effect.

The use of pure silicone oil as an antifoam agent, although its persistence is good, due to the existence of high interfacial tension with water, resulting in silicone oil is difficult to disperse in the foaming medium, which reduces the antifoaming efficiency. Pure silicone oil defoamer is more suitable for non-aqueous systems, in which the presence of dispersants and emulsifiers is not allowed. When used, the coating method is usually adopted, i.e., the silicone oil is directly applied to the system's charging port, nozzle port, and container side wall, or hung on the velvet and mesh structure, in order to expand the contact area with the foaming system, so as to achieve the purpose of eliminating foam.

Polydimethylsiloxanes with terminal hydroxyl groups can improve the dispersion of silicone oils in water, which in turn enhances their defoaming effect. For example, branched polydimethylsiloxanes with terminal hydroxyl groups have significantly improved foam inhibition properties in water compared to dimethicones. However, the siloxane bond is easily attacked by ionic reagents, which to a certain extent limits its application in strong bases, strong acids, and other systems.

(2) Solution-type silicone defoamer

In order to improve the dispersion of silicone oil in some foaming systems, you can use solution-type silicone antifoam agents. This antifoam agent is the silicone oil dissolved in a solvent or a mixture of solvents prepared. Commonly used solvents include gasoline, kerosene, cyclohexane, toluene, and xylene. The use of silicone oil solution as an antifoam agent can be based on the characteristics and requirements of the foaming system, the appropriate viscosity of the silicone oil and solvent for preparation, and then directly added to the foaming system for defoaming.

(3) Silicone cream-type defoamer

In addition, silicone paste-type defoamer is also a common choice. It is made by kneading silicone oil with high fineness powders such as silica, alumina or carbon black in kneading and mixing machines to produce a viscous paste. The addition of solid particles further improves the defoaming efficiency. Silicon paste-type defoamers can be used either by pre-coating them on the system charge ports, container sides, or mesh or by dissolving them in a suitable solvent and adding them directly to the foaming solution for defoaming. Generally speaking, the latter is more effective than the former.

The preparation process for an emulsion-type silicone antifoam agent, usually an oil-in-water emulsion, has been described in detail in the previous section. This defoamer is characterized by easy dispersion in aqueous systems, so it is very suitable for defoaming aqueous systems. Although ionic emulsifiers have a better emulsification effect, they are more commonly used in industrial production as they tend to trigger foaming, so non-ionic emulsifiers are more often used. Studies have shown that the smaller the particle size of a silicone emulsion, the better its defoaming ability. However, too small particles will require more emulsifiers and also increase the viscosity of the emulsion, thus reducing the defoaming performance. Therefore, it is appropriate to choose the emulsion particle size of 1-10μm.

(4) Emulsion-type defoamer

Silicone oil emulsion-type defoamer is the most widely used silicone defoamer, with the largest amount. When used, just add the emulsion directly into the aqueous phase foaming system, and you can get the excellent defoaming effect. In order to ensure the defoaming effect and the accuracy of measurement, it is usually not recommended to use the silicone oil emulsion with a concentration of more than 10%; instead, it should be diluted to less than 10% with cool water or foaming liquid. Care should be taken to avoid dilution with liquids that are too hot or too cold to prevent breakage of the emulsion. The diluted emulsion should be used up within a short period of time to maintain its stability. If needed, thickeners can be added to further improve the stability of the emulsion.

During operation, depending on the system, the silicone oil emulsion can be added at once before the system is running, or it can be replenished in batches. For continuous operation processes, silicone oil emulsions should be added continuously or intermittently at appropriate locations in the system.

In addition, the temperature, alkalinity, and acidity of the foaming system need to be considered when using emulsion-type defoamers, as silicone oil emulsions outside their range of use may break the emulsion prematurely, resulting in reduced or ineffective defoaming. Generally, the dosage of emulsion is (10 to 100) x 10-6 (by silicone oil) of the weight of the foaming liquid. Although the dosage may vary in special cases, the optimum dosage usually needs to be determined experimentally. It should be noted that methyl silicone oil is non-toxic and non-hazardous and is therefore permitted to be used as a food additive. However, the emulsifiers used are limited to five specific varieties such as glycerol fatty acid esters and sorbitan fatty acid esters.

Methyl silicone oil is usually used in solution or emulsion form, but after being added to the foaming fluid and stirred, circulated, or heated, the dispersed silicone oil gradually agglomerates, making it difficult for the antifoam agent to remain in contact with the foam, and the foam is regenerated. In order to maintain the longevity of the antifoam agent, it is critical to maintain its initial state of dispersion. For this reason, the introduction of hydrophilic groups in the polydimethylsiloxane chain, such as polyether, can effectively improve its emulsification performance, and even achieve self-emulsification. In recent years, the development trend of silicone antifoam agents is to silicone-polyether block copolymerization or graft copolymerization direction. This type of antifoam agent combines the advantages of silicone and polyether, significantly improving the defoaming ability. At the same time, through the silicone molecular chain in the block or graft hydrophilic polyethylene oxide chain or ethylene oxide - propylene oxide copolymerization chain, to achieve the self-emulsifying properties. This means this kind of defoamer can be evenly dispersed in the foaming medium, with a large spreading coefficient and high defoaming effect, which becomes a new kind of high-efficiency defoamer. Particularly suitable for the use of general silicone oil emulsion or general silicone oil emulsion is difficult to work occasions.

(5) Silicone resin

Silicone resin defoamer is widely used in many fields, including petroleum, chemical, electroplating, printing and dyeing, pulp/paper, sugar, fermentation, medicine, medical, food, and water and wastewater treatment. As an additive to the production process, it can improve the efficiency of processes such as filtration, dewatering, and washing, improve the discharge of wastewater containing suspended solids, increase the storage capacity of containers, and enhance the effectiveness of distillation or evaporation equipment.

In aqueous defoamers, silicone is usually used in conjunction with other ingredients such as surfactants and emulsifiers. It can diffuse rapidly in aqueous systems, lowering surface tension and eliminating foam. At the same time, the good film-forming property of silicone resin can form a protective film on the surface of the liquid, preventing the foam from arising again.

Silicone resin can be used as one of the main components in oil-based defoamers. Due to the low surface tension of the oily system, the effect of silicone resin is more obvious. It can quickly diffuse to the surface of the liquid, destabilize the foam, and eliminate the foam.

An emulsion-type defoamer is an emulsion formed by dispersing an antifoam agent in water. Silicone resin can play the role of stabilizing the emulsion and improving the defoaming effect in the emulsion-type defoamer. It can interact with other components in the emulsion to form a stable system, and at the same time form a protective film on the surface of the liquid to prevent foam generation.

4. How to apply silicone defoamer in the production process?

(1) Choose the right silicone defoamer:

According to the required application and field, we should choose the suitable silicone defoamer. Different products have different characteristics and uses, and they can be selected according to production needs and performance requirements. Different from mineral oil, silicone resin defoamers have very low surface tension, which is slow to frost and high temperatures, and are easily crushed. If the defoamer has been frozen must be vigilant to frost, and test before manipulation.

(2) Determine the amount of use:

According to the actual needs and relevant process parameters to determine the amount of defoamer. In general, the initial use of the amount can be estimated based on experience, and then gradually adjusted according to the actual results.

(3) Pre-dilution:

The silicone defoamer and water or other solvents for pre-dilution. In the process of dilution, it should be stirred constantly to ensure that the defoamer is fully dissolved. Because the emulsion is not uniform will be easy to produce a layered environment, affecting the antifoam agent manipulation results, it is needed to avoid frequent emptying.

(4) Join the production process:

According to the process needs, at the appropriate time, a pre-diluted silicone defoamer was added to the production process. According to the actual need to choose to join directly or to spray, slide into the way to join.

(5) Pay attention to the use of skills:

In the use of the process, we must pay attention to the timely mixing, so that the antifoam agents are distributed. According to the actual situation, the stirring speed can be adjusted to ensure the uniform dispersion of the defoamer.

(6) Observe the effect:

After adding the antifoam agent, it is needed to closely observe the defoaming effect. If necessary, the amount of defoamer can be adjusted to achieve the desired defoaming effect.

(7) Pay attention to safety:

Silicone-based defoamers should pay attention to protective measures during use, and avoid contact with eyes, skin, and respiratory tract. If contacted inadvertently, it should be rinsed with water immediately, and if there is any serious discomfort, medical attention should be sought as soon as possible.

(8) Storage and maintenance:

After use, keep the silicone defoamer in a sealed place, and avoid direct sunlight and high-temperature environments. If precipitation or deterioration occurs in the make, it is recommended to replace it with a new antifoam agent.

To summarize, silicone antifoam agent is a very practical chemical additive, can help to reduce the production process foam generation, and improve production efficiency. Simple to use, but in the use of the process need to pay attention to the safety and effectiveness of the observation, to ensure the quality of the product and the smooth progress of production.

5. How to store silicone defoamer?

Silicone defoamer is a common type of defoamer, its correct storage and use is the key to ensuring product quality and safety. Prolonged violent oscillation or strong shear (such as manipulation of mechanical pumps, homogenizers, etc.) or stirring will break and destroy the stability of the defoamer, so pay attention to the storage of silicone resin defoamer. The following are the correct storage methods and precautions for silicone defoamer:

(1) Storage environment: Silicone defoamer should be stored in a dry, cool, and well-ventilated storage room. Avoid direct sunlight and high-temperature environments to prevent product quality damage.

(2) Packaging containers: Silicone defoamers are usually supplied in sealed packaging containers (e.g., plastic bottles, buckets, or drums). When storing, it is needed to make sure the containers are intact and remain sealed to prevent moisture and impurities from entering.

(3) Avoid mixing: Silicone defoamers should be kept stored separately from other chemicals to prevent mutual contamination or chemical reactions. It is needed to clear labeling and categorization in the storage area is recommended.

(4) Prevent freezing: Some silicone defoamers may freeze or solidify at low temperatures. If the storage environment is expected to be exposed to low temperatures, measures should be taken to prevent icing and to return it to a liquid state if needed.

(5) Caution about sources of ignition: Since silicone defoamers are usually flammable substances, storage areas should be kept away from open flames, high temperatures, and sources of ignition. It is needed to ensure that the storage area meets fire safety requirements and complies with relevant fire regulations.

(6) Compliance: When storing and using silicone defoamers, follow local regulations and safety practices. It is needed to know the product's Safety Data Sheet (SDS) and follow the recommended safe handling procedures.

(7) Periodic Inspection: Periodically inspect the storage conditions and packaging containers of the silicone defoamer to ensure that there are no leaks, damage, or deterioration. If any abnormality is found, appropriate measures should be taken promptly, such as replacing the container or consulting the supplier.

In conclusion, proper storage methods and precautions can ensure the stability and safety of silicone defoamers. Following storage conditions and safe operating procedures will help protect product quality, reduce safety risks, and extend the effective service life of the defoamer. If there are any questions or special circumstances, it is recommended to consult the supplier of the organosilicon defoamer or professional advice.

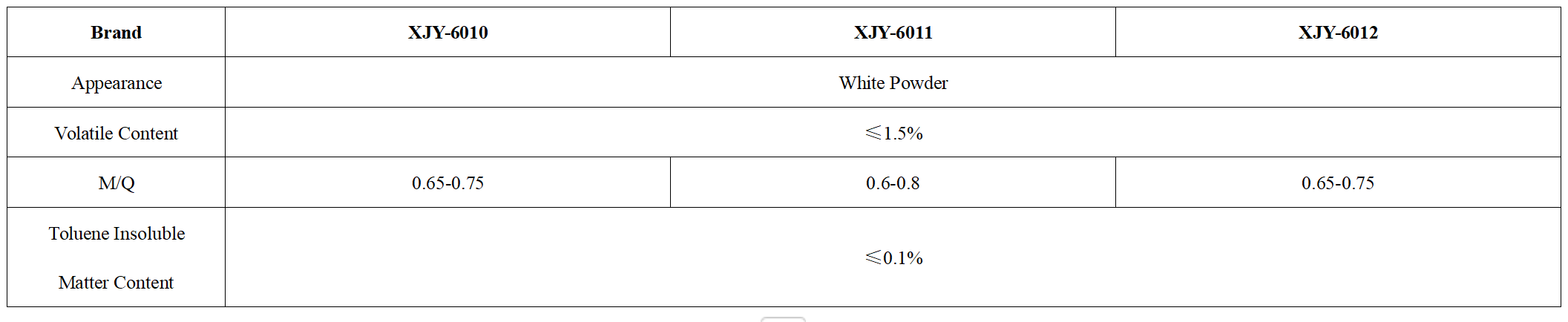

XJY-6010/XJY-6011/XJY-6012 Methyl MQ Silicone Resin for defoamer is a solid powder resin. This resin provides good antifoaming, hydrophobic, and water-repellent properties.

6. What is the dilution method for silicone defoamer?

Silicone resin defoamer can be diluted at the moment of use, but the stability of the defoamer at the same time dilution will be sharply reduced as a result, such as the occurrence of delamination, so it is recommended to try to manipulate the thickening agent for dilution.

So silicone defoamer is not recommended to use water to open thinning, because if you use water to open thinning, it will break the viscosity system of the defoamer itself, if the control is not good, it will produce delamination, or even emulsion-breaking situation, such as this defoamer performance will be greatly reduced.

Silicone resin defoamer must pay attention to adjust the PH value of the system because the PH value will affect the true system of acidity and alkalinity, and later manipulation of the results, it is recommended that we use PH test paper to detect the acidity and alkalinity; then it is necessary to correct regularly if long time not corrected, it will lead to the measurement of the effectiveness of the inaccuracy and the measurement of the time to stir not evenly. If it is not even, the effect is not the same in different locations, and it will also be affected by the temperature.

7. How to make silicone defoamer perform better?

Silicone defoamer has been widely used in many aqueous systems such as chemical, paper, coating, food, textile, pharmaceutical, and so on (such as carpet extractors) with its wide performances, excellent defoaming performance, good stability, low surface tension, and environmental protection, and many other advantages. How can the competitiveness of the product be improved?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry as well as more than 15 related patents and technical support. Our silicone raw material products can meet the needs of the defoamer field and support the provision of diversified customized solutions.