The potting adhesive market continues to expand, thanks to the rapid development of electronics, automotive, optoelectronics, and other industries. In the future, with technological innovation and the application of new materials, potting compound products will be more diversified to meet the needs of different fields. At the same time, the improvement of environmental awareness will also promote the potting compound market to the green, environmental protection direction. What are the characteristics of silicone potting compounds?

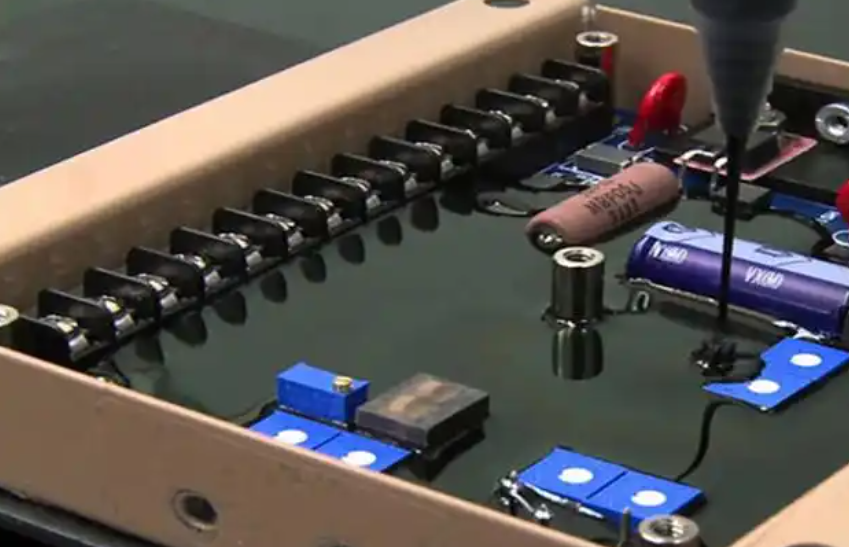

The silicone potting compound is often used for thermal conductivity, heat dissipation, sealing, and anti-vibration materials used in electronic components. Thermally conductive potting refers to all components on the PCB circuit board for potting, so that the heat generated by the components of the PCB board through the thermally conductive potting adhesive can be quickly diffused to the external thermal conductivity of the substrate (aluminum or thermal conductivity of ceramics, etc.), and finally directly to the external environment.

There are four aspects to introducing silicone potting compounds:

- What are the applications of silicone potting compounds?

- What are the problems of silicone potting adhesive?

- What is the difference between silicone potting compound and epoxy potting?

- How to make silicone potting compounds perform better?

1. What are the applications of silicone potting compounds?

Thermally conductive potting compound is mostly a two-component set of materials, consisting of A and B parts. Before curing has good fluidity, room temperature curing linear shrinkage stress is very low, after curing has excellent electrical insulation properties, excellent aging resistance, and hydrophobic moisture sealing properties, at the same time has excellent heat transfer, non-corrosive to a variety of substrates. At present, it has been widely used in the thermal conductive potting of LED lamps and the thermal conductive insulation sealing of other electronic components.

As LED products have been widely used in outdoor lighting, such as tunnel lights, street lights, etc., these products will be used in the process of contact with water vapor, acid rain, and other harsh conditions, the requirements of PCB circuit boards and electronic components there are insulated, moisture-proof, leakage-proof, shock-proof, dust-proof, corrosion-resistant, anti-aging and other requirements. Circuit board surface waterproof coating is mainly used to protect the circuit board and its related equipment from the erosion of the bad environment, so as to improve and extend their service life, to ensure the use of safety and reliability.

XJY-8205 Methyl Vinyl VMQ Silicone Resin is a solid powder resin, that can be used as reinforcing material in liquid silicone rubber. Adding silicone MQ resin to the potting compound can enhance its high and low-temperature resistance, prolong the service life, apply to various materials, and be applied to various electronic components in power supplies.

2. What are the problems of silicone potting adhesive?

(1) Applying glue paste outflow problems

Reason analysis: usually hand-pressure gluing gun is by applying pressure to the gun, “active axis” to push forward so that the glue is squeezed out to complete the construction process, if you choose a thin bottle series of products, then in the gluing process the bottle will be under pressure to produce a certain amount of expansion, such as in the use of the process if you only stop the pressure on the glue gun, then the thin bottle from the original expansion and contraction recovery. Thin bottle by the original expansion contraction recovery, coupled with the glue gun's “active axis” of inertia and forward thrust, even if the glue gun stops applying pressure, the glue nozzle of the glue will continue to flow out a little bit, which will bring inconvenience to the constructor and will affect the quality of construction.

Solution: In use, because the construction needs to stop gluing, should immediately use your hand to quickly press the iron part of the glue gun spring (usually we use the glue gun that hand thumb lightly press can), so that the “active axis” forward inertia reduced to zero, because the bottom cover stops being pressurized, the glue bottle expansion and contraction restoration of the pressure will make the bottom cover backward slightly, so that the bottom cover to stop being pressurized, the glue bottle expansion and contraction restoration of pressure will make the bottom cover backward a little bit, so that the construction quality will be affected by the inconvenience. The bottom cover is backward slightly, which will greatly reduce the probability of glue outflow.

(2) Adhesive curing process speed is slow

Reason analysis: the curing speed of condensed silicone depends on the amount of catalyst, and the temperature relationship and curing time are not great.

Solution: Add a more appropriate curing agent, but not too much.

3. What is the difference between silicone potting compound and epoxy potting?

Potting compound is a kind of glue used for the encapsulation and protection of electronic components, which can prevent the components from being affected by humidity, dust, vibration, corrosion, and other environmental factors, and improve the reliability and stability of the components.

Potting compounds according to their main components can be divided into epoxy potting compounds and silicone potting compounds, they have certain differences in performance, use, curing method, and so on.

(1) the main components

Epoxy potting adhesive: a two-component glue composed of epoxy resin and curing agent, in which the epoxy resin is a polymer compound containing two or more epoxy groups, with good adhesion, heat resistance, chemical resistance, and electrical insulation. A curing agent is a chemical reaction with the epoxy resin, so that the forms of three-dimensional mesh structure of the compound, common curing agents are amines, anhydrides, polyamides, and so on.

Silicone potting adhesive: two-component adhesive composed of silicone resin and curing agent, in which the silicone resin is a polymer compound containing silicone-oxygen bonds, with excellent resistance to high and low temperatures, weathering, hydrophobicity, and anti-aging properties. A curing agent is a kind of chemical reaction with the silicone resin, so that the formation of a three-dimensional mesh structure of the compound, the common curing agent has a silane coupling agent, peroxide, platinum catalyst, and so on.

(2) Performance characteristics

Cured epoxy potting compound:

With high hardness and strength, it can effectively protect electronic components from external shock and vibration. At the same time, it also has good adhesion and electrical insulation, can form a strong bond with most materials, and prevents leakage and interference of electrical signals.

Cured silicone potting compound:

With low hardness and elasticity, it can effectively buffer the stress and strain on electronic components. At the same time, it also has excellent resistance to high and low temperatures and hydrophobicity, which can be in the temperature range of -60 ℃ ~ 200 ℃ to maintain stable performance, and prevent the intrusion of water and moisture.

(3) Uses

Epoxy potting adhesive application:

Encapsulation and bonding of electronic products, such as LED driver power supply, transformers, sensors, controllers, and so on. Used for: general electronic products, for electronic products with special requirements, such as high temperature, waterproof, anti-corrosion, etc., you need to choose a special potting compound.

Silicone potting adhesive application:

Packaging and bonding of high-end electronic products, such as automotive electronics, aerospace, medical equipment, new energy, etc.. Higher performance requirements of electronic products, such as high and low-temperature resistance, waterproof, anti-corrosion, anti-aging, and so on.

(4) Curing method

Epoxy potting compound curing method mainly has room temperature cures and heating curing two kinds.

Room temperature curing: epoxy potting compounds generally need about 24 hours to fully cured; heating curing: epoxy potting compounds can be in a few minutes to a few hours to complete the curing, the specific time depends on the curing temperature and the type of curing agent.

Generally speaking, room temperature curing epoxy potting compound is suitable for small batch production and manual operation, while heat curing epoxy potting compound is suitable for mass production and automated equipment.

Organic potting compound curing methods are mainly room temperature curing, heat curing, and moisture curing three.

Room temperature curing: silicone potting compounds generally need about 24 hours to be fully cured; heating curing: silicone potting compounds can take a few minutes to a few hours to complete the curing; the specific time depends on the curing temperature and the type of curing agent.

Moisture curing: Silicone potting compound needs to absorb moisture in the air before the curing reaction can occur;

Therefore, it is necessary to expose the adhesive to air for a period of time before use or add a certain amount of moisture to the adhesive. Moisture-curing silicone potting compound has the advantages of fast curing speed, no bubbles, and no shrinkage, but there are also shortcomings such as incomplete curing, moisture, and so on.

(5) Advantages and disadvantages

Epoxy potting compound: Advantages: fast curing speed, high bonding strength, good electrical insulation properties, inexpensive, and so on;

Disadvantages: curing shrinkage, poor temperature resistance, easy to embrittle.

Silicone potting compound: Advantages: curing shrinkage is small, good temperature resistance, good flexibility, good aging resistance, etc.; Disadvantages: slow curing speed, low bonding strength, higher prices.

According to the use of electronic products environment: If electronic products work in harsh environments such as high temperature, low temperature, humidity, corrosion, etc., you need to choose a silicone potting compound.

According to the performance requirements of electronic products: If the electronic products the potting gel elasticity, flexibility, aging resistance, and other high requirements, you need to use silicone potting gel.

4. How to make silicone potting compounds perform better?

Silicone potting compound in electronic components application of the following advantages: elastic, can withstand drastic temperature changes, excellent weather resistance, strong adhesive force, electrical properties such as superior soft elastic coating materials, can a good release of pressure, high temperature 200 ℃, easy to repair. How to improve the competitiveness of your products?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry as well as more than 15 related patents and technical support. Our silicone raw material products can meet the needs of the potting compound field and support the provision of diversified customized solutions. Please contact us to know the lead times.