When it comes to food safety, most people's attention is still stuck on the food itself, that “zero additives, natural” food is safe, ignoring the food packaging with food “close contact”. In the injection mold production process, the role of the mold release agent is to make the mold plastic products can be successfully separated from the mold, to avoid damage to the mold and products.

Food-specific silicone mold release agent is a special mold release agent, used in the production of food processing. Its main function is to release the mold of food products so that the food products can be detached from the mold more easily without being broken or deformed. The role of food-grade silicone mold release agent is even more important because it can ensure that the production of food packaging materials in line with hygiene standards, will not have an impact on human health.

The following six aspects of the silicone mold release agent:

- What is mold release?

- How to choose food-grade release agent?

- How to use silicone mold release agents?

- How to compare silicone mold release agents with traditional mold release agents?

- What are the precautions for silicone mold release agents?

- How to make silicone mold release agent perform better?

1. What is mold release?

Specifically, the mold release pin is a pinhole on the template to draw the product out of the cavity, and through the positioning pin to ensure the positioning of the product. The release template is an openable and closeable plate-like structure on the mold, which is generally connected to the moving template of the injection molding machine. When the injection molding machine opens the template, the stripper plate separates from it, thus pushing out the product.

An ejector device can better assist in demolding. It ejects the product from the stripper plate by the action of the ejector rod to avoid the difficulty of demolding or the deformation of the product due to the adhesion of the product.

In addition, the surface treatment of the mold will also affect the multiple-part release effect. Common surface treatment has mirror polishing, electroplating hard chrome sandblasting, etc., in order to improve the mold finish and smoothness, and reduce the friction between the product and the mold, so that the product is easier to take off.

The injection mold demolding principle is through the mold structure design, demolding system, as well as mold surface treatment, and other factors of the total comprehensive role, to achieve the injection molded products from the mold to ensure that the injection molding process is carried out smoothly.

2. How to choose a food-grade mold release agent?

(1) Understand the composition of the product

When choosing a food-grade mold release agent, you first need to understand the composition and nature of the product to ensure that it meets the national health standards and relevant regulatory requirements. At the same time, it is necessary to pay attention to the environmental performance of the product and choose the product that meets the environmental requirements.

(2) Consider the food contact area

In the selection of a food-grade mold release agent, you need to consider the food contact area and type and select the appropriate product. For example, for large-area food contact products, choose colorless and transparent release agents that do not contain harmful substances.

(3) Focus on brand reputation

When choosing a food-grade mold release agent, you can choose some well-known brands, guaranteed brands are more likely to gain the trust of consumers.

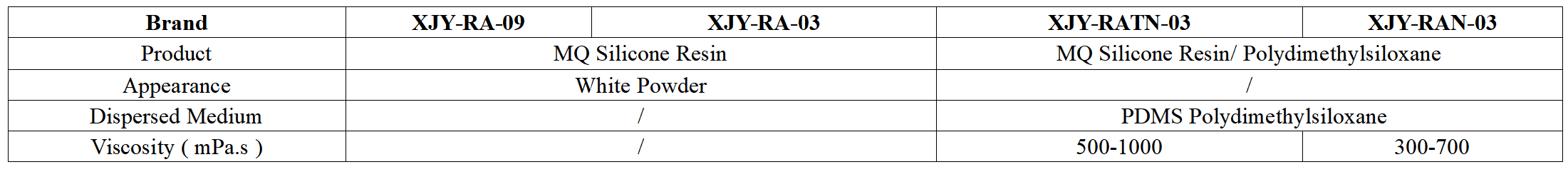

XJY-RA/XJY-RAN MQ Silicone Resin is a polymerization of tetrafunctional silicon (Q) and monofunctional methyl silicon (M) in the field of silicone high-temperature, semi-permanent and permanent mold release agents. Silicone mold release agents are specially formulated to be resistant to high and low temperatures, have low surface tension, and are non-corrosive to metals. Adding silicone resin (5-15%) can significantly improve the strength of the silicone oil film, in the field of high-temperature casting and other areas of good application.

3. How to use silicone mold release agents?

The injection mold release principle refers to the injection molding process, the plastic products have been injection molded from the mold process. Injection mold release mainly depends on the structural design of the mold, material selection mold surface treatment, and other factors to achieve.

First, in the injection molding process, the plastic melts and enters the mold cavity through the injection nozzle to fill the entire cavity. When the plastic filling is completed, further pressure is applied so that the plastic completely fills the cavity and forms the shape of the product.

When the plastic is in the mold then, during the injection molding process, the mold needs to withstand the high pressure from the injection system of the injection molding machine.

After cooling and hardening in the cavity, the product needs to be removed from the mold. At this point, the demolding system plays a key role.

The demolding system mainly consists of demolding pins, demolding plates, ejectors, and ejector rods. They work in tandem to push the product out of the mold at the end of injection molding.

Before applying the silicone mold release agent, the mold needs to be cleaned and dried. Then, spray the silicone mold release agent evenly at a distance of about 15-20 cm from the surface of the mold, taking care not to let the silicone mold release agent come into direct contact with food.

(1) Use according to instructions

When using a food-grade mold release agent, you need to use it in strict accordance with the instructions. Do not arbitrarily change the method of use or the amount of use, so as not to affect the quality and safety of the products.

(2) Control the usage amount

When using a food-grade mold release agent, pay attention to the control of the amount used. Using too much mold release agent will cause the surface of the product to be greasy, affecting the appearance and quality, as well as wasting resources.

(3) Regular replacement

When using a food-grade mold release agent, it should be replaced regularly to ensure its effectiveness and safety, easy release. Expired mold release agents may cause contamination and influence the products.

4. How to compare silicone mold release agents with traditional mold release agents?

In the production process of plastic packaging materials, mold release is an important part of ensuring product quality. Improperly selected release agents may cause toxic and harmful residues, which can become “invisible killers” that are harmful to human health.

Compared with ordinary release agents, silicone mold release agents can give full play to the physical properties of silicone, in order to ensure the release performance without producing any harmful substances, safer and more environmentally friendly. The details are as follows:

Silicone mold release agent

(1) Stable components, safe and harmless

(2) Efficient mold release, low additive amount

(3) Good lubrication effect, can improve Processing efficiency, reduce scrap rate

(5) Non-flammable, high temperature resistance

(6) Oxidation resistance and not easy to scale

(7) Non-volatile, to avoid producing thick coating and smoke during curing process work.

Common mold release agents

(1) May contain harmful substances

(2) Easy to stick to the film, not easy to remove the mold

(3) Easy to stick to the dust, the subsequent stacking process will also produce a strange odor

(4) Unclear mold release handwriting

(5) Easy to scale on the mold

(6) Unable to pass the brand requirements and export testing

5. What are the precautions for silicone mold release agents?

(1) Food-specific mold release agents can only be used for food processing, and can not be used in other industries in the production process.

(2) Be careful not to leave too much mold release agent when wiping the mold, so as not to affect the quality of food.

(3) In the process of use, if there is a strange odor or other abnormalities, you should stop using it immediately.

(4) Do not spray the mold release agent on untreated food surfaces or other items.

(5) The mold release agent should be stored in a dry, cool place, away from fire and direct sunlight.

6. How to make silicone mold release agent perform better?

Non-migratory silicone mold release agents based on silicone resin are stable and non-migratory, showing a long service life. Part of the silicone mold release agent with water as the medium, environmental protection and easy to deal with, after coating the water evaporation to form a release film, suitable for the environmental requirements of the occasion. How to improve the competitiveness of your products?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry and more than 15 related patents and technical support. Our silicone raw material products can meet the needs of the release field and support the provision of diversified customized solutions.