Vinyl MQ resins have the advantages of high transparency and very low volatile matter. It also has excellent properties in terms of high-temperature resistance, moisture resistance, water resistance, and insulation. What are the applications of vinyl silicone resins?

Vinyl MQ resin has a wide range of uses, it can be used as the base material of LED encapsulation adhesive, and also be used as the reinforcing material of liquid silicone rubber, pressure-sensitive adhesive, highly transparent silicone gel, and liquid silicone rubber, hot vulcanized silicone rubber mixing adhesive, and the reinforcing material of shell-less potting adhesive of semiconductor components, the reinforced silicone rubber has no color and transparency, and the mechanical strength is high.

Here are five aspects of introducing vinyl silicone resin:

- What is vinyl silicone resin?

- What are the product characteristics of vinyl silicone resin?

- How to synthesize vinyl silicone resin?

- What are the applications of VMQ?

- How to improve the performance of silicone products?

1. What is vinyl silicone resin?

Vinyl silicone resin is a new type of silicone polymer material with a three-dimensional (non-linear) structure composed of molecules with the Si-O bond as the skeleton, including free radical coupling between vinyl and methyl groups. Thanks to its long-chain globular molecular structure, it is endowed with good mechanical properties and excellent properties such as resistance to high and low temperatures, electrical insulation, moisture-proofing, and water-proofing.

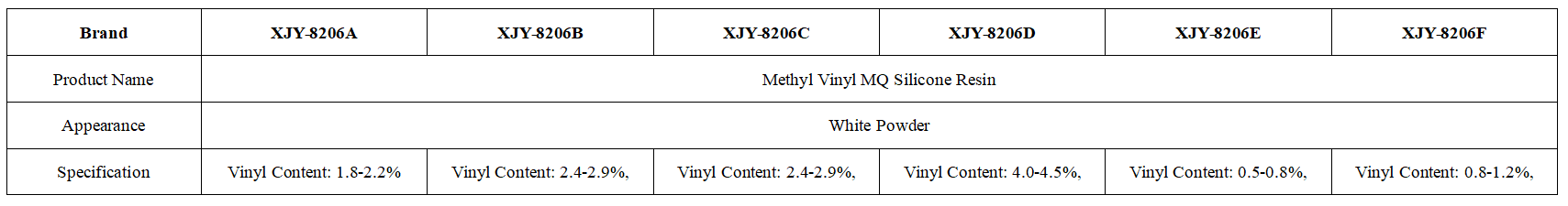

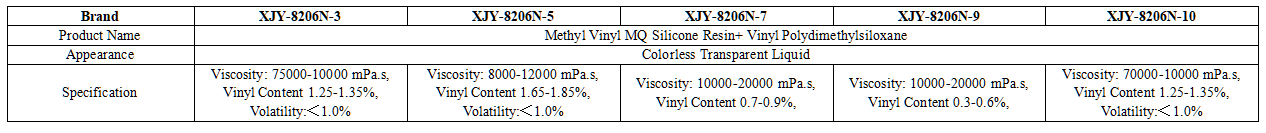

XJY-8206 Methyl Vinyl VMQ Silicone Resin a cross-linked semi-inorganic blend polymers with a highly cross-linked structure. Methyl Vinyl VMQ Silicone Resin is a very unique class of organo-silicon polymer polysiloxane compounds with a double-layer structure of compact globular material.

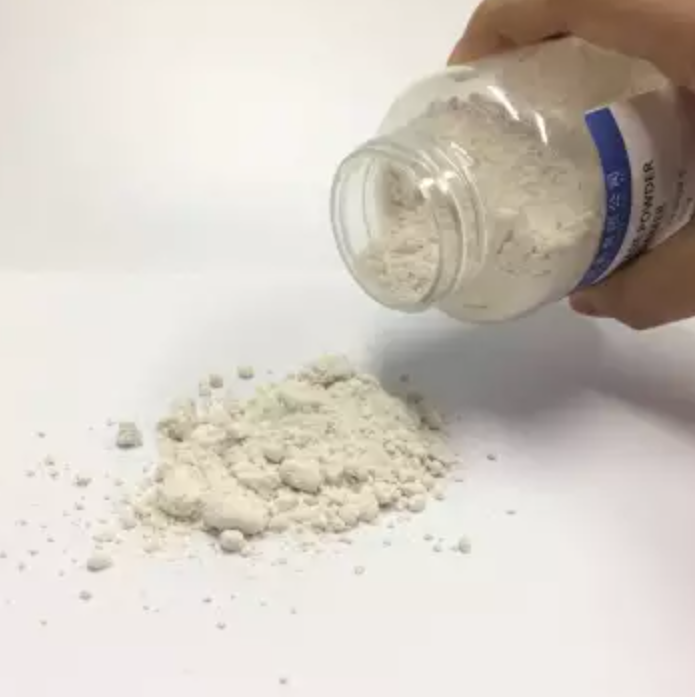

Methyl Vinyl VMQ Silicone Resin is available in solution (vinyl t structure fluids) form in addition to powder form:

2. What are the product characteristics of vinyl silicone resin?

(1) High light transmittance performance, light transmittance can reach over 98%, and can provide a high refractive index.

(2) Excellent mechanical strength, provides desired hardness and excellent atmospheric resistance, can be used for a long time under an environment of -30℃-250℃.

(3) Very low volatile matter and impurity content, impurity content is less than 50 ppm.

(4) Good film-forming properties, moderate flexibility, and corrosion resistance, resistance to ultraviolet irradiation.

3. How to synthesize vinyl silicone resin?

(1) Take vinyltrimethoxysilane as monomer, prepare vinylsilicone microspheres by hydrolysis polycondensation, and blend it with PLA to make vinylsilicone/PLA composites.

(2) Methyl vinyl silicone resin was produced by using tetraethoxysilane, Methyltriethoxysilane, Dimethyldiethoxysilane, dimethyl vinyl ethoxysilane, n-butanol, and aqueous solution of HCl as raw materials.

(3) Vinyl silicone resin was prepared by hydrolysis co-polymerization using mixed Chlorosilanes and siloxanes as monomers.

(4) Vinyl silicone resin was prepared from vinyl triethoxysilane base polymers.

(5) Vinyl MQ silicone resin was prepared by using ethyl orthosilicate, tetramethyldivinyl disiloxane and hexamethyldisiloxane as raw materials and hydrochloric acid as catalyst, and chlorine ions were removed by water washing.

4. What are the applications of VMQ?

Vinyl Silicone Resin is a very unique class of organosilicon polymer polysiloxane compounds, which are compact spheres with a double-layer structure. The introduction of vinyl gives it excellent silicone hydrogen addition properties.

(1) Raw materials for silicone pressure-sensitive adhesives

Vinyl MQ silicone resin is the most important use is the preparation of silicone pressure-sensitive adhesive raw materials.PSA is a kind of adhesive polymer material.PSA has unique physical properties, including high viscosity, high adhesion, plasticity, and weather resistance. Methyl vinyl silicone resin to improve PSA cohesion, in the formulation, can improve PSA adhesion stability, and reduce surface migration to avoid the ghosting phenomenon.

(2) Reinforcement filler for adhesive silicone rubber and transparent silicone rubber

Vinyl MQ silicone resin can be used as adhesive silicone rubber, transparent silicone rubber, and potting materials, LED encapsulants, and other adhesives in the reinforcing filler.

Liquid Silicone Rubber (LSR) is a non-toxic, heat-resistant, highly resilient, flexible thermosetting transparent material with excellent transparency, tear strength, resilience, anti-yellowing, thermal stability, water resistance, good air permeability, heat aging, and weathering resistance, while the viscosity is moderate, easy to operate, and the products are highly transparent. Vinyl MQ is used as a reinforcing material for LSR and is characterized by good transparency, good fluidity, and good reinforcing properties.

(3) Medical Gel:

The role of medical gel is mainly to be able to reduce and relieve skin inflammation, can promote skin recovery, but also can play a role in relieving local pain. Silicone resin is non-toxic and odorless, non-irritating to the skin can be applied in medical use. For different vinyl content resin, you can adjust the proportion of silicone hydrogen addition to control the degree of crosslinking.

(4) Optical gel:

Methyl vinyl silicone resin has good transparency, strong resistance to yellowing, and can be adapted to different formulations through the vinyl content to adjust the modulus of the gel, and control the point of stress absorption rate, in the field of optical devices, biomedicine and optoelectronics, etc. has an important role.

(5) Isolating agent regulator:

Isolating agent, as the name implies, plays a role in the isolation of the additive, in different areas of the specific reference to different. Commonly used in rubber processing, such as film isolating agents, is a class of operation-type additives, its main role is to prevent the film or semi-finished product surface bonding. Methyl vinyl silicone resin can be used as a separator of the peeling force regulator and, at the same time, can improve the cohesion of the separator, to prevent the separator from sticking to the phenomenon of degumming.

(6) Fabric coating:

Silicone-coated fabrics are a kind of fabric with a silicone coating applied to the surface to enhance its performance and function. Organic silicon coating can provide the fabric surface waterproof, oil, flame retardant, abrasion and chemical resistance, and other characteristics. Adding methyl vinyl MQ silicone resin can improve the coating strength, coating feels, waterproof, temperature, and aging resistance.

5. How to improve the performance of silicone products?

Vinyl silicone resin has excellent heat resistance, radiation resistance, film-forming properties, adhesion, water repellency, aging resistance, and resistance to ultraviolet irradiation. The introduction of vinyl, hydrogen-containing groups in the molecular structure can be used for silicone-hydrogen addition modification. How to improve the competitiveness of your products?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry as well as more than 15 related patents and technical support. Our silicone raw material products can meet the demand for silicone resins and support the provision of diversified customized solutions.

![]()