As a chemical product with excellent waterproof function, silicone waterproofing agent is widely used in construction, automobile, textiles, and other fields. With the acceleration of global urbanization and people's demand for better housing quality, the demand for silicone waterproofing agents in the construction industry continues to increase, in addition, environmental protection awareness makes environmentally friendly materials favored, further promoting the development of silicone waterproofing agents market. Currently, there are a number of large and medium-sized suppliers in the market, competition is fierce, but technological innovation and brand building are still the keys to enterprise development. How is silicone waterproof applied?

Silicone waterproofing agent is not only suitable for seepage and leakage prevention of external walls (silicone rubber coatings, silicone sealant, silicone adhesive), but also can be used for waterproofing, anti-pollution, and anti-weathering of ancient buildings, stone, granite, galvanized metals and other finishes (not wood) to prevent mold and moss growth on the wall in wet weather. For concrete pavement blocks and inorganic thermal insulation material surfaces, it has a water-repellent treatment effect, especially suitable for all kinds of face tiles and granite walls. Its unique breathable design, not only can form a water-repellent membrane on the external wall surface invisible to the naked eye but also ensures that the wall surface of the water emitted maintains dryness, effectively preventing the internal wall surface from moisture and shedding problems, like a transparent and breathable “waterproof raincoat” for the building.

The following five aspects of the application of silicone waterproofing agent:

- What types of silicone waterproof agents have?

- How can silicone waterproof agents make the building impermeable?

- What are the applications of silicone waterproofing agents?

- What is the construction process of silicone waterproof agents?

- How to make silicone waterproof agents perform better?

1. What types of silicone waterproof agents have?

Silicone waterproofing agent has two properties: water-based and oil-based.

(1) A water-based organosilicon waterproofing agent is colorless or light yellow, it is mixed into the cement mortar, but also can play the role of retarder, water reducer, and enhancer. Therefore, it is suitable for use in the construction industry, exterior wall finishes, underground engineering, antique buildings, pools, brickwork, cement, gypsum products, and perlite as the main material for insulation materials and rural roof waterproofing, moisture-proof, anti-pollution treatment.

(2) Oil-based silicone waterproofing agent is transparent, generally used for glazed surfaces, ceramic tiles, floor tiles, ceramics, etc., can be appropriately added to some of the solvent dilutions, easy to use.

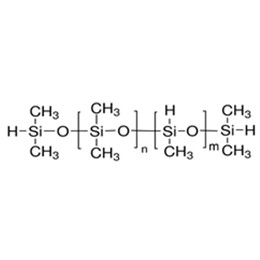

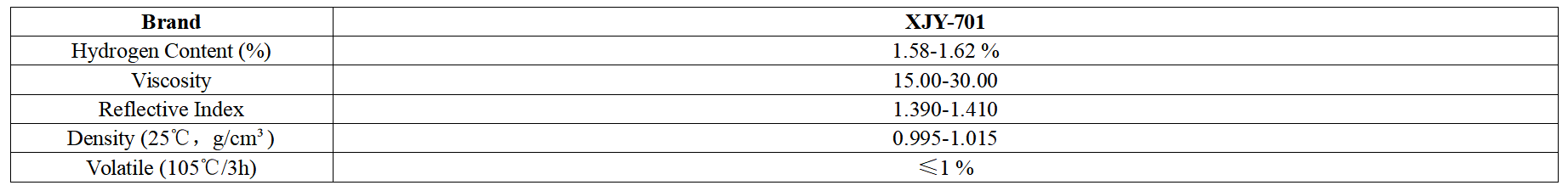

XJY-701-Polymethylhydrosiloxane

Under the action of metal salt catalyst, cross-linking film formation at low temperature, forming a waterproof film on the surface of many materials, can be used as a waterproofing agent for fabrics, glass, vinyl tiles, ceramics, paper, leather, metal, cement, marble, galvanized metal and so on.

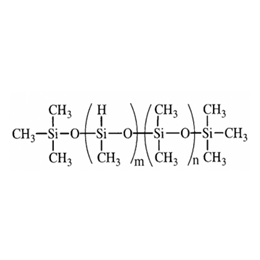

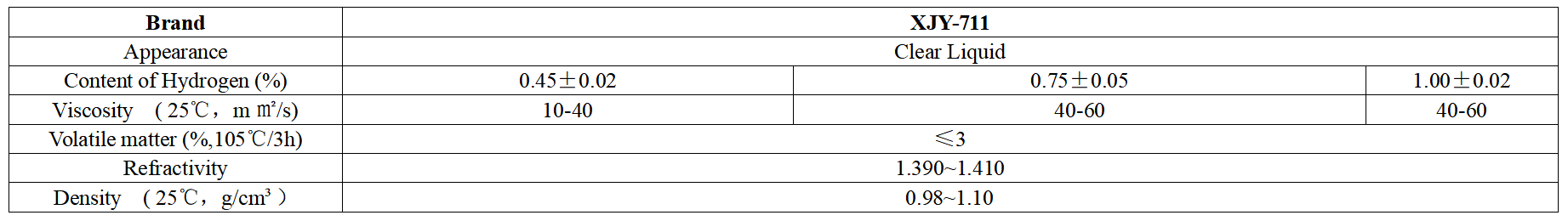

XJY-711 Hydrogen Terminated Methylhydrogensiloxane/Dimethylsiloxane Copolymer

It can be used as a waterproofing agent for fabrics and buildings.

2. How can silicone waterproof agents make the building impermeable?

Silicone waterproofing agents to improve the densification of building materials and seepage resistance are mainly realized in the following ways:

(1) Silicone waterproofing agent in the active ingredients can penetrate into the interior of the building materials, especially concrete and mortar in the micro-pore space and capillary channels. When the waterproofing agent is in contact with these pores and channels, it will produce colloids or precipitates, blocking or cutting off these channels, thus effectively reducing the possibility of water penetration.

(2) Silicone waterproofing agent and building materials in certain components of the chemical reaction, the formation of a layer of strong waterproof membrane. This waterproof membrane not only has excellent hydrophobicity, can prevent water penetration, but also can improve the denseness and overall strength of building materials.

(3) Silicone waterproofing agents can also improve the microstructure of building materials, making them more dense and uniform. Optimizing the internal structure of the material can reduce the channels and paths of water infiltration, thus improving its impermeability.

(4) Silicone waterproofing agents can also synergize with other additives in the building materials to improve the densification and impermeability of the materials. For example, it can be used together with water reducers and expansion agents to further optimize the working performance and durability of concrete or mortar.

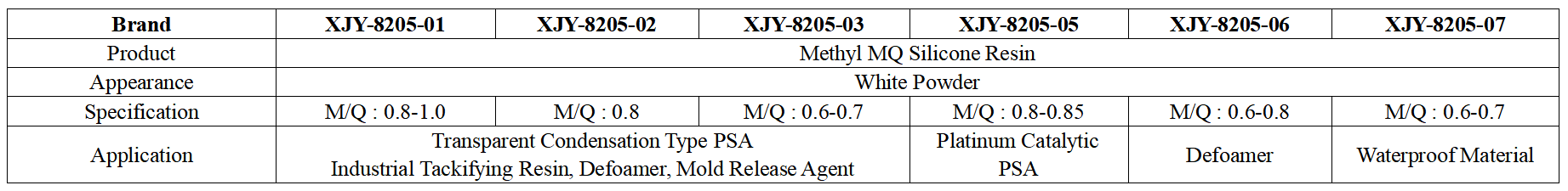

XJY-8205 Methyl MQ Silicone Resin

It is a solid powder resin with excellent water repellency, forming a durable film that will not shrink and can be used as a water repellent.

3. What are the applications of silicone waterproofing agents?

(1) Spraying anti-seepage construction: organosilicon waterproofing agent diluted with 15 times of water and sprayed on the surface of cement surface, bricks, tiles, gypsum boards, ordinary paint walls, bridges, and tunnels, and other water-absorbing inorganic building materials surface for seepage resistance to moisture treatment, with excellent results.

It is widely used in the internal and external walls of various buildings, especially for solving the indoor mold problem caused by water seepage on the east wall and north wall, which is common in civil housing. In addition, it can also be widely used for indoor decoration before the moisture-proof and mold-proof treatment, industrial plant walls inside and outside the anti-pollution cleaning, weathering, acid rain treatment, as well as reservoirs, water towers, cisterns, sewage treatment plants and agricultural irrigation channels waterproofing project; for the ancient buildings, monuments, ceramic tiles, library and archives, precision instruments and computer rooms, power distribution rooms, warehouses and so on can be applied.

(2) It can be used for plasterboard, perlite waterproofing additive, and waterproofing agents accounting for 3% of the stirred raw materials.

(3) It can be used for stone waterproof protection, silicone waterproofing agent diluted with 15 times water sprayed on the surface of the stone, 24 hours later with good waterproof protection.

(4) For textiles, a silicone waterproofing agent is added 1-2 times diluted water sprayed on the surface of the fabric, or the textile in the diluted liquid and then wrung out, dried at about 80 degrees both good waterproof effects.

(5) For paper products, silicone waterproofing agents add 1-1.5 times the water dilution, spraying or soaking and drying can have a good waterproof moisture effect.

4. What is the construction process of silicone waterproof agents?

Silicone waterproofing agent construction is generally divided into grass-roots surface cleaning, repair cracks, and spray construction of three procedures. (This process is also the main process of repair and leakage of our external walls

(1) Clean up the grass-roots surface

Spray silicone waterproofing agent before the grass-roots surface dust, moss spots, and other pollutants are cleaned up. General dust and floating soil can be rinsed with water or wiped with a rag; oil, rust stains, and moss spots need to be carefully cleaned with detergent, and then rinse the residual detergent with water.

(2) Repairing cracks

The grass-roots leakage is divided into capillary water absorption leakage and cracks, and holes seepage into two categories. Organic silicon waterproofing agent to deal with capillary pore water absorption leakage is very effective.

But if there are large cracks or holes in the grass-roots level, a single spray silicone waterproofing agent often can not solve the problem, because if it rains with gusty winds, the rain is still able to push the larger wind pressure through the cracks, holes deep into the substrate.

For this reason, must choose the appropriate material embedded repair cracks, and holes and then spray a silicone waterproofing agent.

(3) Spray silicone waterproofing agent

According to the use of materials you use the manufacturer's ratio and construction methods, in strict accordance with the process operation on the line. Pay attention to labor protection measures and stability.

5. How to make silicone waterproof agents perform better?

Silicone waterproofing agent for external walls with unique performance, suitable for porous inorganic grass-roots such as concrete, ceramic tiles, clay tiles, stone, and other waterproofing and protection does not bear water pressure. It is mildew resistant and shows excellent waterproofing and seepage resistance, stain resistance, heat resistance, color retention, and weathering resistance in scenarios such as brick walls, exterior wall coatings, and natural stone finishes. When waterproofing tile walls, the original substrate color can be kept unchanged. How can the competitiveness of the product be improved?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry as well as more than 15 related patents and technical support. Our silicone raw material products can meet the needs of the waterproofing field and support the provision of diversified customized solutions.

![]()