Pressure-sensitive adhesive applications continue to broaden, the market demand continues to grow, and environmental awareness and sustainable development policies to promote the silicone PSA products market demand have also gradually increased. What are the bonding properties of silicone PSA?

Silicone PSA usually refers to silicone polymer-based pressure-sensitive adhesives, or silicone-modified acrylic and rubber-based pressure-sensitive adhesives these low surface energy materials. They are superior to traditional acrylic and rubber-based pressure-sensitive adhesives in terms of performance, with good resistance to chemicals, water, oil, solvents, high and low temperatures, thermal degradation, and oxidative degradation. These characteristics make the silicone pressure-sensitive adhesive able to successfully bond a variety of difficult-to-bond materials, including unsurfaced polyolefins (such as PET, PE these low surface energy substrates), fluoroplastics, polyimide, and polycarbonate.

The following five aspects of the advantages and applications of silicone pressure-sensitive adhesive:

- What is PSA?

- What are the components of PSA tape?

- What affects the PSA performance?

- What is the bonding mechanism of silicone PSA?

- How to make PSA performance better?

1. What is PSA?

Adhesive tape is a special type of adhesive, this glue is coated on the substrate processed into a strip, and made of reel supply, including solvent-activated adhesive tape, heating-type adhesive tape, and pressure-sensitive adhesive tape. For example, there is daily medical use of rubber paste and electrical insulation that belongs to the PSA tape.

The main components of pressure-sensitive adhesive include rubber and resin types, such as polyacrylate or polyvinyl ether two types, the substrate requires uniformity, small expansion, and good solvent wettability, including:

(1) Fabrics such as cotton, glass cloth, or non-woven fabrics.

(2) Plastic films such as PE, PP, PVC, and polyester film.

(3) Paper such as kraft paper, glass transparent paper, etc., the original degree of the substrate between 0.1-0.5mm.

2. What are the components of pressure-sensitive adhesive tape?

① Pressure-sensitive adhesive

② Substrate material

③ Substrate treatment agent

The role of the primer is to increase the adhesive strength between the adhesive and the substrate, in order to remove the tape will not lead to adhesive and substrate disengagement and staining of the surface to be adhered to, and to make the tape has reusability. Commonly used primer is partially vulcanized chloroprene rubber with isocyanate, modified chlorinated rubber.

④ Backside treatment agent

The back side of the treatment agent is generally made of Polyacrylate, PVC, and other materials formulated. It can play the role of an isolation agent. Double-sided adhesive tape must add a layer of isolation paper such as semi-hard PVC film, PP film, or kraft paper.

3. What affects the performance of PSA?

3.1 Material composition

The pressure-sensitive adhesive does not need to be heated, with finger pressure can be bonded, it is an anti-peel strength adhesive. Pressure-sensitive adhesive performance varies depending on the composition.

(1) Rubber-based pressure-sensitive adhesive is mainly natural rubber as the main raw material, due to the high relative molecular mass, low glass transition temperature, and good compatibility with the tackifying resin, so the resulting pressure-sensitive adhesive holding power is very good, low-temperature performance is also good, fast adhesion and adhesion are better, the main drawback is poor aging resistance.

(2) Acrylate pressure-sensitive adhesive mainly by acrylate monomer copolymerization, transparency, cohesion strength, and adhesive properties are good, especially for the polar adhesive surface center and the porous surface has good adhesive properties, and aging resistance is excellent.

(3)Thermoplastic elastomer pressure-sensitive adhesive is mainly composed of styrene-based elastomers SIS and SBS, made of solvent-based pressure-sensitive adhesive with low viscosity, high cohesive strength, peel strength. Because of the molecular structure contains double bonds so not aging resistance, but after oxidation aging resistance will be greatly improved.

(4) Silicone pressure-sensitive adhesive to silicone rubber and silicone resin as the main component, high and low-temperature resistance is very good, the polyolefin and fluorine polymers have good adhesive properties. In the pressure-sensitive adhesive formula, pigment fillers, can be made with color pressure-sensitive adhesive, such as adding the appropriate amount of titanium dioxide can be made into white pressure-sensitive adhesive.

3.2 Relative molecular mass

Relative molecular mass and its distribution on the various properties of pressure-sensitive adhesive have a great impact when reducing the relative molecular mass of pressure-sensitive adhesive can reduce the viscosity of the body, which is conducive to the wetting of the surface of the object to be adhered to, to improve the interfacial adhesion.

However, when the relative molecular mass is too low, the cohesive strength is poor, and the adhesive layer is prone to cohesive damage when peeling. Increasing the relative molecular mass can improve the cohesion, but the relative molecular mass is too large and will hinder the dispersion and wetting. Therefore, the relative molecular mass of the pressure-sensitive adhesive must be within a certain range to obtain good adhesive properties. Relative molecular mass distribution also has a greater impact, generally wider relative molecular mass distribution of pressure-sensitive adhesive has better adhesive properties.

3.3 Glass transition temperature

Glass transition temperature Tg on the performance of pressure-sensitive adhesive has a great impact, Tg different pressure-sensitive adhesive room temperature viscosity and coexistence of elastic modulus increases, peel strength decreases, will lose pressure-sensitive, Tg too low, low cohesive strength, will produce peel damage, therefore, the pressure-sensitive adhesive Tg must be maintained at a certain temperature range is generally -20 ~ 600C.

4. Silicone PSAS bonding mechanism?

(1) In the appropriate pressure, silicone pressure-sensitive adhesive will show nearly liquid viscous flow characteristics. This flow makes the pressure-sensitive adhesive closely contact and penetrate into the surface of the adhesive microporous and groove, thereby increasing the effective contact area between the adhesive and the adhesive, resulting in a lasting adhesive force.

(2) When the silicone pressure-sensitive adhesive products need to be peeled, its elastic properties to resist external forces, especially in the case of high-speed peeling, the pressure-sensitive adhesive can still maintain a high peel strength.

(3) silicone pressure-sensitive adhesive on the surface of the sticky material is also the key to the wetting ability. Good wettability makes the pressure-sensitive adhesive can be close to the surface of the adhesive molecular level, through the intermolecular forces to form a strong interfacial adhesion.

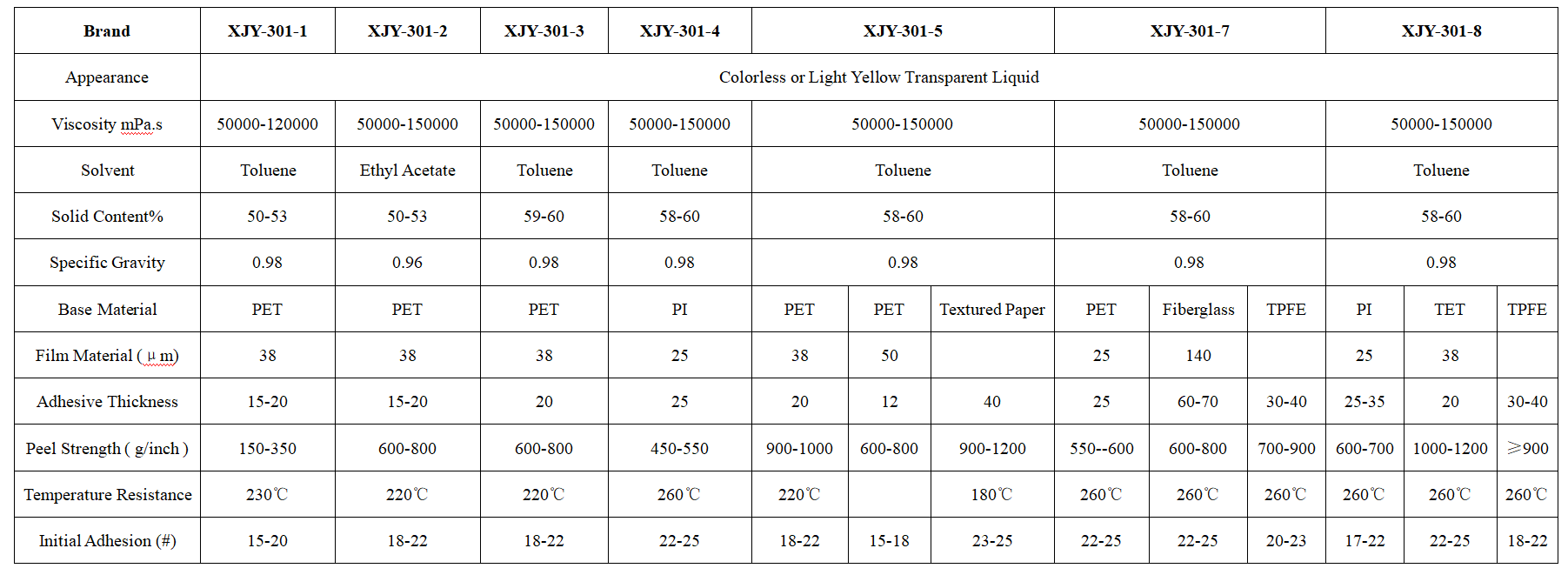

XJY-301 Silicone pressure-sensitive adhesives

It is made from the specific structure of silicone resin and high molecular weight polydimethylsiloxane in cooperation with organic adhesive, which is suitable for specific scene conditions.

Compared with natural rubber, it is characterized by heat resistance, high stability, good electric insulation, good transparency, high peel adhesion, chemical resistance etc. It has a wide range of applications in industrial product processing, electronic processing, optical materials, health care and mica tapes, splicing tapes, protective films other fields.

5. How to make better performance of pressure-sensitive adhesive?

Silicone pressure-sensitive adhesive has excellent resistance to chemicals, water, oil, solvents, high temperature, low temperature, heat degradation, oxidative degradation and other properties; can be bonded with a variety of difficult-to-stick materials, such as non-surface-treated polyolefins (BOPP, PET, PE, etc.), fluorine plastics, polyimide, and polycarbonate. How to improve the competitiveness of products?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry and more than 15 related patents and technical support. Our silicone raw material products can meet the needs of the pressure-sensitive adhesive field and support the provision of diversified customized solutions.