The market for silicone adhesives is vast and has continued to grow in recent years. Its market size is expanding, thanks to its unique properties and wide range of applications. With the rapid development of new energy vehicles, new energy, and other fields, the demand for silicone adhesives will be further enhanced, the market outlook is favorable. Why silicone resin adhesives are more widely used?

Silicone adhesives have superior high and low-temperature performance, can maintain good physical state and electrical properties in -60 ~ 300 ℃; excellent weathering and aging resistance, and long service life; good electrical insulation properties can maintain stable electrical properties under harsh conditions; low stress, low compression permanent deformation, low surface tension, easy to coat and operate; environmentally friendly, and many products have passed the FDA certification.

The following seven aspects of the application of silicone adhesives:

- What is adhesive?

- What kinds of adhesives?

- What are silicone adhesives?

- How to use silicone adhesive?

- What are the precautions for silicone adhesives?

- Why use silicone adhesive in mica tape?

- How to make silicone adhesive perform better?

1. What is adhesive?

Usually, adhesive is defined as through the interface of adhesion and material cohesion and other roles, can make two or more of the parts or materials connected together the natural or synthetic, organic or inorganic class of substances, collectively referred to as adhesive (adhesive) also called adhesive, customarily referred to as glue. Today, we will talk about the characteristics and applications of different types of adhesives.

2. What kinds of adhesives?

(1) Polyurethane adhesive

Polyurethane adhesive refers to the molecular chain containing urethane groups or isocyanate-based adhesive. According to the reaction, composition can be categorized into multi-isocyanate adhesive, isocyanate-based polyurethane adhesive, hydroxyl-containing polyurethane adhesive, and polyurethane resin adhesive.

(2) Polyacrylic Resin

Acrylic resin adhesive is a class of acrylate adhesive, made of acrylic resin, which needs to be cured without air. It is commonly used for sealing, screwing, and fastening of rotating bearings. The disadvantages are that the heat resistance is not high enough, long curing time, and is not suitable for large gaps in the seal.

(3) Hot melt adhesive

Hot melt adhesive is short for hot melt adhesive, it does not use any solvents in the production and application, is non-toxic, tasteless, not pollute the environment, known as “green adhesive”, especially suitable for use in continuous production lines. Hot melt adhesive is a kind of polymer adhesive that is coated in a hot melt state and hardened by cooling to realize bonding. According to the provisions of the national standard, the definition of hot melt adhesive is “in the melting state for coating, cooling into a solid state to complete the bonding of a thermoplastic adhesive”. Solvent-free, 100 percent solid content, mainly composed of thermoplastic polymers.

(4) Silicone Adhesives

Epoxy resin and its curing system with its unique properties and new epoxy resins, new curing agents, and additives continue to emerge, becoming an important class of adhesives with excellent performance, a large number of varieties, adaptability, and a wide range of adhesives.

Silicone sealant can be used for bonding between metal and most non-metallic materials and is widely used in construction, automobile, electronics, electrical appliances, and daily household products.

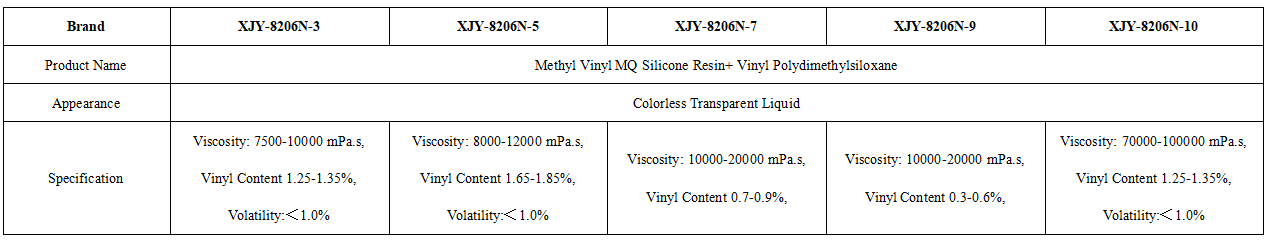

XJY-8206N Methyl Vinyl MQ Silicone Resin

It is a colorless and transparent liquid resin, composed of vinyl MQ silicone resin and vinyl silicone oil, which can be used for LSR and other two-component additive adhesives.

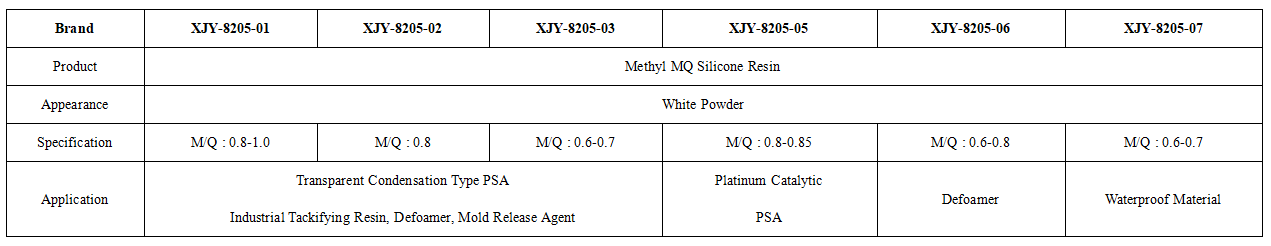

XJY-8205 Methyl MQ Silicone Resin

It is a solid powder resin that can be used as reinforcement material for liquid silicone rubber. Adding MQ resin into the potting adhesive can enhance the temperature changes of the sealant and prolong the service life of the sealant. XJY-8205M/M-02/M-03 Silicone resin is a kind of MQ solution, which is an important raw material for PSA.

3. What are silicone adhesives?

(1) Silicone adhesives include two categories of adhesives (including sealants) based on silicone resins or silicone elastomers.

Silicone resin consists of Si-o-Si main chain space network structure, is connected to organic groups on the silicon atom crosslinked semi-inorganic polymers, at high temperatures can be further condensed to a high degree of crosslinking and hard and brittle resin.

Silicone rubber is a linear to Si-O-si main chain of linear polysiloxane (molecular weight ranging from a few tens of thousands to hundreds of thousands), in the role of curing agents and catalysts to form a number of crosslinked points of the elastomer, by the polydimethylsiloxane-based silicone rubber, also known as silicone rubber.

The former is mainly used for bonding metal and heat-resistant non-metallic materials, the resulting joints can be used in a temperature range of 60 ~ 250 ℃, the latter is mainly used for bonding heat-resistant rubber, rubber, and metal, as well as other non-metallic materials generally can be used in a 60 ~ 200 ℃.

(2) silicone adhesive can be roughly divided into pure silicone adhesive and modified silicone adhesive. Pure silicone organic adhesive mainly consists of active polysiloxane (end hydroxyl silicone rubber, containing hydrogen or vinyl silicone oil), curing agents, catalysts, fillers, and additives.

(3) According to the differences in the curing reaction, and can be divided into condensation, free-radical initiated, and silicone-hydrogen addition molding; according to the composition and function of the different, can be divided into one-component silicone, two-component silicone, and silicone pressure-sensitive adhesive.

4. How to use silicone adhesive?

(1) Clean up the surface to be bonded: ensure that the surface is clean, dry, free of oil and dust to improve the bonding effect.

(2) Check the adhesive: make sure the silicone resin adhesive has not expired, the package is intact, no deterioration.

(3) Apply the adhesive: Use the appropriate tools to apply the silicone resin adhesive evenly on the surface to be bonded to avoid the formation of bubbles or voids.

(4) Docking and fixing: tightly dock the two surfaces to be bonded and use jigs or other equipment to fix them to ensure the stability of the bonding process.

(5) Curing treatment: According to the instructions of the adhesive, place the bonded parts in the appropriate temperature and environment for curing. Curing time and temperature vary from product to product, need to strictly follow the product instructions.

5. What are the precautions of silicone adhesive?

(1) Safety protection: in the operation process, need to wear protective gloves and glasses to avoid direct contact between the adhesive and the skin or eyes.

(2) Environmental control: Ensure that the operating environment is well-ventilated, away from sources of ignition, to avoid volatilization or combustion of the adhesive.

(3) Storage Requirements: Keep the unused silicone resin adhesive in a sealed place and place it in a cool and dry place to avoid direct sunlight.

6. Why use silicone adhesive in mica tape?

Mica is a kind of flaky inorganic mineral material, which is characterized by insulation, high-temperature resistance, glossy, stable physicochemical properties, good heat insulation, elasticity and toughness, and non-flammability, and also has the property of being peeled into a transparent sheet with elasticity. Mica tape is made of flaky mica powder into mica paper, which is adhered to glass fiber cloth with adhesive.

Fire-resistant mica tape as a fire-resistant cable in the main insulation layer plays the most important role, the composition of fire-resistant mica tape materials are mica paper, fiberglass cloth, and adhesive, of which the mica paper is the real fire-resistant insulating role of the material, fiberglass cloth is a reinforcing material so that the fire-resistant mica tape has enough strength, and right adhesive will be the combination of mica paper and fiberglass cloth to become whole. The selection of adhesive must meet the high bond strength between mica paper and glass fiber cloth; mica tape with a certain degree of flexibility and edge curvature, and the inorganic content of the adhesive, i.e., si/r ratio should be large; the amount of charcoal residue after combustion should be low, i.e., combustion does not carbonize the principle of the three are indispensable. Burning is not carbonized is crucial, it directly affects the insulation resistance of the mica tape after burning, silicone adhesive combustion generates white powder sio2, sio2 has good electrical insulation properties, so the silicone adhesive for fire-resistant mica tape is the most ideal adhesive.

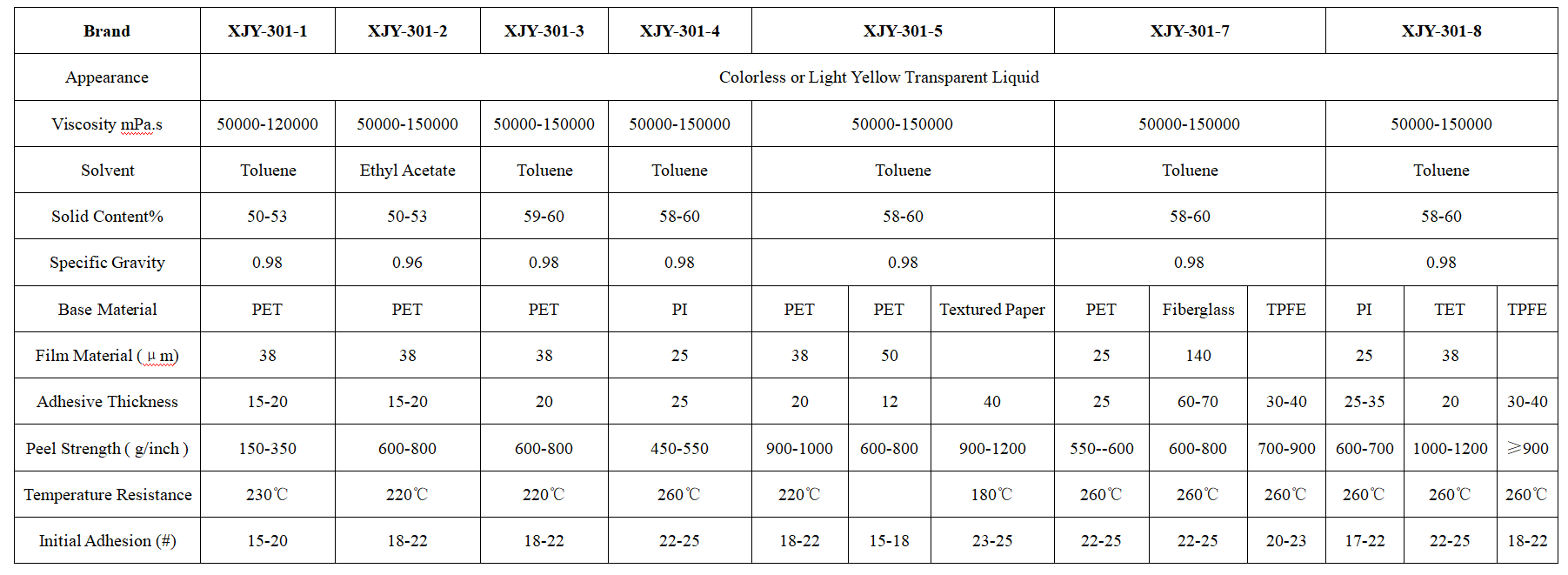

XJY-301 Silicon pressure-sensitive adhesives

It is made of silicone resin and high molecular weight polydimethylsiloxane with a specific structure with organic adhesive, suitable for specific scene conditions. Compared with natural rubber, it is characterized by UV radiation, high stability in extreme temperatures, flexible bonds, good electrical insulation, good transparency, and peel adhesion. It has a wide range of applications in industrial product processing, electronic processing, optical materials, health care, and other fields.

7. How to make silicone adhesive perform better?

Silicone adhesive because of its own molecular structure, making it has many superior performances, with cold, heat, aging, water, moisture, high strength of expansion and contraction fatigue, permanent deformation, non-toxic, and other characteristics uv light resistance. In recent years, the rapid development of such adhesives in the country. It has been widely used in the fields of electronics and electrical appliances, aerospace and aviation, the construction industry(household repairs), automotive applications, and other fields. How can you improve the competitiveness of your products?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry as well as more than 15 related patents and technical support. Our silicone raw material products can meet the needs of the bonding applications field and support the provision of diversified customized solutions.

![]()