With the rising health concerns of the population and the rapid development of pharmaceutical technology, pharmaceutical film-forming agents are increasingly being used in drug formulations. Its market size continues to grow, mainly due to increased consumer demand for drug comfort, safety, and durability, as well as the policy to promote environmental protection and sustainable development. 5. How do silicone film-forming agents perform better?

In addition to skin conditioning agent and cosmetics, Trimethylsilanethoxysilicate also can be used as a key emollient ingredient in formulations for applications such as healthcare and topical medical device lubrication, and topical formulations for direct human contact. This Trimethylsiloxysilicate resin allows the product to form a permeable, long-lasting barrier film with excellent water repellency and humidity resistance, as well as resistance to wiping and rinsing.

There are five aspects to introducing TMS in the medical field:

- How to classify medical film-forming agents?

- What are the features of medical film-forming agents?

- What are the applications for medical film-forming agents?

- Why is silicone film-forming agent applied to medicine?

- How do silicone film-forming agents perform better?

1. How to classify medical film-forming agents?

Pharmaceutical film-forming agents can be categorized into natural and synthetic types according to their composition.

Natural film-forming agents are mainly made from natural plant extracts, such as oxidized starch, gelatin, gelatin stearate, alginate and its salts, carrageenan, saponin, and so on.

Synthetic film-forming agent, on the other hand, refers to the use of chemically synthesized polymers or compounds, such as silicone, polyvinyl alcohol, polyvinyl pyrrolidone, polyacrylates, and so on.

2. What are the features of medical film-forming agents?

(1) Film-forming agent forms a film when used externally, which can protect skin wounds and promote healing.

(2) Film-forming agents can slow down the release of local drugs, so that the drug stays on the wound for a longer period of time, to play a better therapeutic effect.

(3) Film-forming agents have a stable structure and soft texture, and will not irritate the skin during acute inflammation, which is very suitable for use in healing wounds such as surgical wounds.

(4) The film-forming agent has good adhesion and wearability, making it very convenient to use.

3. What are the applications of medical film-forming agents?

(1) Wound protection:

Use after surgery to avoid incision contamination, promote healing, and reduce edema, pain, and infection.

(2) Eczema diseases:

moist eczema, dermatitis, contact dermatitis, and other skin diseases.

(3) Dry skin diseases:

e.g. chapped hands and feet, dry skin, vitiligo, etc.

(4) Other special cases:

such as cancer radiotherapy, chronic wounds, burns, and other special physiotherapy needs.

4. Why is silicone film-forming agent applied to medicine?

(1) Film effect

Silicone film-forming agents show high hardness and flatness after smooth film formation, making the treated surface smoother and more delicate. This high-quality film-forming effect not only enhances the aesthetic appearance of the material but also significantly increases its resistance to abrasion and corrosion. In contrast, ordinary film-forming agent mainly focuses on the basic functions of lubrication, protection, and beautification, and has limited effect on the improvement of physical and mechanical properties of materials. Therefore, in the need for high-strength protection and decorative requirements of the occasion, silicone film-forming agent is undoubtedly a better choice.

(2) Performance Stability

Silicone film-forming agent has excellent oxidation resistance, high and low-temperature resistance, and weather resistance, even in extreme environments, and can maintain stable performance. This stability ensures that the film layer can resist the erosion of external factors for a long time, thus extending the service life of the material. Common film-forming agents are relatively fragile and susceptible to environmental influences such as deterioration, aging, and other phenomena, and their service life is relatively short. Therefore, in outdoor or harsh environments, silicone film-forming agents can show their excellent protective ability.

(3) Scope of application

Due to the significant advantages of silicone film-forming agents in terms of film-forming effect and performance stability, their scope of application is extremely wide. Silicone film-forming agents have become indispensable surface treatment materials in the automotive manufacturing, construction, and high-end electronics industries. It can not only effectively protect the product from environmental damage, but also enhance the overall quality of the product and market competitiveness.

Common film-forming agents, on the other hand, are more often used in everyday scenarios such as cleaning, care, and lubrication, such as household cleaning products and personal care products. This differentiated range of applications also further highlights the high-end positioning and market value of silicone film-forming agents.

(4) Molecular structure and transparency

The molecular structure of silicone film-forming agents has an important impact on their performance. Generally speaking, the simpler and more regular the molecular structure, the higher the transparency of the film. At the same time, molecular weight is also one of the key factors affecting transparency. In practice, the transparency of products can be further enhanced by selecting suitable silicone film-forming agents and strictly controlling the film-forming conditions (e.g., temperature, humidity, time, etc.). In contrast, it is often difficult for ordinary film-forming agents to reach the level of silicone film-forming agents in terms of transparency. Therefore, in the need for high transparency protection occasions (such as optical components and displays, etc.), silicone film-forming agents is more advantageous.

(5) environmental protection and sustainability

With the increased awareness of environmental protection and the popularization of the concept of sustainable development, people also put forward higher requirements for the environmental performance of film-forming agents. Silicone film-forming agent due to its low toxicity, low volatility recyclability, and other characteristics, outstanding performance in environmental protection. It not only reduces the pollution and damage to the environment but also realizes the recycling of resources to a certain extent. In contrast, common film-forming agents may contain some harmful substances or components that are difficult to degrade, posing potential threats to the environment and human health. Therefore, in the pursuit of green production and sustainable development, silicone film-forming agents are undoubtedly more in line with the needs and trends of the times.

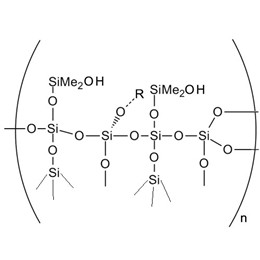

XJY-8203 / 8205 Trimethylsiloxysilicate

It is a silicone polymer whose main chain structure consists of alternating silicon and oxygen atoms. These solid silicones provide film-forming and softening effects, which can provide excellent water resistance and detergent/water wash resistance for many pharmaceutical formulations.

XJY-8203/ 8205 trimethylsilane alkoxysilicates are soluble with a wide range of organic carriers and are compatible in various applications such as.

-Medical creams, lotions, barrier creams

-Pharmaceutical sprays

-New medical gels, etc.

In addition, XJY-8203/8205 Trimethylsiloxysilicate series solid resins can also be used in various skin-friendly cosmetic ingredients formulations, such as nail polish, eye makeup, bath products, hair products, its can pass cosmetic ingredient review.

5. How do silicone film-forming agents perform better?

For the purpose of making the patient experience more comfortable and safe, topical series of drugs that come into contact with the skin form a long-lasting film. It is very important to improve the affinity of the formulation as well as the sensory properties such as skin-friendliness in OTC drug formulations. Silicone film-forming agents are non-toxic, odorless, and non-irritating to meet the needs of the human body and are more trusted by consumers, this subject can also be applied in cosmetic products and skin care products. How can you improve the competitiveness of your finished products?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry and more than 15 related patents and technical support. Our silicone raw material products can meet the needs of the medical field and support the provision of diversified customized solutions.

![]()