Most commercial synthetic elastomers lack adhesion, either to themselves or to other surfaces. Therefore, in order to increase their adhesion, tackifiers are added. In modern industrial production, organic component materials(such as silicone) are attracting attention for their unique properties and wide range of applications. So what are silicone tackifiers?

Tackifier is a chemical that increases the viscosity in water or other solutions, thus enhancing their sticking properties. The main role of the tackifier is to improve the product properties, can promote adhesion, viscosity, stability, and so on.

Silicone tackifiers are silicone polymers with organic groups, between a variety of polymer materials to play a bonding role in the additives, through the interaction with other polymer materials, can increase the material viscosity and adhesion properties, and can be used for a variety of adhesives and sealing materials preparation. Compared with inorganic silicon, it also has good high-temperature resistance, waterproof performance chemical resistance, and thermal stability, and has a wide range of applications in hot melt adhesives, pressure-sensitive adhesives, and other fields.

Here's some information about it:

- What is the mechanism of silicone tackifiers?

- How to classify silicone tackifiers?

- What are the features of silicone tackifiers?

- How to apply silicone tackifier?

- How do silicone tackifiers work?

- How to make silicone tackifiers?

1. What is the mechanism of silicone tackifiers?

The mechanism of the silicone tackifier is mainly realized by changing the fluidity and surface tension of the liquid. Silicone tackifier molecules contain silicone-oxygen bonds, its oxygen atoms and silicon atoms make it have strong stability and high-temperature resistance and can be in a variety of environments to maintain its tackifying effect. When the silicone tackifier is added to the liquid, its molecules will interact with the liquid molecules to form a layer of material similar to the mesh structure, thus increasing the viscosity and stickiness of the liquid. At the same time, a silicone tackifier can also reduce the surface tension of the liquid, so that it is easier to adhere to the surface of the object to improve the bonding properties.

![]()

![]()

2. How to classify silicone tackifiers?

According to their chemical structure, silicone tackifiers are also liquid or solid polymer, can be divided into the following categories:

(1) Silicone rubbers tackifiers

Silicone rubber is a flexible and elastic synthetic material, commonly used in sealing, insulation, and medical fields. Adding an appropriate amount of silicone tackifier in silicone rubber can significantly improve its adhesive strength with a variety of materials in natural and synthetic sources.

(2) Silicone resin tackifier

Silicone resin is a polymer synthetic material with excellent electrical insulation, weather resistance, and high-temperature resistance. By adding a silicone tackifier to silicone resin, the adhesion of products (such as hot melt adhesives, and pressure-sensitive adhesives) to various substrates can be effectively improved.

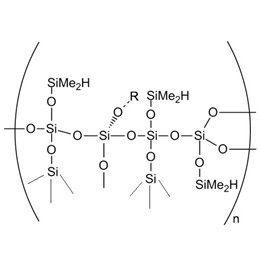

XJY-8207S/M Hydrogen MQ Resin can be used as a tackifier in sealants and silicone resin coatings.

![]()

(3) Silicone oil tackifier

Silicone oil is a class of compounds with silicone as the basic structure, with excellent lubricating properties and chemical stability. Adding a certain amount of silicone tackifier to silicone oil can enhance its wettability and adhesion to various polymers.

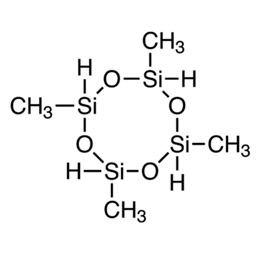

XJY 705 1.3.5.7-Tetramethylcyclotetrasiloxane(D4H) is a kind of reactive silicone containing silicone-hydrogen bonding, which can react with unsaturated olefins by addition. It can be used to prepare synthetic specialty tackifiers.

![]()

3. What are the features of silicone tackifiers?

(1) High viscosity

Silicone tackifiers can significantly improve the adhesion of the bonding material so that it has better durability and stability in the process of use.

(2) High-temperature resistance

Silicone tackifier has excellent high-temperature resistance, can maintain the stability of the bonding material in a wide temperature range environment, not easy to melt or lose.

(3) Chemical resistance

Silicone tackifier has good resistance to chemical corrosive substances and can protect the bonding material from chemical damage.

(4) Weather resistance

Silicone tackifier has good weather resistance, can be in the sun, humidity and oxygen, and other natural environmental influences to maintain the stability of the bonding material and adhesion.

(5) Environmental protection

Silicone tackifiers usually do not contain harmful substances and no pollution of the environment in line with environmental requirements. Silicone tackifiers are widely used in construction, automotive, electronics, aerospace, and other fields commonly used in adhesive sealing, waterproofing, insulation, high temperature, and other processes.

![]()

4. How to apply silicone tackifier?

Silicone tackifiers are widely used in the following areas due to their good performance and wide range of applications:

4.1 Adhesives

Silicone tackifiers have a wide range of applications in the field of adhesives and can improve the adhesive properties of various polymer materials. In the production of universal adhesive, structural adhesive, and other adhesives, the addition of an appropriate amount of silicone tackifier can significantly improve its adhesion and weather resistance.

4.2 Coatings

Silicone tackifiers are also more commonly used in coatings. By adding the appropriate amount of silicone tackifier to a variety of coatings, you can effectively improve the film-forming properties of coatings and the ability to adhere to a variety of substrates. Especially in the preparation of architectural coatings, marine coatings, and other high-performance coatings, silicone tackifiers have become an important and indispensable component.

4.3 Plastics

Silicone tackifiers also have a wide range of applications in plastics processing. In the production of polyvinyl chloride (PVC), polyethylene (PE), polypropylene (PP), and other plastic products, the addition of a certain amount of silicone tackifier can effectively improve the adhesion of plastic products to a variety of substrates. For example, in the production of plastic films, the addition of an appropriate amount of silicone tackifier can significantly improve the film adhesion and sealing strength.

![]()

4.4 Rubber

Silicone tackifiers also play an important role in the production of rubber products. In the production of rubber sheets, rubber tubes, rubber shoes, and other products, adding a certain amount of silicone tackifier can effectively improve the adhesive properties of rubber products and tear resistance. Especially in the production of tires, the application of silicone tackifiers can significantly improve the adhesive strength and durability of tires on a variety of materials.

4.5 Personal care

Silicone tackifiers in the field of personal care products also have a wide range of applications. In the production of shampoo, shower gel, and other personal care products by adding an appropriate amount of silicone tackifier, you can improve the product's moisturizing degree and adhesion ability, thereby improving the use of the effect and comfort.

4.6 Medical

In the medical field, silicone tackifiers also play an important role. In surgery, silicone tackifiers can be used to prepare surgical glue for bonding and sealing wounds to improve surgical results and wound healing speed. In addition, silicone tackifiers can also be used in the preparation of medical tapes and dressings, to increase their adhesive capacity and waterproof performance.

4.7 Agriculture

Silicone tackifiers can be used in the preparation of pesticides and fertilizers. Silicone tackifiers can increase soil stabilization for bare soil adhesion and fertilizers in the field of agriculture, force, and permeability for soil particles, and improve their utilization and effectiveness. At the same time, silicone tackifiers can also improve soil water retention and fertilizer retention, reduce soil erosion of soil surface, and dust control as wet slurry, prevent soil disturbing activities, it binds soil particles to improve crop yield and quality.

![]()

5. How do silicone tackifiers work?

As a functional additive, silicone tackifiers can play a good performance in various fields:

(1) Improve adhesive properties:

The addition of silicone tackifiers can effectively improve the adhesive properties of a variety of polymer materials so that it is more firmly adhered to a variety of substrates.

(2) Improve coating performance:

Adding silicone tackifiers to coatings can significantly improve the film-forming properties of coatings as well as the wettability and adhesion to the substrate, thereby improving the protective effect and service life of the coating.

(3) Optimize plastic processing:

Adding silicone tackifiers in plastic processing can improve the processing performance and adhesive properties of plastic products, and improve the yield and quality of plastic products.

(4) Enhance the performance of rubber products:

Silicone tackifiers can improve the tear resistance of rubber products, weather resistance, and adhesive properties, to extend the service life of the products.

6. How to make silicone tackifiers?

As an important functional additive, silicone tackifiers are widely used in the fields of adhesives, coatings, plastics, rubber, and personal care. Its good chemical properties and wide range of applications make silicone tackifiers one of the important and indispensable raw materials in modern industrial production. How to make your products more competitive?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers that produce silicone products in China, with more than 30 years of R&D and manufacturing experience in the silicone industry as well as more than 15 related patents and technical support. Our silicone raw material products can meet the needs of silicone tackifiers and support the provision of diversified customized solutions.