Due to their versatile physico-chemical properties and high performance, silicones are synthetic materials that have been used in the textile industry since the 1950s. Silicones give fabrics excellent water repellency and a unique style. As a result, fabric finishing has become the most important application area for silicones. So how to use silicone for fabric?

Silicone is a commonly used textile additive, its main role is to enhance fiber abrasion resistance, water repellency, oil resistance, softness and feel, and other aspects of high performance, some silicone even has flame resistance. At the same time, silicone can also promote the plasticization of the fiber surface, so that it is more easily absorbed by the dye, thus improving the dyeing effect.

Silicone is a compound with a special chemical structure and has a wide range of applications in fiber processing. Its main role is as the surfactant, which can reduce the surface tension of the liquid, improve the softness and gloss of the fiber, as well as increase the water resistance, resistance to high temperature, and abrasion resistance of the fiber, it also can be used in the coat. Silicone applications in fiber processing mainly include three aspects: wetting agent, softener, and antistatic agent.

Here’s some information about it:

- What are the properties of silicone?

- What are silicone surface-wetting agents?

- What is silicone softener?

- What are silicone antistatic agents?

- How to choose silicone?

1. What are the properties of silicone?

The main structure of the silicone silicon-oxygen skeleton, and is surrounded by hydrogen atoms or organic groups covered. The bonding energy of the silicon-oxygen bond is larger than that of the carbon-carbon bond, i.e., the chemical bonding force is strong. Therefore, silicones are stable to high temperature and chemicals. In addition, the charge difference between silicon and oxygen atoms is large, and the silicon-oxygen bond is in the middle of covalent and ionic bonding, so it is a relatively stable structure, and it is difficult for the molecules to lap with the neighboring molecules when they vibrate with a large amplitude, i.e., the distance between the molecules becomes larger and the gravitational force between the molecules becomes smaller. Because of this chemical structure, the physical properties of silicone for the surface tension are small, it is heat-resistant, with temperature resistance, smoothness, and lubricity being good. Therefore, it is widely used in various processes of fiber processing because of its high performance.

![]()

The physical form has silicone oil, gel, and resin three types.

(1) Silicone oil is a chain structure, with the freedom of molecular movement, and fluidity, due to different degrees of polymerization, its viscosity can be freely adjusted. The realization of the substituent group of the denaturation is especially easy, so the physical properties of the change range are also very large. Such as water repellency and water absorption can have completely different physical properties, so silicone oil is the most silicone class in the textile.

(2) Silicone molecules have a reticulated structure. Changing the number of crosslinking points can make the molecular freedom of movement change, especially through the choice of crosslinking agent type, and crosslinking conditions, can get different physical properties of the product. As a fiber-processing silicone, its development prospects are very broad.

(3) Silicone resin crosslinking density is large and insoluble, but its prepolymer can be dissolved in solvents. It has a fast cure speed and a short working time.

![]()

![]()

2. What are silicone surface wetting agents?

Silicone surface wetting agent is a class of chemicals, its main component is silicone compounds. Silicone compounds have a unique chemical structure so that it has excellent surface activity and wetting properties, in various fields and have a wide range of applications.

2.1 What are the features of silicone surface-wetting agents?

(1) Silicone surface wetting agents can play a role in a wide range of temperatures and pH ranges, with low surface tension, high wettability, excellent interfacial activity and stability, and other characteristics.

(2) Silicone surface wetting agent also has good corrosion resistance and thermal stability and can adapt to a variety of complex environmental conditions.

(3) The role of silicone in the wetting agent is mainly to improve the wetting ability of the fiber. Fiber surface adsorption of water molecules and other impurities, the presence of these impurities will affect the fiber dyeing and other subsequent processing.

(4) Silicone wetting agent can reduce the surface tension between water molecules and the fiber surface, making it easier for water molecules to penetrate into the fiber, so as to better clean the fiber surface.

![]()

Silicone wetting agent has a very wide range of applications and can be used for cotton yarn, chemical fiber, silk, and other kinds of fiber treatment. In the production process of yarn, silicone-wetting agents can replace traditional lubricants and lubricants, reduce machine failure, and greatly improve production efficiency. At the same time, in the dyeing process, silicone wetting agents can make the dye more evenly distributed in the fiber, so as to get more bright colors.

Attention, you need to wear rubber gloves when using silicone-wetting agents.

![]()

3. What is silicone softener?

Softener is a kind of Polysiloxane polymer and polymer compound, suitable for natural fiber textiles such as cotton, wool, silk, linen, and human hair.

3.1 What are the features of silicone softener?

(1) It is soluble in water, the aqueous solution is extremely stable, good compatibility;

(2) It can give the fabric feels soft, smooth, plump, and has good drape and fluffiness;

(3) It has excellent water absorption and good air permeability;

(4) It has moisture absorption, anti-static;

(5) It has good resilience, wrinkle resistance;

(6) It has a stable working fluid, no emulsion breaking, and no oil bleaching;

(7) It is very small yellowing at high temperature.

![]()

3.2 Why choose silicone softeners?

The role of silicone in the softener is mainly to improve the softness and gloss of the fiber. Traditional softeners are mainly made of fatty acids and chemical substances such as ricinoleic acid, the disadvantage is that it is easy to cause fiber bonding and balling. Silicone softener with its unique chemical structure and molecular chain length, can penetrate into the fiber, thus improving the softness and gloss of the fiber, while reducing the fiber bonding and pilling phenomenon.

Silicone softeners also have a wide range of applications and are ideally suited to treat various fibers such as cotton, synthetic fibers, woolen fabrics, and other textile products that have thickness. In-home textiles and silicone softeners can make blankets and bedding softer and more comfortable to meet the requirements of people's comfort. In the apparel industry, silicone fabric soft treatments are also commonly used in the manufacture of shirts, pants, and jackets to improve the comfort and quality of clothing.

![]()

3.3 How to make silicone softener?

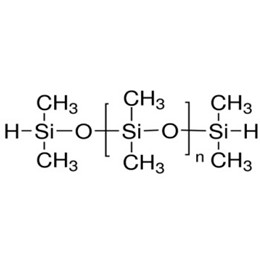

XJY-701 Polymethylhydrosiloxane can be used as a softener for synthetic fiber.

![]()

XJY-707 Hydride Terminated Polydimethylsiloxanes can be dissolved in aromatic hydrocarbons/petroleum hydrocarbons and other organic solvents, insoluble in water, due to the molecular structure containing active hydrogen atoms, can be synthesized through the silicon-hydrogen addition reaction of copolymer polymers, which can be made into a series of activated silicone oil. It can be used to make natural and synthetic fiber softeners.

![]()

4. What are silicone antistatic agents?

Silicone antistatic agent is a kind of anionic special silicone surfactant, belongs to a kind of chemical material, and molecular weight is PH value. With the improvement of people's living standards, the consumption of fiber products is increasing, the annual consumption of chemical fibers around the world has reached 17 million t/a, the consumption of spinning oil up to 180,000 t/a, as one of the components of the spinning oil antistatic agent consumption has also increased. In addition, the spinning, weaving, and fabric finishing process will also be used as the antistatic agent.

4.1 What is the performance of silicone antistatic agents?

(1) Antistatic properties;

(2) Lipophilic and hydrophilic properties;

(3) Good compatibility with silicone oil;

(4) Soft and smooth;

(5) Good hydrophilic and sweat-absorbing properties.

4.2 Why choose silicone antistatic agents?

The role of silicone in the antistatic agent is mainly to reduce the static electricity between the fibers. Fiber easily produces the accumulation of electric charge in friction or other physical effects, which leads to the generation of static electricity. Static electricity not only affects the health and comfort of personnel but also damages the normal operation of machines. Silicone antistatic agents can adsorb and neutralize the charge on the surface of the fiber to effectively reduce the electrostatic effect between the fibers.

![]()

4.3 How to apply silicone antistatic agent?

Silicone antistatic agent has a wide range of applications and can be used for cotton and wool, modal, and other fibers.

(1) It can be used in a variety of chemical fiber textiles and wool, cotton, silk, hemp, fibers, fabrics, clothing, and a variety of manufactured goods.

(2) It can as an antistatic treatment of polyurethane products, plastic products, and rubber products as an additive antistatic agent.

(3) It can be added to coating for an antistatic effect and is used for silicone-coated fabrics. Silicone-coated fabrics have many high performances.

![]()

5. How to choose silicone?

Silicones are used as wetting agents, softeners, and antistatic agents in fiber processing. Through these applications, it can effectively improve the high performance and quality of fibers, increase production efficiency and added value of products, and meet the needs and wants of people for fiber products. How to make your products more competitive?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry and more than 15 related patents and technical support. Our silicone material products can meet the needs of silicone textile additives and support the provision of diversified customized solutions.