Mold releases are an important part of the molding industry. Sticky parts were the status quo in the early days of the molding industry, and even with advances in technology and improvements in mold design and materials used to make molds, release agents still play an important role in reducing cycle times and helping to improve the productivity of injection molding. Mold-release agents have many types, such as petroleum jelly. So what are silicone mold-release agents?

After the use of traditional release agents, a certain amount of release agent may remain on the surface of the product, affecting the quality and performance of the product, especially on some products with very high surface requirements, such as automotive shells, cell phone shells, and painted wall, etc., which will have an impact on the appearance of the product; and traditional release agents are often chemically strong chemicals, which may cause a certain degree of contamination to the environment and human health. If not handled properly, it may have an impact on the biological environment.

Silicone mold release agent is a silicone compound, silicone oil, and silicone resin prepared from siloxanes, is a better isolation of the release agent, and the mold pollution is small. There are high and low-temperature resistance, small surface tension, easy to become a uniform isolation film, long life of the mold release non-toxic, good luster, friendly to the environment, and so on. Silicone mold release agent is the current rubber and plastic release agent in the mid-range market mainstream products, in polyurethane, rubber, polyethylene, and PVC resin processing and high-temperature castings, tire molding, automotive seat cushions and other fields have a wide range of applications.

Here’s some information about it:

- What is the role of release agents?

- How to classify silicone release agents?

- What are the features of silicone release agents?

- How to process the silicone release agent?

- How to choose silicone release agents?

- How to make silicone release agents?

1. What is the role of release agents?

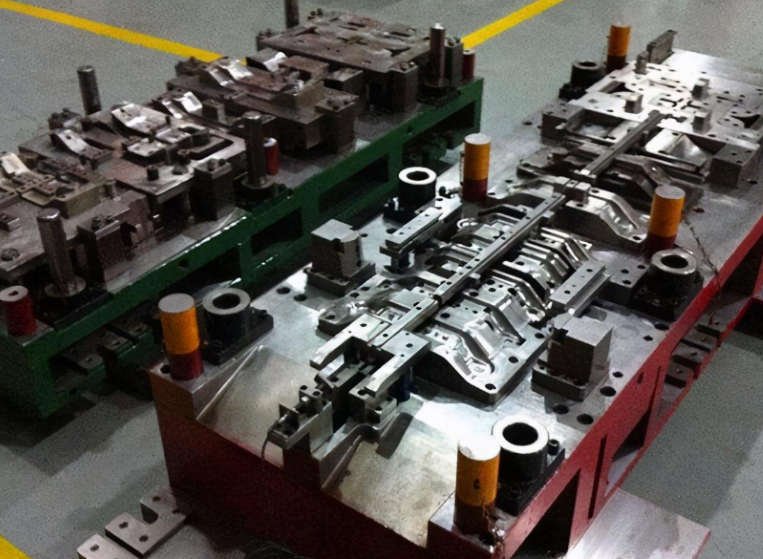

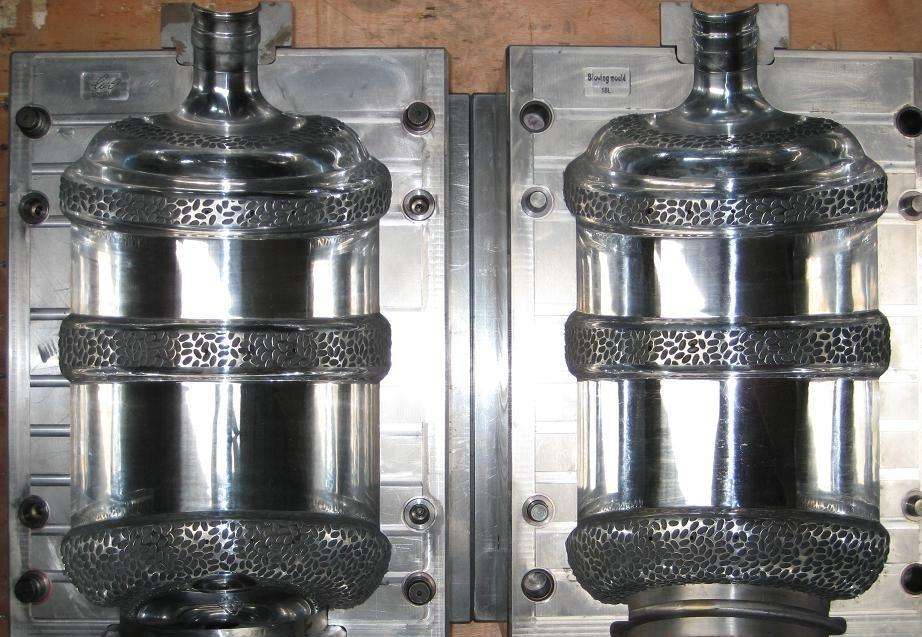

The mold release agent is a kind of interfacial film layer, its role is to separate two easily adhesive objects, commonly used in mold making of rubber, die cast, and plastic products. In the rubber products in the molding process, due to the uneven surface of the mold, rubber, and plastic and the negative pressure between the mold and physical adsorption and other reasons, will cause rubber and plastic products and mold adhesion between the mold and is difficult to peel off, so the emergence of the release agent is best results to solve the problem, the basis of the mold release agent, including organic, inorganic and polymers and so on.

2. How to classify silicone release agents?

There are many types of silicone mold release agents.

2.1 By composition, usage, and form

Silicone mold release agents can be divided into organosilanes and their solutions, silicone resins and their solutions, silicone rubber and their solutions, silicone oils, and their solutions, as well as silicone aerosol.

(1) Organosilane

The base material of siloxane release agents is Alkoxysilane or Chlorosilane, commonly used silane release agents include Methylethoxysilane release agent, Methylchlorosilane release agent, and Phenylchlorosilane release agent, etc., which include two kinds of solids and liquids, the liquid one refers to the combination of the base material of the above release agents and organic solvents.

(2) Silicone resin

Silicone resin and its solution of the base material for silicone polymers, such as methyl silicone resin or methyl phenyl silicone resin, etc., and its solution state of the solvent is usually coated with mold release agent on the surface of the mold and the use of heating to form the work of alcohol or gasoline, and the solution state of the use of the wider, so as to achieve the separation of the rubber plastic and the mold between.

(3) Silicone rubber

Liquid silicone rubber itself is a release agent, but we usually use a solution of silicone rubber dissolved in organic solvents, together with crosslinking agents and catalysts, etc., the use of the same method is to be coated on the surface of the mold, so as to achieve the separation of plastic materials and molds.

(4) Silicone oil and its solution, ointment, silicone aerosol

Silicone oil release agent base material for silicone polymers, mainly including Methyl silicone oil and Methyl phenyl silicone oil, the main component of this release agent is silicone oil or dissolved in gasoline and other solvents to form a solution, while the ointment is based on the use of silicone oil added to the mica, diatomaceous earth, and other components, thus forming a semi-solid state of the release agent. Silicone aerosol is also based on silicone oil as the main base material, while equipped with Freon butane and other substances, its work process is the same as other mold release agents.

2.2 By service life

According to the life classification, the silicone mold release agent can be divided into temporary mold release agent, and semi-permanent mold release agent. Temporary mold release agent refers to the use of the process of its base material is not a new consumption of mold release agent, mainly refers to the inert silicone oil type of release agent. Semi-permanent mold release agent refers to the use of its basic materials in the process of basic non-consumption of mold release agent, mainly referring to the silicone resin type of release agent.

3. What are the features of silicone release agents?

Compared with non-silicone type release agents, the features of silicone release agents specially formulated are very different.

Different types of silicone release agents characteristics are different, the silicone oil type and aerosol type release agents used only through a simple spray can be achieved by separating the purpose of the mold; The ointment-type release agent for the surface of the mold is not smooth, more suitable; water emulsion silicone release agent without gasoline and other organic solvents, will not cause pollution to the air.

(1) Silicone mold release agent form of diversity, solvent type, and can be dissolved in the base material in gasoline and other solvents used;

(2) Silicone mold release agent heat-resistant, will not appear due to high temperature caused by the decomposition or carbonization of the release agent;

(3) From the stripping force of the release agent, the silicone material release agent has a relatively small stripping force and is easy to produce;

(4) Due to the characteristics of silicone materials and high-temperature resistance, there will be no toxic substances in use;

(5) Silicone mold release agent has a long service life and is widely used, which helps to improve the productivity of enterprises and bring economic benefits to enterprises.

4. How to process the silicone release agent?

There is a procession video of a silicone release agent to learn on the Internet. In the processing of silicone mold release agent, due to the material itself and the different properties of the processing conditions, the process characteristics of the release agent, and the use of different features, the processing conditions are also very different, so specially formulated a different production process according to the different characteristics of the production of silicone release agent in the production of the process of the impact of a number of factors to pay attention to.

Therefore, according to different process characteristics, and different mold-releasing agents using different production programs, the stripping force of the mold-releasing agent requires a small, usually chosen very small viscosity of the silicone oil as the base material, the advantage lies in the easy-to-peel; for the molding temperature of the mold releasing agent, to use high-temperature-resistant materials, such as silicone resins; and for the larger hot compression molding molds, the mold releasing agent should be used in silicone oil or silicone rubber aqueous emulsion. According to the finished product from the mold to peel the way also needs to use different mold release agents specially formulated.

4.1 Specific issues to note are as follows:

(1)Material and features:

Including the polarity of the material, the melt viscosity, the ability to bond to the mold, etc.

(2)Process conditions:

Including the production temperature, time, and the movement of the track edge from the mold, etc;

Such as the number of processing, size, and processing accuracy requirements.

(4) Processing mold conditions:

Such as the material of the mold, shape, and size, the characteristics of the mold surface as well as the requirements of the application, the specific requirements, etc.;

(5) Use of performance:

Including mold-releasing agent application and removal conditions, mold-releasing agent use temperature and working life, peeling force, etc.

5. How to choose silicone release agents for your applications?

Silicone mold release agent has many forms, and the applicable materials and processing technology is also different, such as organic compound silane is usually used in corrosion-resistant glass and ceramic materials, and aerosol silicone mold release agent can be used in the processing of small products. Water emulsion silicone release agents can be used in large-scale hot mold processing; non-migratory silicone release agents can be used to emphasize the adhesive coating rubber and plastic products release.

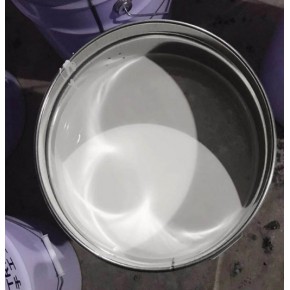

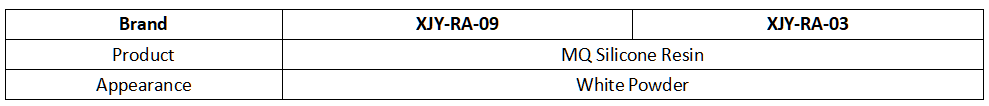

XJY-RA-09/03 MQ Silicone Resin is a high molecular weight silicone resin in the form of white powder with good film-forming ability and a long-lasting mold release effect.

Applications:

(1) It can provide durable release film for epoxy resin, melamine, methacrylic acid vinegar, phenolic resin, polyvinyl acetate, and polyurethane vinegar when manufacturing plastic parts;

(2) It can be used to release silicone glass laminates as well as silicone molded plastic tubes and parts;

(3) It can be used to provide a release function for wood molding operations, metal casting, and rubber gaskets;

(4 )It can play a good role in polyurethane vinegar mold release: especially polyvinyl acetate, polyurethane acetate shoe soles, and so on.

(5) It can be used in microcellular automotive parts and furniture (whole skin) molding; and performs efficiently in automotive parts: bumpers, crash pads, dashboards, etc.

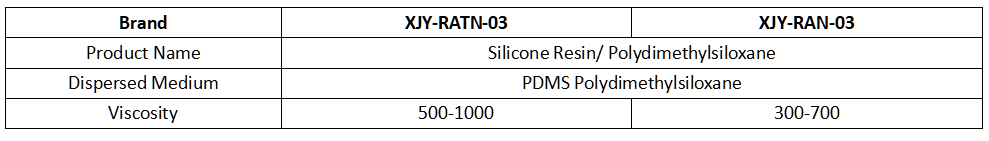

XJY-RATN-03/XJY-RAN-03 Silicone Resin/Polydimethylsiloxane, a colorless or light yellow transparent liquid that can be used as a mold release agent specially formulated in plastics.

(1) It can be used as a mold release agent in the manufacturing process of plastics, adhesives, and elastomers to provide a durable release film.

(2) It can also be used for polyurethane mold release; microcellular automotive parts and furniture mold release; and automotive parts: bumper, crash pads, and dashboard mold release.

6. How to make better silicone release agents?

In the rubber products in the molding process, the use of release agents is very wide, and compared with other release agents, this mold release agent specially formulated production process, production process, and performance have great advantages, with easy-to-use, high-temperature resistance; it will not cause molded parts to fade; it is available to dilute by a solvent; it has lower surface tension and other properties. How to make your products more competitive and determine suitablity?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry and more than 15 related patents and technical support. Our silicone MQ resins can meet the needs of silicone mold release agents and support the provision of diverse customized solutions.