Waterborne paints are a new type of environmentally friendly coating using water as the main solvent, also known as water paint, used by spray gun, after the water evaporates can form coating, which is widely used in construction, automotive, industrial coatings, and other fields. Compared with traditional solvent-based paint and first coat, water-based coatings can be directly coated and constructed on wet surfaces and in humid environments; water-based coatings are well adapted to the surface of the material and have strong coating adhesion and less volatile organic compounds, they also can reduce VOC emissions. So why apply silicone additives to waterborne paints?

Hydrophobic Polysiloxane-polyether Copolymers are characterized by a high degree of incompatibility with the foam medium (water/surfactant solution). At the same time, it is compatible with the coating medium. This ensures its highly efficient defoaming ability with a tendency not to produce shrinkage. Many paint film maladies such as shrinkage, poor substrate wetting, and orange peel are caused by differences in surface tension.

Silicone additives can reduce the surface tension of waterborne paint and keep them constant at lower levels without producing differences in surface tension, thus solving many of the problems caused by surface tension. In addition to reducing surface tension, such additives can also increase surface wettability of waterborne paint, so that scratch resistance is improved.

Here’s some information about it:

- How to classify silicone additives?

- How do silicone additives work?

- What are the advantages of silicone additives?

- What are the precautions of silicone additives?

- How to make silicone additives?

1. How to classify silicone additives?

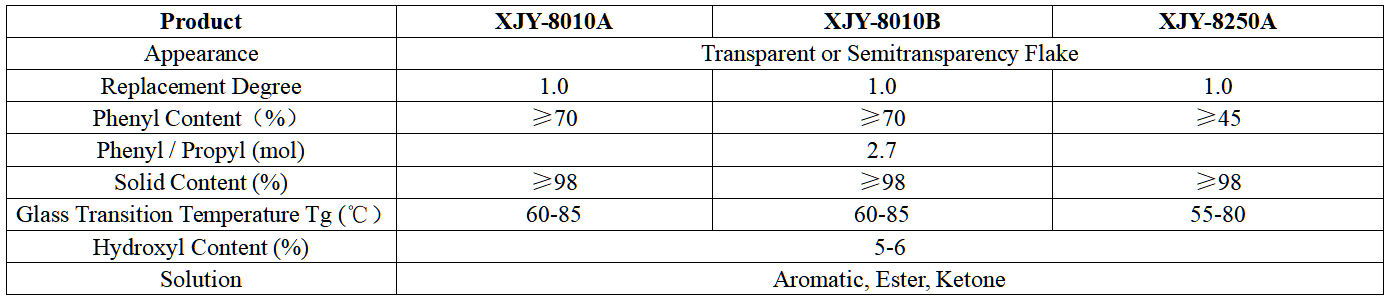

Compared with the oil-based system, waterborne paint, due to water as the dispersing medium, the high surface tension is easy to cause the coating is easy to shrink, the system is easy to bubbles, the pigment is difficult to disperse, the substrate is difficult to adhere and wet, and other shortcomings, so a variety of additives are applied to the water-based system. Silicone additives rely on their molecular structure, and have low surface tension and high surface activity, so it is widely used in waterborne paint as well as solvent-based paints. The chemical structure can be divided into two main categories, silicone and silicone oil, as follows.

![]()

(1) Siloxanes are generally small molecular weight compounds and are used as adhesion promoters, cross-linking agents, dispersing agents, wetting agents, etc. in waterborne paint or solvent-based paints.

(2) Silicone oil by controlling the size of the molecular weight, for the control of the branched chain structure, the group can be synthesized with different properties of the additives to adapt to the needs of different systems, have good performance in waterborne paint or solvent-based paints.

![]()

2. How do silicone additives work?

Most of the additives used in waterborne paint systems are surface surfactants, so they are generally used to solve the problems between the coating and the coating and the substrate by lowering the surface tension (coating-air interface) and interfacial tension (pigment-filler-system interface, coating-substrate interface, etc.), and then improve the performance of the coating. The following mainly introduces the principle of the role of various types of additives.

2.1 As adhesion promoter

For ceramics, glass, plastics, metals, and other substrates, the role of chemical bonding can be very good for promoting the adhesion between the coating and the substrate, organosilanes through hydrolysis, the formation of silicone hydroxyl can be hydroxyl with the surface of the substrate, through the bonding can be very good to form a solid adsorption layer, while R in the reactive groups can be formed with the resin in the group of the formation of cross-linking reaction, thereby forming a bridge between the resin and substrate role.

2.2 As silicone substrate wetting agent

In the process of water-based paints application, metal, wood, plastic substrates, and other surfaces are prone to more difficult wetting agents, which leads to shrinkage phenomenon, and silicone wetting agents for such substrates have a good wetting effect.

Rapid wetting of the substrate is a dynamic process, the wetting agent through rapid movement to the surface of the system, reduces the surface tension of the system to achieve the rapid wetting effect.

The migration process of surfactant can be characterized by the dynamic surface tension, the lower the dynamic surface tension, the faster the surfactant migrates from water to the interface, the migration process is mainly affected by the molecular chain structure, molecular weight size, viscosity of the system and the strength of ions.

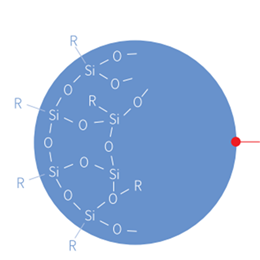

Aqueous systems use more silicone wetting agents generally Polyether-modified silicone oil, the relative molecular mass is small, n = 0 ~ 3, x = 1 ~ 10. At the same time, a large number of CH3 chain external extensions greatly reduces the surface tension, research shows that when the hydrophilic group is in the middle position of the chain segment, the best effect.

Due to the special properties of silicon, there are many benefits of applying it in waterborne coatings, it can effectively reduce the surface tension of the paint film and enhance the surface smoothness. In addition, the structure of silicone-containing highly stable can make the paint film weathering improved, and the occurrence of yellowing declines.

3. What are the advantages of silicone additives?

3.1 Weathering and abrasion resistance

The application of silicone additives in water-based paint can greatly enhance their weathering resistance. This means that the waterborne paint is more resistant to oxidation, UV rays, and moisture, which extends the service life of the coating. In addition, silicone additives can also improve the abrasion resistance of the coating, so that it is less susceptible to wear and damage during use.

3.2 The gloss and transparency

Silicone additives can increase the gloss and transparency of waterborne paint to give it a more attractive appearance. This is especially important for applications requiring high gloss or transparency of paint surface, such as printing and packaging.

3.3 Reduce the surface tension of coatings

Silicone additives reduce the surface tension of aqueous coatings, making them easier to flow and level. This helps to improve the surface smoothness of the coating and reduces the risk of air bubbles or poor uniformity during coating application.

3.4 Improve adhesion and stain resistance

Silicone additives can improve the adhesion resistance of waterborne paint, reducing stickiness and making coating surfaces easier to clean and maintain. In addition, they can also enhance stain resistance, making the coating less susceptible to the adhesion of dirt and contaminants.

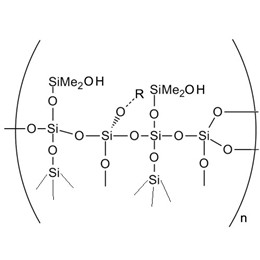

XJY-8010/8250 Flake Methyl Phenyl Silicone Resin/Flake Silicone Resin are silicone resins with hydroxyl functional groups, which can be used in solvent-borne high-temperature coating additives and other solvent-based paints to enhance the waterborne paint' resistance to high temperatures, weathering, waterproofing, and hardness, is also environmentally friendly paint.

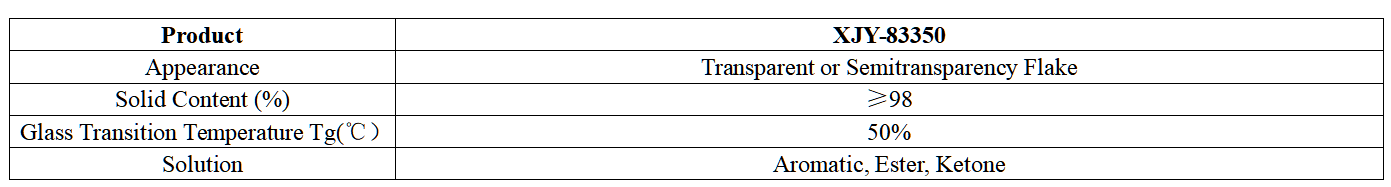

XJY-83350 Polyester Modified Flake Silicone Resin is a polyester-modified methyl phenyl silicone resin intermediate, which can be used in various waterborne paints to improve its performance.

4. What are the precautions of silicone additives?

4.1 Compatibility test

Before introducing silicone additives into waterborne paint formulation, it is important to conduct a compatibility test. Different types of silicone additives may be incompatible with other coating components, so you need to make sure they are compatible with other components in the coating formulation.

4.2 Usage Control

Be sure to use the correct amount of silicone additives. Excessive amounts of silicone additives may cause the waterborne paint to appear unevenly glossy or tacky, while insufficient amounts may not be utilized to their advantage.

4.4 Construction conditions

Conditions such as temperature, humidity, and air pressure during waterborne paint application can affect the performance of silicone additives. Always make sure that the construction conditions are appropriate to obtain the best results.

4.5 Safety Measures

When handling silicone additives, appropriate safety measures must be taken to safeguard the operator, including wearing appropriate personal protective equipment, ensuring good ventilation, and following the recommendations on the safety data sheet.

To ensure optimal results, the amount of silicone additives used needs to be reasonably controlled, and attention needs to be paid to coating compatibility, construction conditions, and safety measures. Through proper application and careful handling, silicone additives can provide solvent-based paint with excellent performance and appearance for a variety of applications (such as waterborne automotive paint).

5. How to make silicone additives?

Any coating that uses water as a solvent or as a dispersing medium can be called a water-based coating. Waterborne coatings are a relatively new type of coating in the current coatings market. The use of silicone additives in waterborne coatings provides a variety of advantages to the coating, including improved weathering, gloss, and clarity, reduced surface tension, and enhanced adhesion and stain resistance. How to make your products more competitive?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry as well as more than 15 related patents and technical support. Our silicone raw material products can meet the needs of silicone waterborne paints and support the provision of diversified customized solutions.