With the improvement of people's living standards, antibacterial and anti-odor, antistatic, waterproof, and moisture permeability, oil and stain resistance and other functional fabrics are more and more popular with consumers, which also shows that the market demand for functional fabric products is growing. In order to adapt to the market demand, the textile processing plant for the research and development of functional fabric products and production efforts are also growing, the application of functional textile auxiliaries is more and more widely used, and commonly used are waterproofing agents, and so on.

Silicone waterproofing agent is a special chemical material, that can apply maximum repellency in a single application, with waterproofing, moisture, oil, static, and weather resistance and other functions, widely used in textiles, construction, automotive, leather boots, aerospace electronics, factory waterproofing, and other fields. Then why use silicone water repellent on textiles?

In the textile field, silicone water repellents can enhance the waterproof performance of woven fabrics, and apply maximum repellency. After the textile is treated, it no longer wrinkles when exposed to water and is less likely to harbor mold and bacteria, extending the life of the garment. In addition, silicone water guard can make the fiber surface become smooth, have better breathability, and be more comfortable.

Here’s some information about it:

- Why need textile waterproof?

- How to classify textile water repellent?

- Why can silicone water repellent be waterproof?

- What are the precautions for using silicone water repellents?

- How to improve silicone water repellent?

- How to make silicone water-repellent performance better?

1. Why need textile waterproof?

At present, consumers have higher and higher performance requirements for textiles, and consumers are more and more inclined to buy functional textiles, such as fly-knit sports shoes and sleeping bags, boat covers with excellent waterproof effect, punching jackets with repels water, cold-proof, warmth and other characteristics, quick-drying clothes with fast moisture absorption and sweat removal, and anti-bacterial and anti-odor socks and so on.

Adding water repellents to the finishing gives textiles a waterproof effect. In the past few years, amazing developments have been made in cotton and its blends.

Textiles made of synthetic fibers such as polyester are highly hydrophobic and prone to static electricity, making it easy to deposit dirt from daily use, and oily dirt also adheres firmly to textiles, making it difficult to remove dirt and wash them. So it is very important to make the textiles have durable waterproof performance and anti-static ability in daily life and some special industries.

![]()

2. How to classify textile water repellent?

2.1 Paraffin-aluminum soap

Its advantages are cheap and easy to use; its disadvantage is poor washing performance, and feels rough and hard, instead of aluminum salt and zirconium salt, the finishing effect will improve, but it will increase the cost.

2.2 Hydroxymethyl melamine derivative class

Its advantage: durable water repellency, and softening effect, can be used alone; Its disadvantage: needs to be combined with resin to improve the feel.

2.3 Chromium stearate compounds

Its advantage: durable water repellency; Its disadvantage: chromium ions in the structure of the fabric color light green, will increase the difficulty of dyeing, and chromium ions do not meet the environmental requirements

2.4 Pyridinium quaternary ammonium salt class

Its advantages are durable water repellency and a soft effect; its disadvantage is that it produces unpleasant gases at work, needs a well-ventilated area, affects the working environment, and the treated fabrics are prone to yellowing and color changes

2.5 Fluorocarbon waterproof and oil-proof agent

Its advantages are good waterproof, oil and dirt repellent effect, good hand feel, and washing resistance; its disadvantage is that the use of perfluorocarbon compounds is increasingly restricted due to environmental toxicity

2.6 Non-fluorine waterproofing agent

Its advantages are fluorine-free, safe, and environmentally friendly, in line with environmental requirements; and cheaper than fluorocarbon waterproofing agents; its disadvantage is that in the current market of fluorine-free waterproofing agents only waterproofing effects, there are no oil and dirt effects

2.7 Silicone water repellent

Silicone waterproofing agents can be self-crosslinking film, finish fabrics with breathability, apply maximum repellency, and need to be shared with hydroxyl silicone oil emulsion to increase film toughness and strength. Silicone can also be specially formulated for restoring factory waterproofing.

![]()

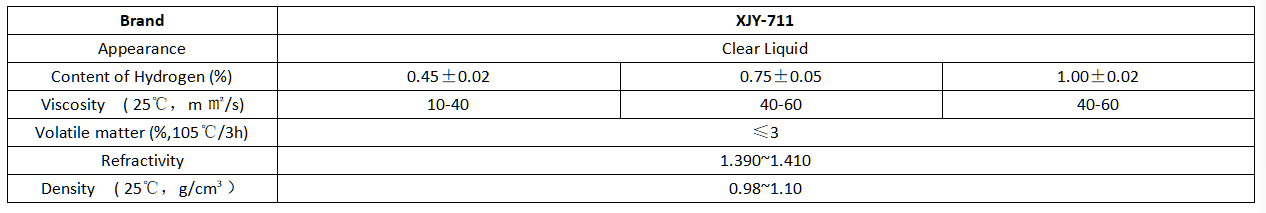

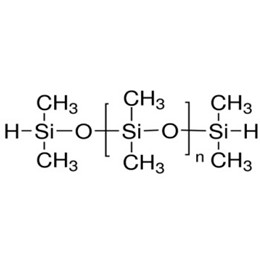

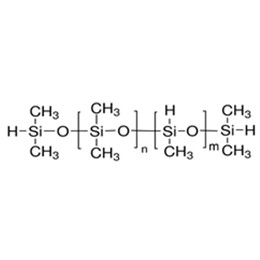

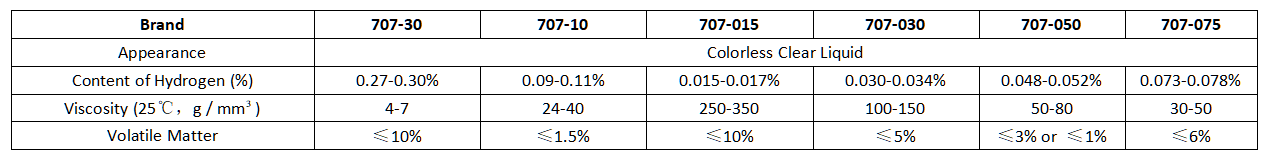

XJY-701 Polymethylhydrosiloxane under the action of a metal salts catalyst, low temperature can be crosslinked into a film, in a variety of substances on the surface to form a waterproof membrane, and can be used as a heavy duty water repellent for fabrics.

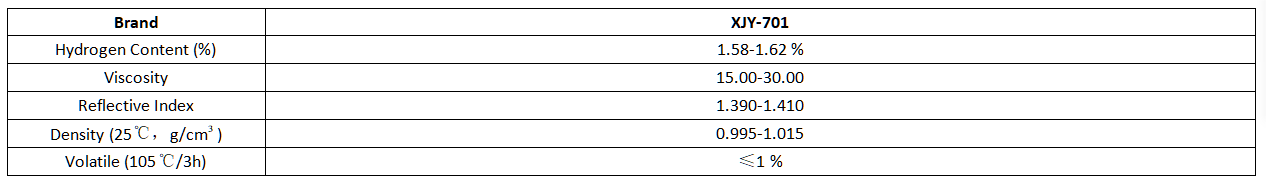

XJY-711 Hydride-Terminated Methylhydrosiloxane /Dimethylsiloxane Copolymer can be used as a heavy-duty water repellent and finishing agent for fabrics after specially formulated, and can apply maximum repellency.

XJY-707 Hydride-Terminated Polydimethylsiloxanes can be used as heavy-duty water repellent and softener for natural and synthetic fiber fabrics.

3. Why can silicone water repellent be waterproof?

Silicone waterproofing agent is inexpensive, non-toxic, and in line with the concept of green development, with excellent comprehensive characteristics, and thus its application prospects. This is mainly due to the main chain of silicone polymers is usually interactively ordered -Si-O - links, molecular side chain containing different carbon numbers of alkyl, amino and carboxylic acid groups, etc., mainly.

Generally speaking, in the application, the main chain of its molecules in the silicon-oxygen atoms due to the strong electronegativity and close to the surface of the material into a film, on the contrary, the side chain will be away from the surface layer arranged in the periphery of the performance of different roles. Silicone's excellent waterproof ability is attributed to its low surface energy, the most common waterproofing agents in this category are Hydroxyl silicone oil, Dimethicone, and Hydrogen silicone oil.

Textiles treated with silicone waterproofing agent can achieve significant waterproofing effect, the main reason is the polymer film on the fiber surface, its molecular side chain contains functional groups arranged in the direction of the air, and the active groups easily react cross-linking and easy to bond with the fiber, and ultimately a layer of smooth film covering the surface of the fiber after fully cured, and play a role in blocking the infiltration of water, oil droplets, etc. textiles.

![]()

4. What are the precautions for using silicone water repellents?

Silicone waterproofing agents used in various types of textile finishing have been a welcome achievement, due to the silicone waterproofing agent raw materials's low price, breathable and soft effect, and other comprehensive performance is excellent, and has a high cost-effective, prompting silicone products in the textile industry have been widely used. It is worth noting that: silicone water repellents only need a small amount to make the textile have obvious hydrophobicity, the soft effect is good, and can enhance the textile shape retention and so on. If the dosage is too much, it generates a double-layer silicone membrane on the polar surface, hydrophobicity decreases, and water washing resistance decreases, which may be due to the hydrolysis of siloxane and the swelling effect of fibers in the water, resulting in rupture of the silicone membrane, so it needs even coverage.

In addition, the application effect of certain unmodified single components still reveals different degrees of disadvantage. Hydrogen-containing silicone oil because of its high activity of the Si-H bond, with the help of a catalyst, can be grafted with different functional groups to modify it, on the one hand, to change its molecular structure, access to the functional groups in different industries in the application of the effect of unique. And continue to work on the development of new types of multi-stylized, multi-functional silicone products, it is a potentially unlimited, far-reaching, and extremely valuable direction of research.

![]()

![]()

5. How to improve silicone water repellent?

Fluorine polymers are difficult to degrade and extremely hazardous, and the textile feel and softness of textiles after treatment are significantly worse than other adverse effects. On the other hand, compared with fluorine-based products, silicone waterproofing agent products are less oleophobic. For fluorine, silicon polymer's disadvantages, in order to make up for their shortcomings, to take the fluorine, silicon jointly introduced into the polymer and then set the two sides of the excellent characteristics of one, complement each other, play its characteristics.

Preparation of fluoro silicone finishing agent has excellent hydrophobicity, oleophobicity, resistance to high and low temperatures, anti-fouling, and other comprehensive application characteristics, its R&D progress has been the attention of the masses, and very application potential.

![]()

6. How to make silicone water-repellent performance better?

With the improvement of people's living standards, people for textiles put forward more functional requirements, not only requiring textiles to have waterproof and stain-resistant features but also to maintain the original soft feel of textiles, moisture permeability, air permeability, and other properties. Silicone waterproofing spray is widely used in the textile field, such as sleeping bags, and boat covers. How to improve the competitiveness of your products specially formulated? Add the products to the cart add now.

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry as well as more than 15 related patents and technical support. Our raw silicone products can meet the needs of silicone water repellents and support the provision of diversified specially formulated customized solutions.