After the Industrial Revolution, the automobile industry thrived, and various new materials were introduced to manufacture automobiles. Silicone as one of the representatives is no exception, so why use silicone for cars?

Silicone materials have good tear resistance, and are suitable for automotive airbags, seat belts, and other parts that need to withstand stretching and tearing, to improve the safety of the car;

Silicone materials have a low coefficient of friction, which can reduce damage to prolong the service life of the automotive parts;

Silicone materials also have excellent heat insulation and weather resistance and are available in various forms in the automotive industry.

Silicone materials also have excellent heat and insulation resistance and weather resistance, there are a variety of forms that can be applied to various parts of the car.

The following five aspects of the characteristics of silicone materials and how to applied to the automotive industry:

- What are the advantages of silicone?

- Is silicone safe?

- What silicone raw materials can do in the automobile?

- What silicone products bring to automobiles

- How to make the car's performance better?

1. What are the advantages of silicone?

(1) Color variety: Silicone materials have good colorability, and can be made into different colors, suitable for automotive interior parts, exterior parts, and other parts that need to be beautiful to meet the individual needs of consumers.

(2) High weather resistance: Silicone materials can resist ultraviolet rays, weathering, and other factors to keep the color bright and long-lasting and extend the service life of auto parts.

(3) Easy to clean: Silicone materials with low surface energy are easy to clean, and suitable for automotive interior, exterior parts, and other parts that will be cleaned frequently.

(4) Good abrasion resistance: Silicone materials have good abrasion resistance and are suitable for automotive tires, brake pads, and other parts that bear damage to improve the car's service life.

![]()

2. Is silicone safe?

(1) Non-toxic and harmless: Silicone materials are non-toxic and harmless and are suitable for automotive interior parts, exterior parts, and other parts in direct contact with the human body, to ensure the health of the occupants. Silicone materials in the combustion of smoke and gas produced are non-toxic and harmless, suitable for automotive interior parts, exterior parts, and other parts that need safety and environmental protection, are suitable for repair applications.

(2) Easy to recycle: Silicone materials are easy to recycle in line with the requirements of sustainable development to help reduce environmental pollution.

(4) High flame retardant grade: Silicone materials have a high flame retardant grade, suitable for automotive engines, exhaust systems, and other parts of the need for fire prevention, to improve the safety of automobiles.

(5) Good self-extinguishing: Silicone materials have good self-extinguishing, when the fire source is removed, it can be automatically extinguished, reducing the risk of fire spread.

![]()

3. What silicone raw materials can do in the automobile?

3.1 Silicone resin

Silicone resins have excellent heat resistance, weather resistance, and electrical insulation, they are very suitable for use in the automotive industry. Silicone resins can manufacture many components such as automotive seals, gaskets, hoses, shock absorbers, tires, and brake pads. Silicone resins can also make automotive coatings, paints, and polishes to protect automotive surfaces from corrosion and wear.

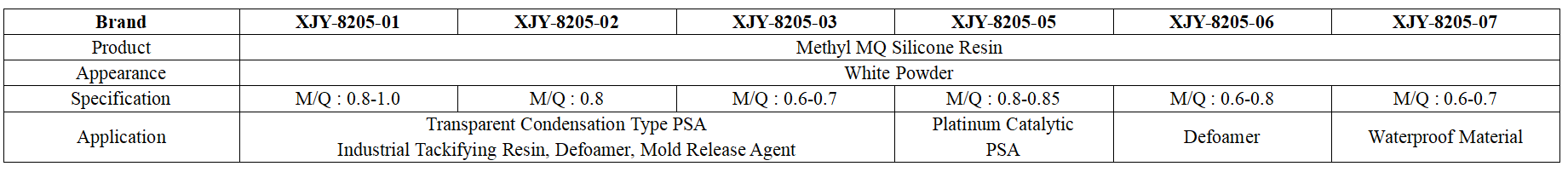

XJY-8205 Powder Series Methyl MQ Silicone Resin is a solid powder resin. This resin will form long-lasting durable films to provide excellent transfer and water resistance. XJY-8205-07 has been widely used in automotive water repellents by end customers.

3.2 Silicone Sealant

Silicone sealants have excellent heat resistance, weather ability, and waterproofing properties, automotive sealant is suitable for automotive sealing to prevent coolant leaks and repair tube cracks. Silicone sealants can seal automotive doors and two surfaces windows, automotive glass, automotive engines and transmissions, and other components. Silicone sealants can also be used in automotive electrical systems and electronic components to prevent moisture and dust intrusion.

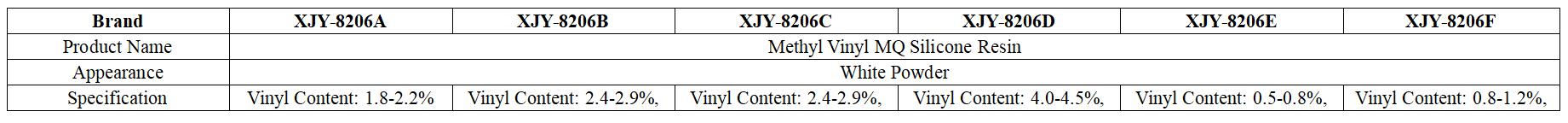

XJY-8206 Methyl Vinyl MQ Silicone Resin is a solid powder resin. This resin is used for additive molding of silicone rubber without strong fillers, as a base material for high transparency and high hardness silicone, which can be used in silicone sealants, such as low-temperature gasket applications.

XJY-8206N Series Solution Methyl Vinyl MQ Silicone Resin is a colorless and transparent liquid resin consisting of Vinyl MQ Silicone Resin and Vinyl Silicone Oil. It can be used for LSR liquid additive silicone rubber, LED encapsulation adhesive, and other two-component additive adhesives, all of which can be used in the automotive field, and can be automotive sealant in the automotive field.

3.3 Silicone coatings

Silicone coatings have excellent heat resistance, weather resistance, and corrosion resistance, they are very suitable for automotive painting. Silicone coatings can also effectively protect the surface of automobiles from the erosion of ultraviolet rays, rain, acid rain, and salt spray, it also has good decorative properties, making the surface of automobiles more beautiful.

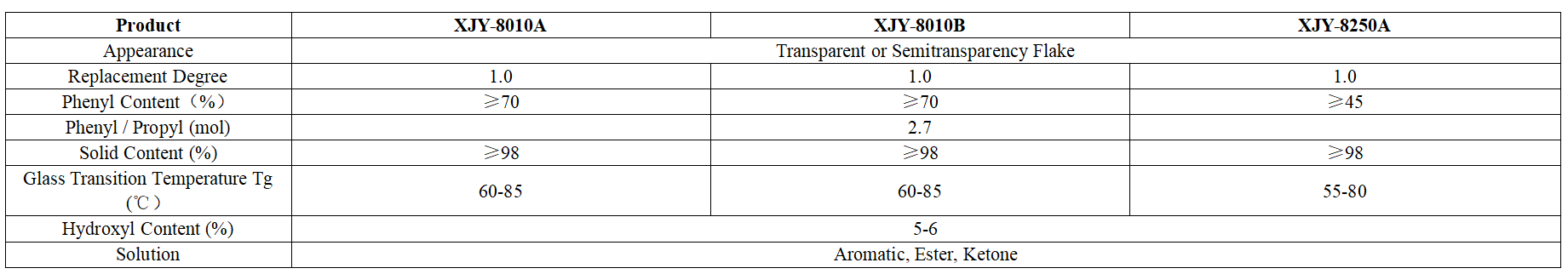

XJY-8010A/B/XJY-83350 Flake Silicone Resin can be used in high-temperature-resistant powder coatings and liquid coatings. The primary feature of silicone resin is its excellent heat resistance, which hardly decomposes at 200℃ or even higher, it can be used to prepare various heat-resistant coatings, and its heat-resistant insulation grade can reach H class. Silicone resin also has excellent weather resistance, ozone resistance, arc resistance, hydrophobic moisture resistance, salt spray, mold resistance, and other properties. For example, with more than 20% silicone resin-modified coating, its water resistance, yellowing resistance, temperature resistance, ultraviolet resistance, and other properties significantly improved.

3.4 Silicone surfactant

Silicone surfactants have excellent surface activity, permeability, wettability, and dispersibility, which can effectively reduce surface tension to improve the leveling and gloss of coatings and the adhesion and weathering resistance of coatings. Silicone surfactants have various applications in the automotive industry, including automotive coatings, automotive cleaners, automotive polishes, automotive interior care agents, automotive adhesive products, and so on. Silicone surfactants in automotive coatings can improve the leveling and gloss of coatings and the adhesion and weather ability of coatings, extending the service life of coatings.

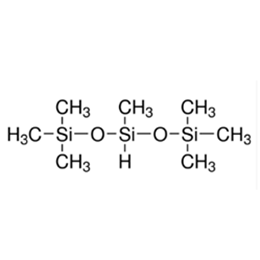

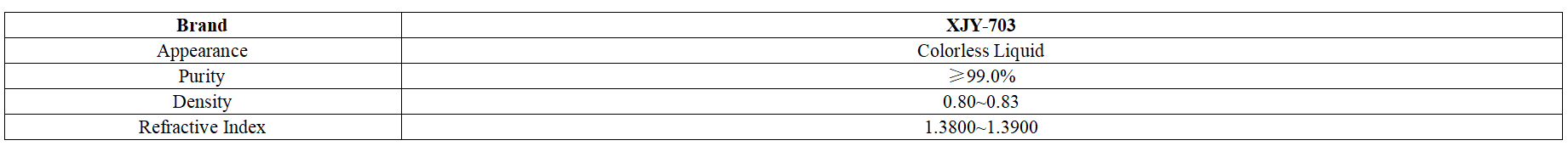

XJY-703 Bis(Trimethylsiloxy)/Methylsilane contains highly active silicon hydrogen bonding, is the basic raw material for the synthesis of Polyethylene Cxide Modified Heptamethyltrisiloxane, is a pesticide additive, coatings additives, and other special structure surfactants.

3.5 Silicone emulsion

Silicone emulsions have excellent weather resistance, aging resistance, high-temperature resistance, low-temperature resistance, chemical resistance, and hydrolysis resistance, they can effectively protect cars‘ surfaces from the external environment. Silicone emulsions have many applications in the automotive industry, including automotive tires rubber products, interior materials, sealants, and so on. Silicone emulsions in automotive tires can improve the wear and wet slip resistance of tires to extend the service life of tires.

3.6 Silicone grease

(1) Lubricating effect

Silicone grease has excellent lubricating properties, low coefficient of friction, can reduce wear, and prolong the life of parts. Silicone grease has good antioxidant properties and can prevent parts in high-temperature corrosion and aging. Silicone grease has good water and moisture resistance and can protect the parts underneath the wet environment during normal work.

(2) Sealing effect

Silicone grease has good weatherproof seal performance and can prevent leakage and penetration to ensure the system works normally. Silicone grease can resist extreme weather and temperature changes, to ensure the sealing effect stays flexible. Silicone grease has good compatibility, it is compatible with a variety of materials and is easy to use and maintain.

![]()

(3) Vibration damping effect.

Silicone grease has good shock absorption properties and can absorb shock and vibration, it reduces the damage to parts. Silicone grease has good fluidity and can be uniformly distributed on the surface of the components to enhance the damping effect; it has good high-temperature resistance and can be maintained in a high-temperature environment vibration damping performance, to ensure that the system works properly.

(4) Insulating effect

Silicone grease has good insulating properties, which can prevent leakage and short circuits between electrical parts and ensure the safe operation of the system; it has good corona resistance and arc resistance, which can prevent corona and arc from occurring in electrical parts and improve the reliability of the system.

![]()

(5) Corrosion prevention

Silicone grease has good anti-corrosion properties, which can prevent metal parts from corroding in humid acidic and alkaline environments, and prolong the life of the parts; it has good weather resistance and temperature resistance, which can resist extreme weather and temperature changes, and ensure that the anti-corrosion effect is long-lasting and stable.

Silicone grease can be used as a heat transfer medium for electronic components, electrical equipment, and industrial equipment heat dissipation; it can be used as a damping fluid for shock absorbers, hydraulic buffers, and reducers, etc.; it has good compatibility with a variety of metal materials compatible with easy to use and maintain.

4. What Silicone Products Bring to Automobiles

4.1 Silicone tires

Silicone tires have excellent abrasion resistance, grip, and wet performance, they are very suitable for high-performance cars; they also have good heat resistance and weather resistance and are very suitable for use in hot or cold areas; the rolling resistance is small and can improve the fuel efficiency and range of the car.

![]()

4.2 Silicone polish

Silicone polish has an excellent polishing effect and protective effect, which is very suitable for automobile polishing; it can effectively remove scratches, stains, and oxidized layers on the surface of the automobile, making the surface of the automobile brighter; it can also form a protective film to protect the surface of the automobile from the erosion of dust, dirt, and rainwater.

4.3 Silicone shock absorber

Silicone shock absorber has excellent shock absorption and energy absorption and are very suitable for automobile shock absorption; they can effectively absorb the vibration and impact generated in the process of automobile driving to improve the comfort of the car ride; They also have good heat resistance and weather resistance and are very suitable for use in hot or cold areas.

4.4 Silicone leather

Silicone leather is a new type of environmentally friendly leather, silicone is a raw material, and this new material and microfiber, non-woven fabrics, and other substrates are combined, processed, and prepared for various industry applications. Silicone leather uses solvent-free technology, the silicone coating bonded to various substrates, made of leather. Compared with traditional leather, silicone leather is hydrolysis resistant, has low VOC, no odor, environmental protection, resist vibration, and other performance advantages. In a long time of use or placed in the case, PU/PVC and other synthetic leather will make the leather within the residual solvents, plasticizers continue to release, on the liver, kidneys, heart, and nervous system development have an impact on the silicone leather is more environmentally friendly and safe to the human body without stimulation.

![]()

Sileather automotive leather is the most durable and luxurious animal-free vegan leather on the market, a perfect combination of nature and technology. Sileather uses a raw material, natural quartz ore, which is organically processed to form a high-performance silicone resin, greatly reducing dependence on fossil energy and defining the inherent excellence of Sileather. Leather can be used extensively in automotive seating and automotive interiors.

4.4 Silicone Foam

Compared with traditional carbon-based foams, this material can resist low and high temperatures (-55-250° C), high flame retardancy (V-0), and low smoke concentration. In addition, the material's excellent aging resistance and weathering performance are excellent, it is all kinds of high-performance sealing, shock absorption, cushioning, sound insulation, protection, insulation, and fire prevention of the ideal material.

Silicone foam has strong elasticity to mechanical fatigue and excellent resistance to compression set and creep resistance. Silicone foam provides high-performance sealing and protection for lithium-ion batteries in electric vehicles. These include cell gaskets (soft pack cell gaskets, square shell cell gaskets); vibration damping support - cooling plate support gaskets gas sealing; square shell cell exhaust valve sealing (effective sealing between the exhaust valve and the exhaust channel ensures that hot gases are discharged from the set channel), and so on.

![]()

TeksioTM High-Performance Silicone Foam is a foam material formed by foaming Polysiloxane, which maintains the excellent characteristics of silicone polymers, such as resistance to high and low temperatures, insulation, and weathering, and combines the low density of foam materials with excellent acoustic and vibration resistance.

5. How to make the car's performance better?

Silicone materials, including silicone resins and silicone oils, have excellent physical and chemical properties, weather and water resistance, and high-temperature resistance, they can be used in a variety of industrial applications, such as plastics. They have also played a huge role in automobile manufacturing in recent years. How to improve the competitiveness of your products?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry as well as more than 15 related patents and technical support. Our silicone raw material products can meet the needs of the automotive field and support the provision of diversified customized solutions.