In the extraction of oil fields, there will be some foreign air mixed with the surface-active substances of oil fields to produce bubbles, the strata contained in the natural gas overflow will also produce bubbles. A large number of bubbles will lead to oil droplets scattered, affecting oil quality, causing serious environmental pollution, and even serious harm to human health. So it needs to use antifoam agents. So why choose silicone defoamer in the petroleum industry?

Using silicone defoamers can reduce the height of the foam layer to prevent the overflow of the top, it greatly reduces the carrying capacity of heavy oil and tar powder of the oil and gas out of the tower. Silicone defoamers have a certain target, they can effectively eliminate and inhibit the foam when containing a large amount of water and dissolved gas crude oil generating in the process of gas separation, transportation, tank loading and others, to improve the efficiency of the oil and gas separator work efficiency and tanker trucks, tanker loading efficiency.

This article will introduce the application of silicone defoamers in turn, and how silicone defoamer plays a role in these applications:

- Why is foam in the petroleum industry?

- Why defoaming is needed?

- What are the advantages of silicone defoamer?

- Why add silicone oil to silicone defoamer?

- What is the process of silicone defoamer used in the petroleum industry?

- What is the use method of silicone defoamer?

- How to make silicone defoamer performance better?

1. Why is foam in the petroleum industry?

Oilfield foam is generally generated in the coke tower, with the viscosity of the material in the coke tower and the formation of solids, a stable foam layer will be generated.

(1) When natural gas is spilled in an oilfield industrial formation, the surfactants in the oilfield have a stabilizing effect on the bubbles, making it too late for the bubbles generated by the slurry to burst and circulate back inside;

(2) Foam generated by the gas and decomposition or fermentation of the treatment agent by high temperature;

(3) Oil field digging and extraction process due to the mixing and air involved.

![]()

2. Why defoaming is needed?

As an important resource of a country, oil plays a vital role in developing the economy and energy. However, during the extraction of oil, various problems are often encountered, one of which is the problem of foam.

When crude oil is extracted and processed, the gas-liquid equilibrium of crude oil is broken by multiple factors such as temperature, pressure, flow rate, and section plug flow, and light hydrocarbons overflow from crude oil and form foam.

The presence of foam can cause pipeline transportation instability and reduce the effective separation space in the equipment, and it may also cause the gas phase to carry oil droplets into the natural gas treatment system, resulting in black smoke from insufficient flare combustion. The foam generation can make the extraction process more difficult and reduce the oil quality.

Oilfield silicone-based defoamer can be widely used in oil mining, oil extraction, oil drilling, oilfield drilling mortar mud, oilfield dewatering drilling fluids, oilfield additives, drilling fluids, drilling fluid, drilling rinsing fluid, oilfield fracturing fluids, oilfield delayed coking, natural gas desulphurization, oilfield desulphurization, oil oil oil and gas separation, delayed coking, oilfield and another process defoamer.

![]()

3. What are the advantages of silicone defoamer?

In the process of crude oil extraction and treatment, the generation of foam will bring about a variety of problems, and the addition of an antifoam agent is a common solution. Silicone antifoam agent has a good effect on oilfield antifoam.

(1) Silicone defoamer control foam ability is strong and fast, has foam suppression for a long time without rebound, low dosage, low price, and will not change the basic nature of the foaming system, chemical stability, non-explosive, non-combustible, heat-resistant, it is a good choice to eliminate the oilfield industrial foam.

(2) Silicone defoamer can quickly solve the bubbles end produced in the oilfield to avoid the impact of production. It is suitable for maintaining high defoaming and foam inhibition performance under high-temperature acid and alkali which can be used in a wide range of temperatures. It can be widely used in various harsh systems to remove and inhibit foam. It can also solve the foam generated in the oilfield industry.

![]()

(3) Silicone antifoam agent is suitable for a variety of poor systems of foam elimination, it can be well dispersed in the oilfield slurry, its chemical nature is stable, and can effectively eliminate other additives produced by the stubborn foam, without affecting the effect of other additives; high temperature, high shear, high pressure, in the process of the oilfield mining industry will not be high temperature and high-pressure loss of defoamer performance, thus effectively improving the efficiency of oilfield mining, reduce the oilfield mining process because of excessive foam.

(4) Silicone antifoam agent has small volatility, good stability at high temperatures, no emulsion breaking and oil drifting phenomenon, and no precipitates, which can avoid the negative impact on the downstream processing and poisoning of a downstream hydrogenation catalyst.

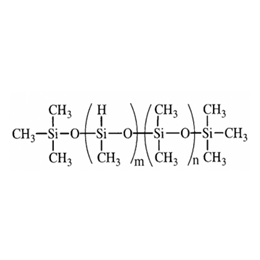

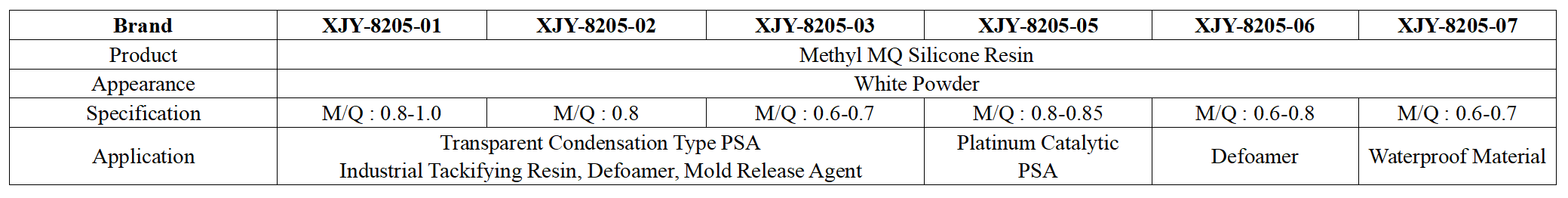

XJY-8205 Powdered Methyl MQ Silicone Resin is a solid food-grade powdery active silicone resin. This resin has excellent transfer resistance and water resistance and forms a long-lasting film, which is one of the raw materials of silicone emulsion defoamer in aqueous systems and can be used in food processing, coatings, and oil extraction.

4. Why add silicone oil to silicone defoamer?

A. Silicone oil is difficult to dissolve in lubricating oil, it is in a dispersed state and conducive to adsorption on the bubble film to break the bubble;

B. Silicone oil has mineral oil similar to Alkyl, it can squeeze into the bubble film, and weaken the molecular gravity;

C. Silicone oil has low surface tension, good penetration, and adsorption on the surface of the bubble film so that the local surface tension is reduced, due to uneven surface tension of the bubble film and bubble breaking. In addition, Alkyl Polyacrylate is also better, with better gas release. Branched-chain amine added to crude gasoline, naphtha, and then added to the lubricating oil, can also be used as an antifoaming agent, add the amount of micro 0.05 ~ 1%, and this antifoaming agent can be added to the metal cutting fluid.

![]()

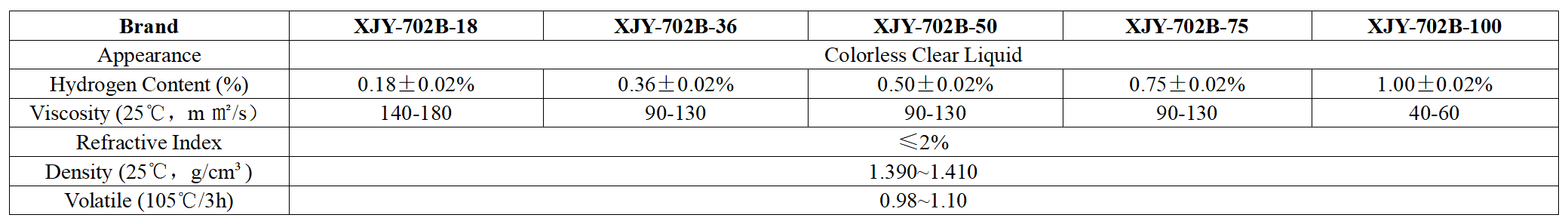

XJY-702 Methylhydrosiloxane / Dimethylsiloxane Copolymer is non-toxic and tasteless, with active groups, under the action of catalysts and double bonds, hydroxyl and other groups can be reacted, in the petroleum industry, metalworking fluids, pulp and paper industry, paints and other industrial applications of organosilicon antifoam agent and other products of the basic raw materials.

5. What is the process of silicone defoamer used in the petroleum industry?

(1) Drilling:

Ethyl silicone oil (or methyl silicone oil layer emulsion) for mud additives.

(2) Oil extraction:

Oil and gas separate, and defoamer ability is good. The melting point is 2.8¬13.9°C higher than the wellhead foam temperature.

(3) Natural gasoline absorption:

Dimethicone is prepared as a 2% solution with gasoline.

(4) Oil and gas separation emulsion breaking:

A. Oil and gas separation: adding 0.025~0.0065mg/Kg in crude oil can increase production capacity;

B. Breaking emulsion: oil and gas separation of crude oil is generally micro-W/O emulsion, adding 0.2mg/Kg or so of the appropriate antifoam agent, can achieve the effect of breaking emulsion and defoaming.

(5) Refining:

In decompression, distillation adds an antifoaming agent, fraction color improvement, and fraction range relaxation, commonly used in a diesel oil solution with silicone oil.

(6) High-energy fuels

Include internal combustion, jet, and aviation fuel with cyanoalkyl polysiloxanes dispersed in high flash point kerosene, and then added to high-energy fuels as a high-efficiency defoamer.

![]()

(7) Asphalt, residual oil:

Add silicone oil amount of 0.2 × 10-6 ~ 2.0 × 10-6

(8) Delayed coking, decoking, and descaling:

Defoamer added reference amount: 0.05 ~ 100 × 10-6

(9) Antifoaming drilling fluid:

High viscosity sulfonate metal salt (calcium petroleum sulfonate: sodium sulfonated asphalt = 1:1), the amount of siloxane added about 100 to 400 × 10-6 or 5 to 15mg/Kg, sulfonate: siloxane close to 1:1 is preferred.

(10) Lubricating oil:

Such as internal combustion engines, automobile lubricants, metalworking fluids, compressor oil, etc.

![]()

6. What is the use method of silicone defoamer?

Silicone defoamer was directly added to the foaming system to ensure its uniform dispersion. If it is to be diluted, do not store the diluted solution for more than 8 hours. For systems with high foaming temperature (>60℃), it is recommended to add it to the system before 60℃ to disperse it evenly to maximize its effectiveness. According to the viscosity of different foaming systems, temperature and stirring, and other factors, 10ppm as a unit, choose a more economical dosage, in general, 30-200ppm dosage can ensure the ideal antifoaming effect.

7. How to make silicone defoamer performance better?

Silicone defoamer is a kind of organosilicon polyether graft copolymer defoamer, which is suitable for maintaining high defoaming and suppressing performance under high-temperature acid and alkali or shear force, and it can be used in a wide range of temperatures. It can also solve the foam generated in delayed coking. Silicone defoamer works great in the petroleum industry. How to make your product work great?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry and more than 15 related patents and technical support. Our silicone raw material products can meet the needs of the defoamer field and support the provision of diversified customized solutions.